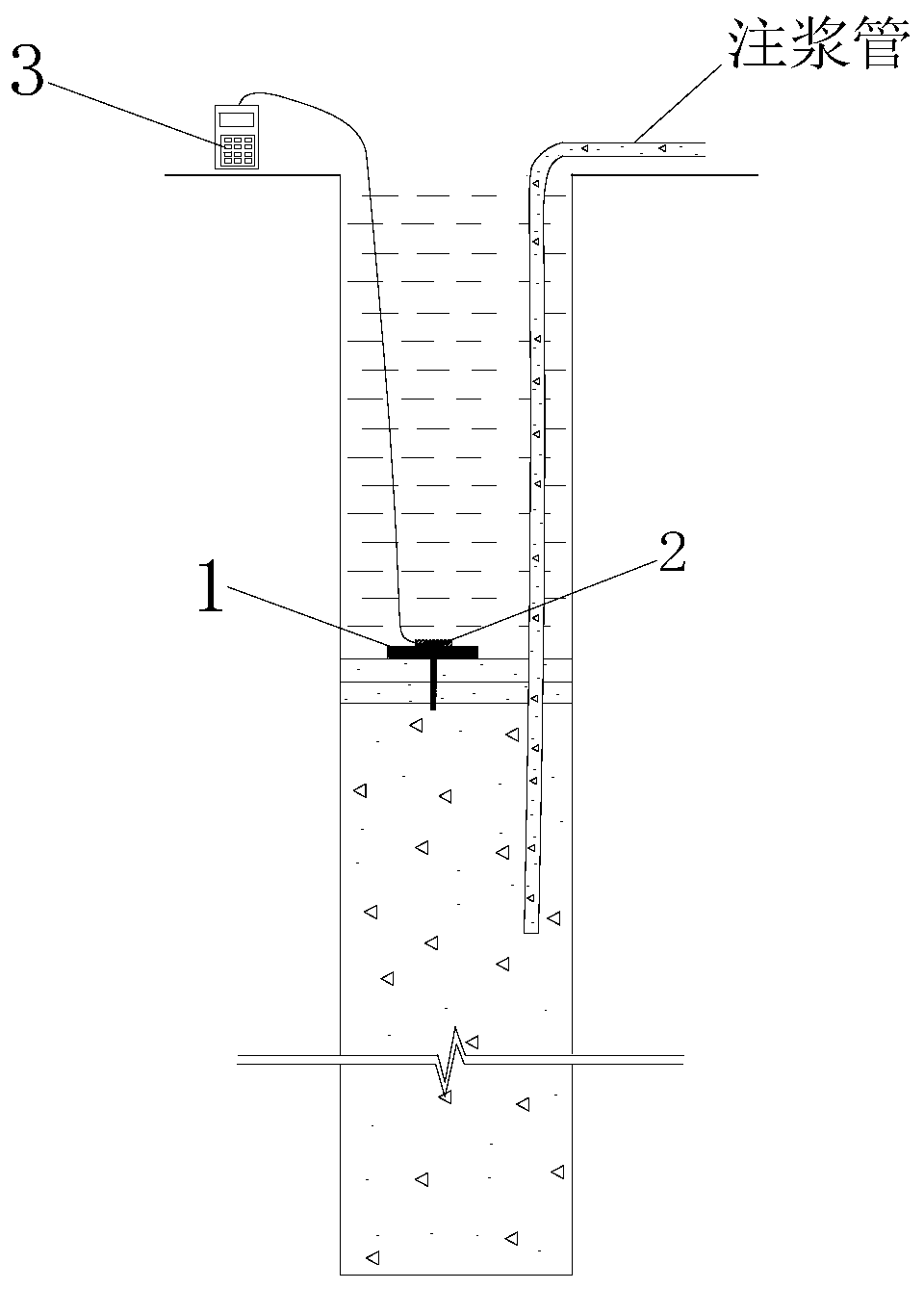

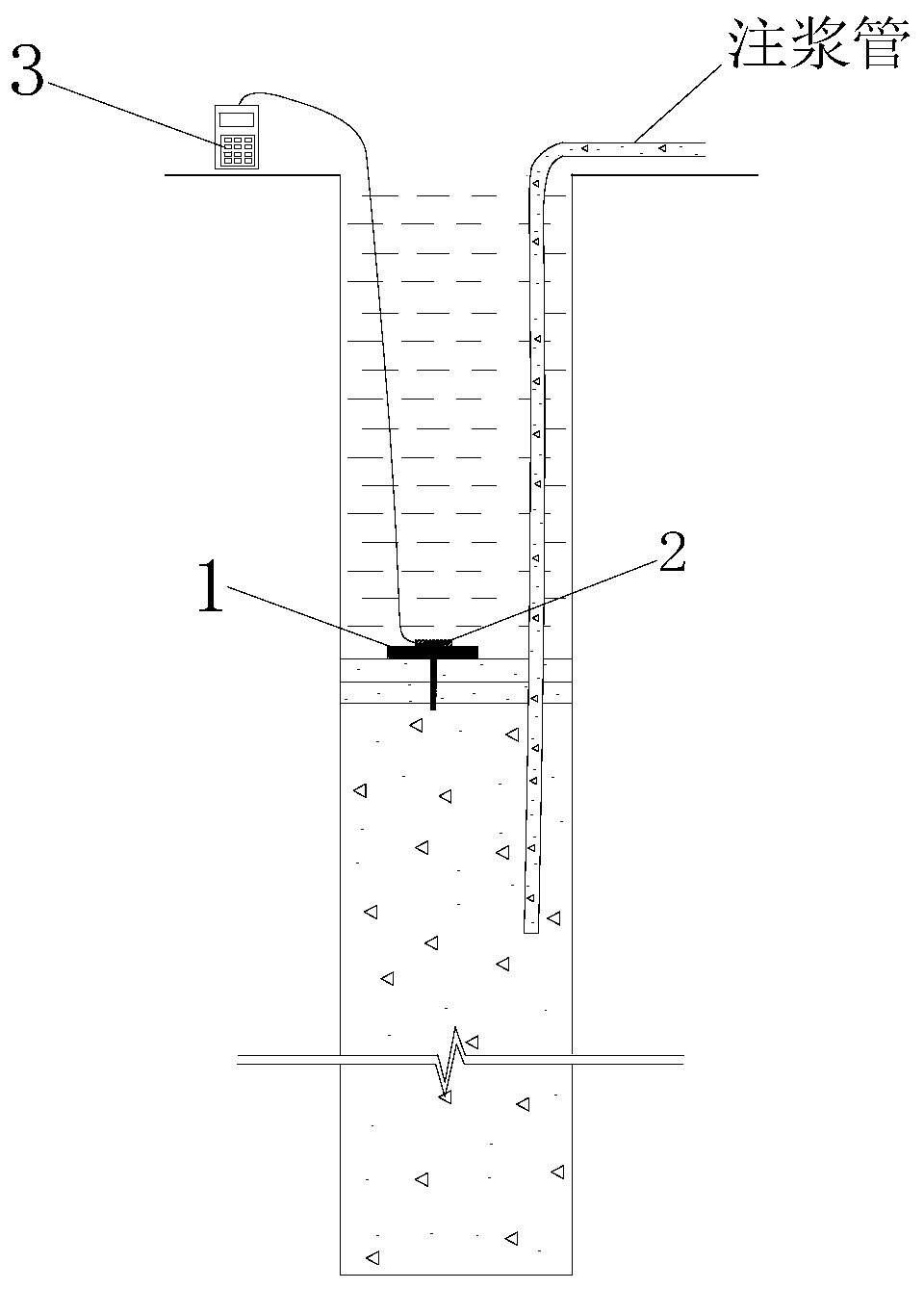

Device for detecting overfilling height of cast-in-situ bored pile in real time and detection method thereof

A technology of bored piles and real-time detection, which is applied in the testing of infrastructure, construction, infrastructure engineering, etc., can solve the problems of affecting the construction progress, inaccurate detection results, and impact on the construction progress, so as to avoid material waste and ensure The quality of the pile body and the effect of improving the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

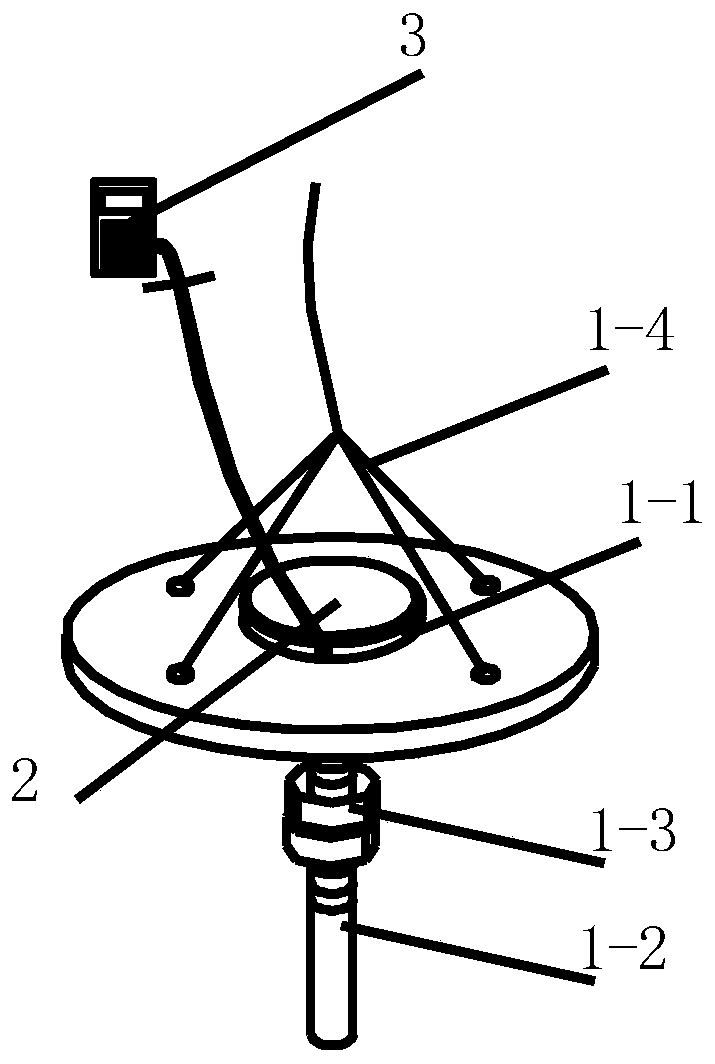

[0042]On the basis of Embodiment 1, further, small holes are arranged at equal intervals on the edge of the floating surface tray (1), and the small holes are used for binding nylon ropes (1-4). Lower the floating surface tray (1) into the drilled hole; further, the number of holes should be ≥3, which is more stable and can prevent the floating surface tray (1) from overturning when it is lowered.

Embodiment 3

[0044] On the basis of Embodiment 1, further speaking, the inner diameter of the circular groove (1-1) is equal to the outer diameter of the pressure box (2), thereby preventing the pressure box (2) from coming out of the circular groove (1-1) , the edge of the circular groove (1-1) is provided with a single wire gap, and the wire of the pressure box (2) is drawn out from the gap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com