Patents

Literature

187 results about "Moisture flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

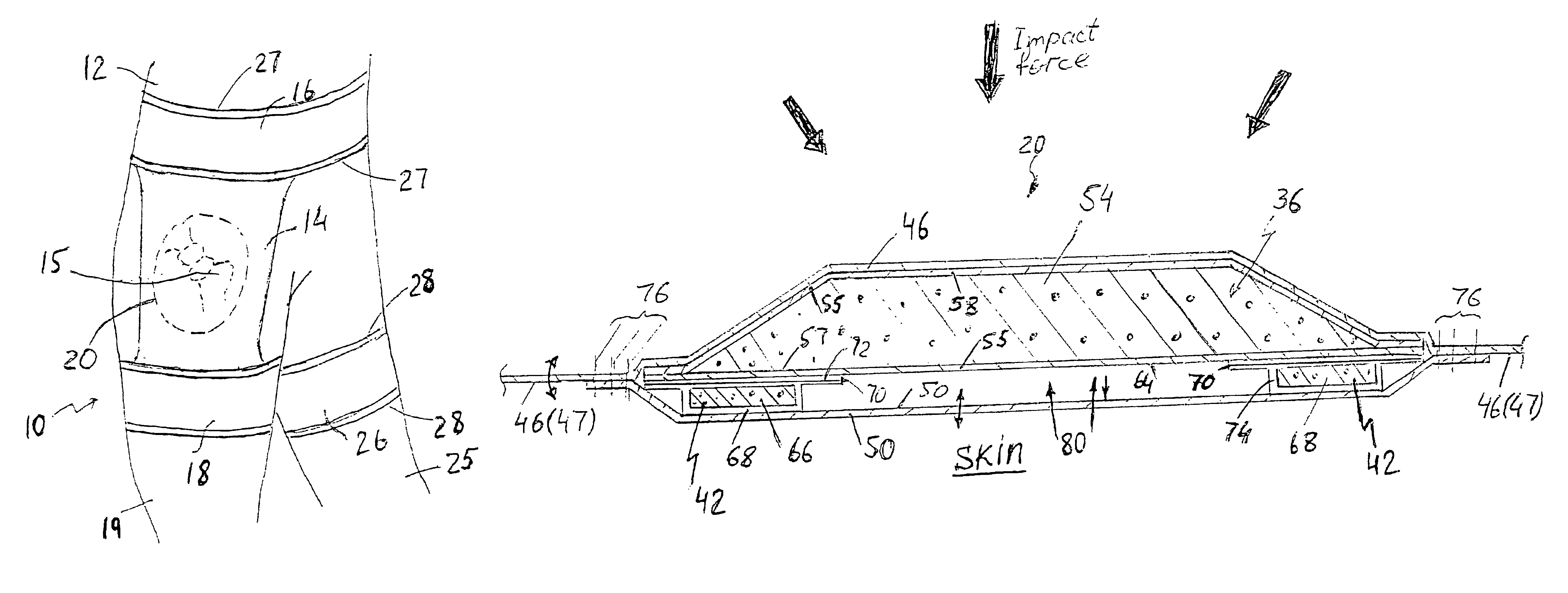

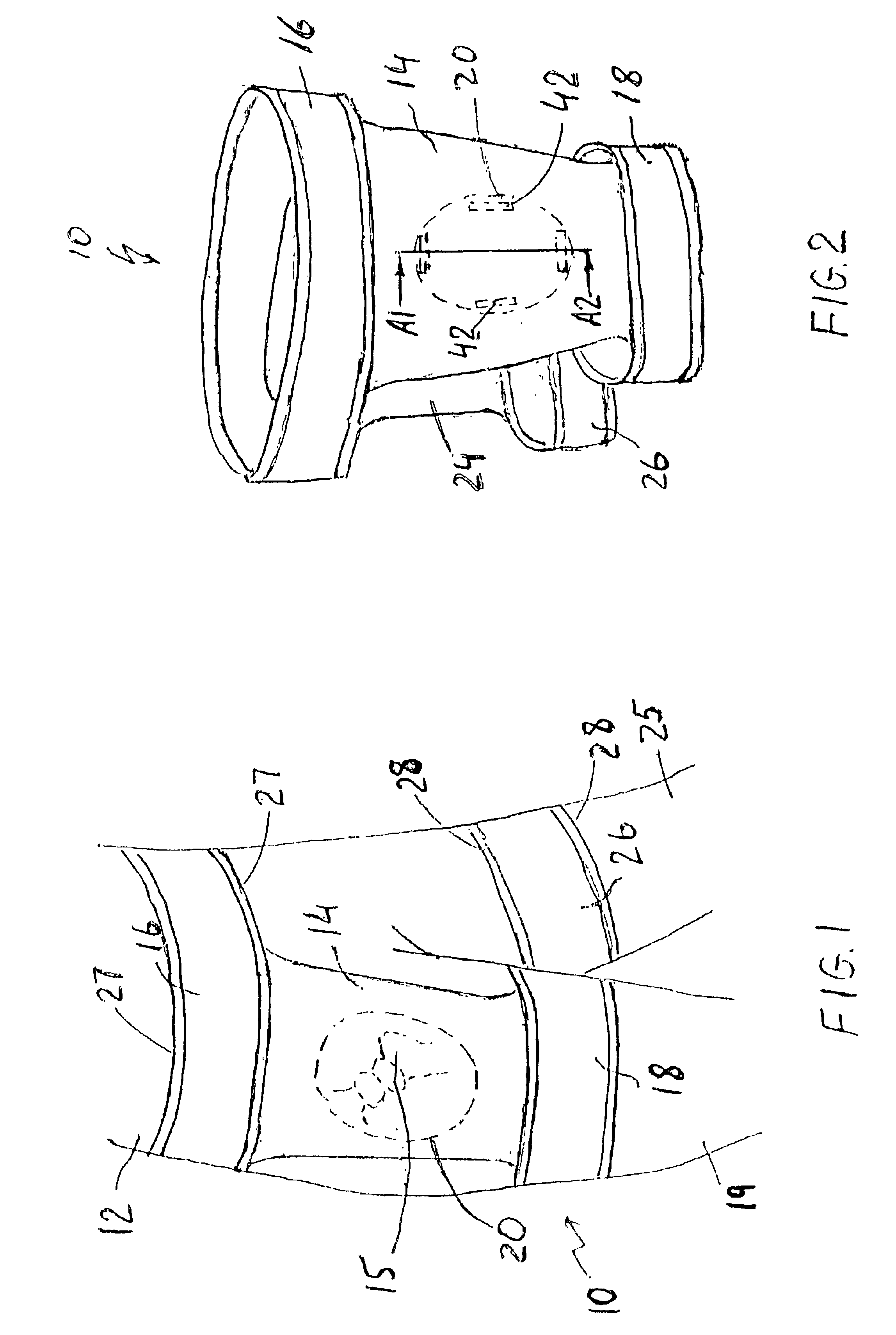

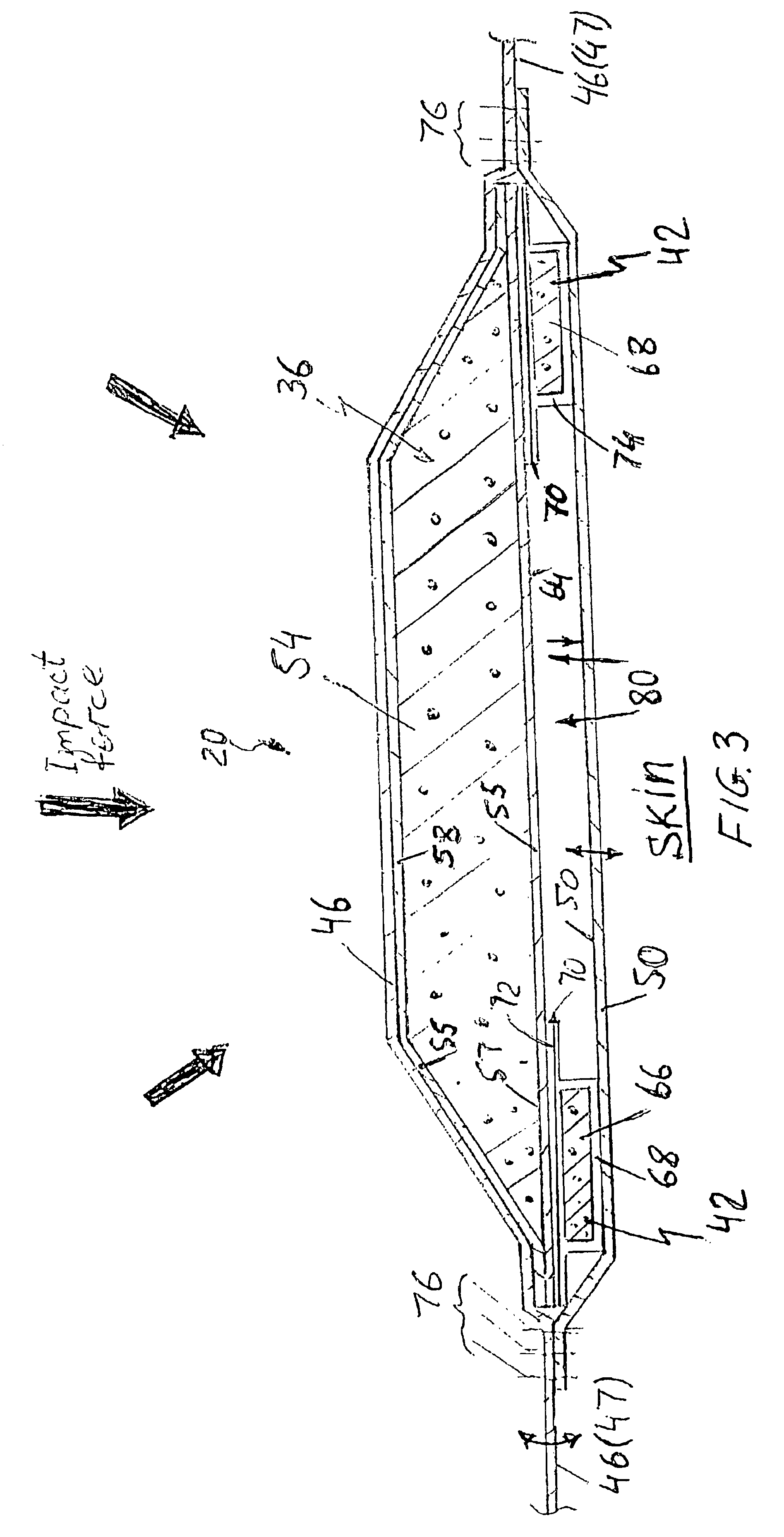

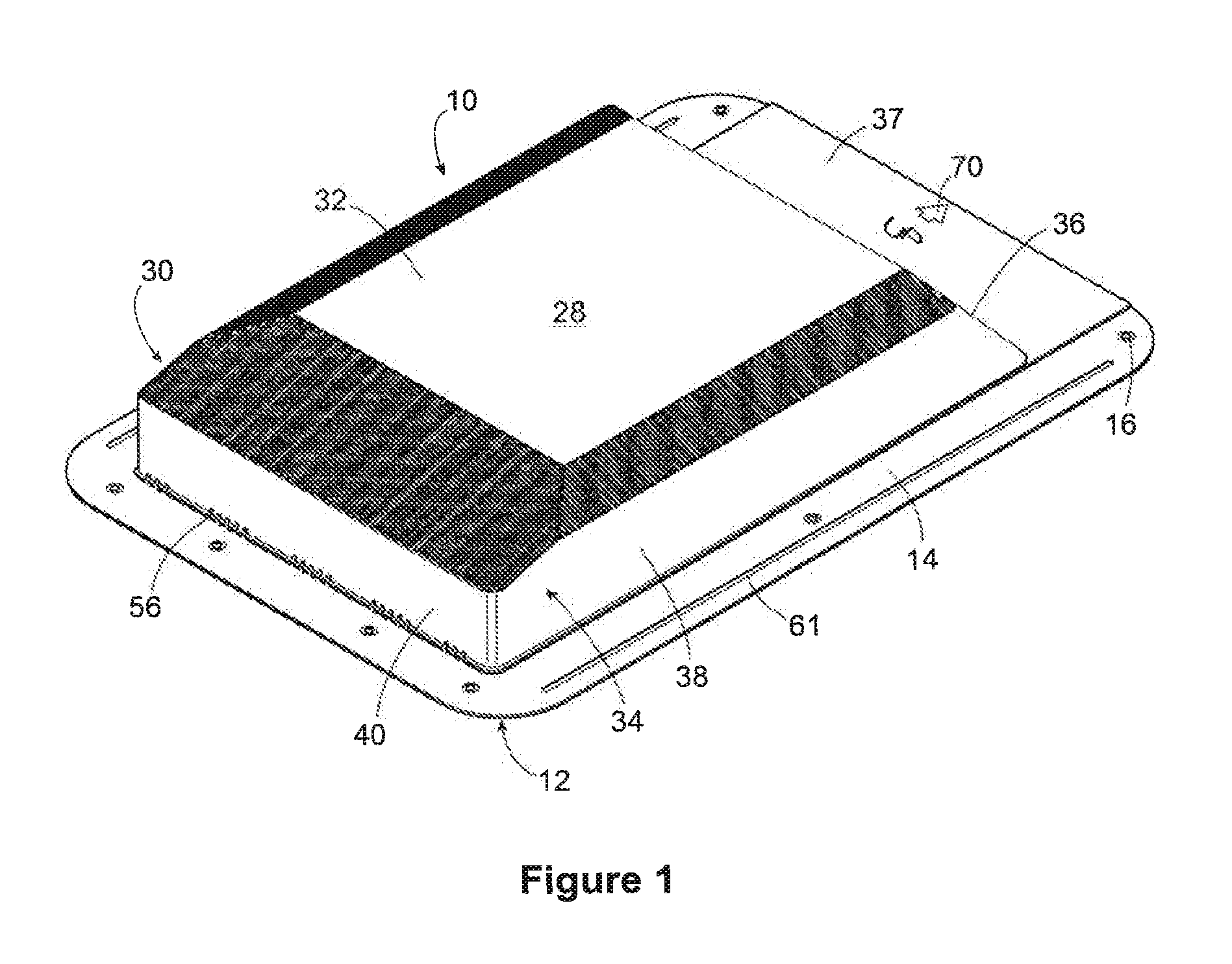

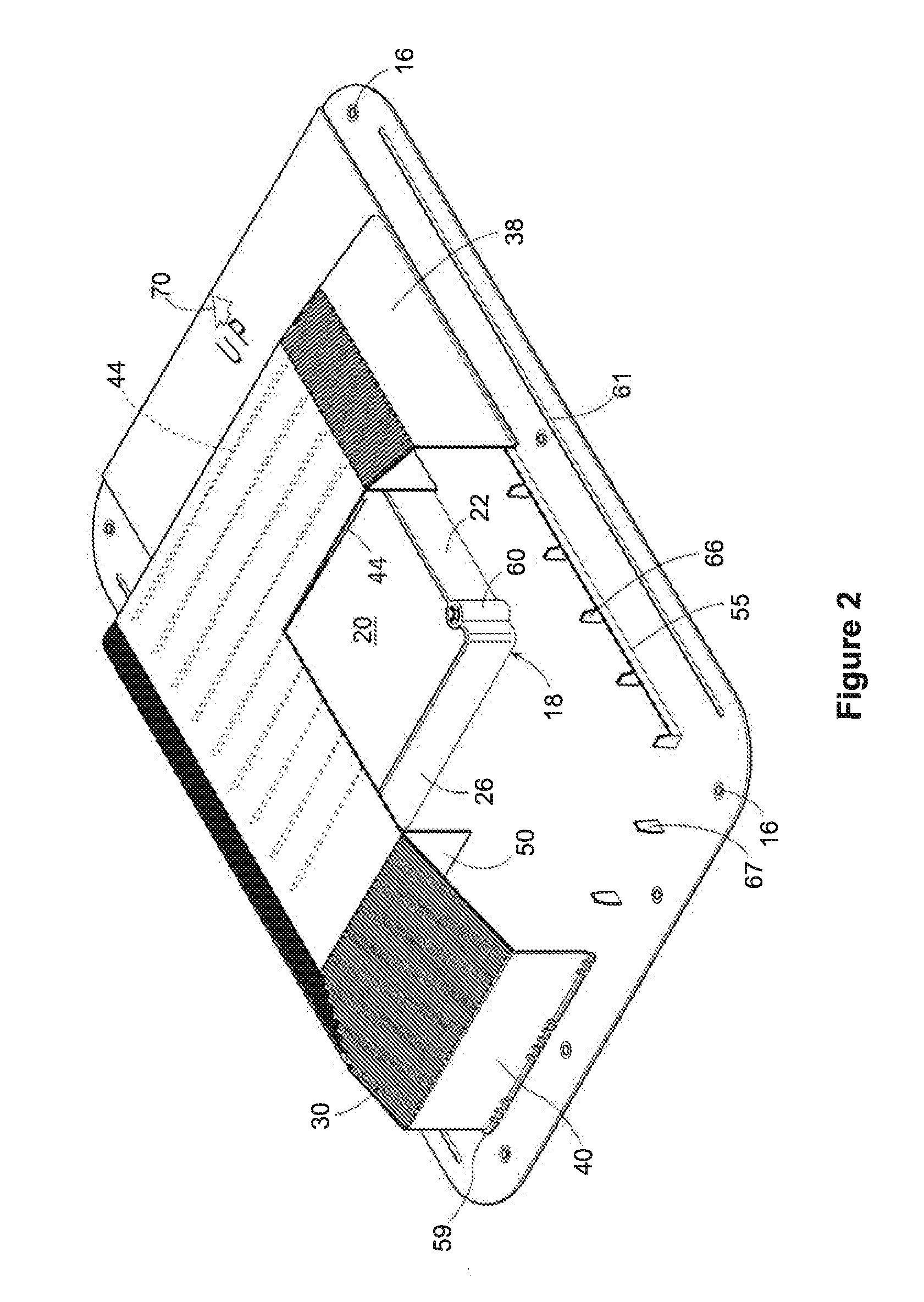

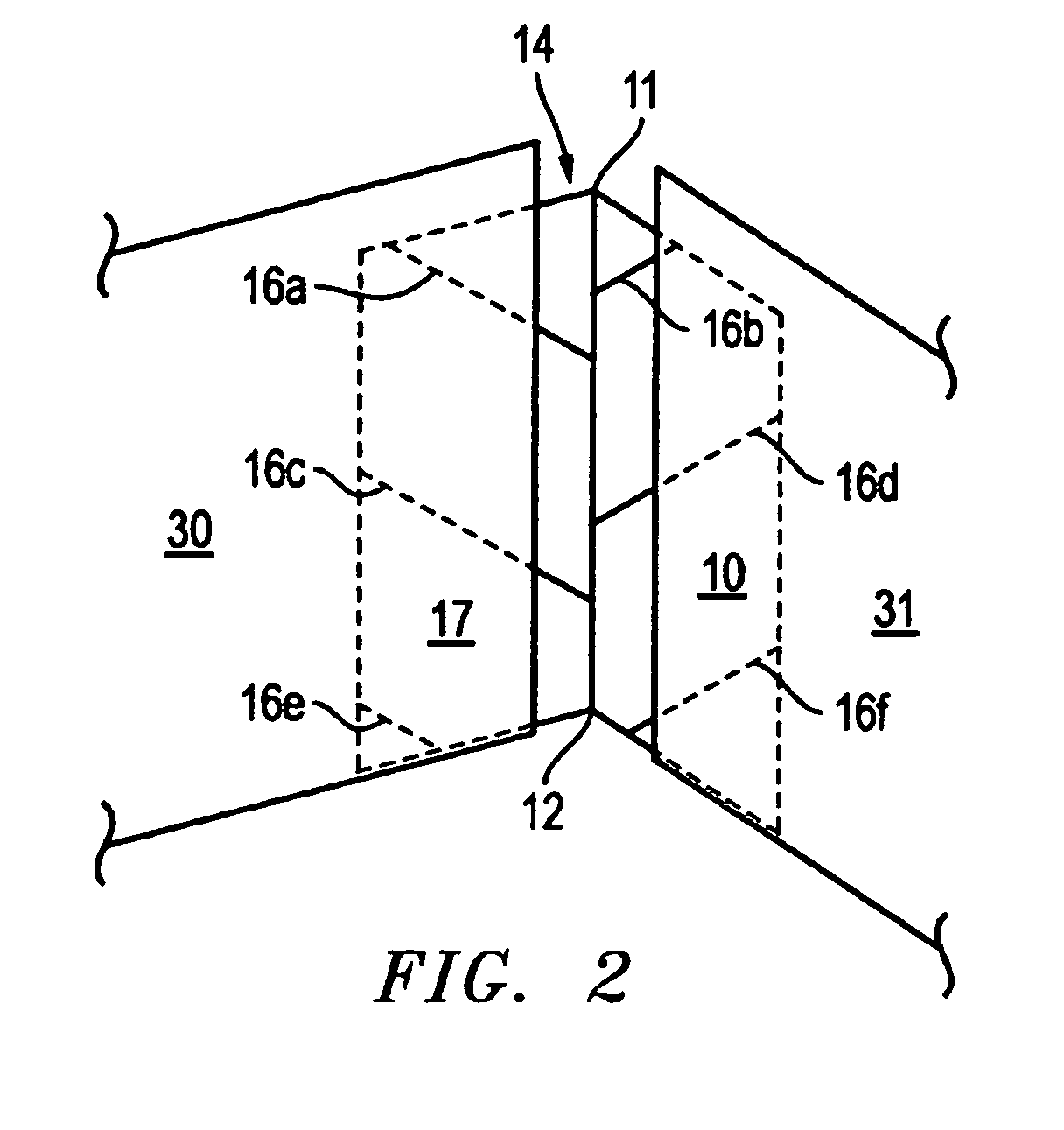

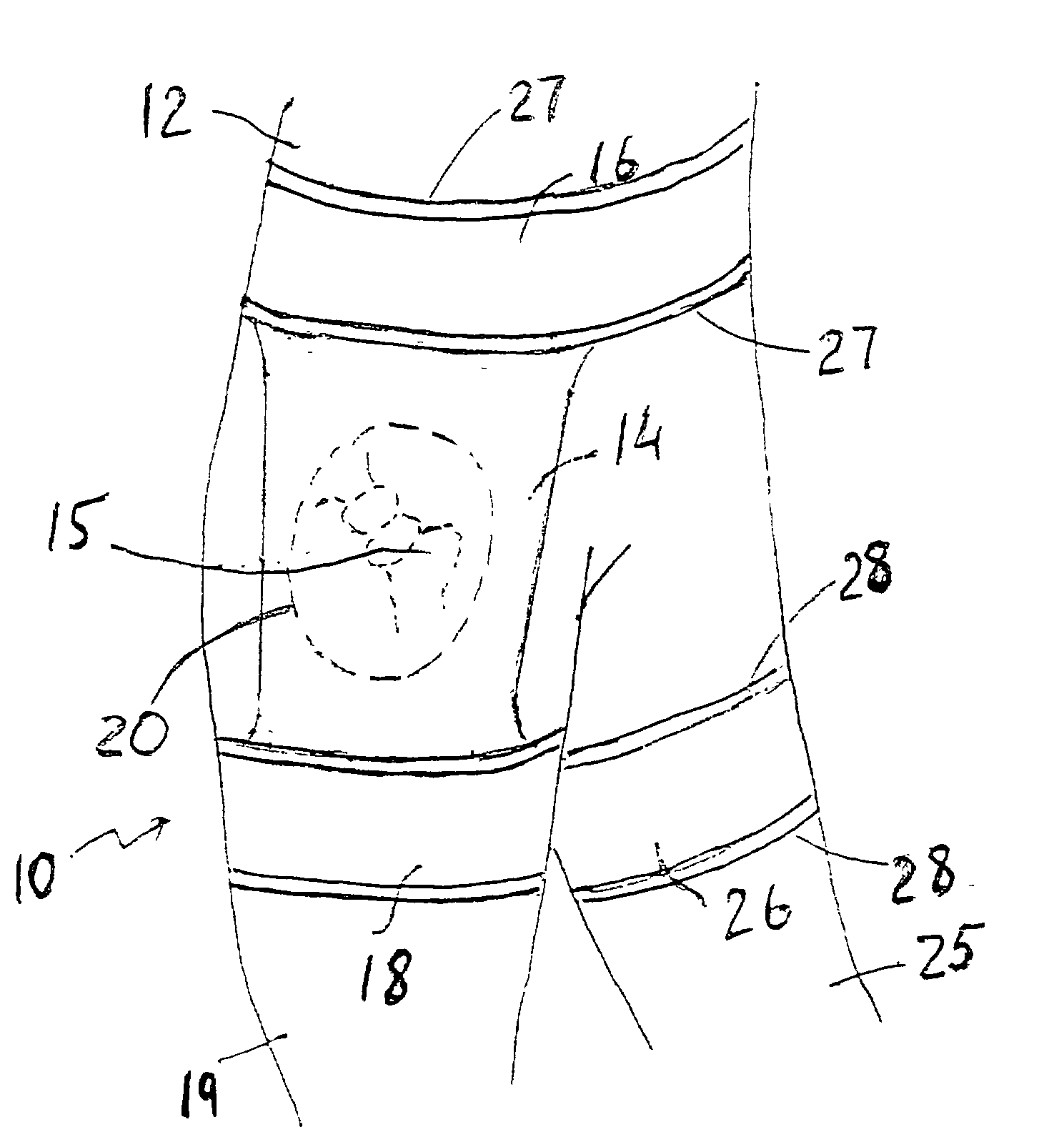

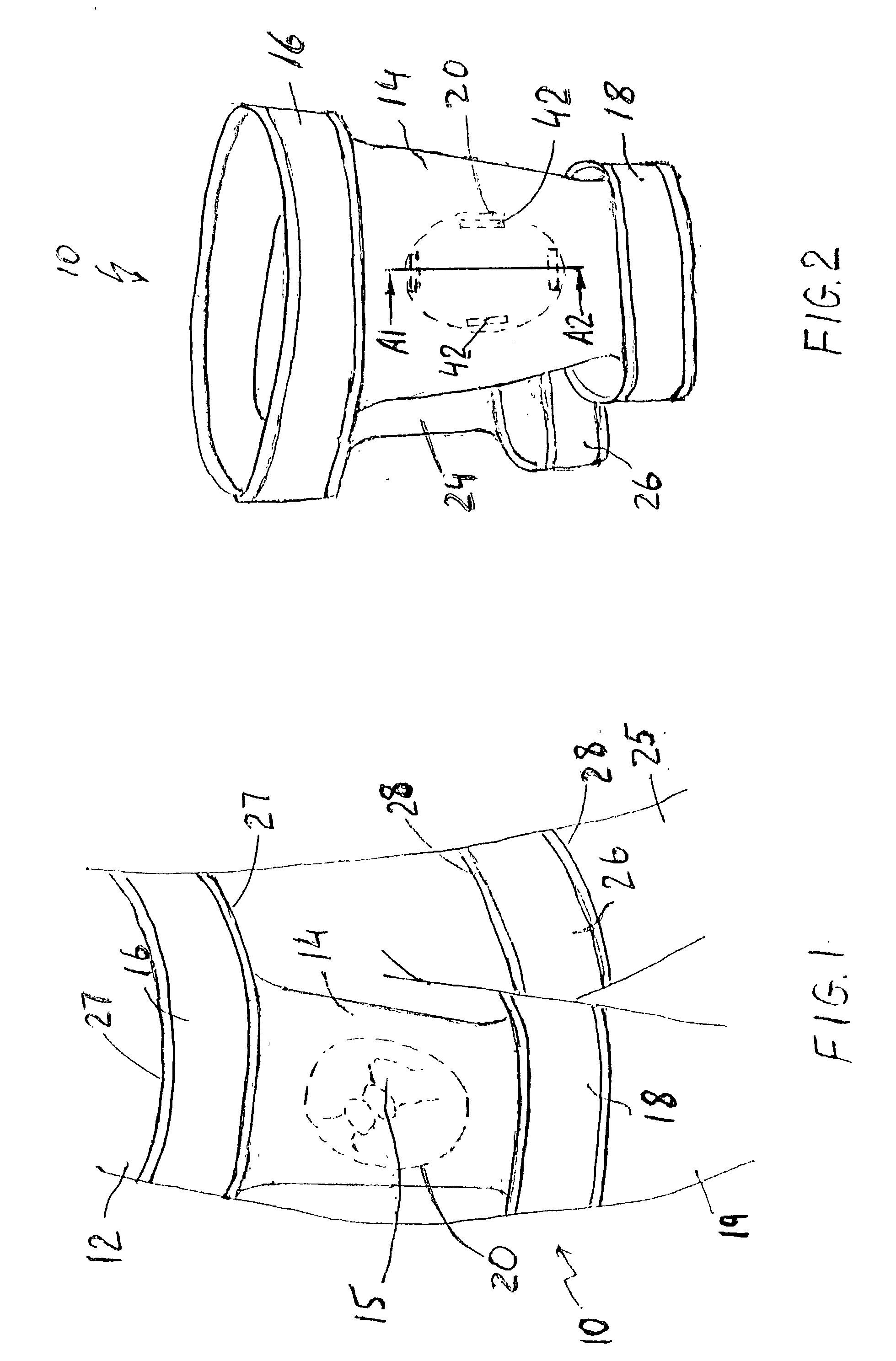

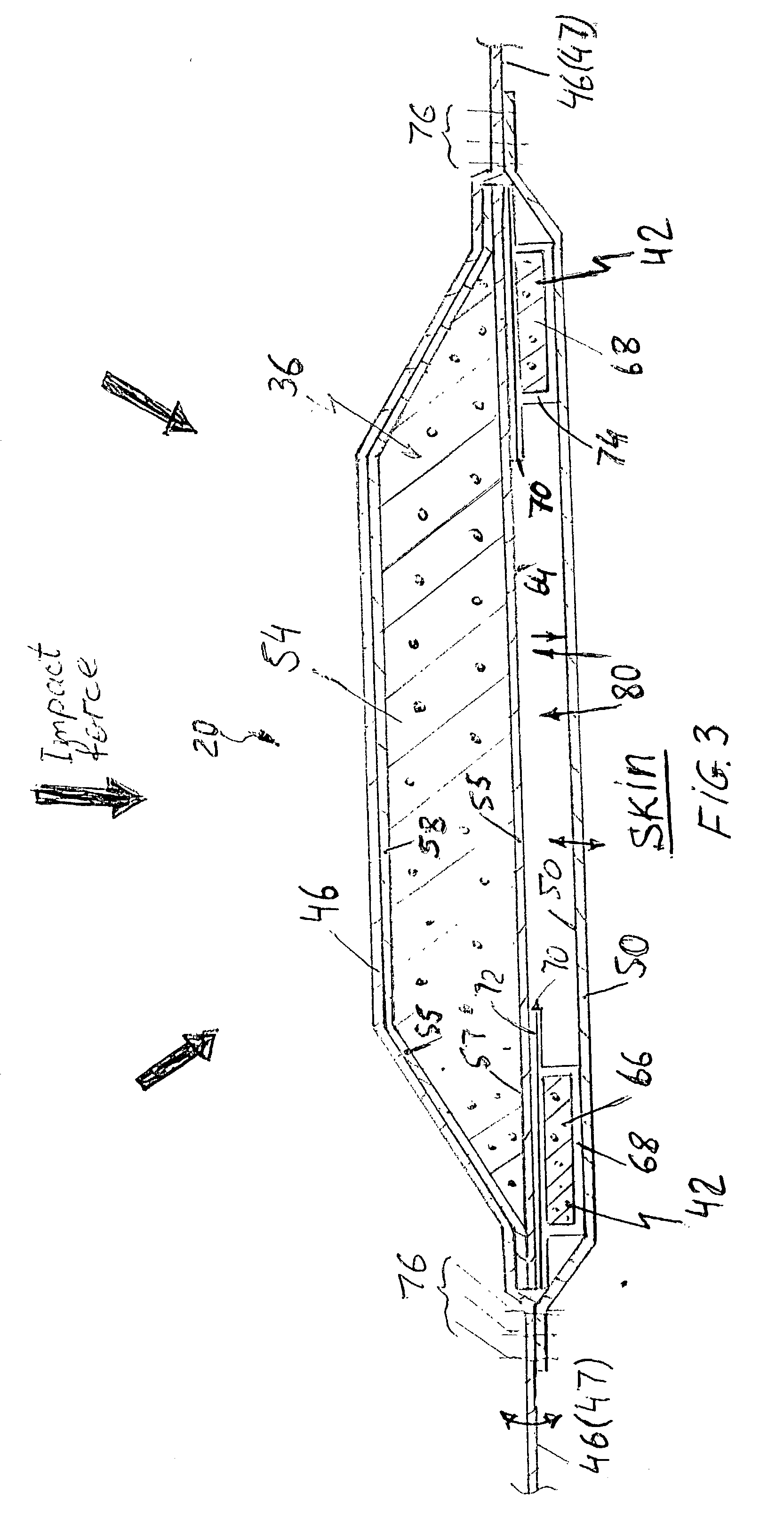

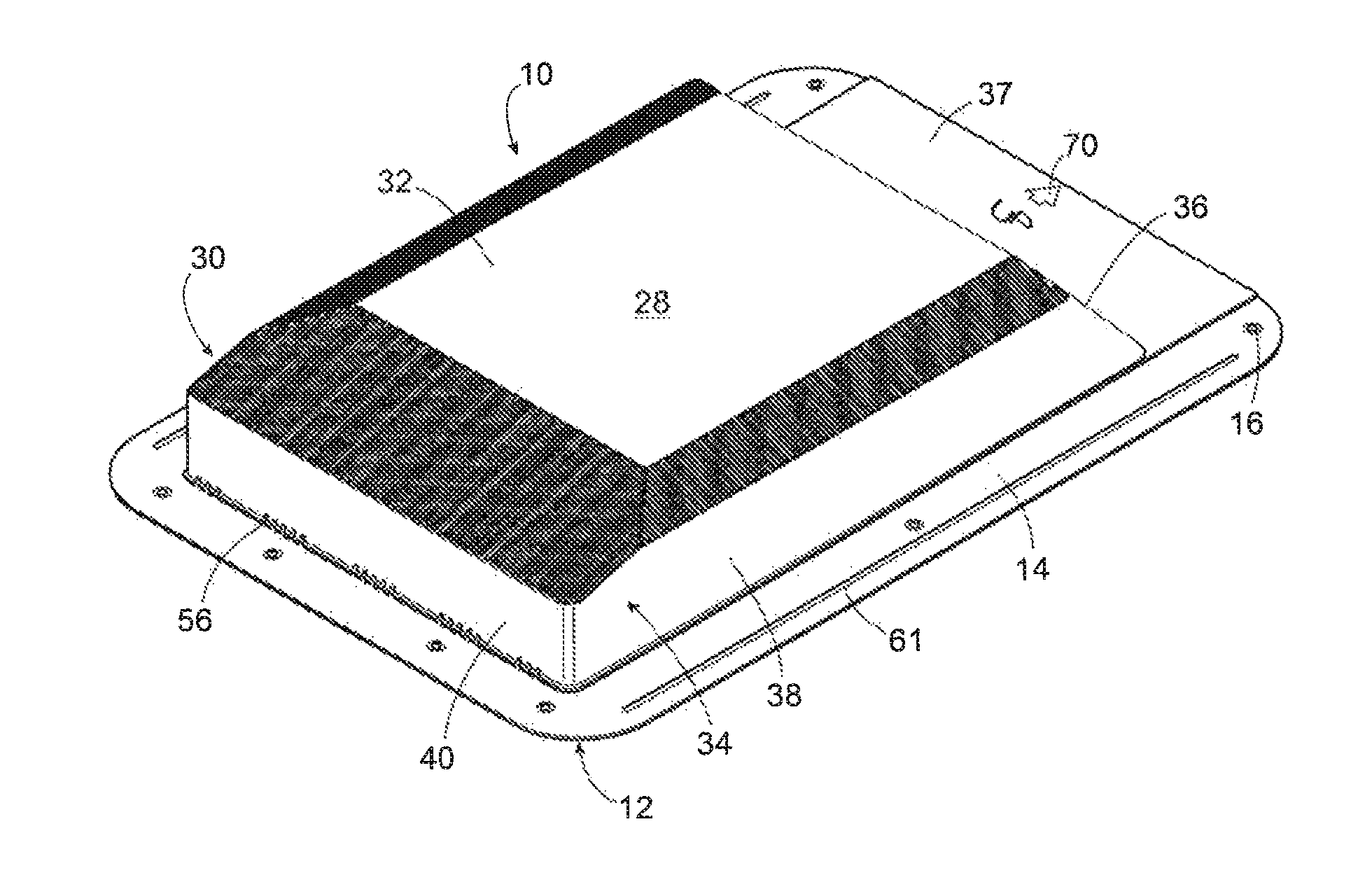

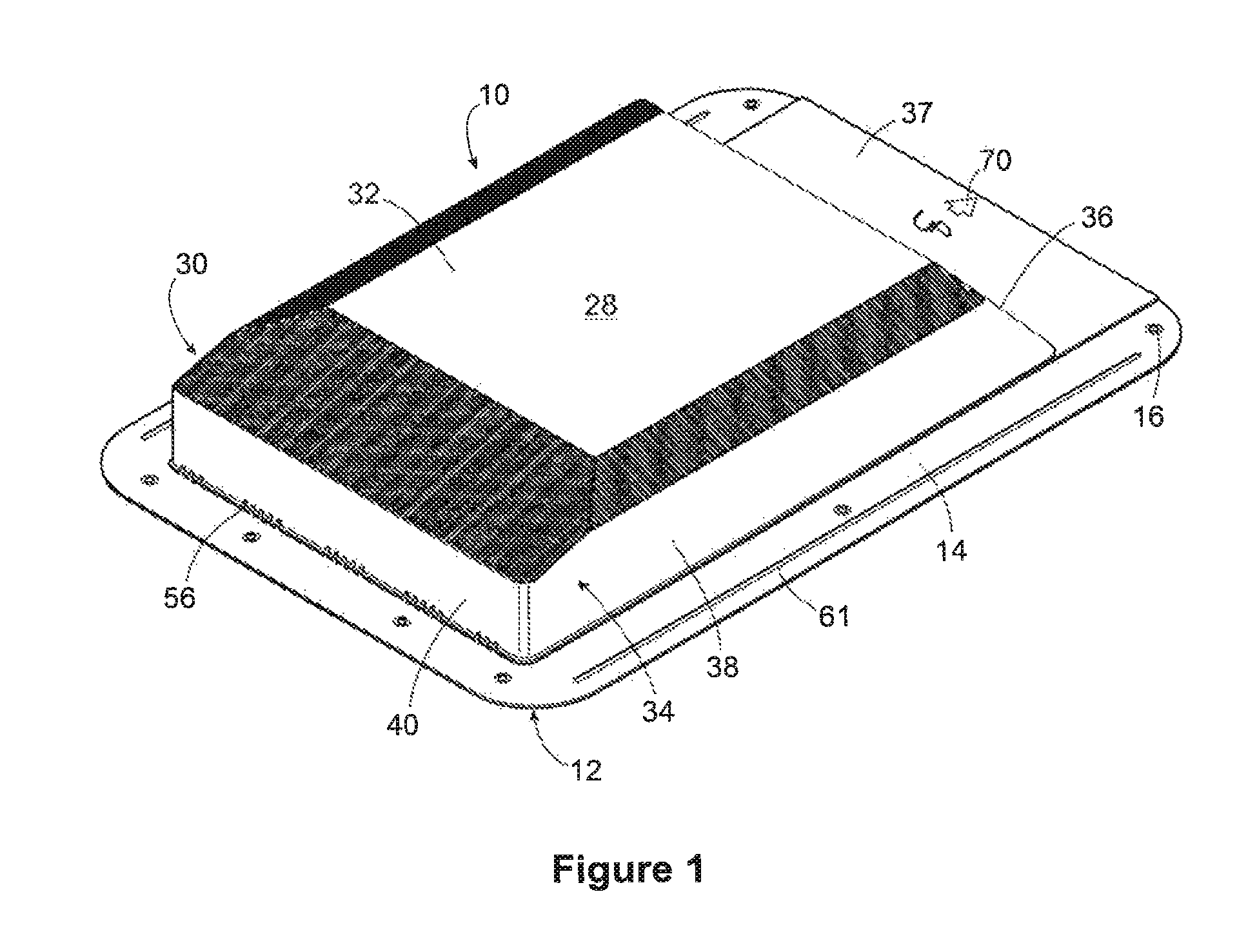

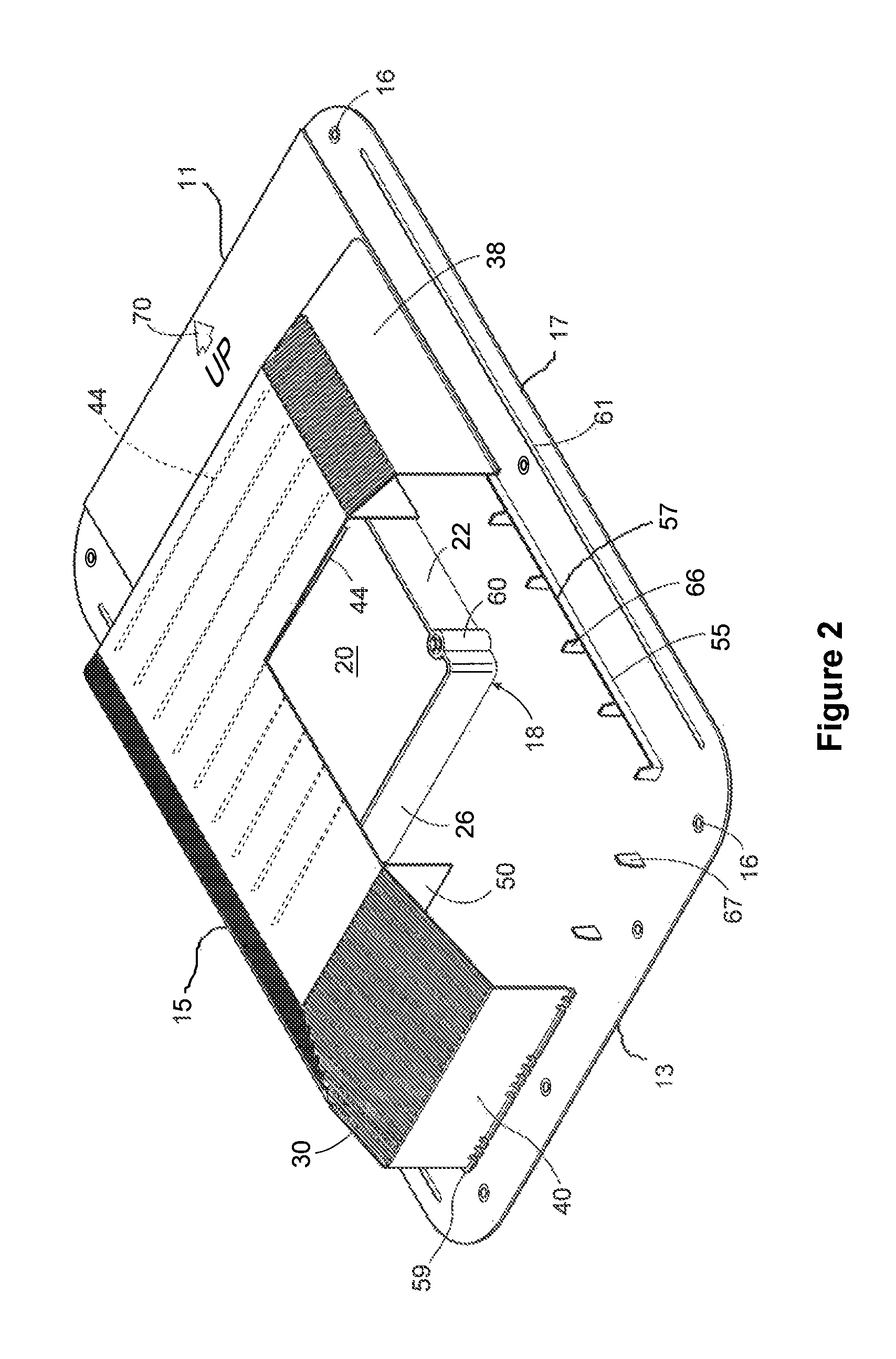

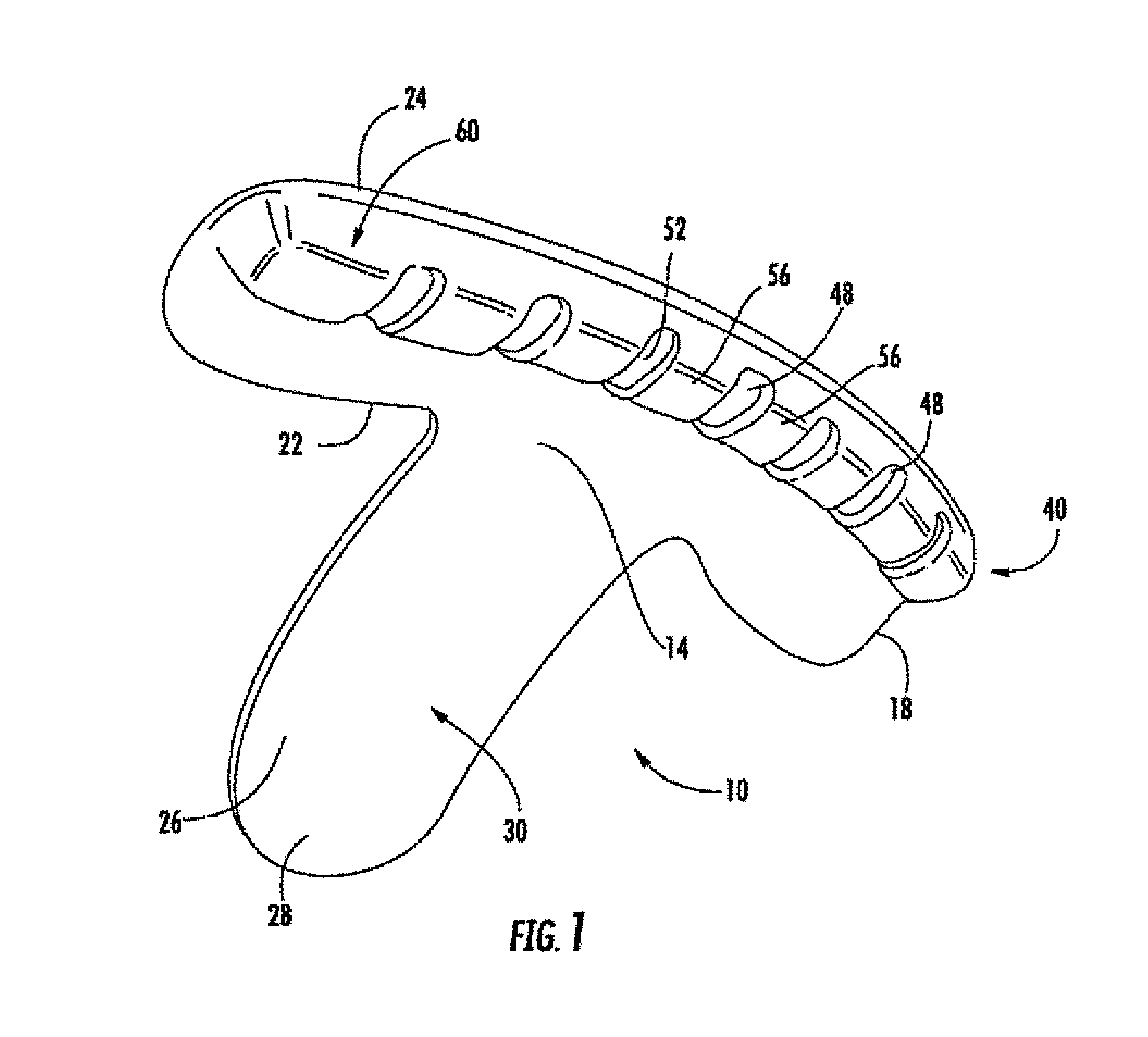

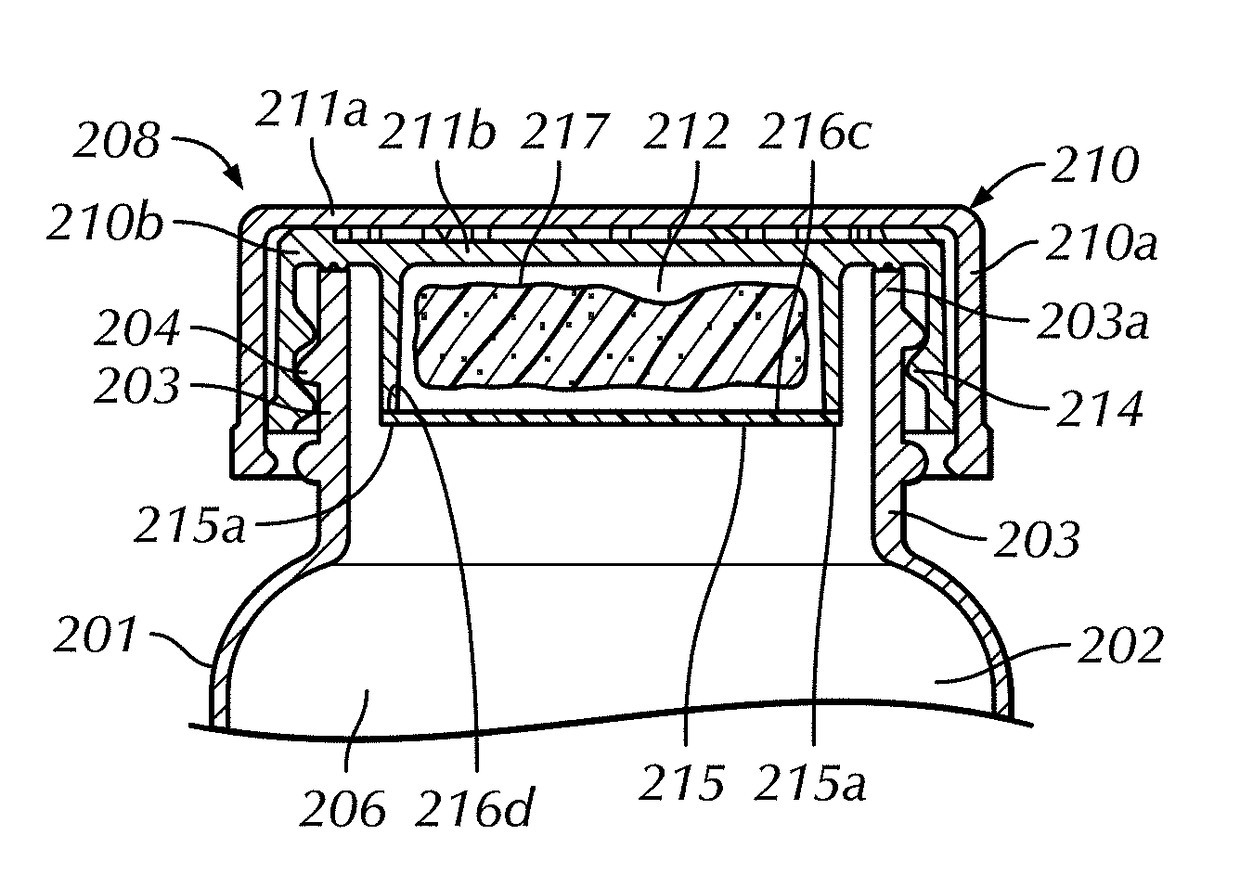

Hip protector system

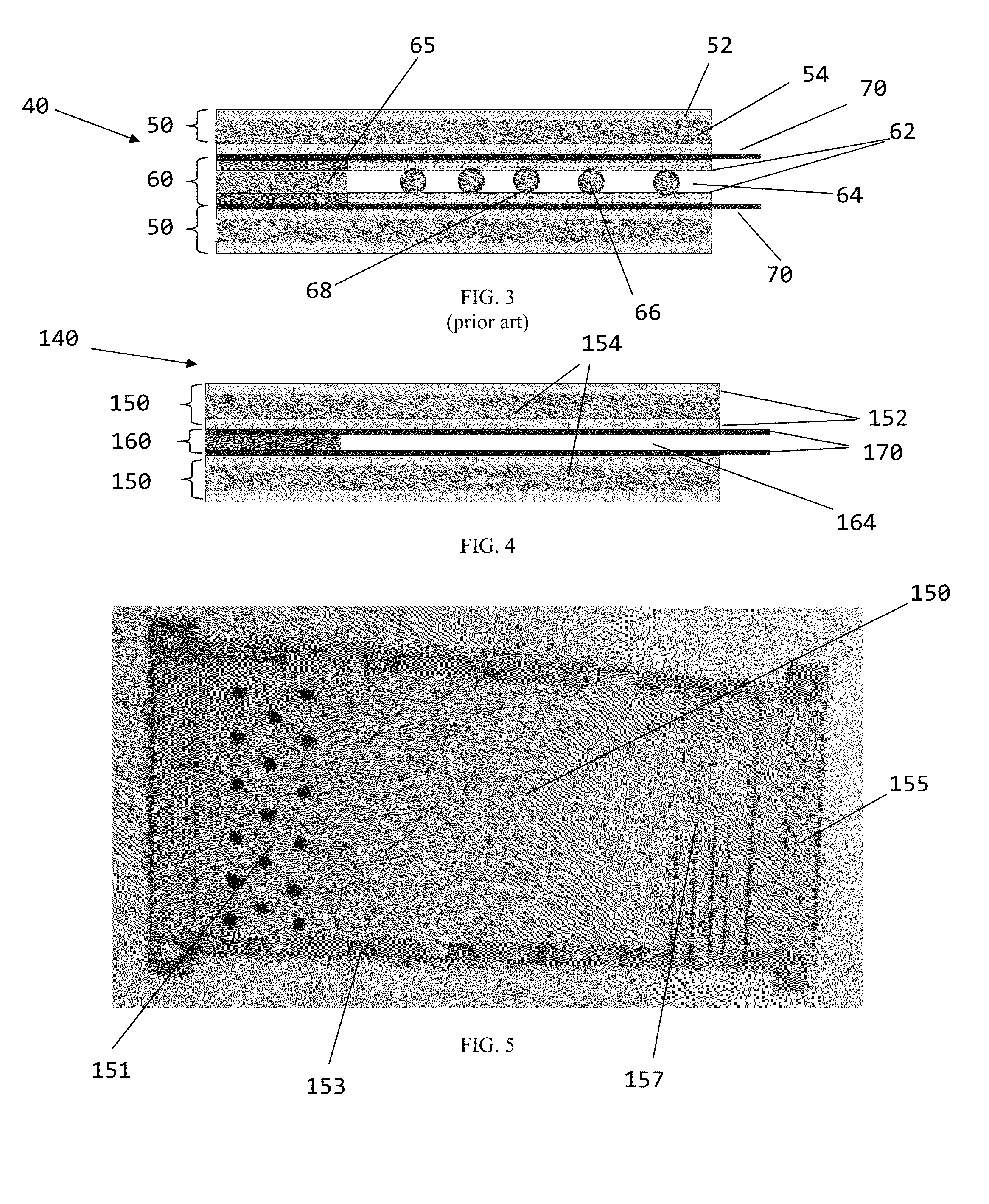

Hip protector (10) worn primarily by the elderly, preventing / reducing hip fractures, resulting from a fall. The protector is made of all-soft materials using a matching pair of hip protective holsters (14 / 24) interconnected by a waist encircling belt (16) from which a pair of protective pad pouches (20) are suspended in the holsters over the user's hips and secured in place by leg encircling bands (18 / 26). The protective pouches include foam bodies (54) with underlying, intermediate, spacer elements (42) and a bottom cover (50), all in combination creating an enclosed, moisture-holding, air chamber (80). The protector is worn under clothing (under pants, bed clothes or swimming trunks, etc.), light weight, easily put on & removed, does not interfere in daily living (sleeping, usual body movements, restroom or bathing activities, etc.), and, when the user sweats, the surface of the user's skin under the hip protector is maintained dry using “one-way-moisture flow” material.

