Online real-time measuring device for outer diameter of traction steel wire rope and measuring method for online real-time measuring device

A real-time measurement, wire rope technology, used in transportation, packaging, elevators, etc., can solve the problems of non-representation, difficult evaluation of test results, unreliable measurement methods, etc., to ensure measurement accuracy and solve the problem of inner wire rope diameter measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

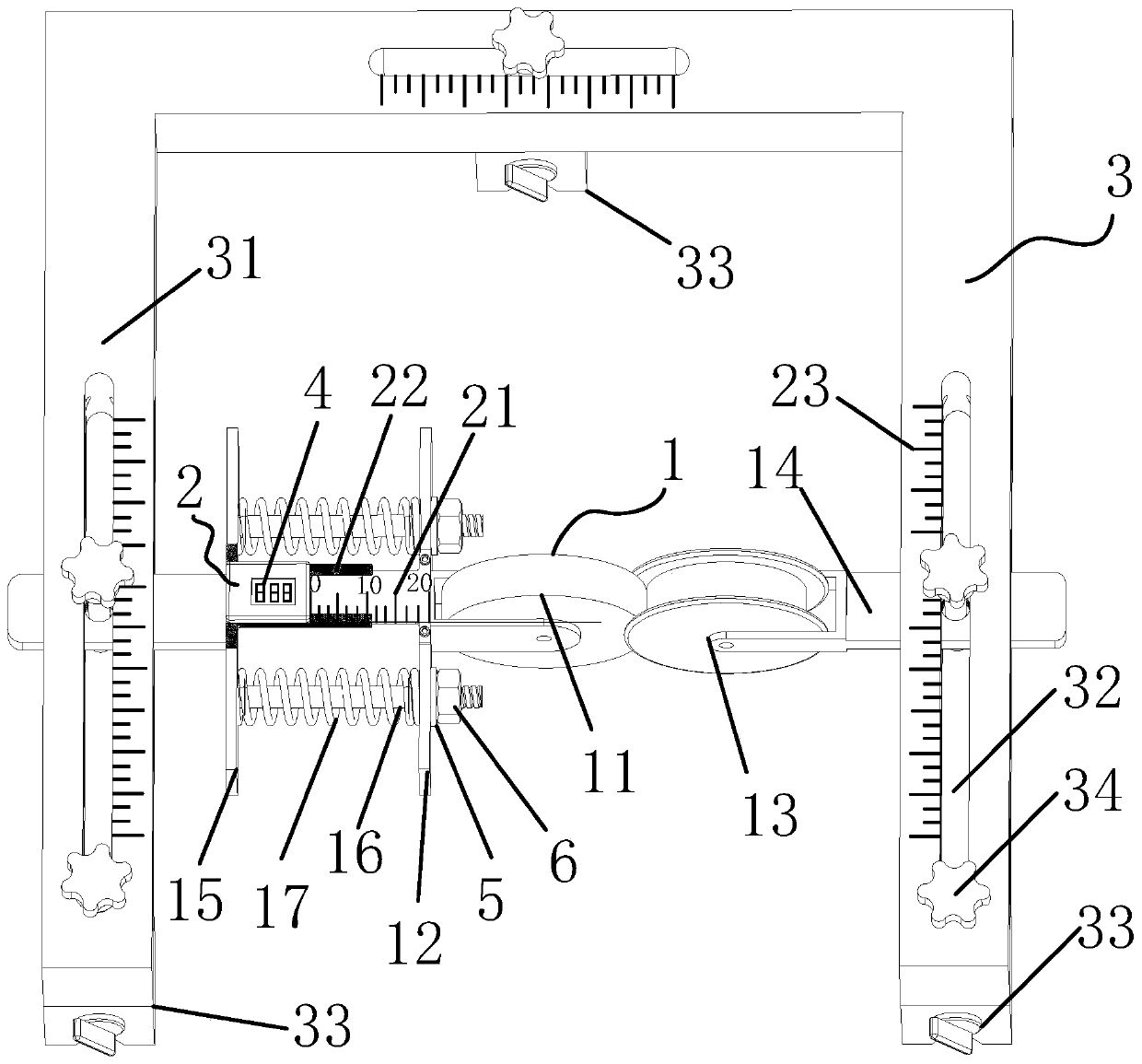

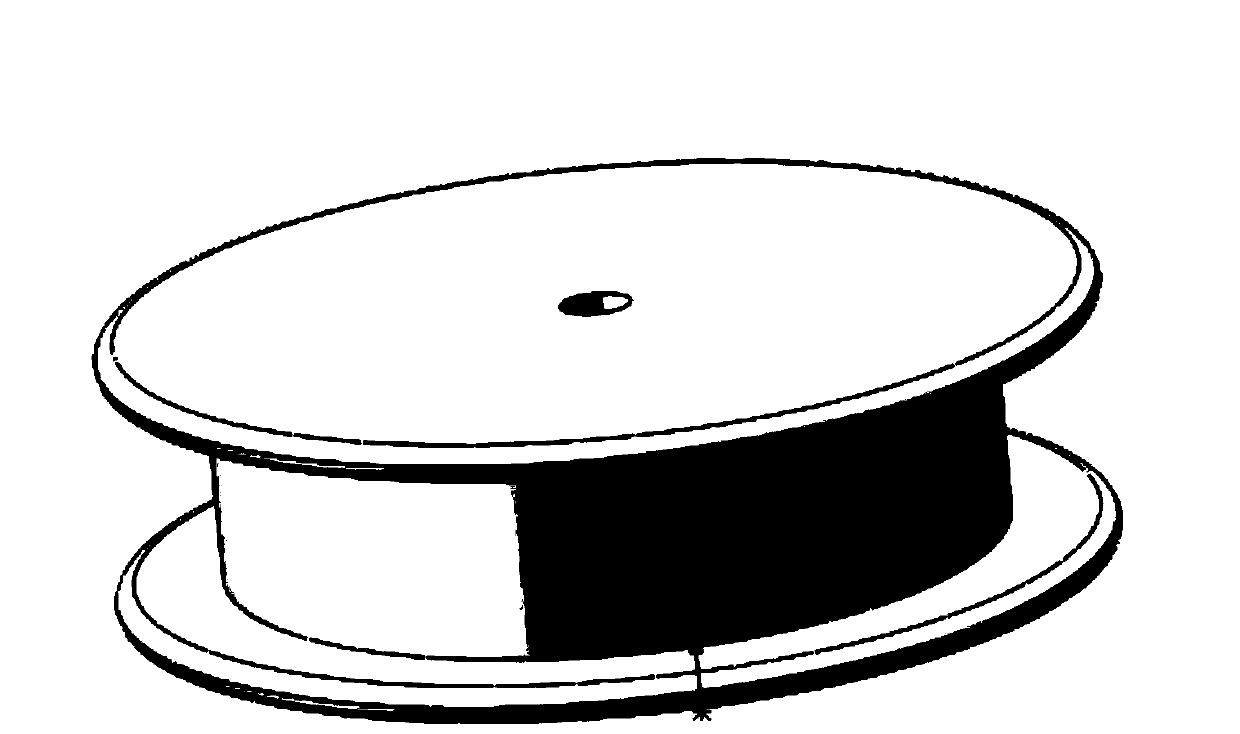

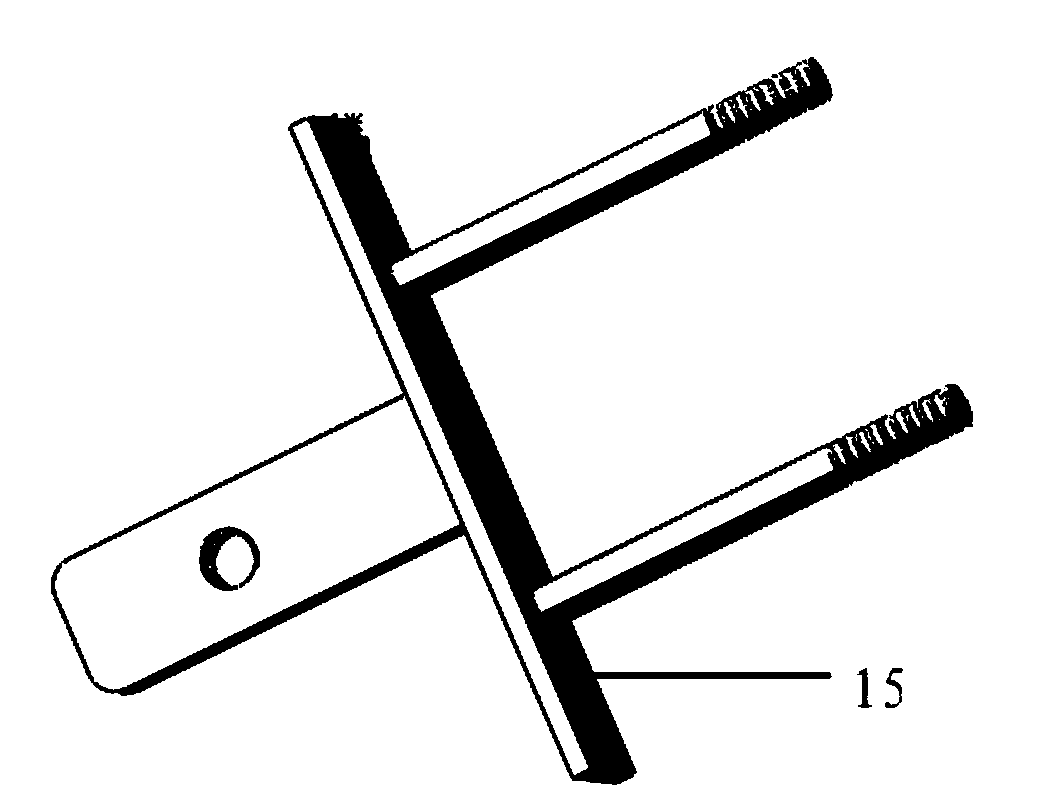

[0026] see Figure 1 to Figure 7 As shown, the present invention provides an online real-time measuring device for the outer diameter of a traction steel wire rope, the device includes a traction steel wire rope preload guide structure 1, a vernier measuring structure 2 and a portal frame sliding structure 3; the traction steel wire rope The pretension guide structure 1 comprises a pretension wheel 11, a pretension wheel support 12, a guide wheel 13, a guide wheel support 14, and a spring support 15; the gate frame sliding structure 3 comprises a gate frame 31, and the gate frame 31 There are sliding grooves 32 on the horizontal side and the vertical side of the brackets on both sides respectively; the spring bracket 15 is arranged on the left side bracket of the door frame 31, and the guide wheel bracket 14 is arranged on the door frame 31 on the right side bracket, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com