Self-excited moisture flow measuring device

A flow measuring device and self-exciting technology, applied in the direction of volume flow measuring device, measuring device, fixed measuring chamber, etc., can solve the problems of difficult to achieve accuracy, difficult to meet user requirements, low liquid content, etc., and achieve convenient detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

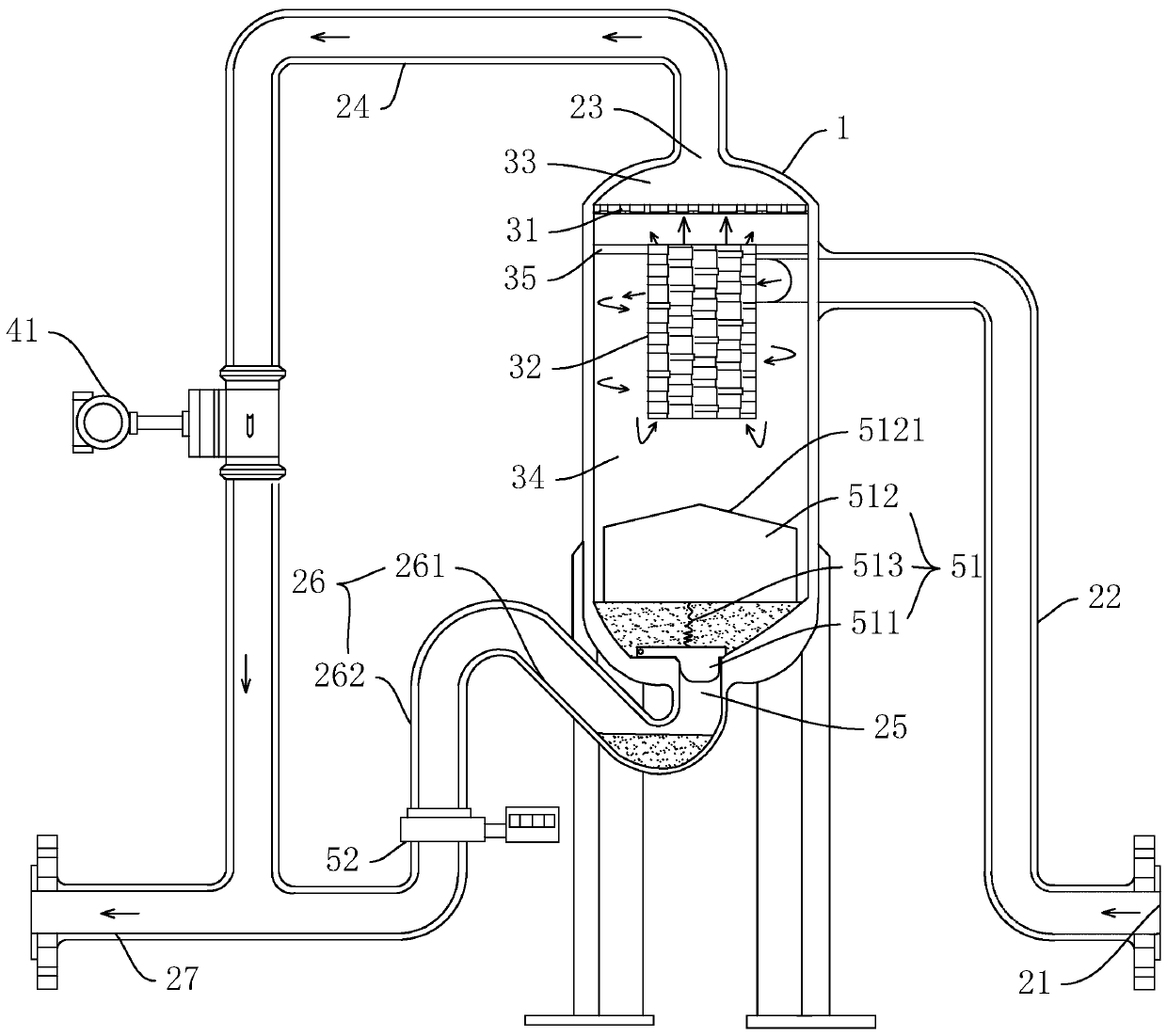

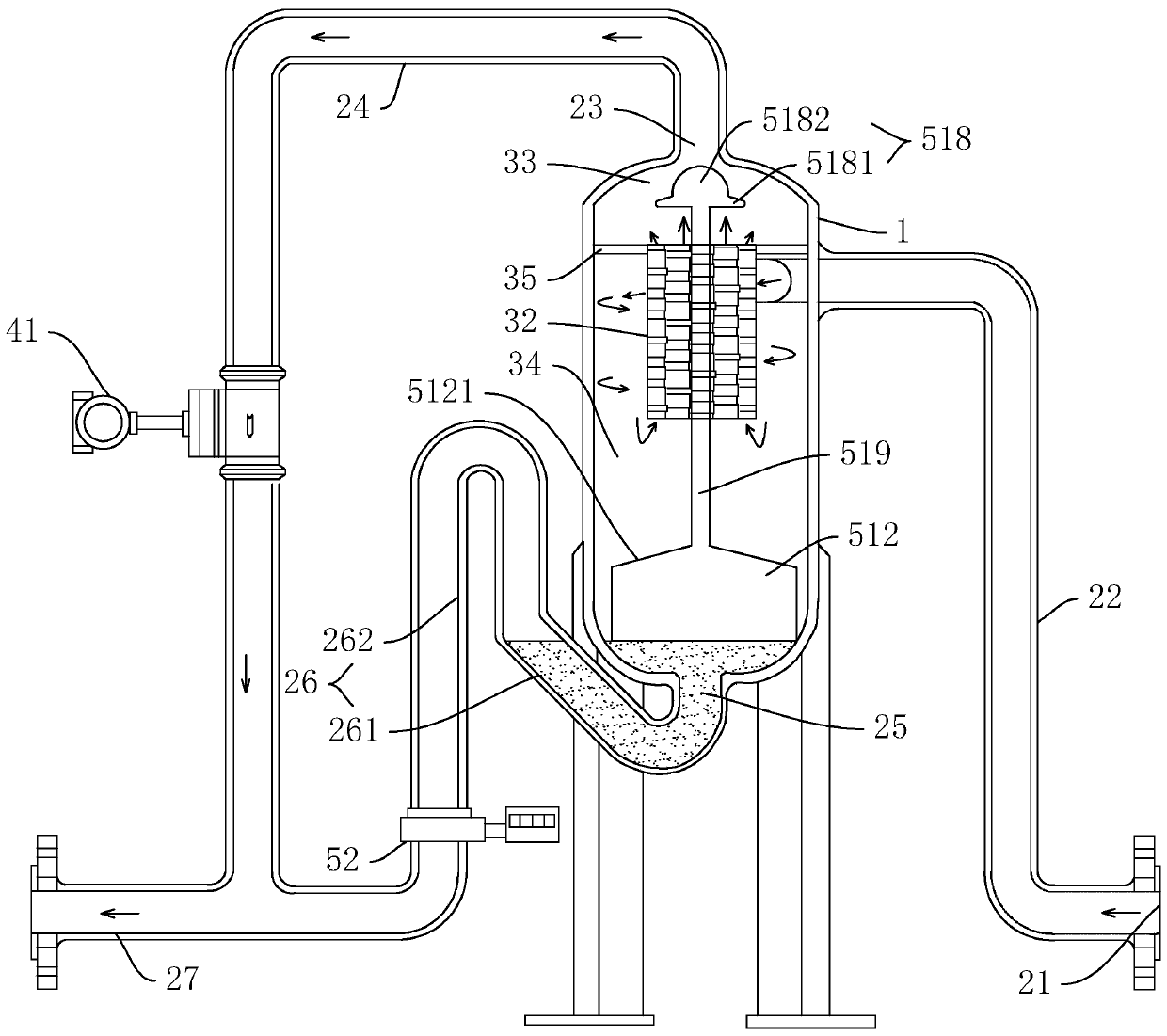