Owner:MELTS MICHAEL

Roof vent

ActiveUS20130078903A1Cheap manufacturingInstallation economyRoof coveringLighting and heating apparatusEngineeringMechanical engineering

A vent for a building has a cover attached to a base. The base has an aperture permitting gas to pass. A moisture directing means on an underside of the cover directs moisture move under the influence of gravity to fall outside of the aperture. The cover may include a slanted side wall portion, with the aperture positioned with its center displaced from the center of the cover toward the slanted side. The base may include a pair of moisture deflecting features along at least a portion of one of the nonslope sides to prevent moisture flowing along the base from within an area on the base covered by the cover to outside of the covered area at the nonslope sides. The base may also include a water deflecting ridge on its underside positioned between a downslope edge and the aperture to deflect water away.

Owner:CANPLAS INDS

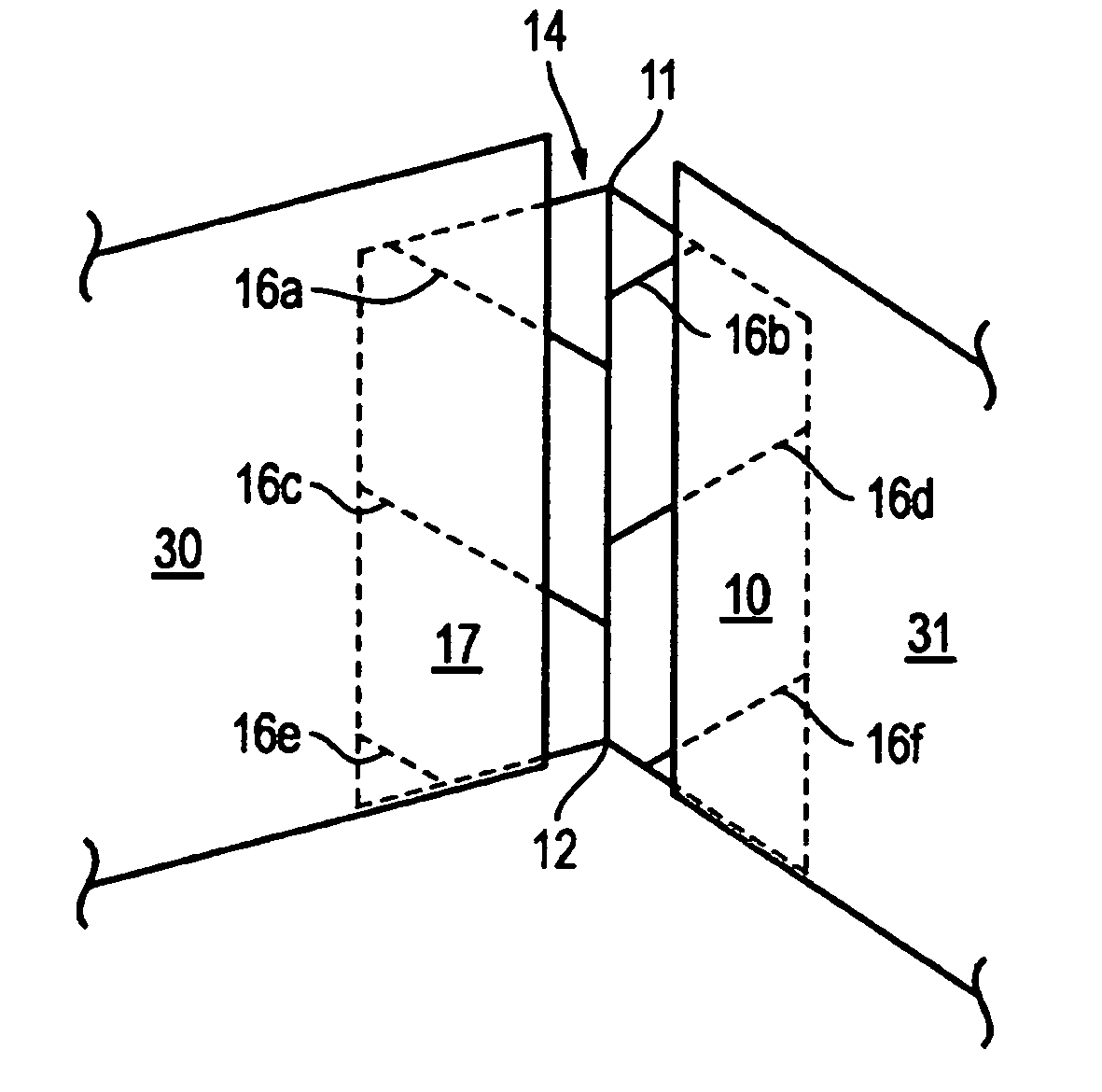

Directional flow flashing

InactiveUS7100331B2Prevent leakageAvoid moisture leakageRoof covering using slabs/sheetsRoof covering using tiles/slatesEtchingWall material

A flashing providing directional vanes, ribbing, scoring or etchings on its working surface which is suitable for joining, or providing backing for, sections of roofing materials, sections of exterior wall material, particularly at corners, and sections of the walls of a bathtub or shower stall and causes accumulated moisture flow to be directed inwardly toward a moisture drainage point for the flashing rather than outwardly toward the surrounding building structure.

Owner:NEHRING WALTER WAYNE

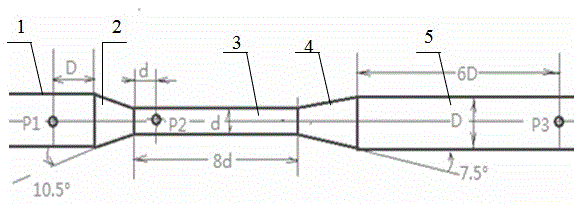

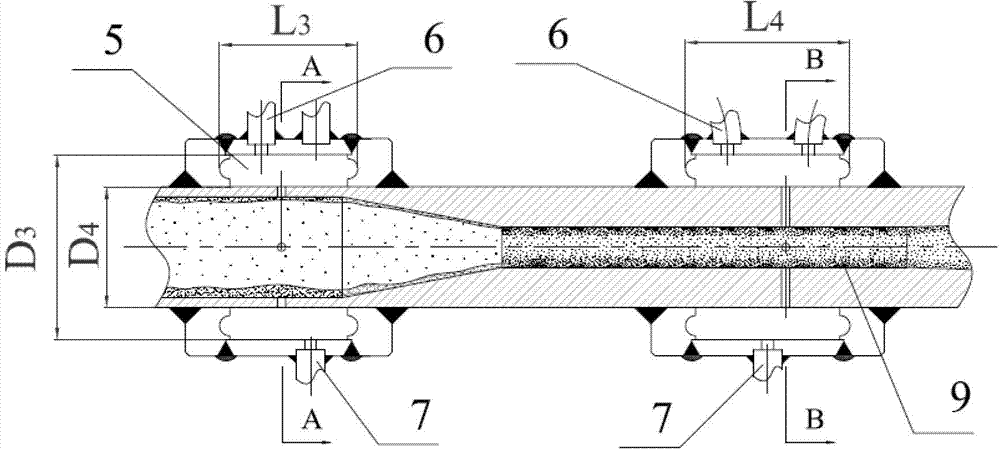

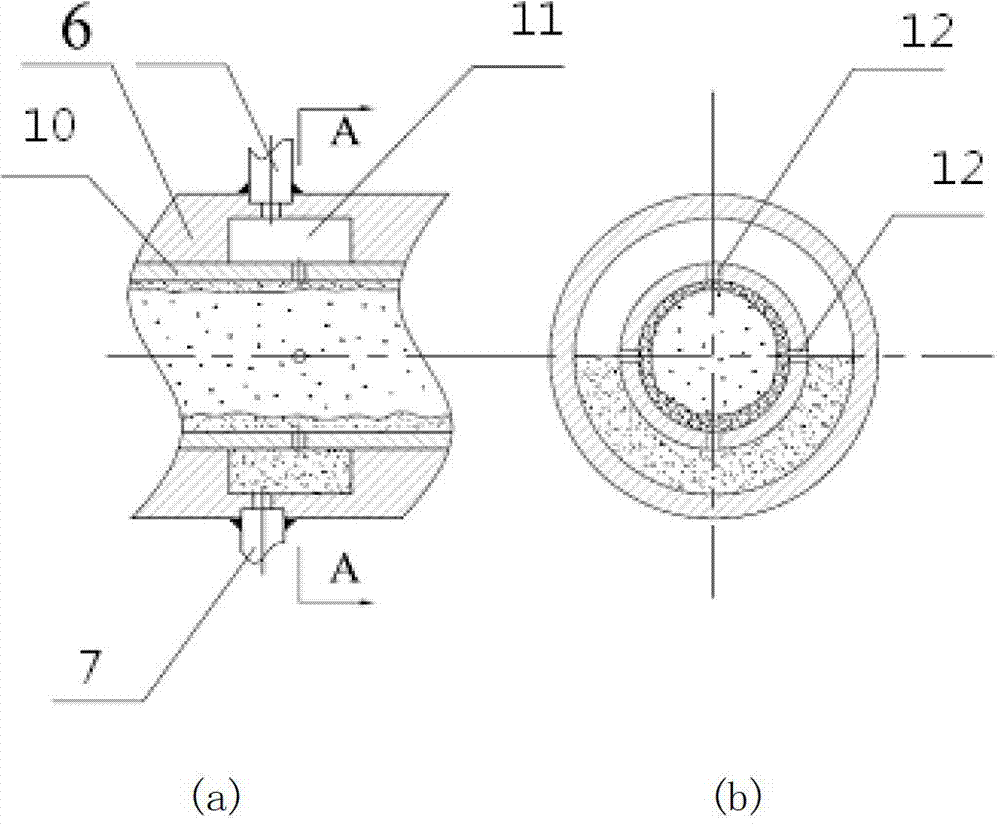

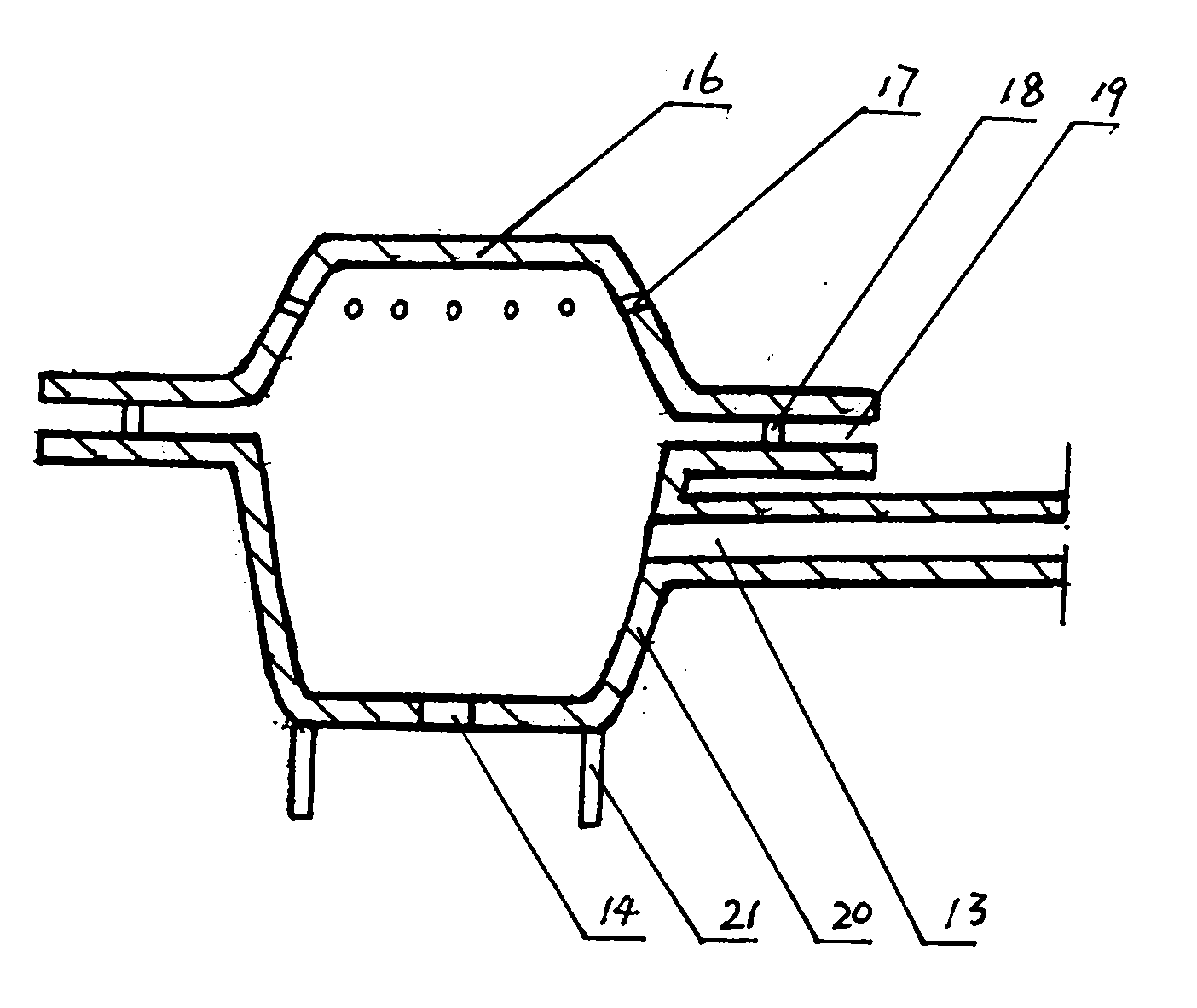

Irregular Venturi flowmeter and method for measuring gas-liquid phase flow in multiphase flow by utilization of irregular Venturi flowmeter

InactiveCN105675070AChange the upstream and downstream symmetrical structure designSimple structureVolume/mass flow by differential pressureIndirect mass flowmetersThroatStraight tube

The invention discloses an irregular Venturi flowmeter, comprising a Venturi tube and at least three pressure probes, wherein the Venturi tube is composed of a front straight tube section, a contraction section, a throat section, an expansion section and a rear straight tube section; all the sections are connected in sequence; the inner diameter of each of the front straight tube section and the rear straight tube section is D; the inner diameter of the throat section is d; each of the contraction section and the expansion section is conical; the structural parameters of the Venturi tube are as follows: beta=d / D=0.45 to 0.75, the length of the throat section is 2d to 8d, the conical degree of the contraction section is 10.5 degrees, and the conical degree of the expansion section is 7.5 degrees. The invention further relates to a method for measuring gas phase flow and liquid phase flow in moisture by utilization of the irregular Venturi flowmeter. The irregular Venturi flowmeter is especially suitable for measuring downhole moisture flow, and is especially used for monitoring the gas phase flow and the liquid phase flow in an underground connected well connecting a main gas reservoir with a related gas reservoir in the process of manual migration and development of related oil-gas reservoirs in real time.

Owner:CHINA NAT OFFSHORE OIL CORP +2

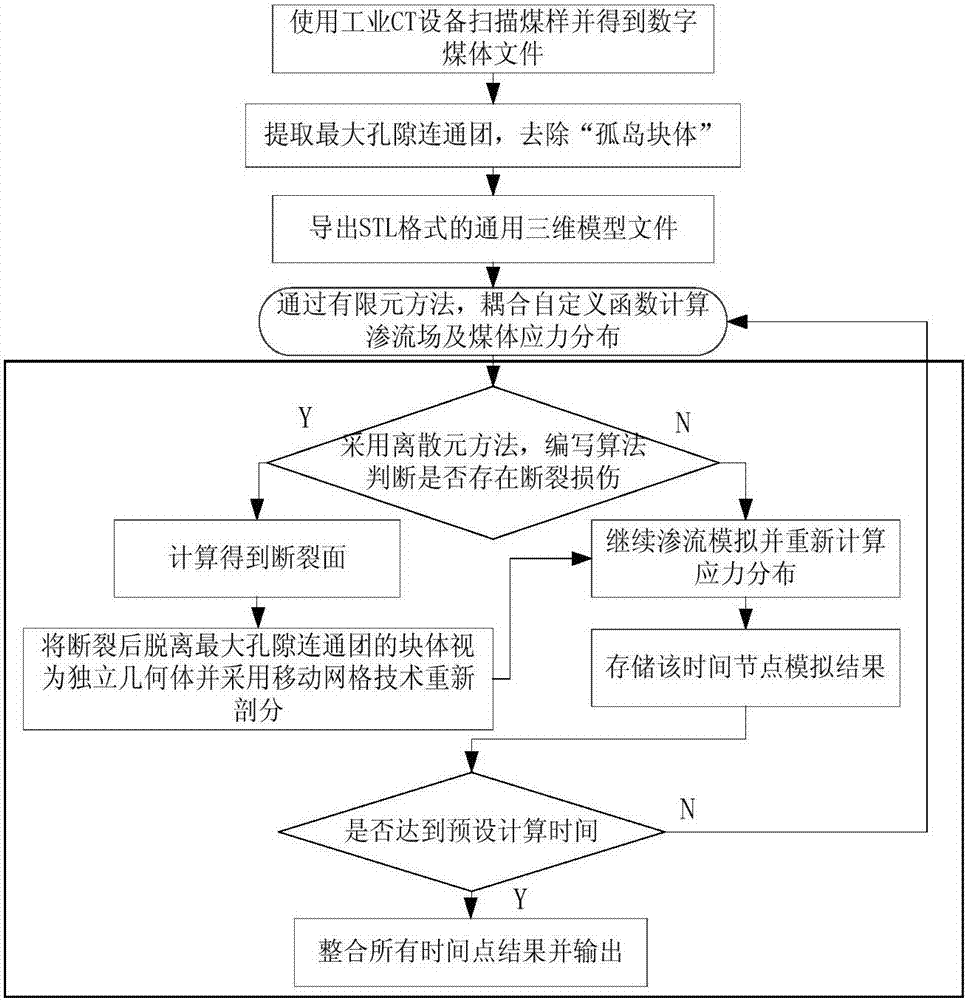

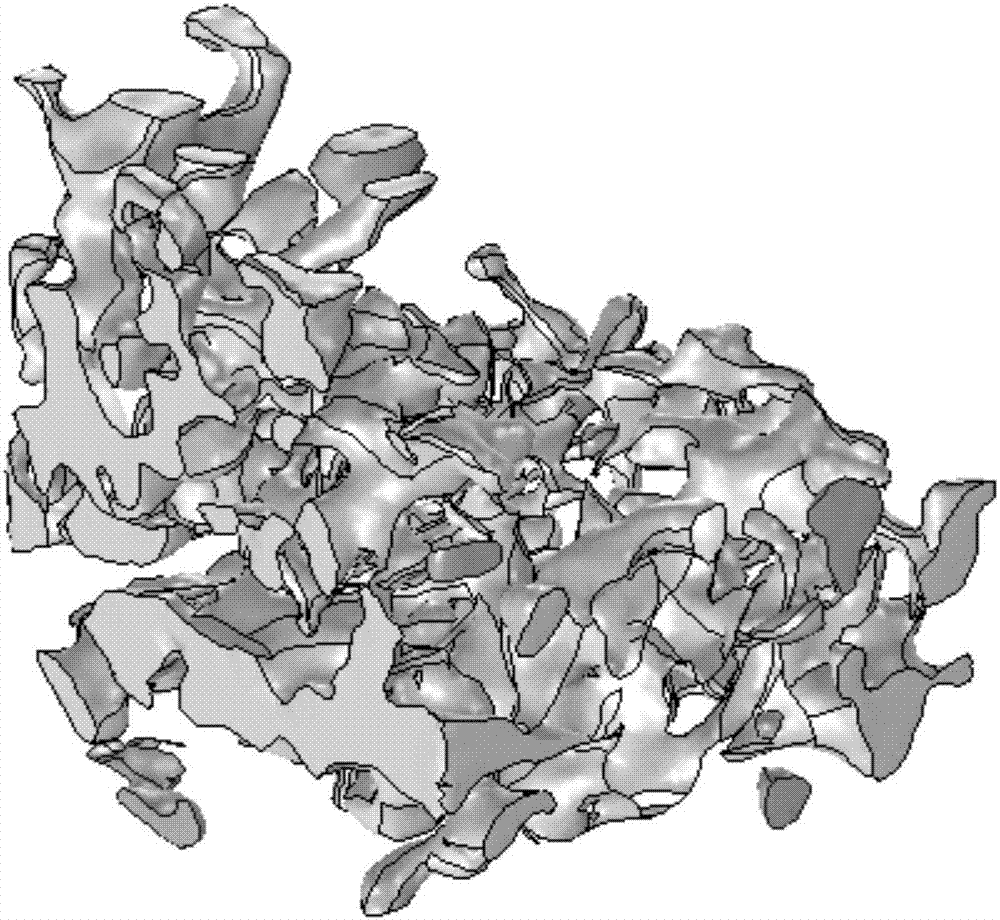

Seepage simulation method for constructing coal body based on finite element-discrete element CT (Computer Tomography)

ActiveCN106960070AFracture RealizationUniversally applicableDesign optimisation/simulationSpecial data processing applicationsPorous mediumMobile grid

The invention discloses a seepage simulation method for constructing a coal body based on finite element-discrete element CT (Computer Tomography). The method comprises the following steps: performing industrial CT scanning to obtain a three-dimensional data body of the coal body, performing three-dimensional reconstruction, and removing an ''island block'' to obtain a general three-dimensional geometric model which can be called by simulation software; writing a coal body fracture discrimination algorithm by a discrete element simulation method, and determining whether the coal body is deformed, even fractured under the action of hydraulic pressure stress; meanwhile, realizing migration of coal body fragments formed after fracture in the coal body along with moisture flow based on an finite element simulation method by a mobile grid method; and performing numerical simulation of a moisture seepage pressure field, a seepage speed field and a coal body moisture increment at the same time in order to reveal deformation and fracture phenomena of the coal body and a migration rule of moisture in a water injection process of a porous medium coal bed to the maximum extent.

Owner:SHANDONG UNIV OF SCI & TECH

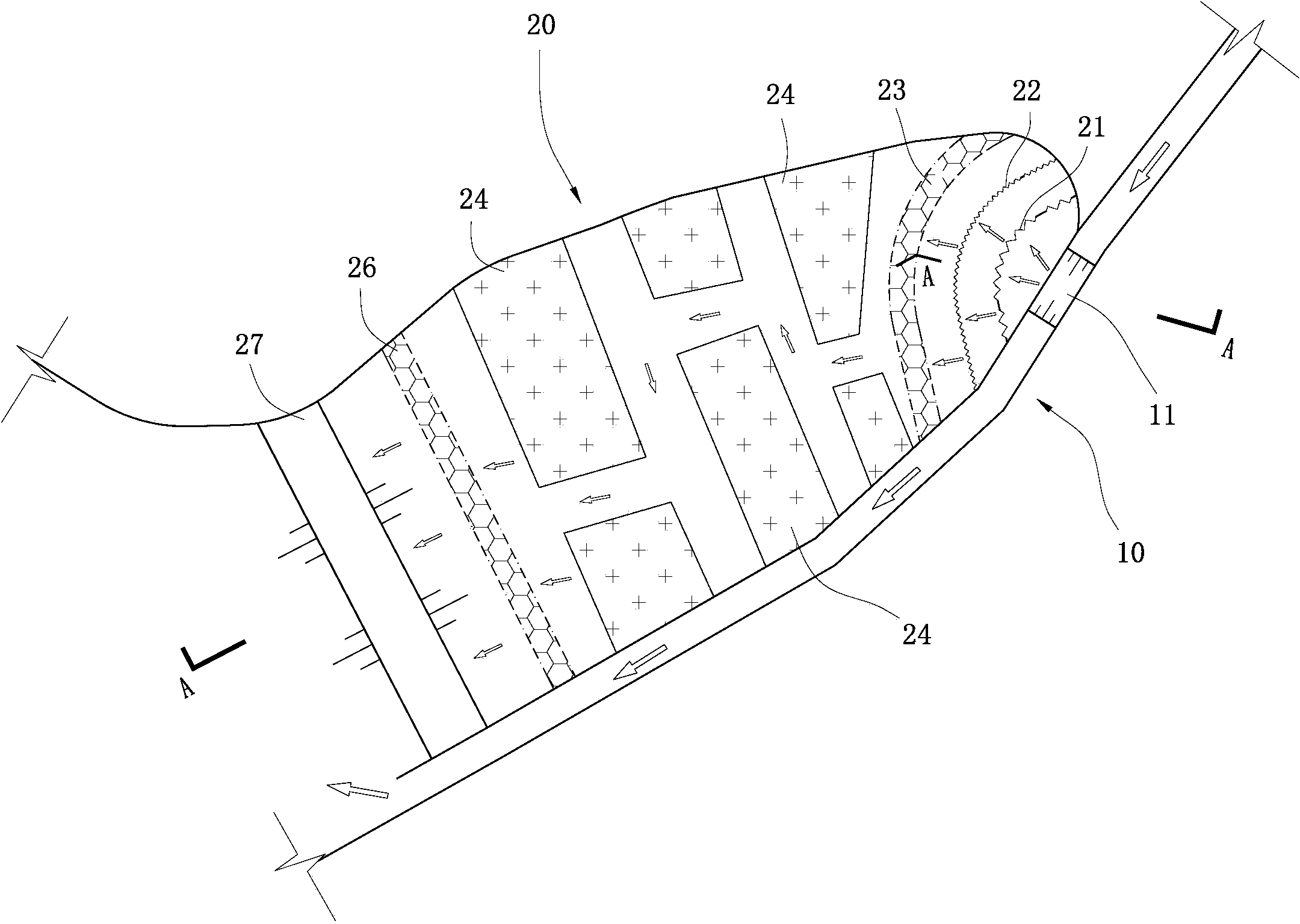

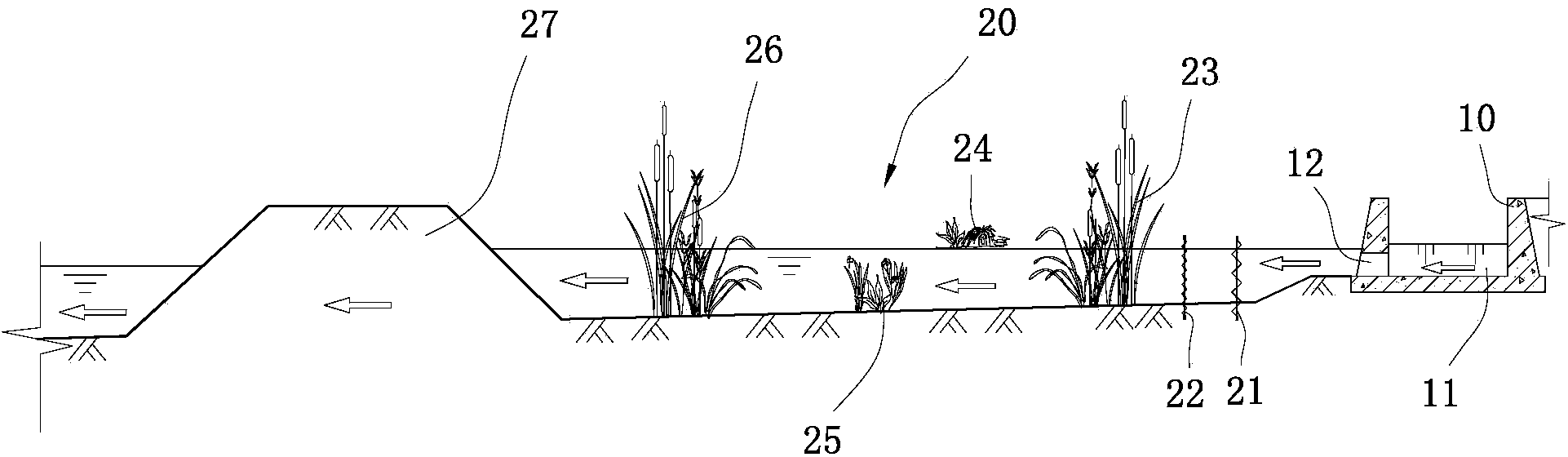

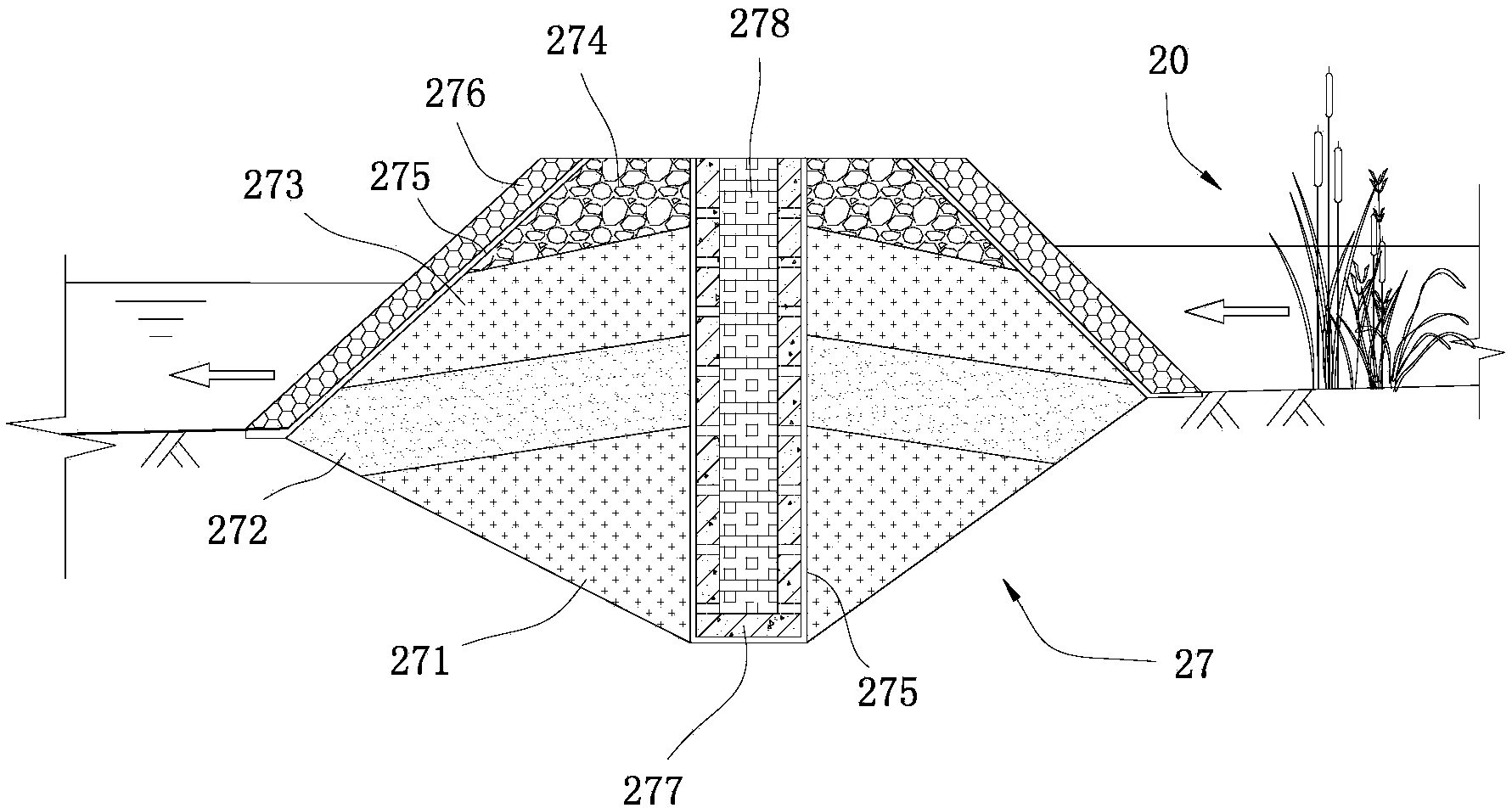

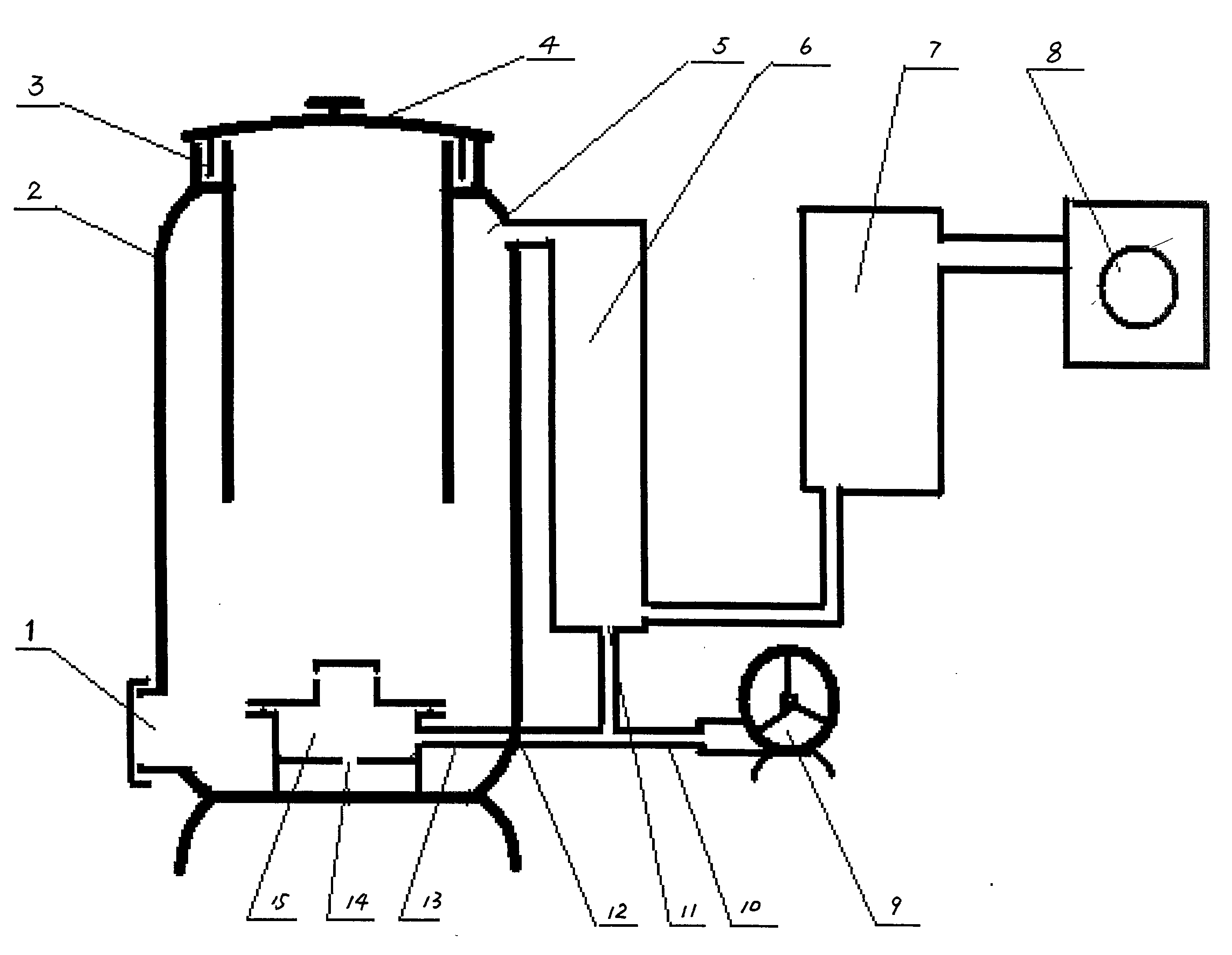

Initial rainwater and mixed rain-sewage overflow water impounding sewage facility