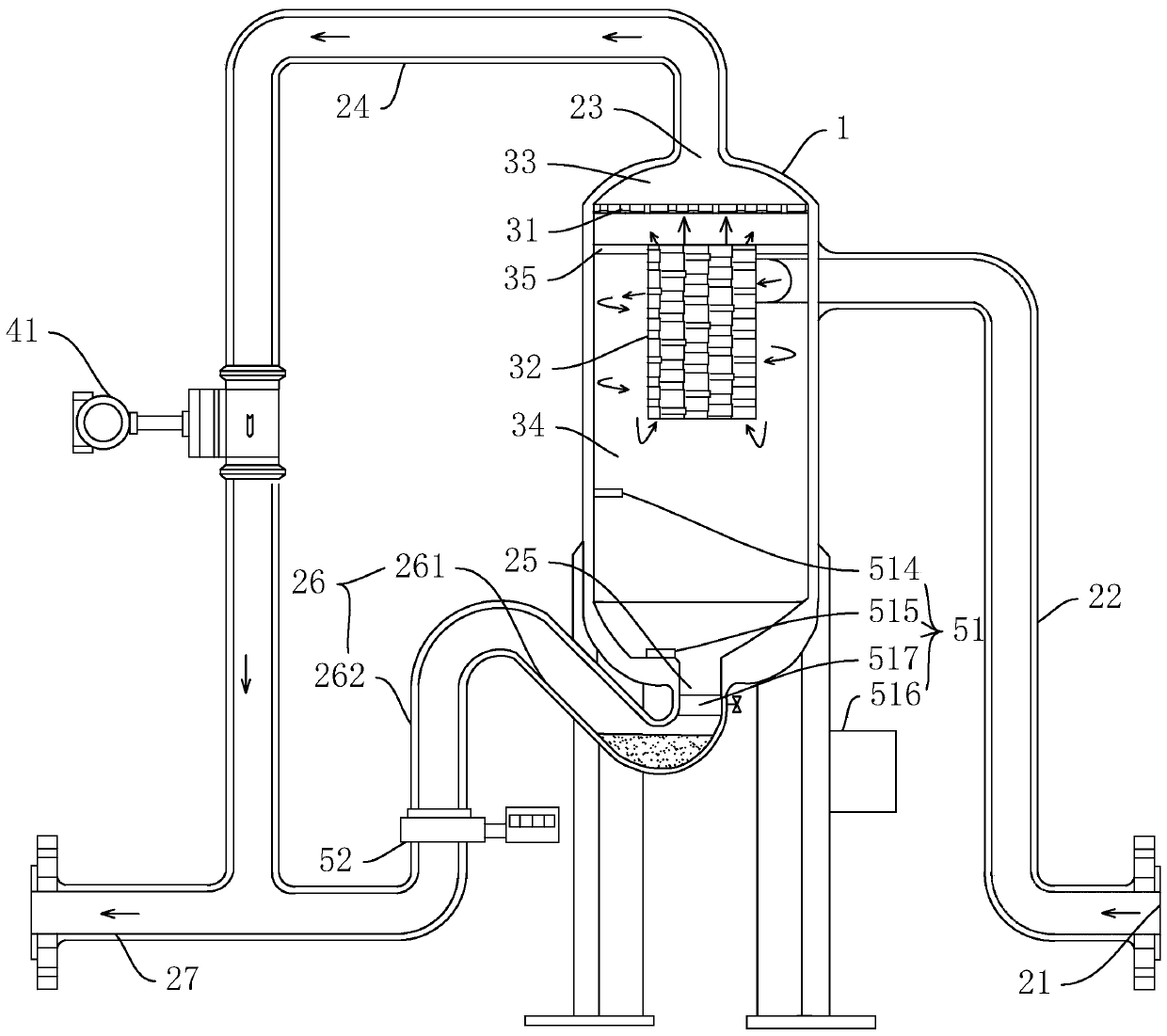

[0034] refer to figure 1 , is a self-excited wet gas flow measuring device disclosed in the present invention. The measuring device can separate the wet gas into dry gas and liquid, and simultaneously measure the two separately. The whole measuring method is simple and novel, and the operation is feasible High performance, the separation of gas and liquid can be detected and measured more accurately without mutual interference.

[0035] like figure 1 As shown, the self-excited wet gas flow measurement device specifically includes a housing 1. The cross section of the housing 1 can be in different shapes such as square, circular, rhombus, etc. In this embodiment, the housing 1 with a circular cross section is preferably used. That is, the housing 1 is cylindrical, and the housing 1 is installed vertically.

[0036] like figure 1 As shown, the housing 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com