ActiveCN103821218ARealize purificationReduce water flowDamsFatty/oily/floating substances removal devicesWater flowSewage

The invention discloses an initial rainwater and mixed rain-sewage overflow water impounding sewage facility comprising a rainwater guide canal and a regulation reservoir arranged beside the rainwater guide canal. The rainwater guide canal is provided with a sinking intercepting channel which is provided with a side guide port communicated with the regulation reservoir. A grille area, a wetland filter plant area and a seepage filter area are arranged in the regulation reservoir sequentially along the water flow direction. Initial rainwater and mixed rain-sewage overflow water are low in flow; when guided via the rainwater guide canal, the initial rainwater and the mixed rain-sewage overflow water fall and flow into the intercepting channel at first and then flow into the regulation reservoir for purification, through the side guide port of the intercepting channel; with the passage of time, water level of the regulation reservoir rises, the intercepting channel is supported up to raise the water level thereof, and accordingly when flowing by the intercepting channel, late rainwater directly overflows from the intercepting channel and flows into downstream water through the lower segment of the rainwater guide canal; therefore, the initial rainwater and mixed rain-sewage overflow water which are severely contaminated, and the late rainwater, which is clean, are discharged separately.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

Hip protector system

InactiveUS20040049827A1Easy to noticeEasy to put inProtective garmentSpecial outerwear garmentsHip protectorMuscles of the hip

Hip protector (10) worn primarily by the elderly, preventing / reducing hip fractures, resulting from a fall. The protector is made of all-soft materials using a matching pair of hip protective holsters (14 / 24) interconnected by a waist encircling belt (16) from which a pair of protective pad pouches (20) are suspended in the holsters over the user's hips and secured in place by leg encircling bands (18 / 26). The protective pouches include foam bodies (54) with underlying, intermediate, spacer elements (42) and a bottom cover (50), all in combination creating an enclosed, moisture-holding, air chamber (80). The protector is worn under clothing (under pants, bed clothes or swimming trunks, etc.), light weight, easily put on & removed, does not interfere in daily living (sleeping, usual body movements, restroom or bathing activities, etc.), and, when the user sweats, the surface of the user's skin under the hip protector is maintained dry using "one-way-moisture flow" material.

Owner:MELTS MICHAEL

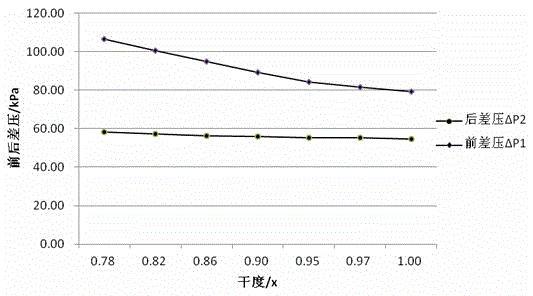

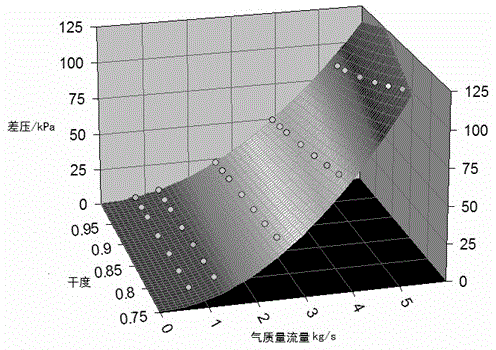

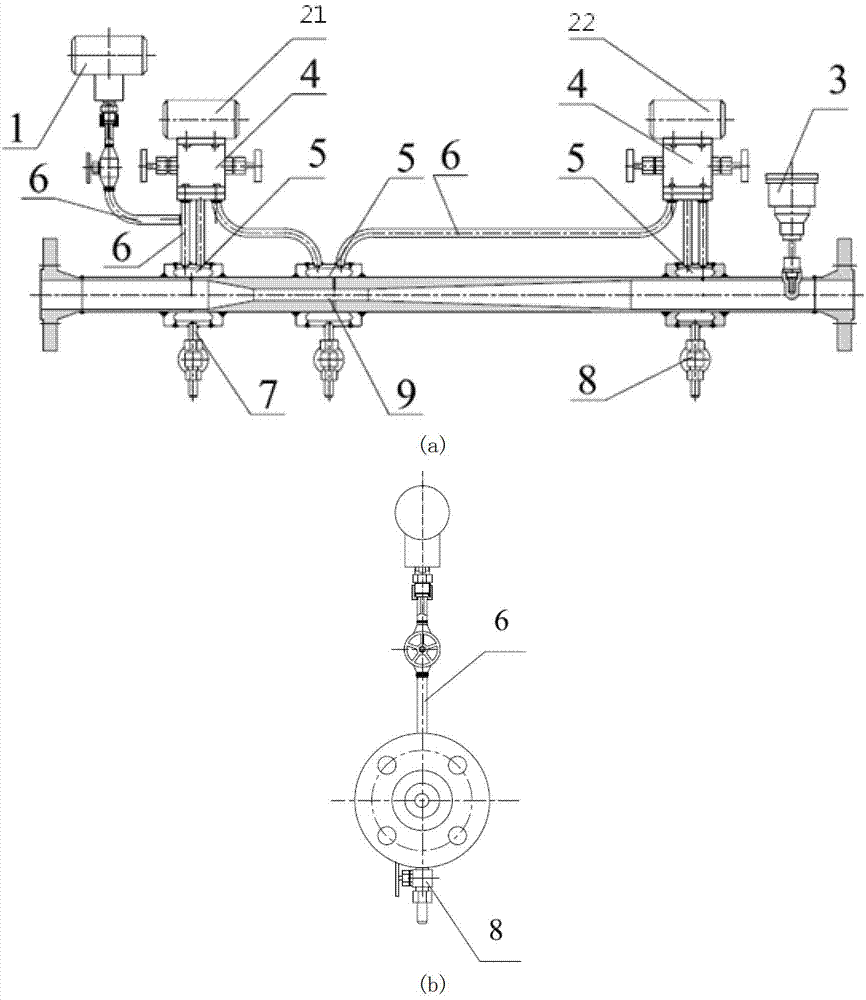

Double differential pressure moisture flow measuring device based on long-throat-neck venturi

ActiveCN103048019AIncrease the lengthEffective isolationVolume/mass flow by differential pressureInternal pressureThroat

The invention belongs to technical field of gas-liquid two-phase flow measurement of wet gas and relates to a double differential pressure moisture flow measuring device based on a long-throat-neck venturi. The double differential pressure moisture flow measuring device comprises a venturi measuring pipeline, a first differential pressure transmitter and a second differential pressure transmitter. A pressure taking position is respectively arranged at the upstream of the venturi measuring pipeline and the mid downstream and the downstream position of the throat, four inner pressure taking holes are arranged on the pipe wall of an identical plane perpendicular to the axis of each pressure taking position, and an annular chamber structure is fixed on the periphery of the four inner pressure taking holes. The first differential pressure transmitter is respectively connected with an external pressure introduction pipe connected with the two pressure taking positions at the upstream and the mid downstream of the throat, and the second differential pressure transmitter is respectively connected with an external pressure introduction pipe connected with the pressure taking position at the mid downstream of the throat and the pressure taking position at the downstream. The measuring device has the advantages of being simple in structure, free of movable parts, reliable in measurement, high in accuracy and simple and convenient to implement.

Owner:TIANJIN UNIV +1

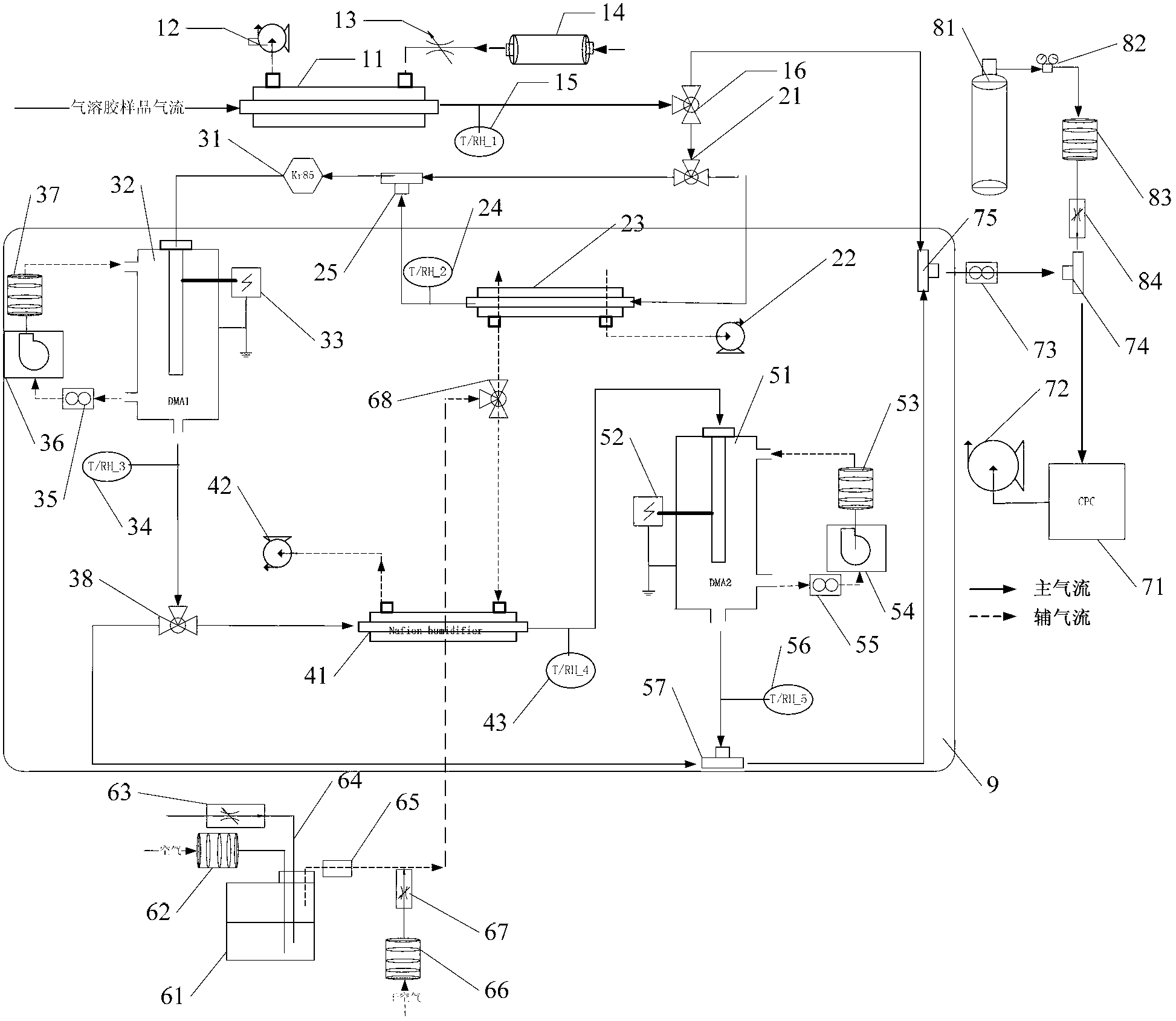

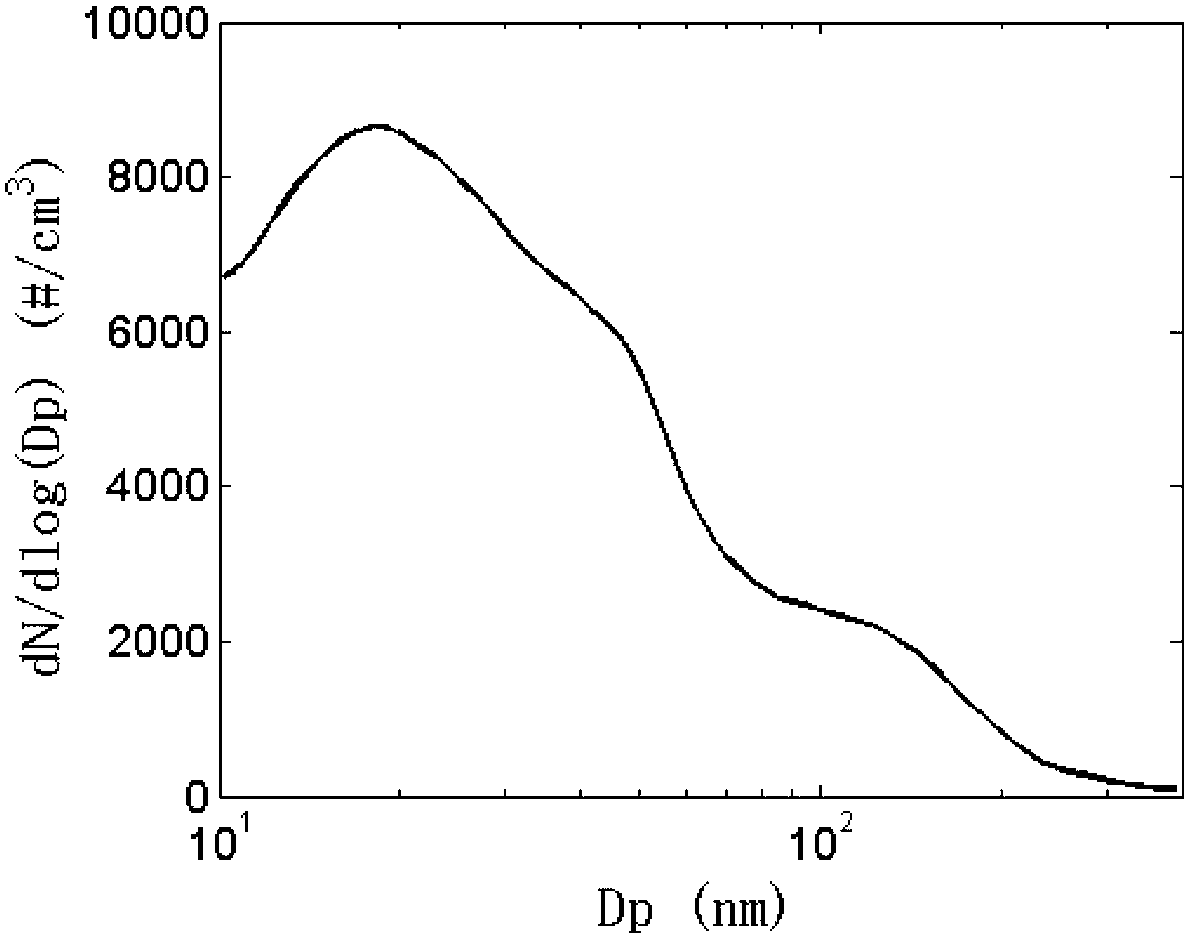

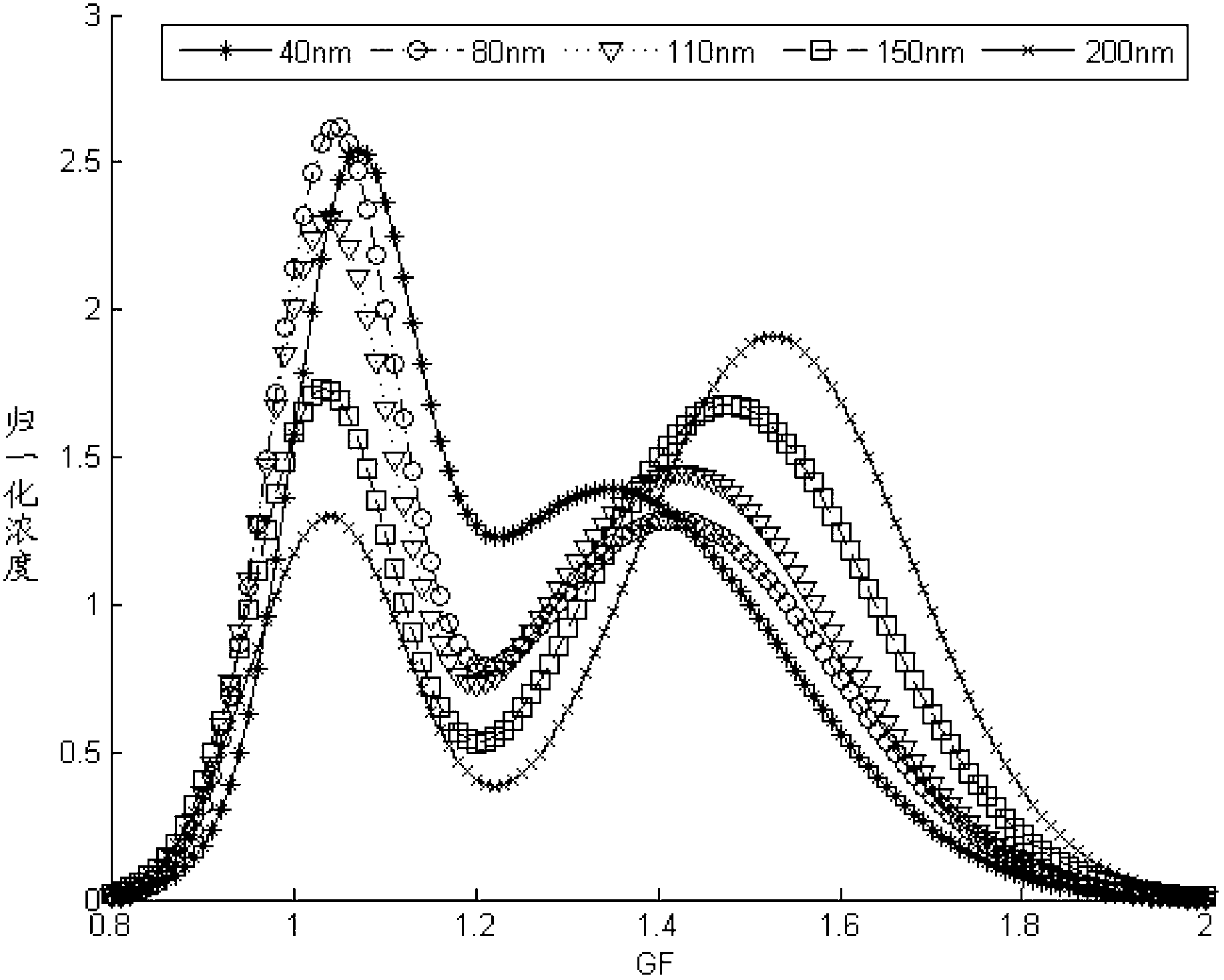

Moisture-absorption characteristic measuring instrument for atmospheric aerosols

InactiveCN102706781AGain a complete understanding of the impact of optical propertiesHigh degree of automationMaterial analysisAir compressionMeasuring instrument

The invention discloses a moisture-absorption characteristic measuring instrument for atmospheric aerosols. The instrument comprises a drying system, a first humidification system, a first particle size sorting system, a second humidification system, a second particle size sorting system, an air moisture flow system, a particle counting system, an air compression system and a data collecting and processing system. Compared with the prior art, the moisture-absorption characteristic measuring instrument for the atmospheric aerosols has the functions of measuring not only the moisture-absorption growth factors and mixing states of the aerosols with various particle sizes but also the dry (wet) particle-size spectra, is high in degree of automation and stability, is helpful to comprehensively learning about the moisture absorption characteristic of all particle-size segments and the influence on the optical characteristics of the aerosols from the moisture absorption, and is significant in researching the atmospheric ash haze forming mechanism and other aspects.

Owner:中国气象局广州热带海洋气象研究所 +1

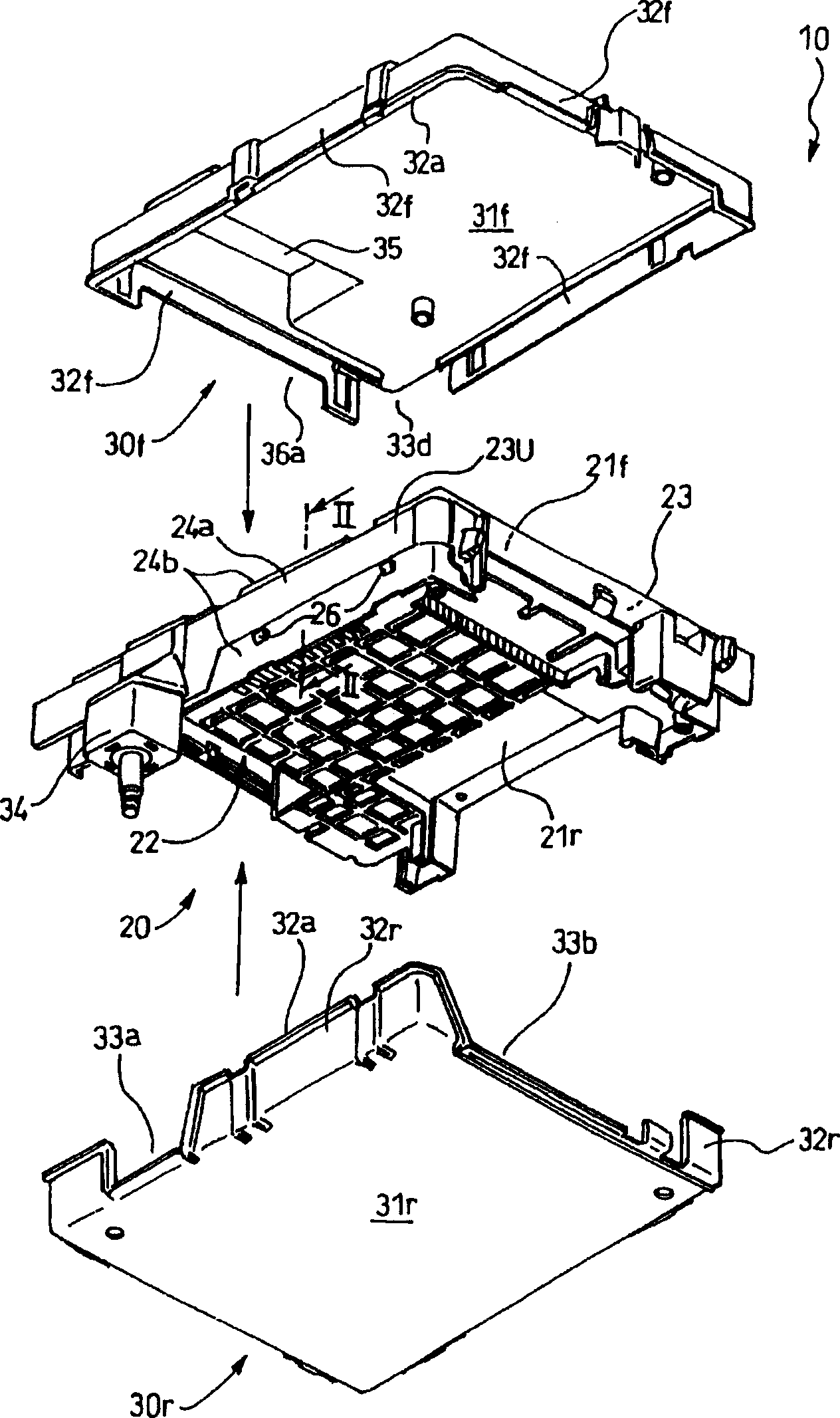

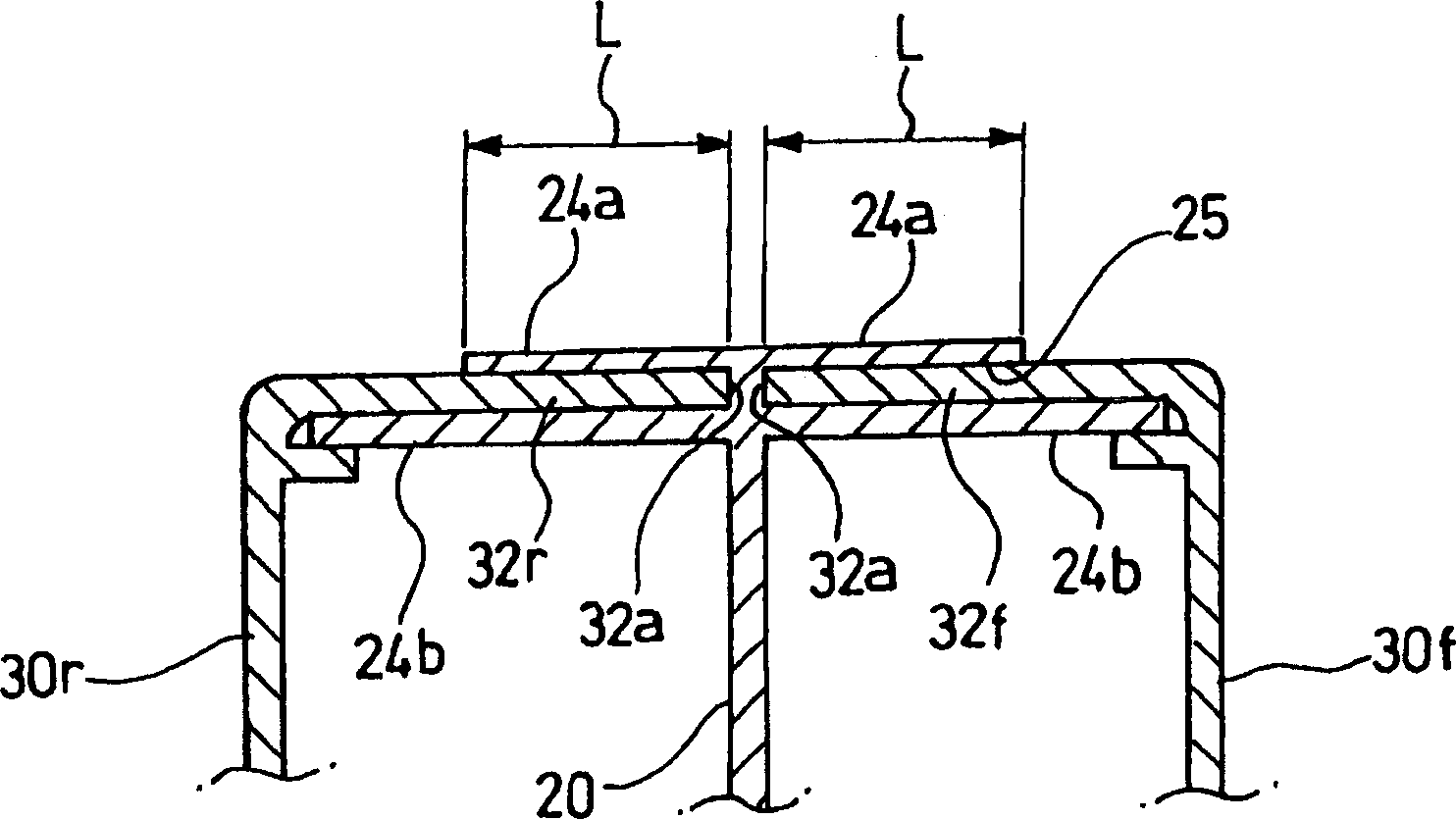

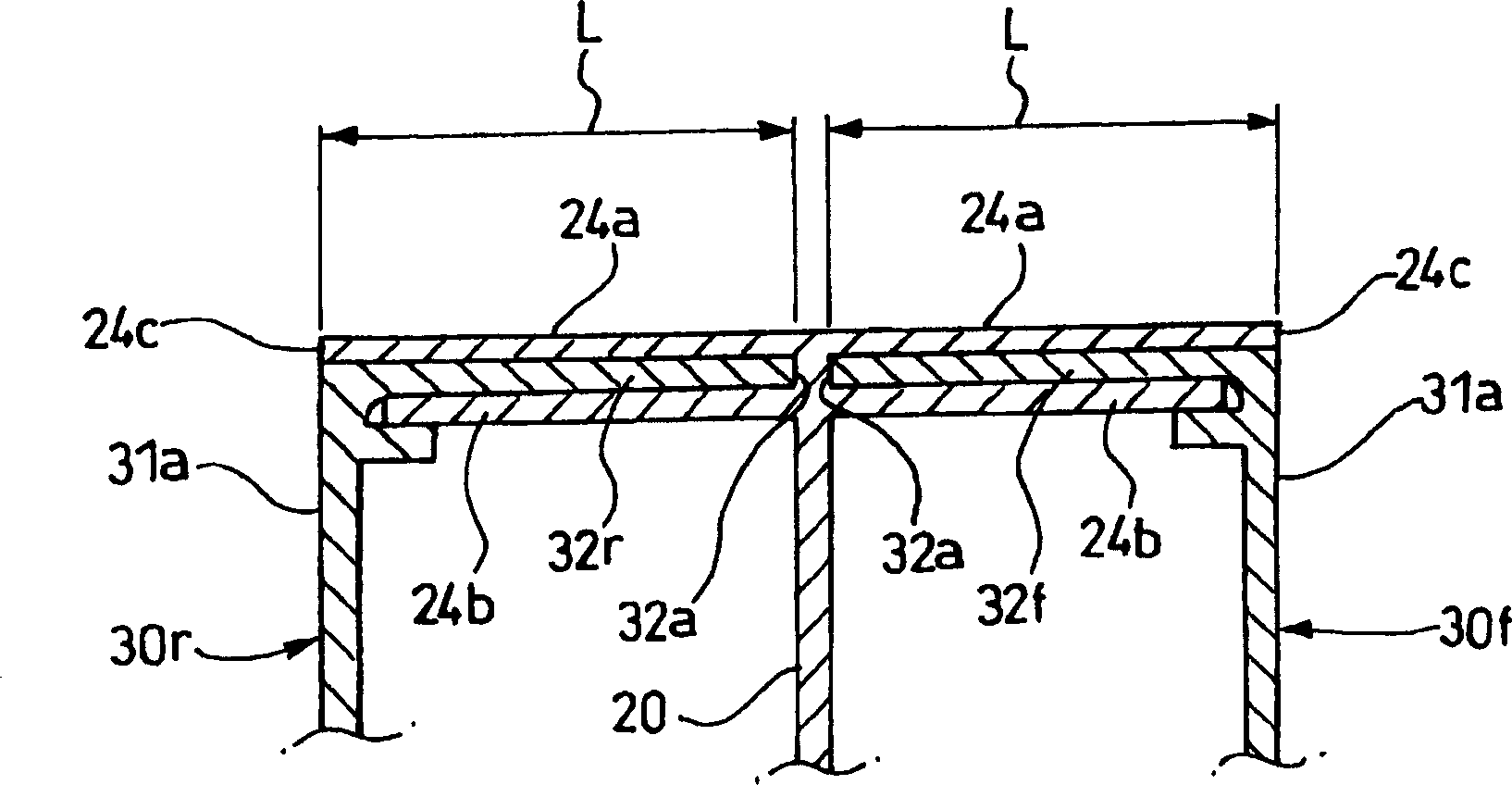

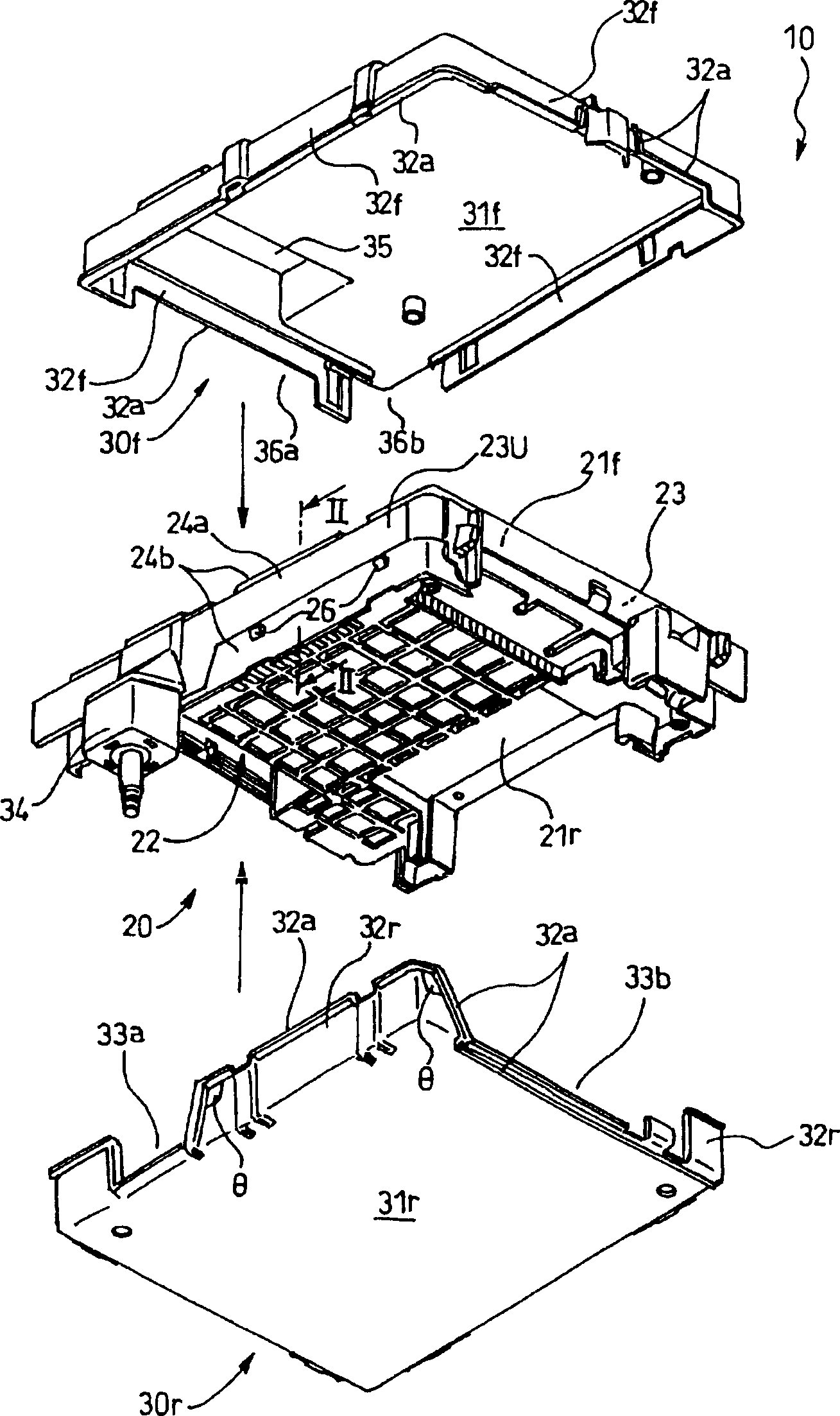

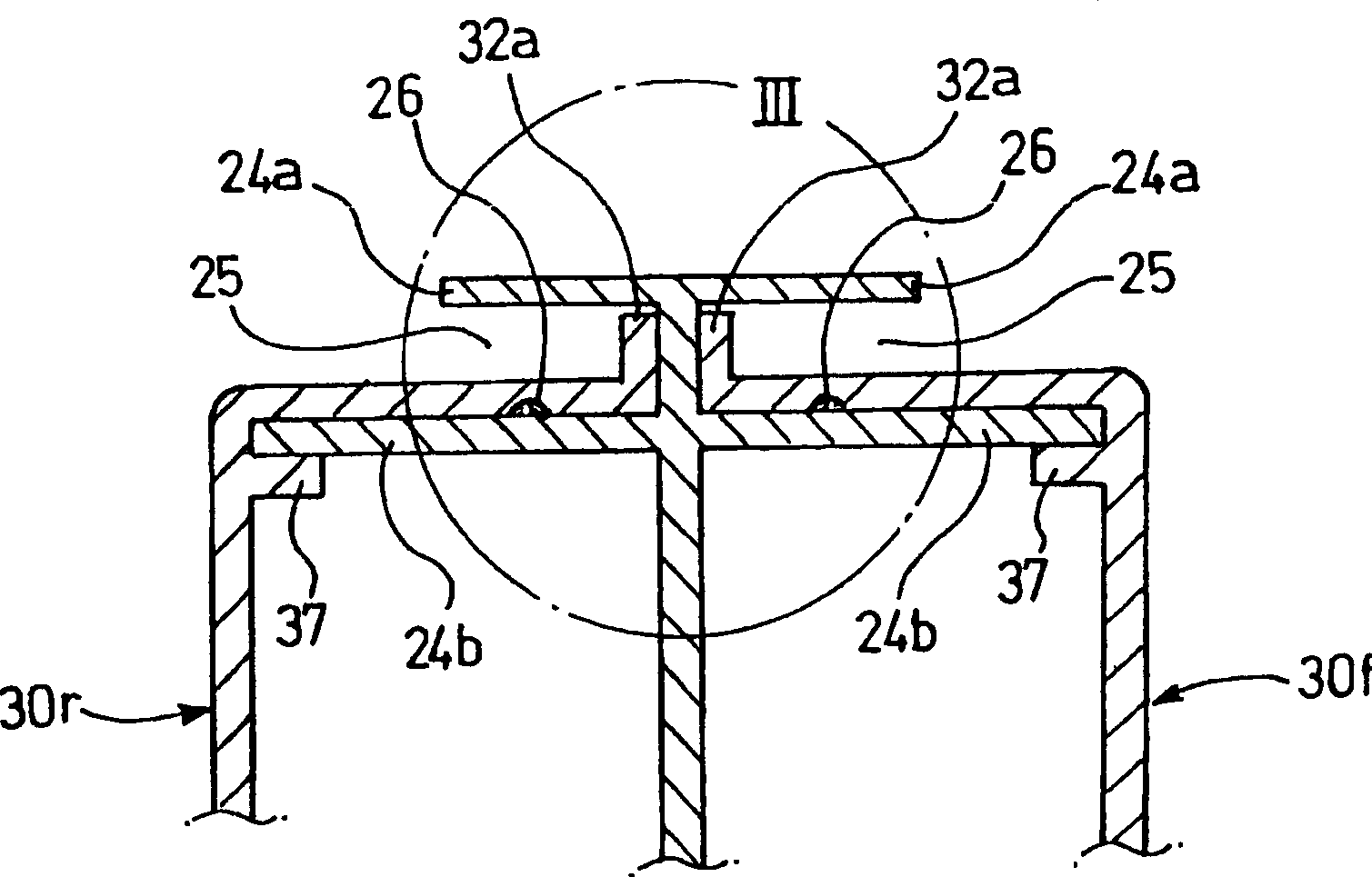

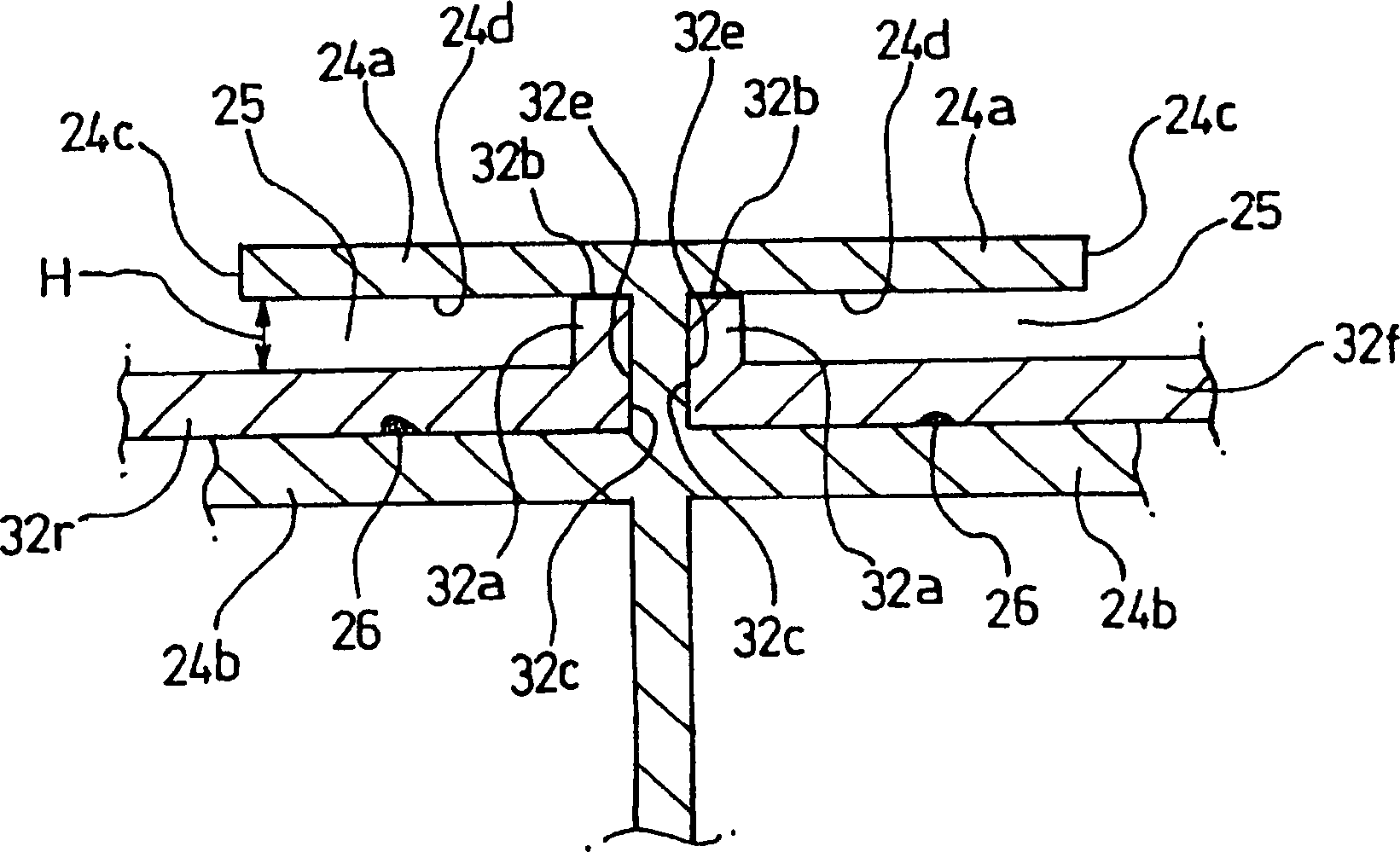

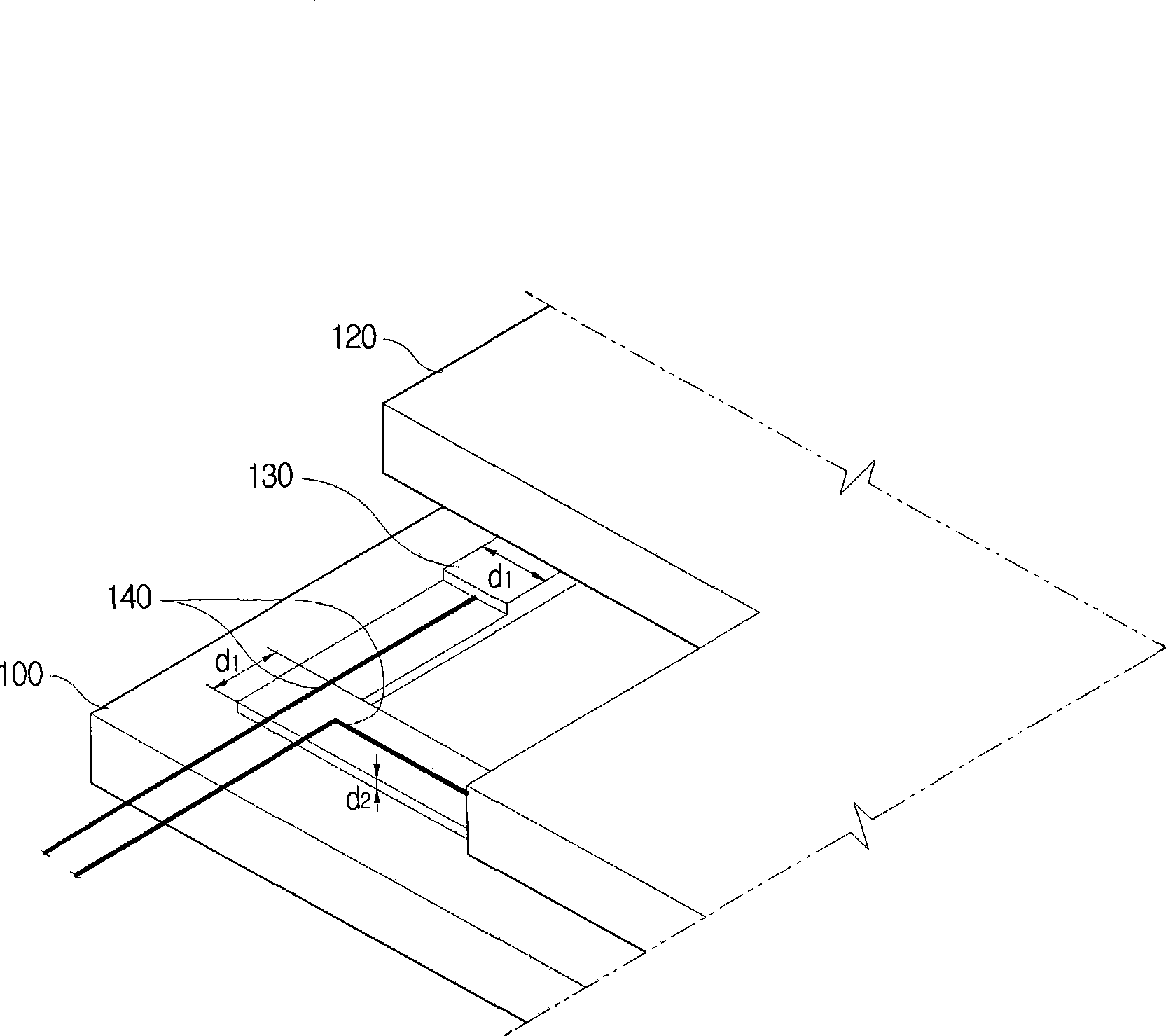

Waterproof structure of electric junction box

InactiveCN1525613AImprove waterproof performanceCasings/cabinets/drawers detailsCouplings bases/casesDouble wallEngineering

To provide a waterproof structure of an electric junction box wherein a waterproof property can be enhanced by a simple construction. The body 20 of an electric junction box 10 is provided with external double walls 24a and 24 so that fitting edges 32a of covering members 30f and 30r positioned on the front side and the rear side of the electric junction box 10 are covered therewith. The external double walls 24a and 24 are so provided that the covering members 30f and 30r are contained therein. Thus, moisture that dropped on the front side of the electric junction box 10 flows outside the covering members 30f and 30r, and the moisture is prevented from entering the electric junction box 10. Even if moisture flows to the body 20 side along the covering members 30f and 30r, and enters the external double walls 24a and 24, the ingress of the moisture into the electric junction box 10 is prevented by the inner wall of the external double walls 24a and 24 provided on the body 20. Therefore, a waterproof effect is enhanced. (C)2004,JPO&NCIPI.

Owner:YAZAKI CORP

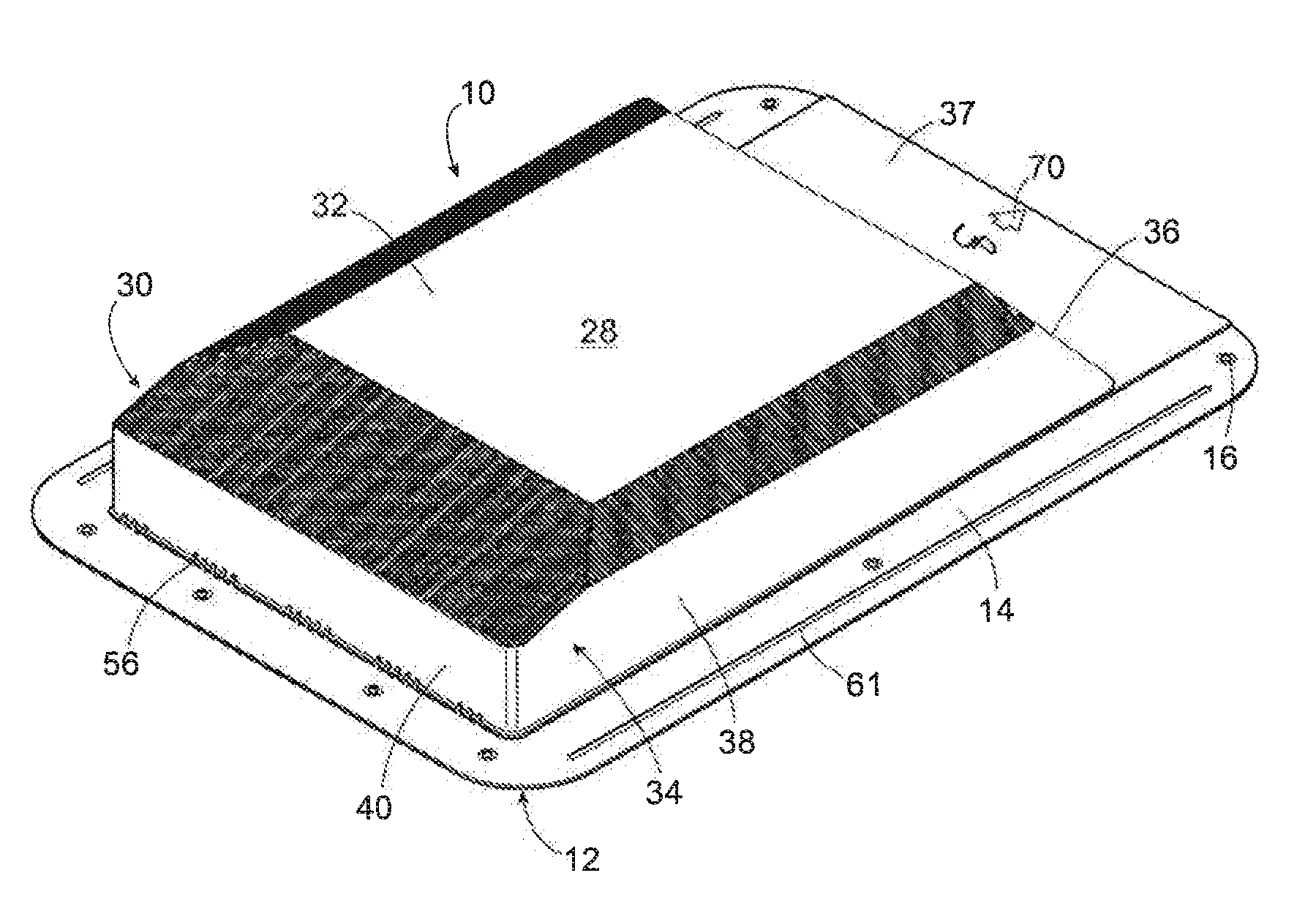

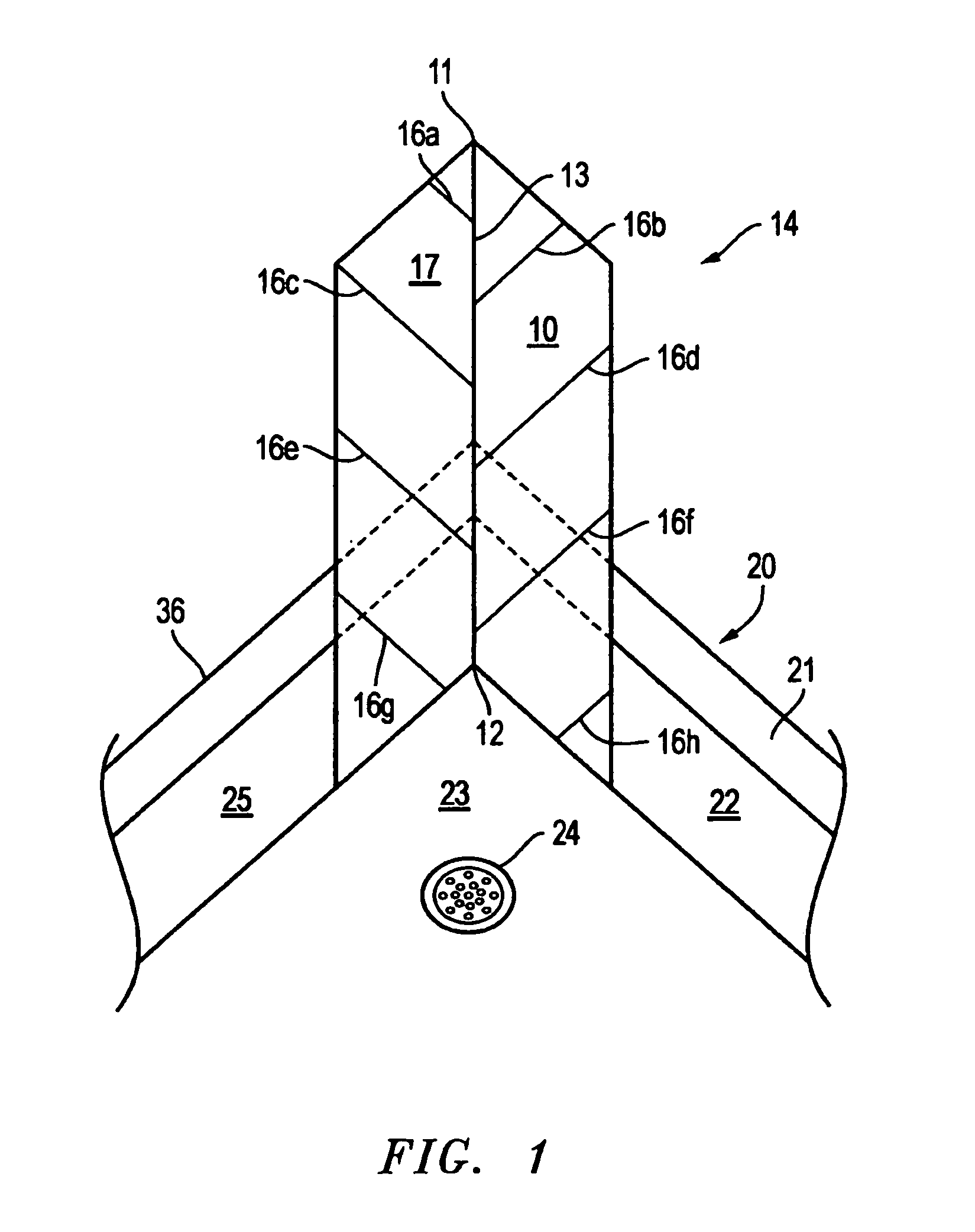

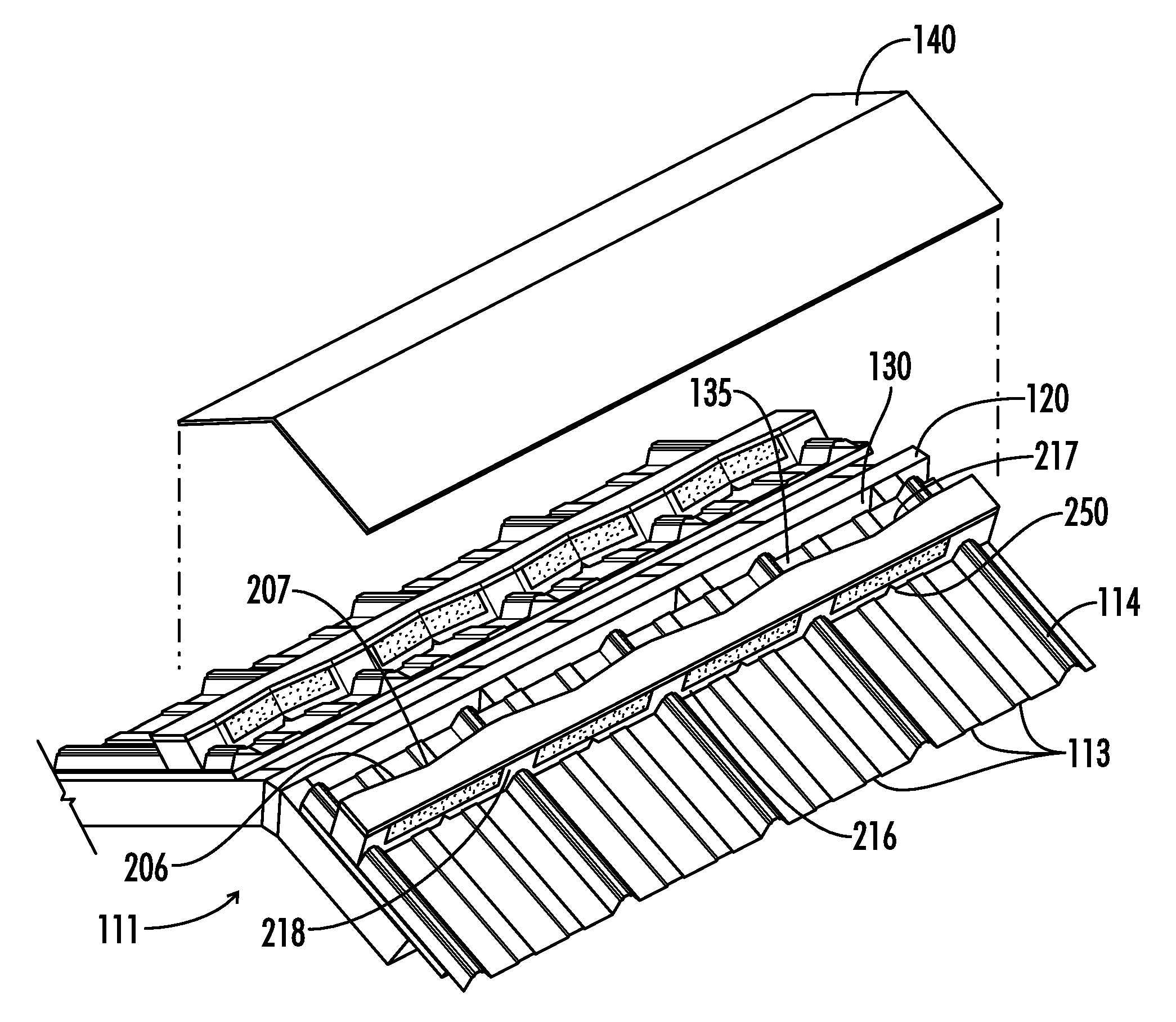

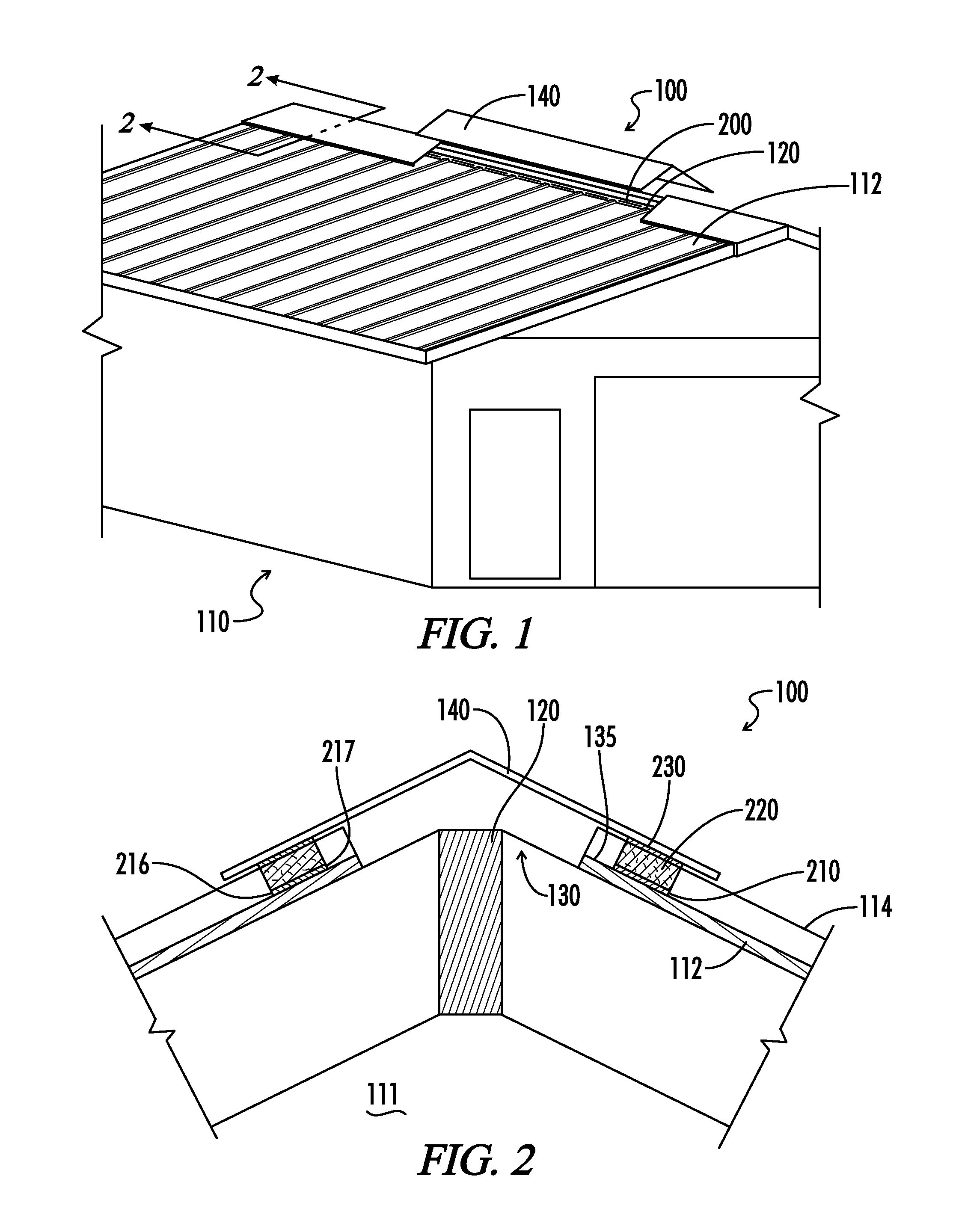

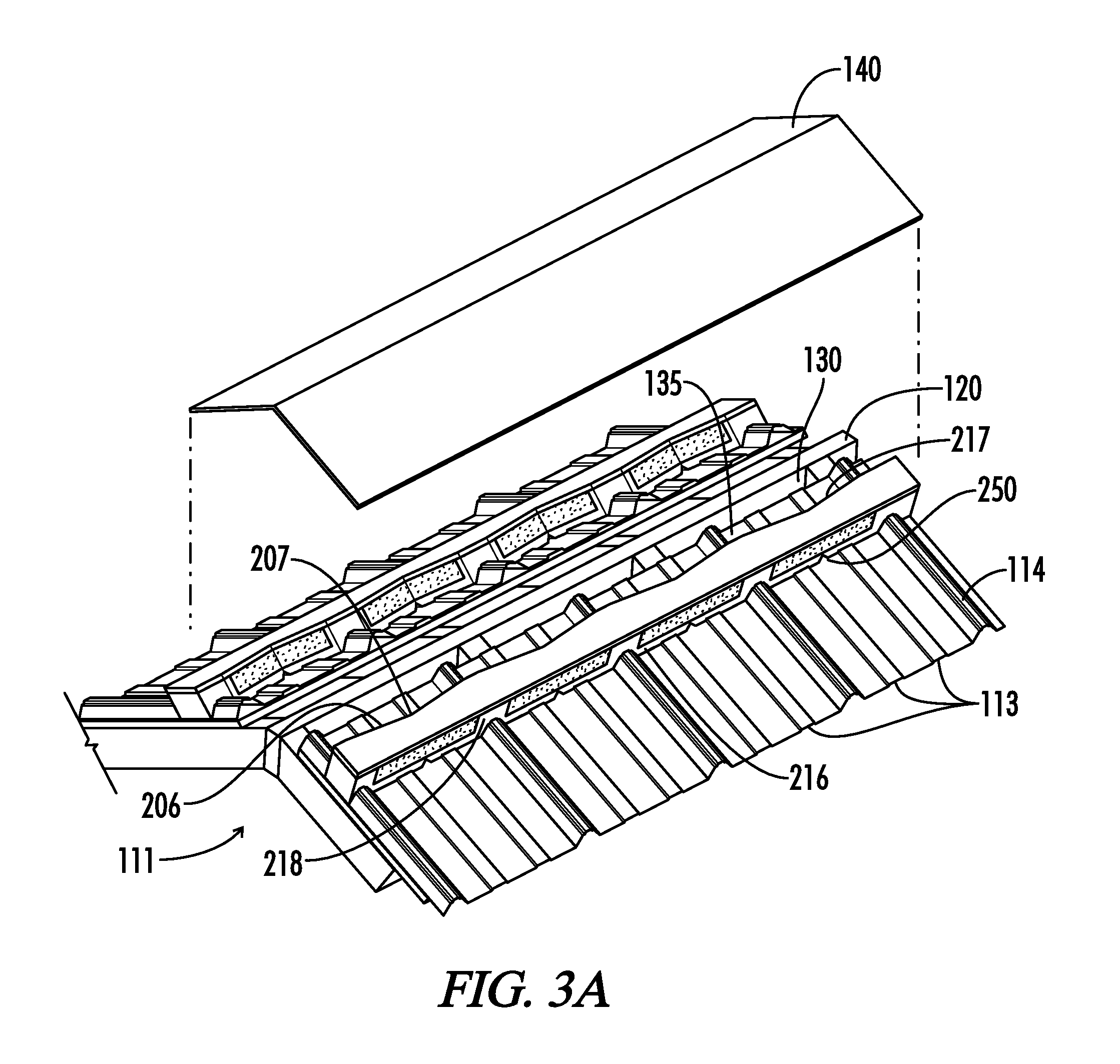

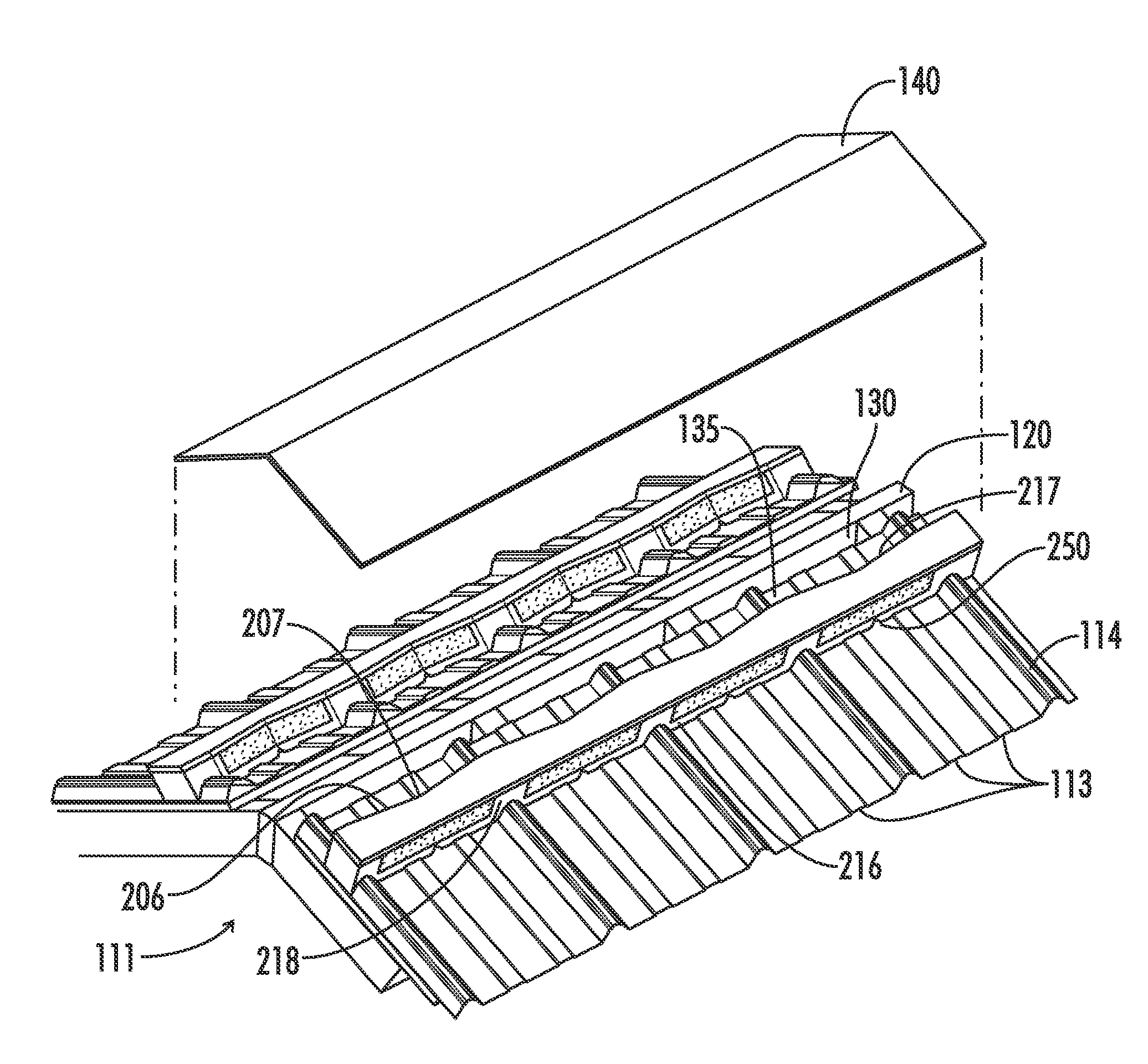

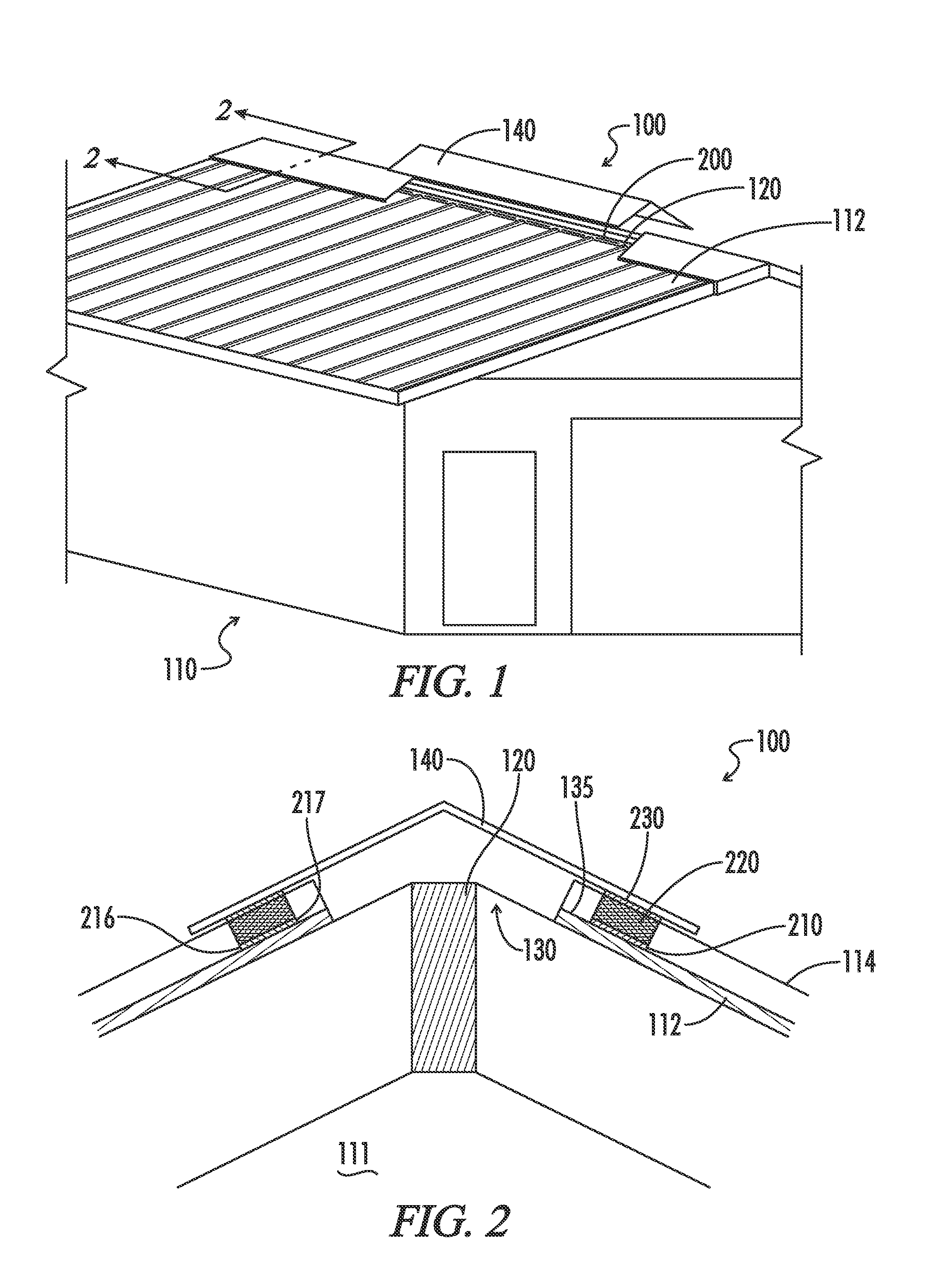

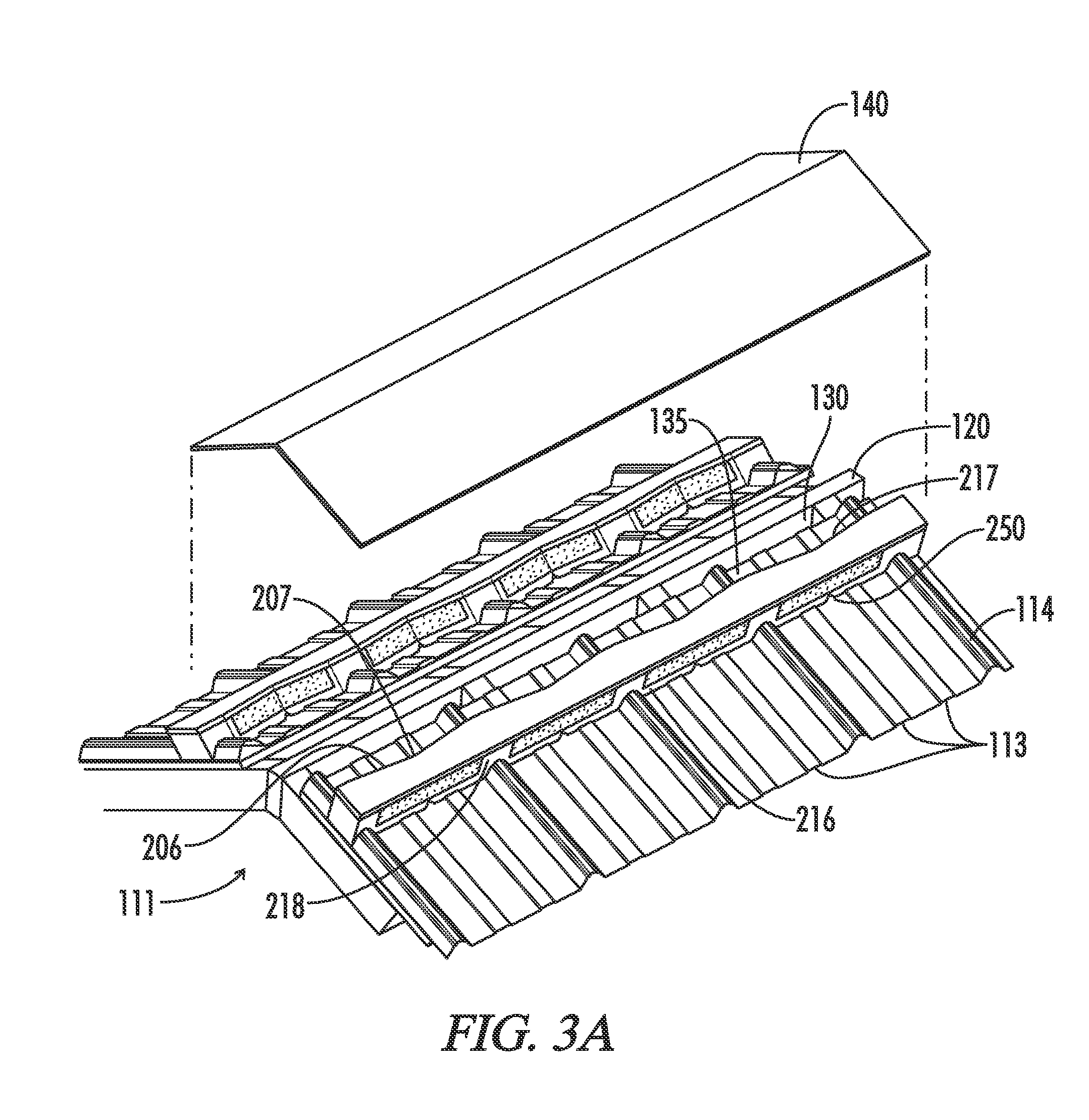

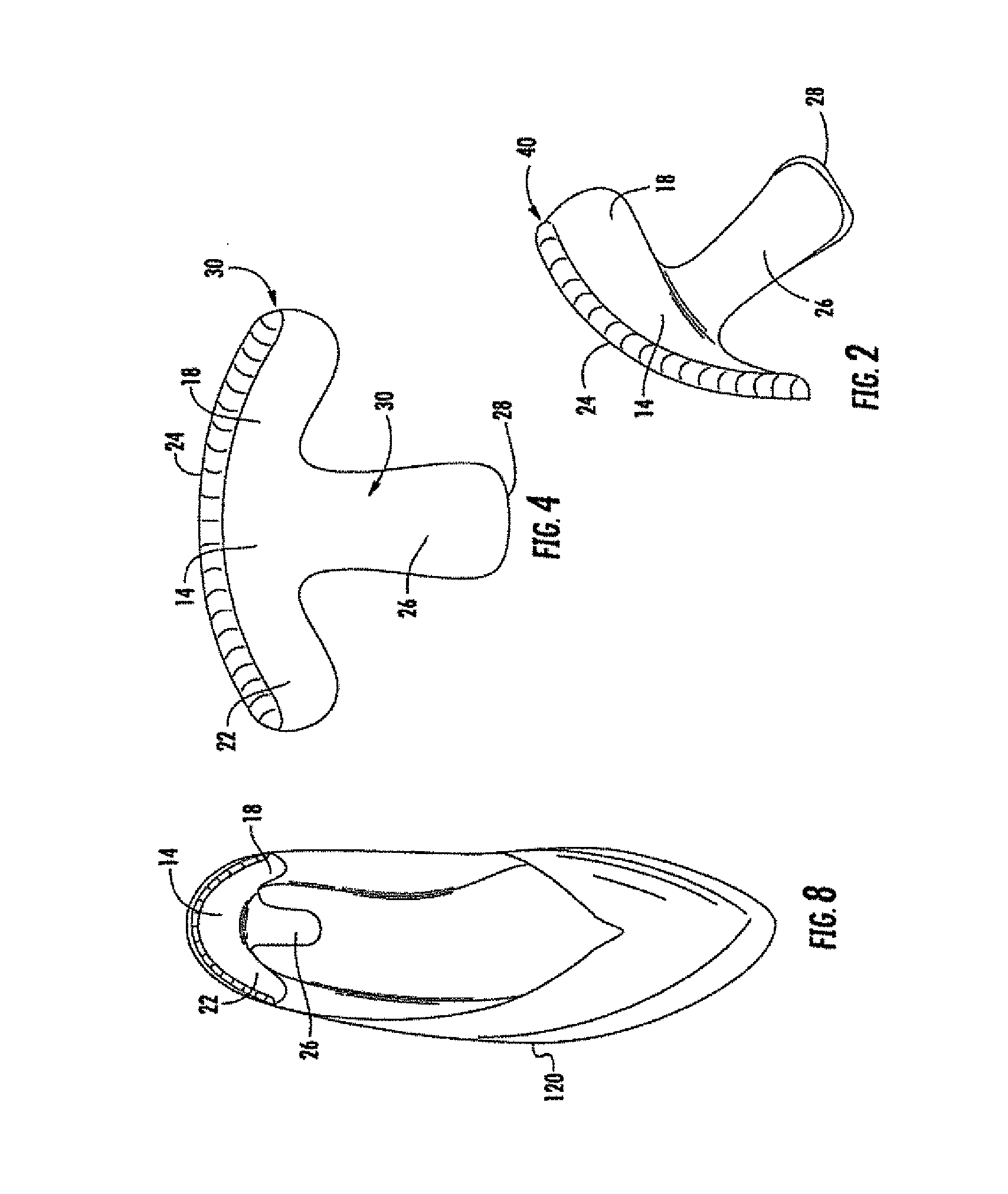

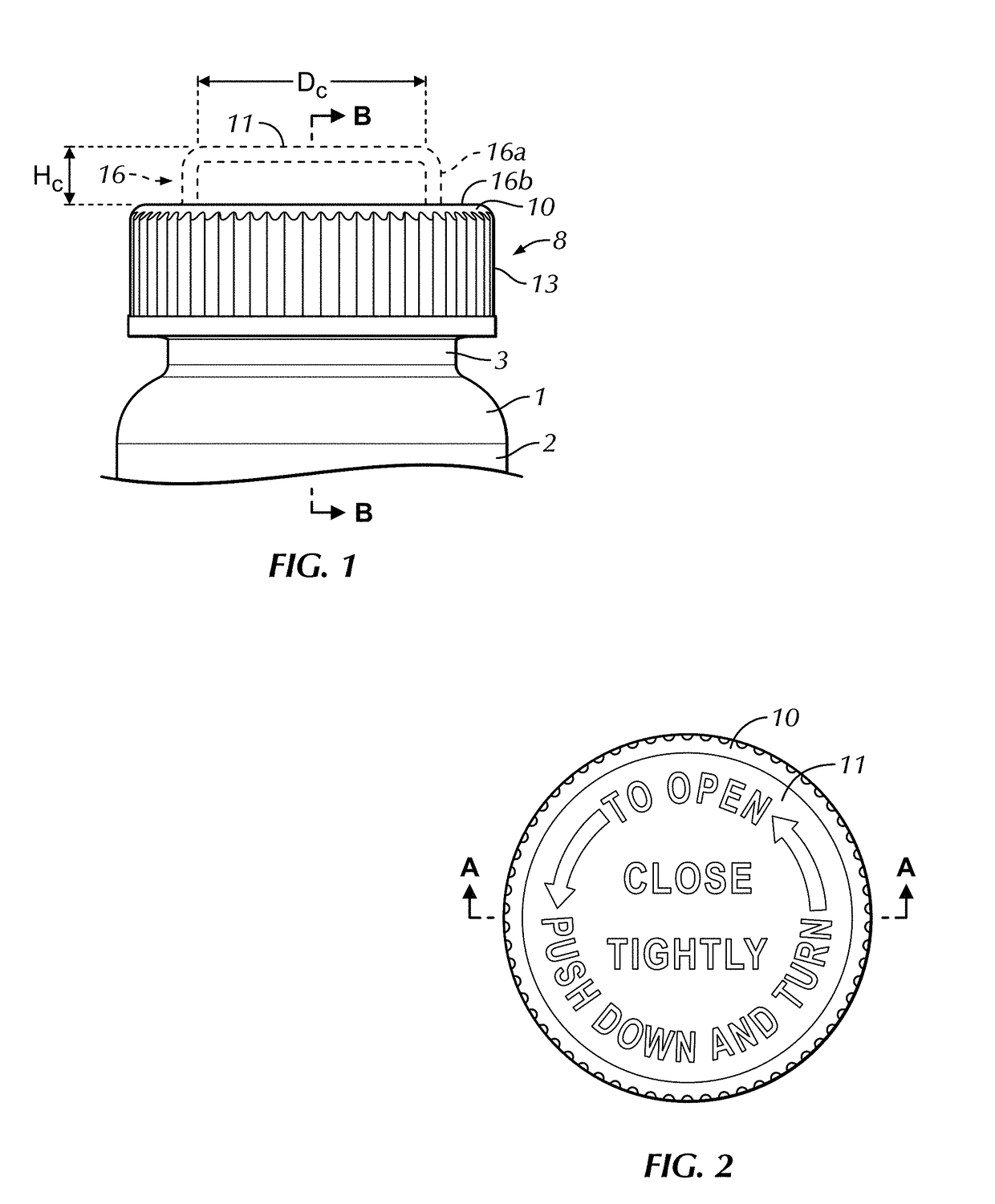

Roof ventilation system

ActiveUS8302352B2Building roofsRoof covering using slabs/sheetsFilter materialMechanical engineering

A roof vented closure strip 200 comprises profile piece 210, filter material 220, and top layer 230, the strip manufactured with at least two different materials combining to fill the space between a ridge cap 140 and a sloped roof 112. The profile piece includes a lower surface 213, side surfaces 215, a front exterior surface 216, a rear interior surface 217. The strip is disposed on the sloped roof such that a lip is formed between strip rear interior surface, and the ridge slot. Filter material fills between the profile piece, the top layer, the front exterior surface, and the rear interior surface wherein the rear interior surface slopes at an angle 206 toward front exterior surface, and one or more moisture channel 250 extends laterally across the width of the strip, such that moisture flows from the lip down and drains through the moisture channel exiting the structure.

Owner:BAHN RICHARD STUART

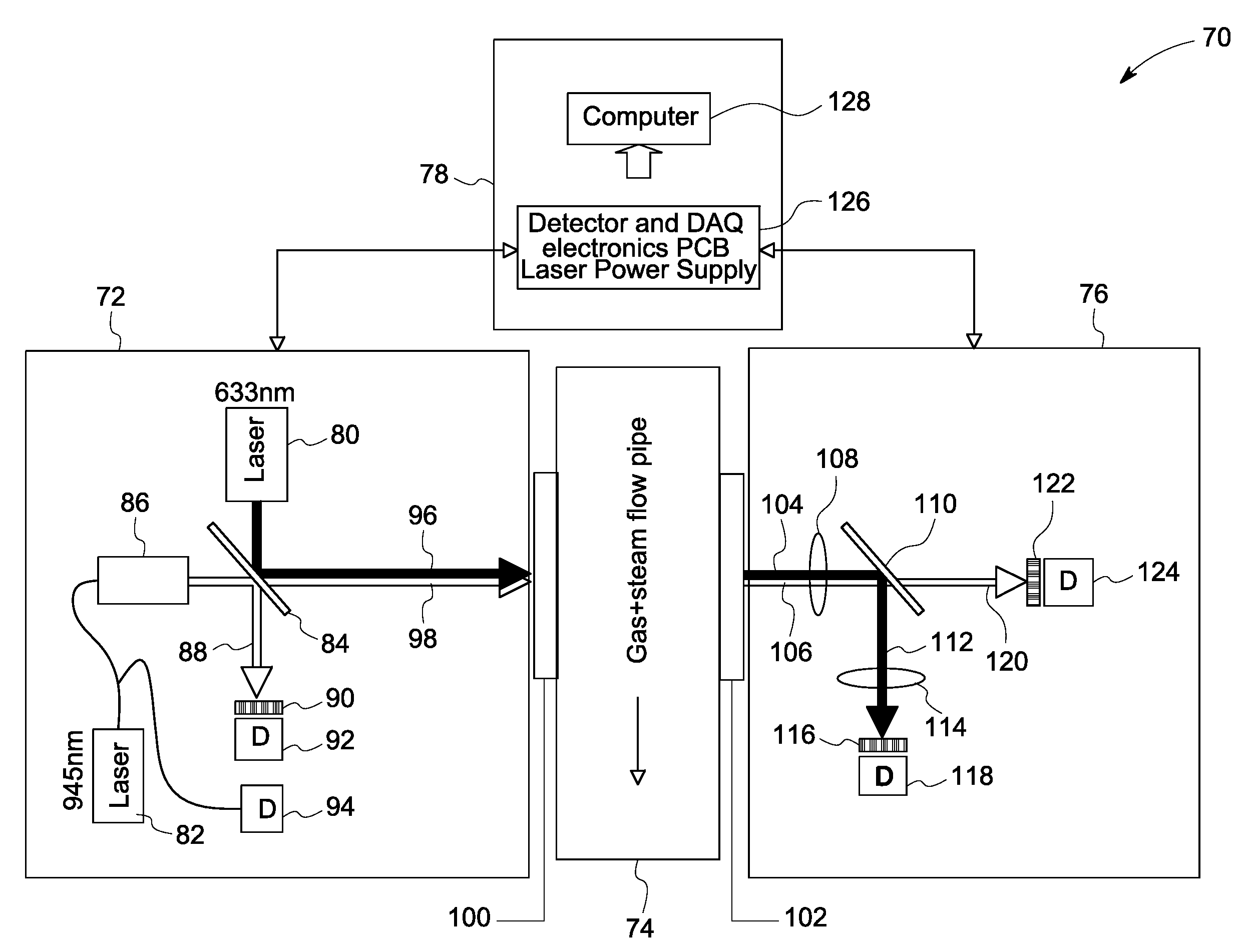

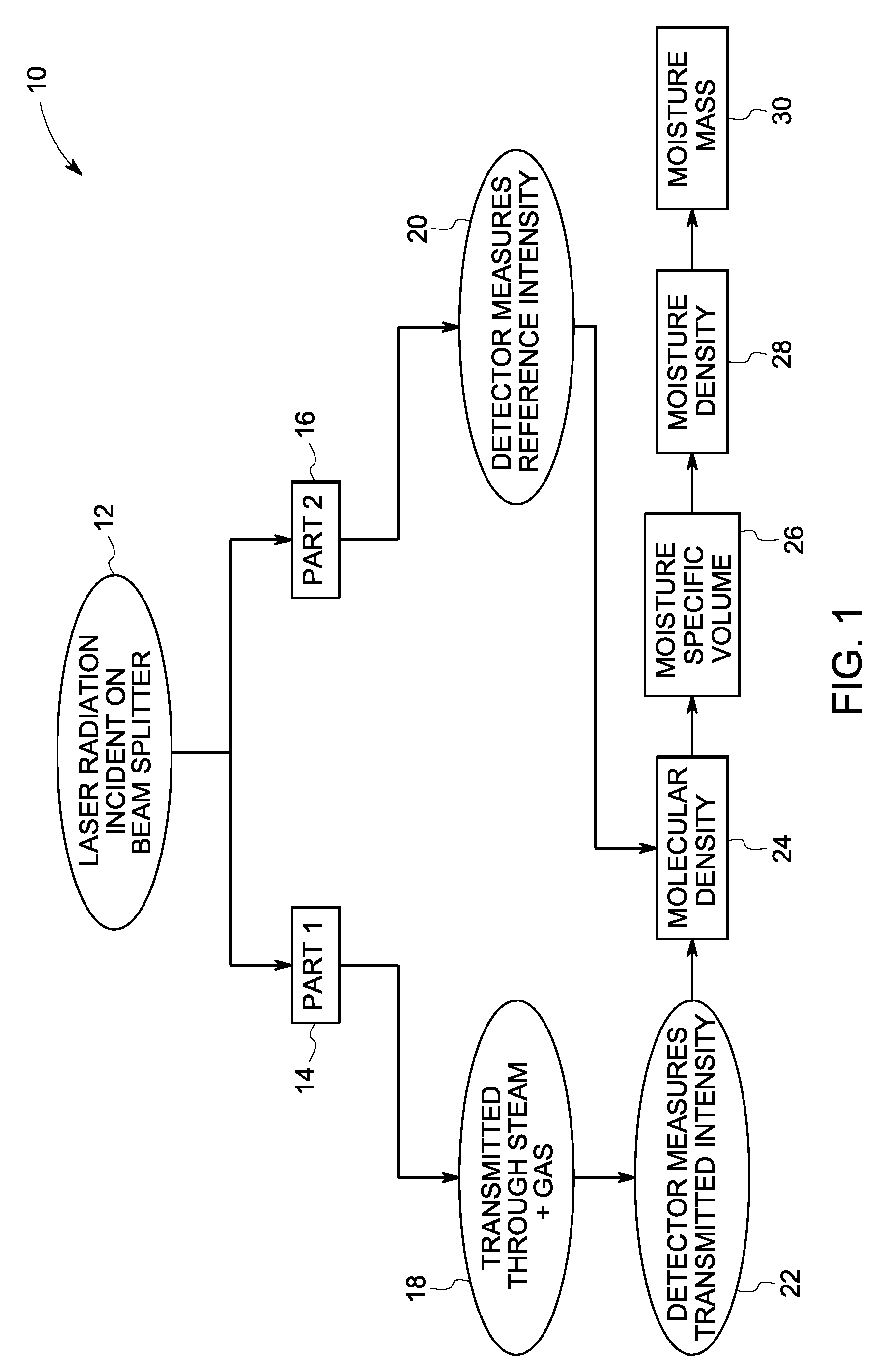

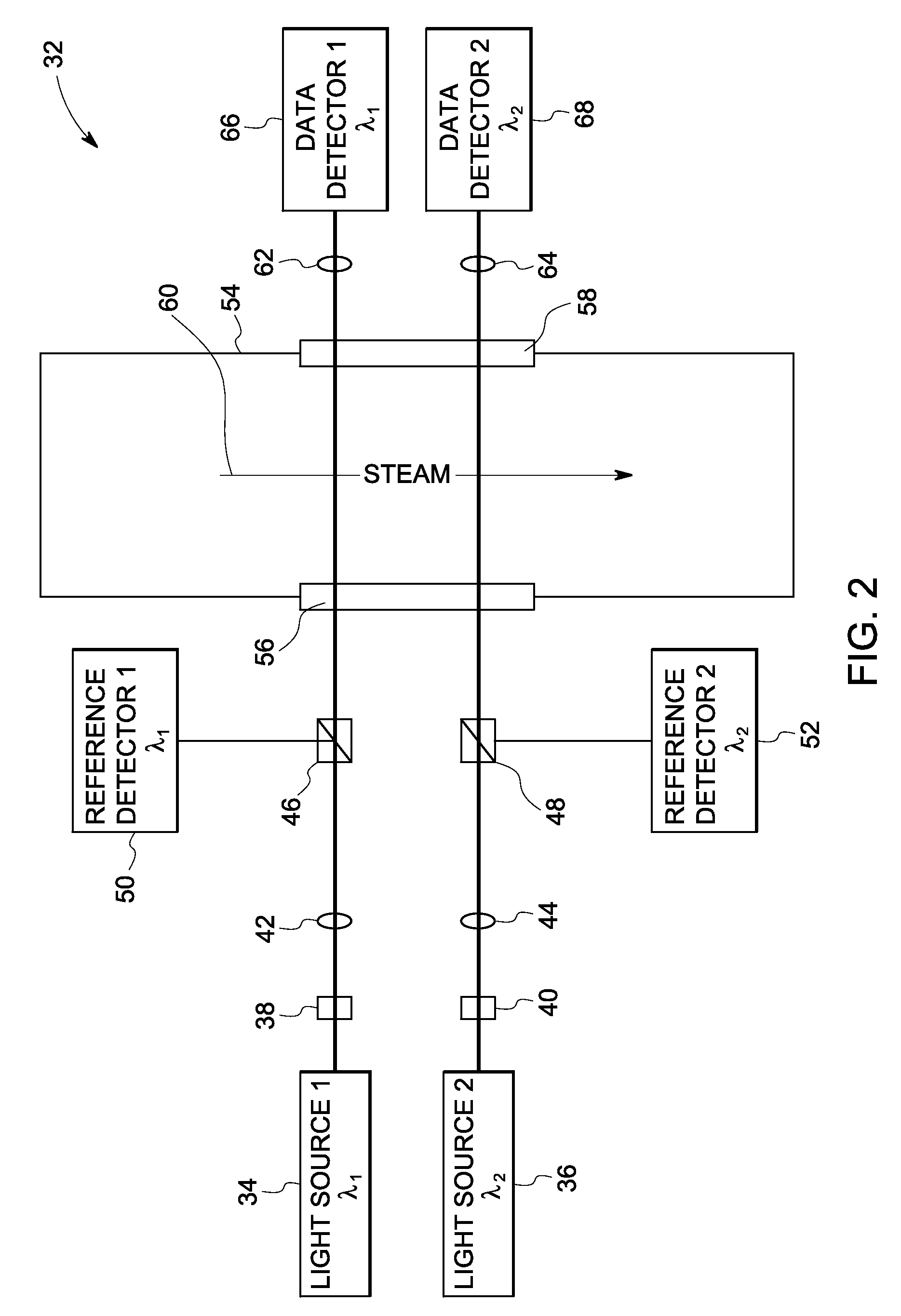

System and method for sensing fuel moisturization

InactiveUS20090101822A1Accurate measurementRadiation pyrometryMaterial analysis by optical meansGas phaseData signal

A fuel moisturization sensor system is disclosed. The fuel moisturization sensor system includes a first light source configured for emitting light through a fuel and moisture flow path at a first wavelength, wherein the first wavelength is at least partially absorbable by the moisture when in a vapor phase and substantially not absorbable by the fuel, and a second light source configured for emitting light through the fuel and moisture flow path at a second wavelength, wherein the second wavelength is preferentially scattered by moisture when in a liquid phase and substantially not absorbed by the fuel or by the moisture when in a vapor phase, a detector system configured to detect light transmitted through the flow path at the first and second wavelengths and to generate a first data signal corresponding to the transmission at the first wavelength and a second data signal corresponding to the transmission at the second wavelength.

Owner:GENERAL ELECTRIC CO

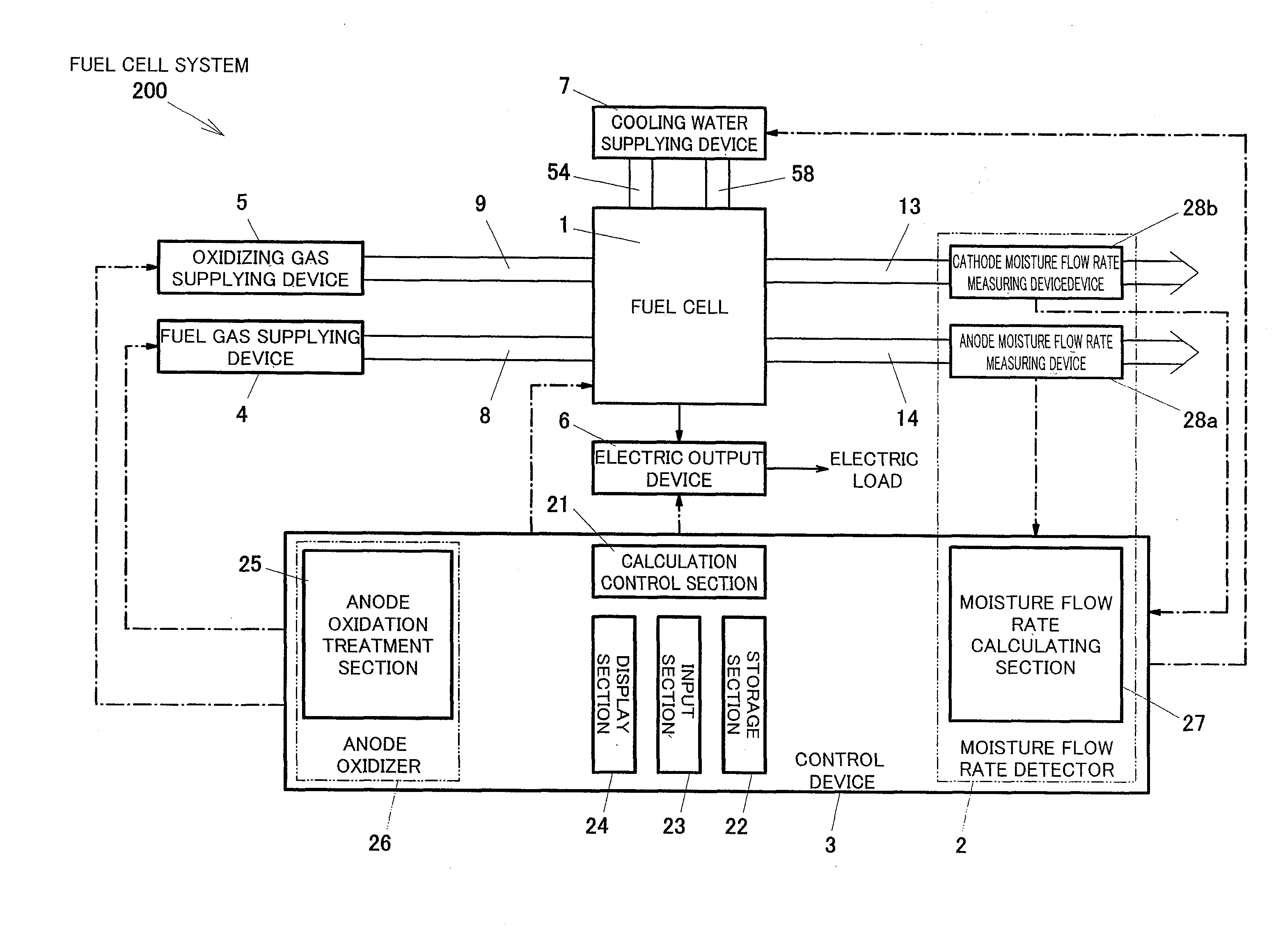

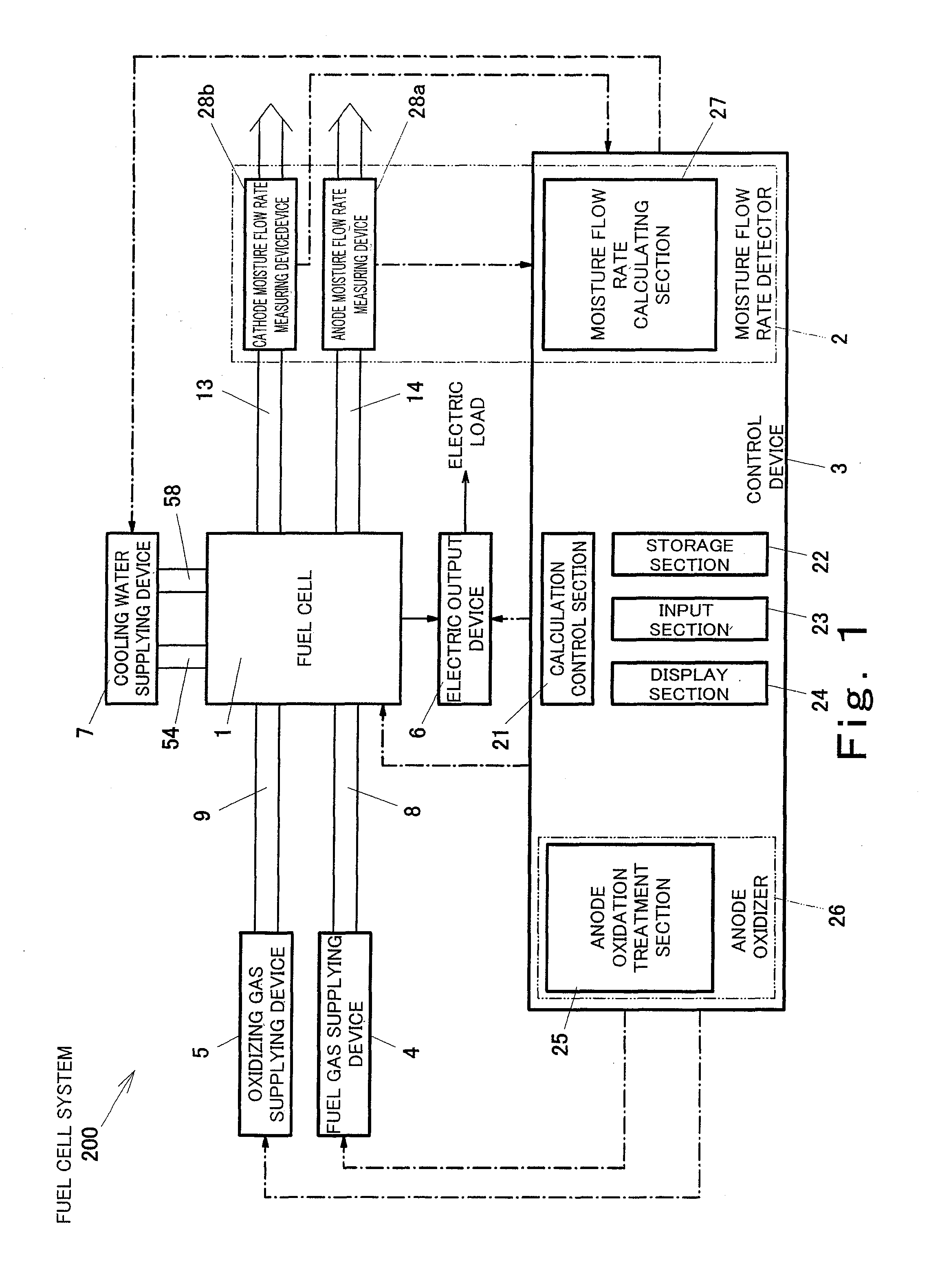

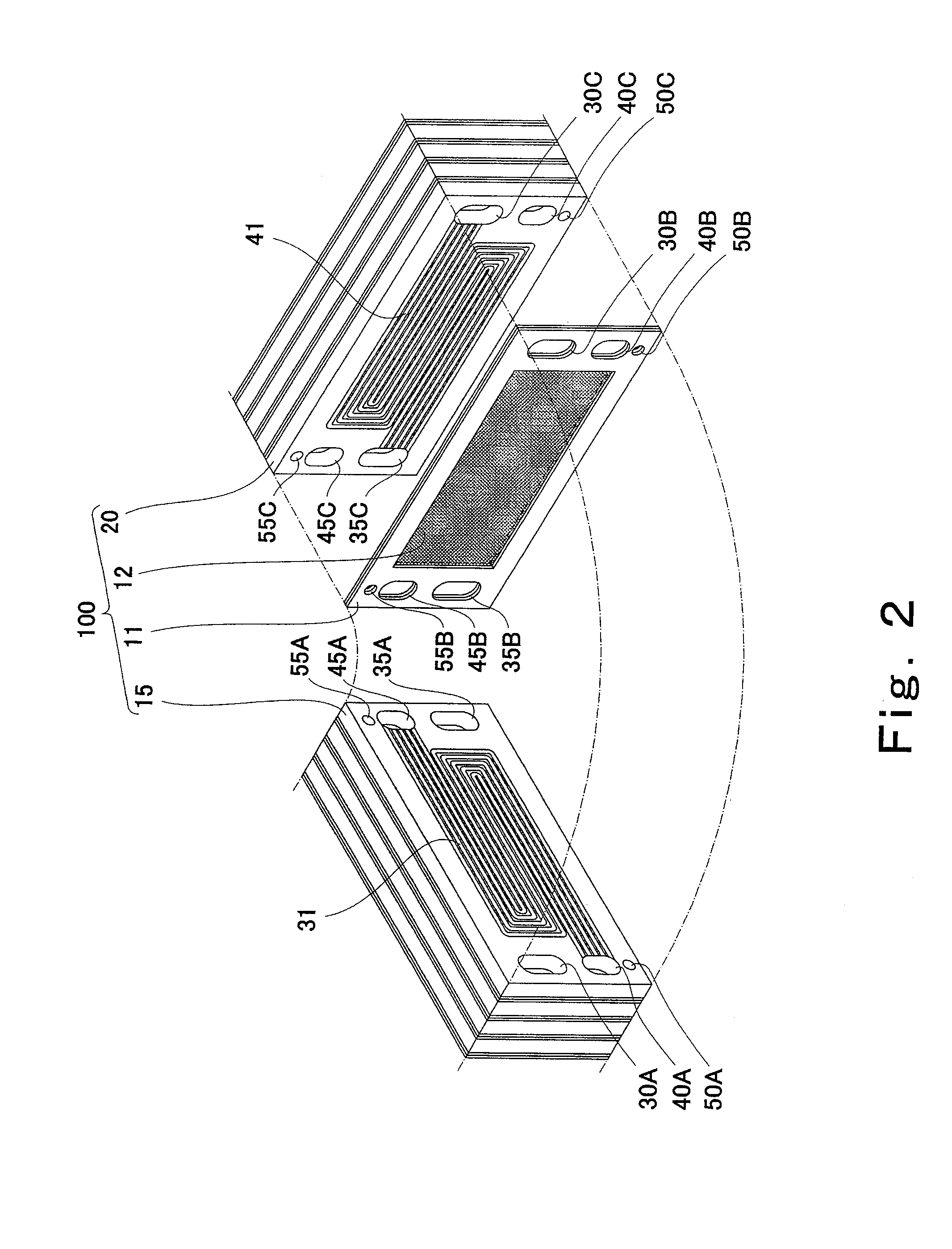

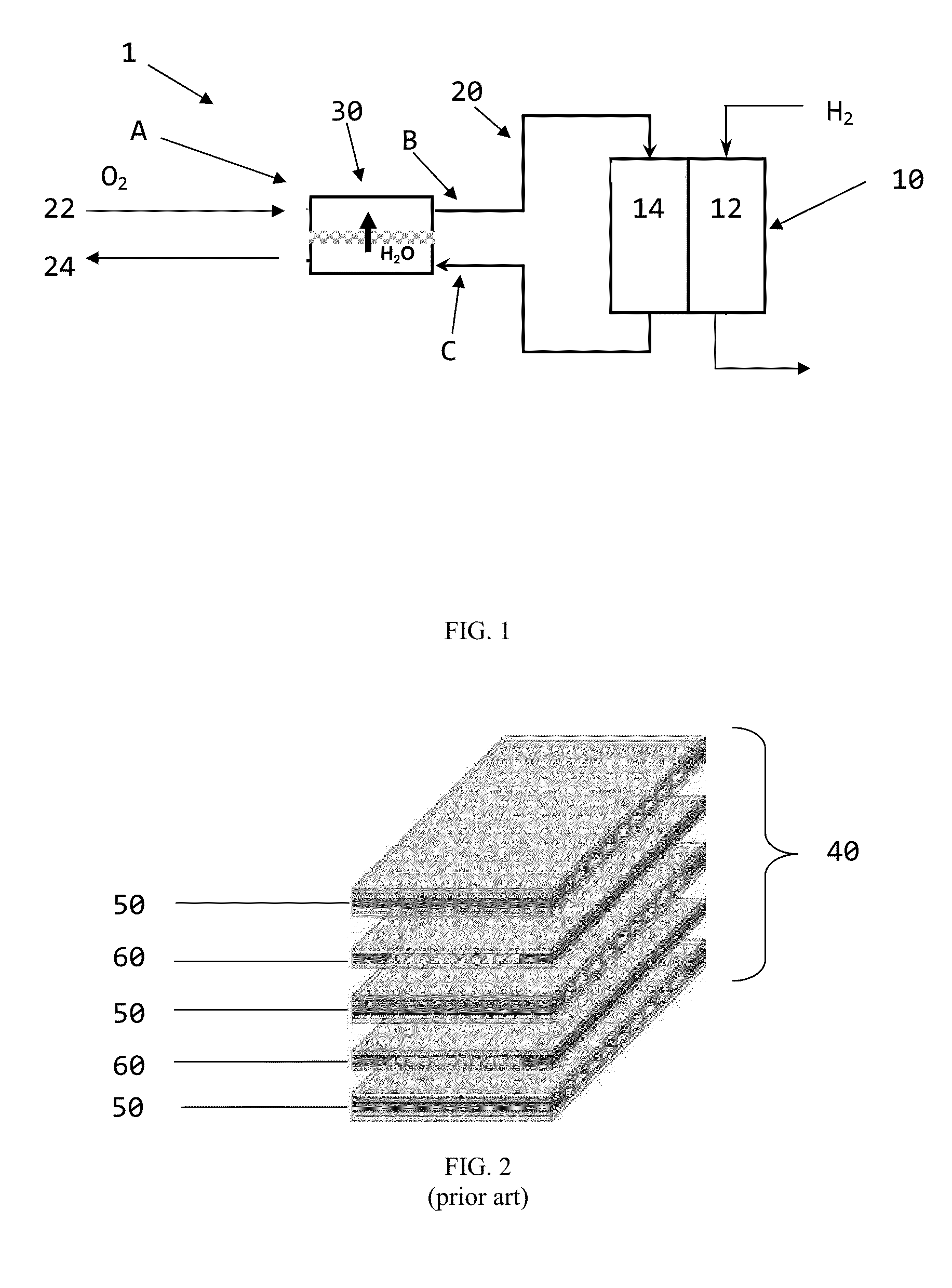

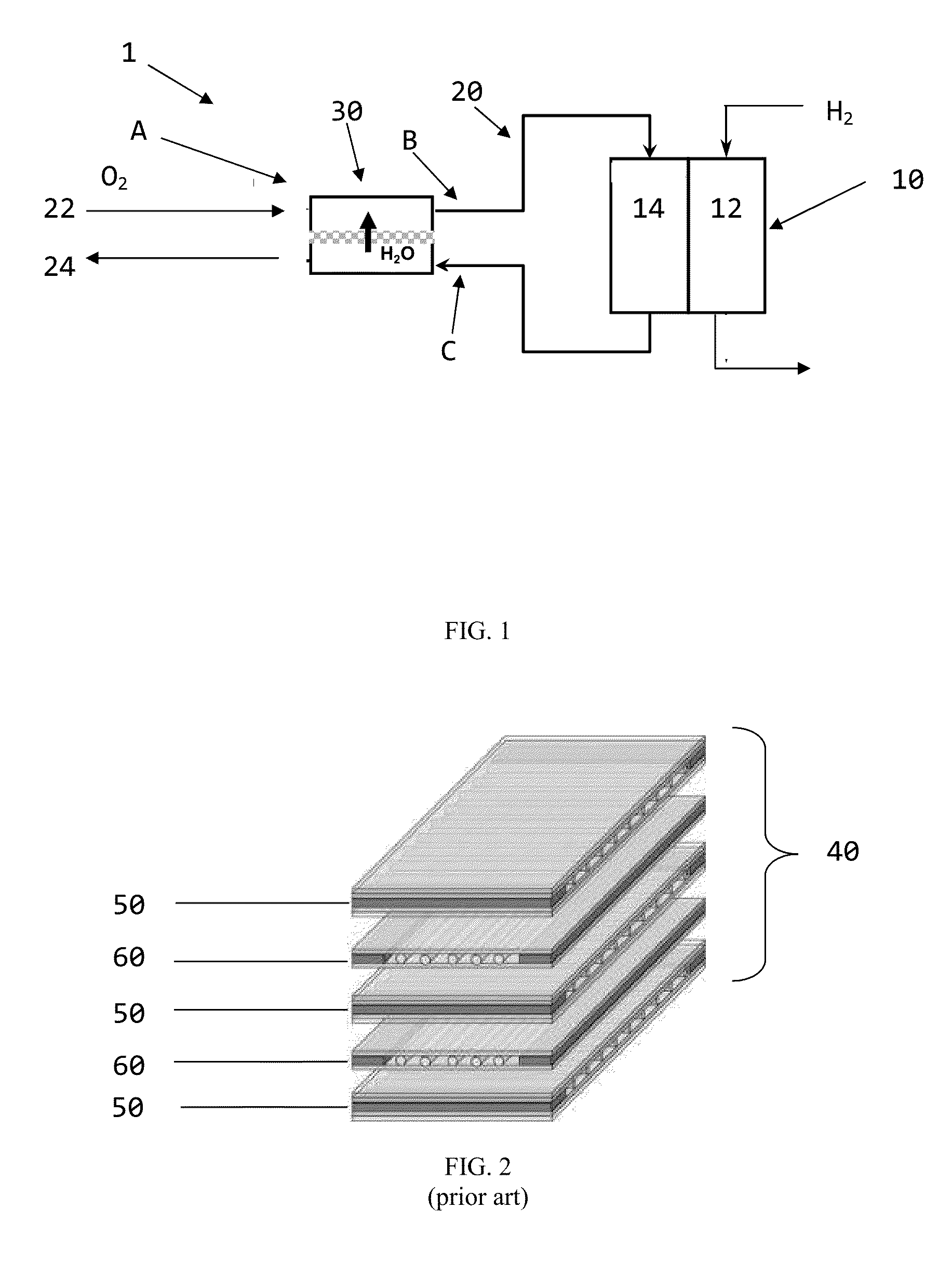

Fuel cell system and operating method thereof

InactiveUS20100233554A1Reducing performance of fuel cellMinimizing deteriorationFuel cell auxillariesSolid electrolyte fuel cellsPolymer electrolytesFuel cells

A fuel cell system of the present invention includes: a polymer electrolyte fuel cell (1) including an MEA (12) having a polymer electrolyte membrane (13), an anode (16a) and a cathode (16b); a fuel gas supplying device (4) which supplies a fuel gas to the anode (16a); an oxidizing gas supplying device (5) which supplies an oxidizing gas to the cathode (16b); a moisture flow rate detector (2) which detects at least one of a flow rate of moisture discharged from the cathode (16b) and a flow rate of moisture discharged from the anode (16a); storage means (22) for storing a reference moisture flow rate that is the moisture flow rate at the time of a reference output of the polymer electrolyte fuel cell (1); and an anode oxidizer (25) which compares the moisture flow rate detected by the moisture flow rate detector (2) with the reference moisture flow rate stored in the storage means (22) and oxidizes the anode (16a) based on a result of the comparison.

Owner:PANASONIC CORP

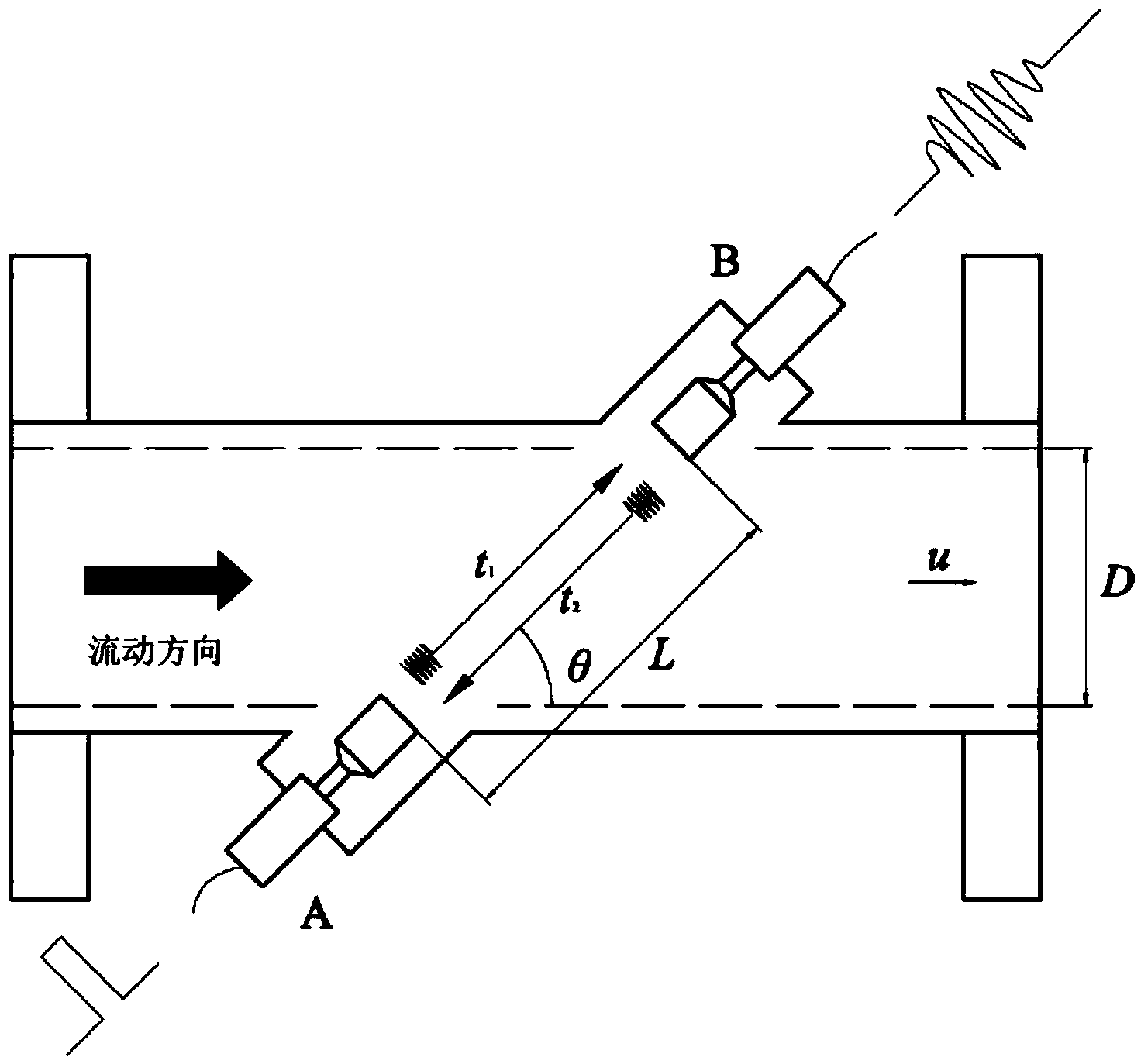

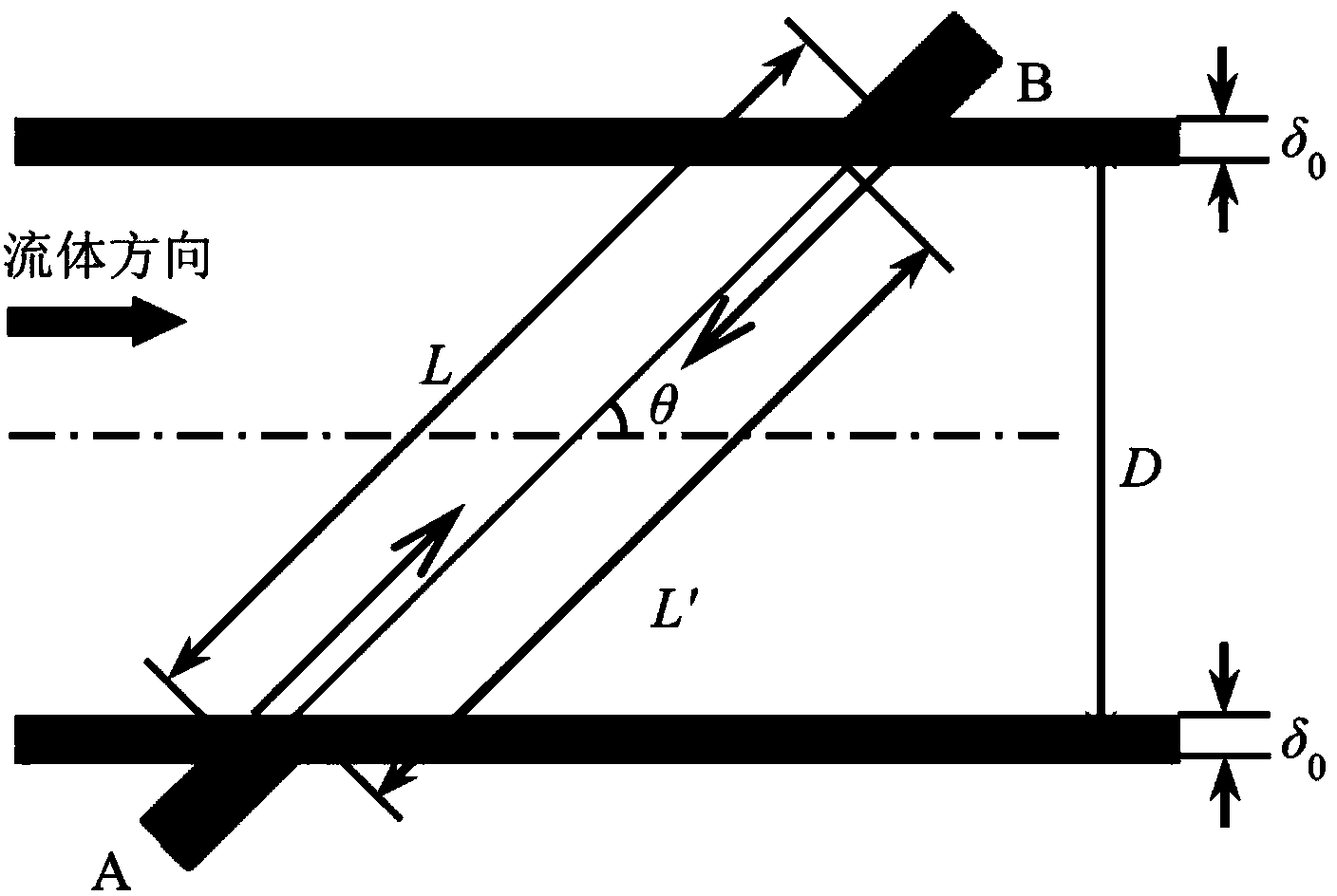

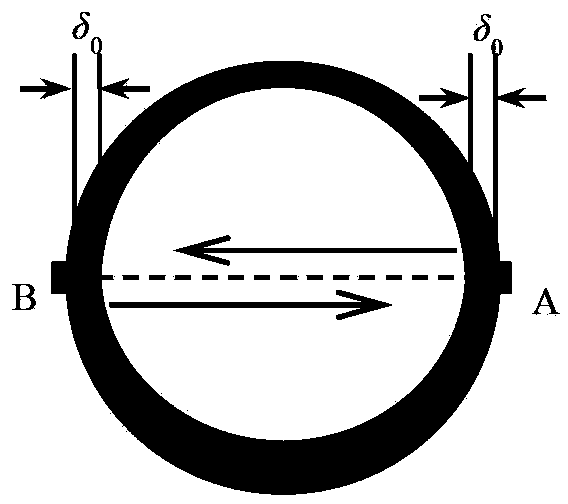

Moisture flow measuring method based on straight through type gas ultrasonic flowmeter

InactiveCN103353319ASimplify conditions reasonablySimple conditionsVolume/mass flow measurementGas phaseHydrology

The invention belongs to the technical field of measurement of two-phase flow, and relates to a moisture flow measuring method based on a straight through type gas ultrasonic flowmeter. The moisture flow measuring method based on the straight through type gas ultrasonic flowmeter comprises the following steps that (1) the straight through type gas ultrasonic flowmeter is fixed on a pipeline where moisture flow measurement needs to be carried out; (2) moisture flow is measured through the straight through type gas ultrasonic flowmeter, and a virtual height flow Qtp is measured; (3) a section gas containing content alpha is solved according to an experience model; (4) the virtual height flow is corrected, and a corrected gas-phase flow value is obtained. The moisture flow measuring method based on the straight through type gas ultrasonic flowmeter is simple and easy to use, has good universality, and is suitable for predicting the gas-phase flow under the condition of annular mist flow in a horizontal and round pipe.

Owner:TIANJIN UNIV

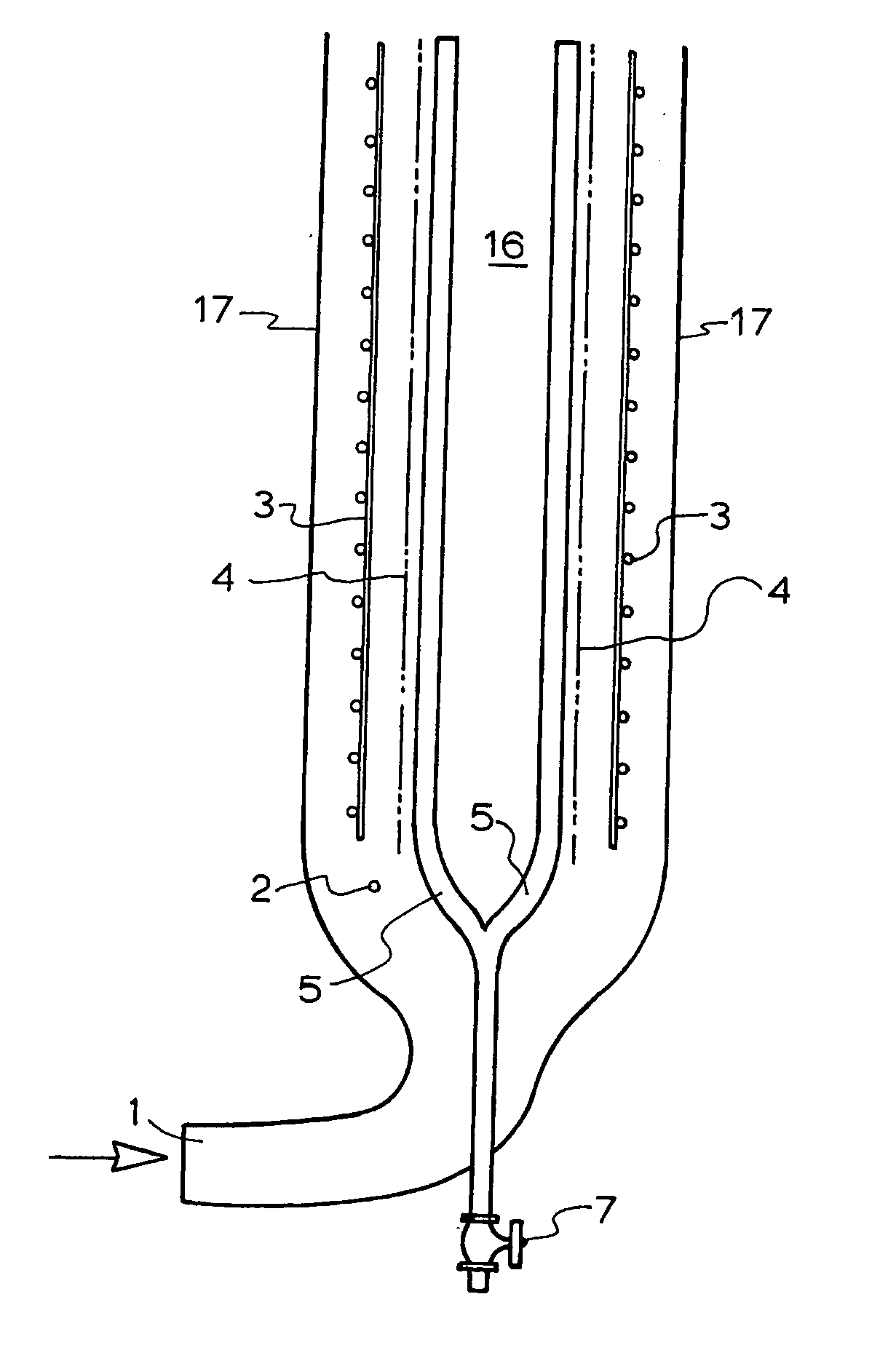

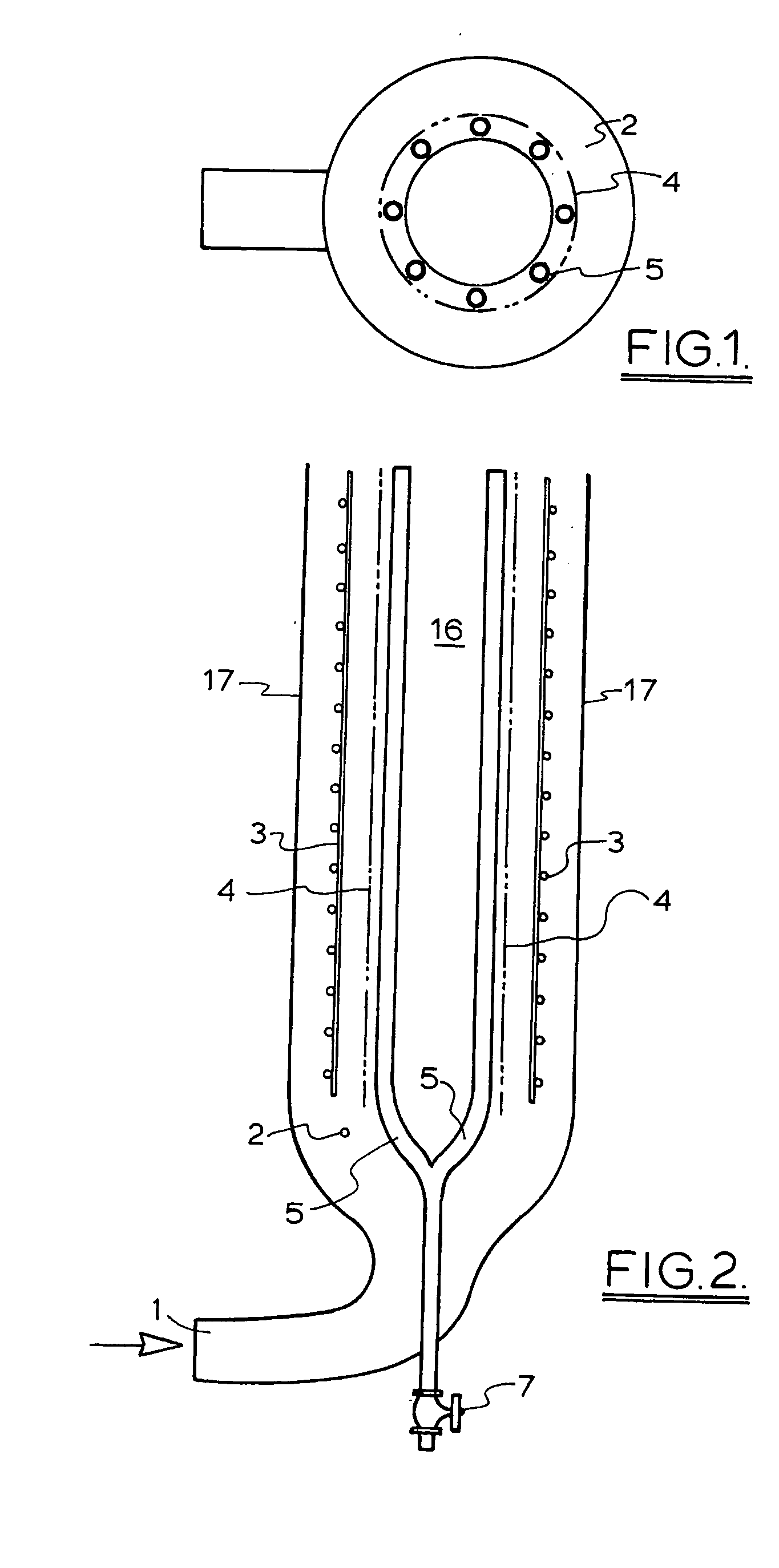

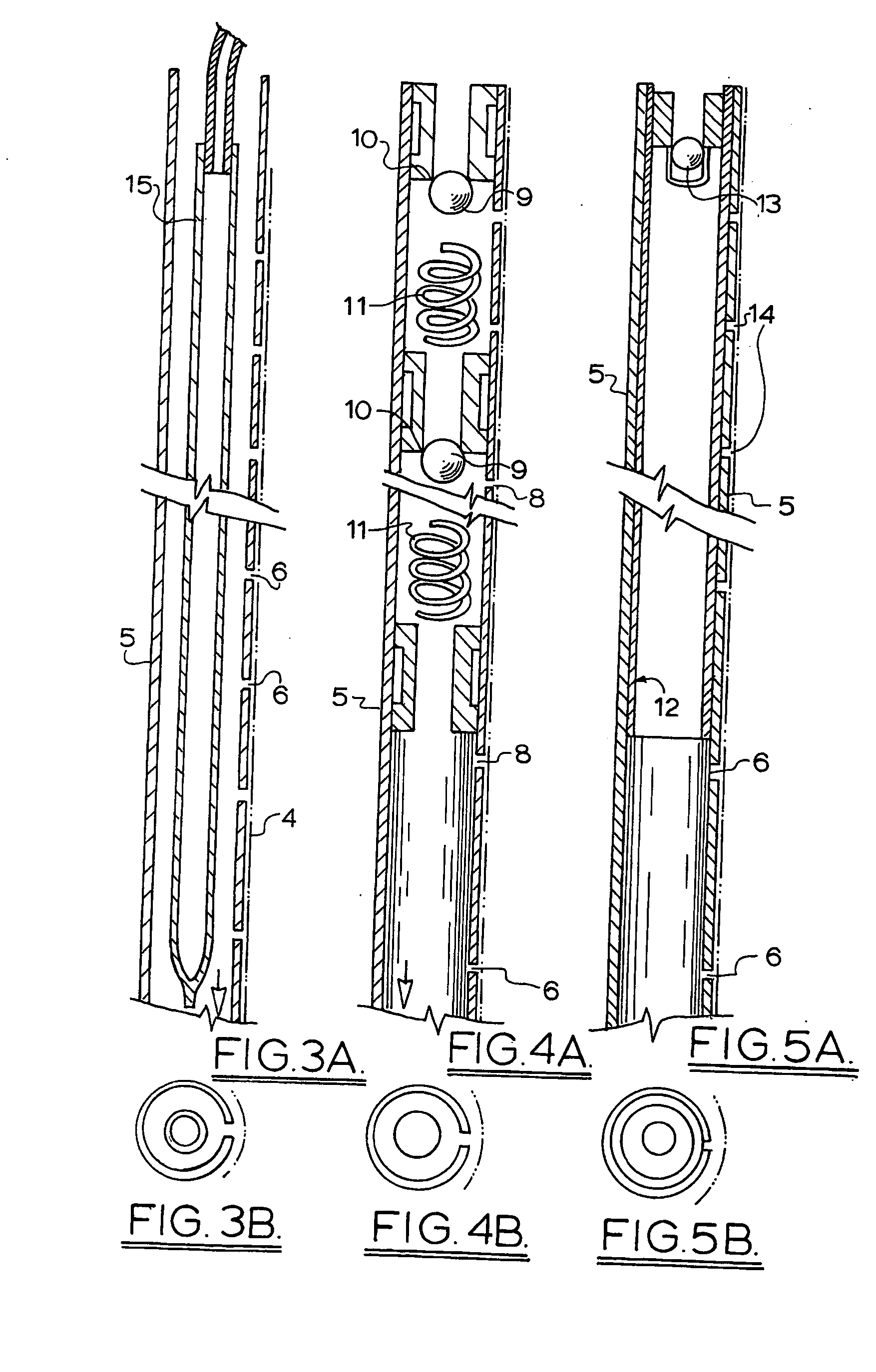

Vertical moulding of concrete

InactiveUS20050156345A1Avoid waterCeramic shaping mandrelsCeramic shaping coresDrainage tubesCivil engineering

A method of moulding long concrete articles in a vertical mould which incorporates a mould liner (17) with drainage tubes (5) used to dewater the concrete when the mould is filled. The improvement is to close off the drainage tubes (5) during the filling of the mould to inhibit water loss in the concrete during filling. The drainage tubes (5) may incorporate one way valves or include inner tubes (15) that may be pressurized to inhibit water entering the drainage tube (5).

Owner:VERTECH HUME

Roof ventilation system

A roof vented closure strip 200 comprises profile piece 210, filter material 220, and top layer 230, the strip manufactured with at least two different materials combining to fill the space between a ridge cap 140 and a sloped roof 112. The profile piece includes a lower surface 213, side surfaces 215, a front exterior surface 216, a rear interior surface 217. The strip is disposed on the sloped roof such that a lip is formed between strip rear interior surface, and the ridge slot. Filter material fills between the profile piece, the top layer, the front exterior surface, and the rear interior surface wherein the rear interior surface slopes at an angle 206 toward front exterior surface, and one or more moisture channel 250 extends laterally across the width of the strip, such that moisture flows from the lip down and drains through the moisture channel exiting the structure.

Owner:BAHN RICHARD STUART

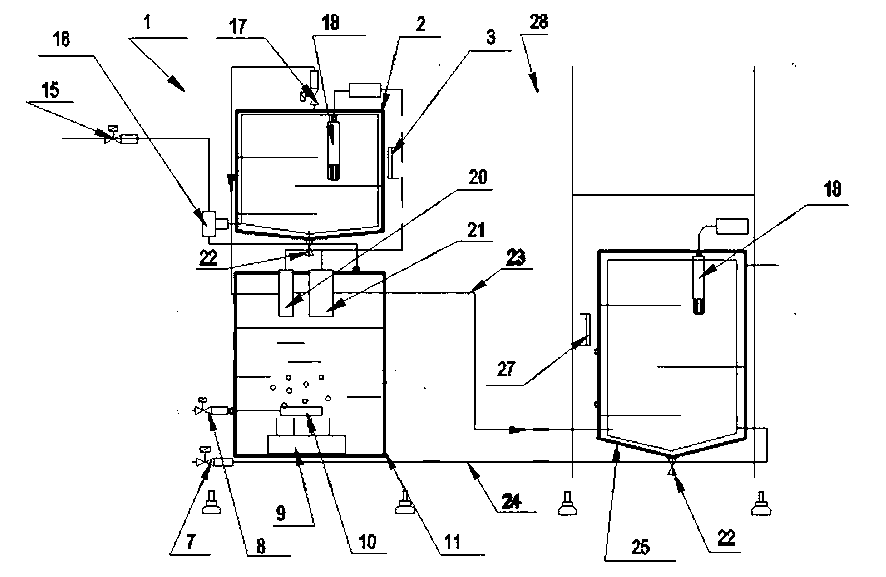

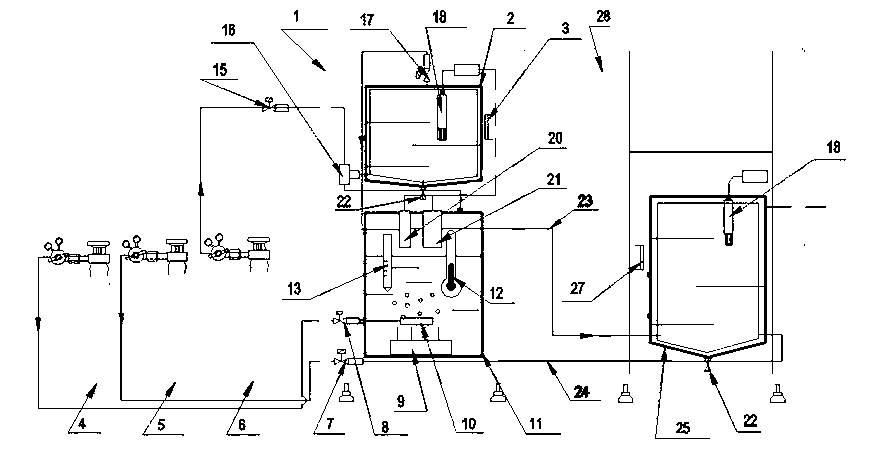

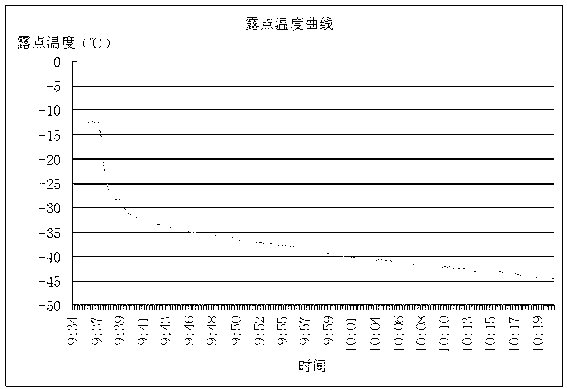

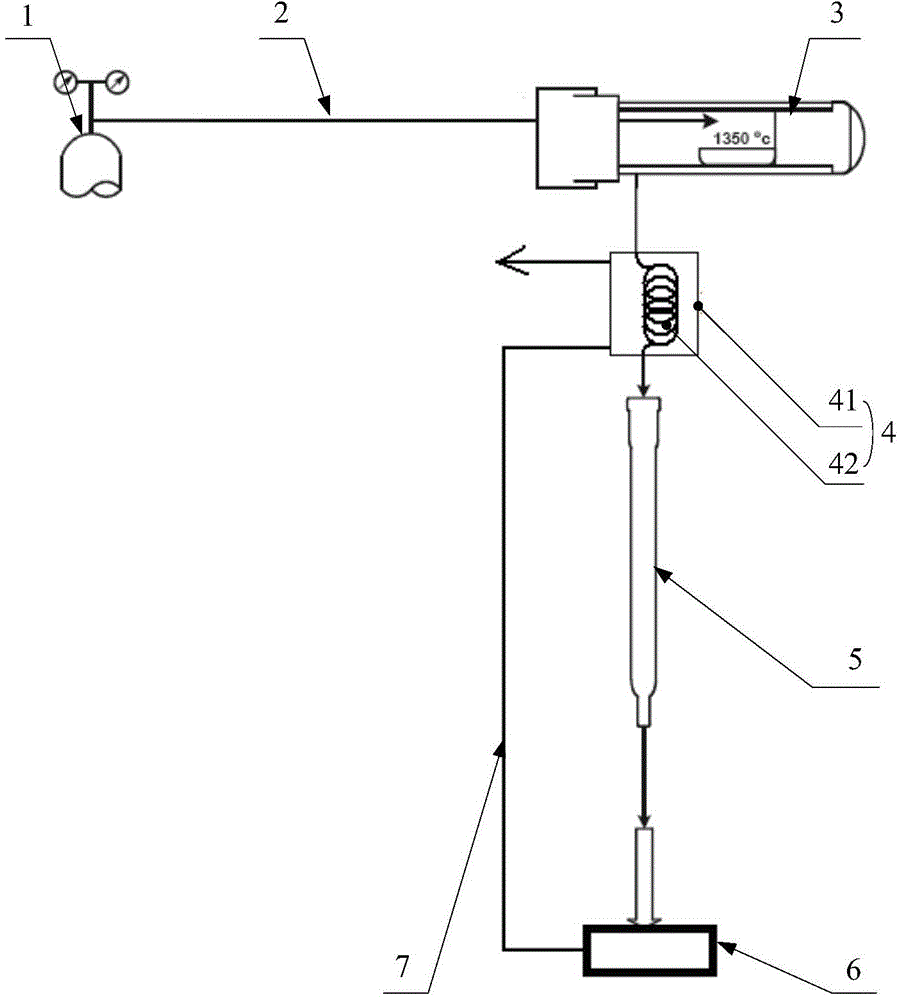

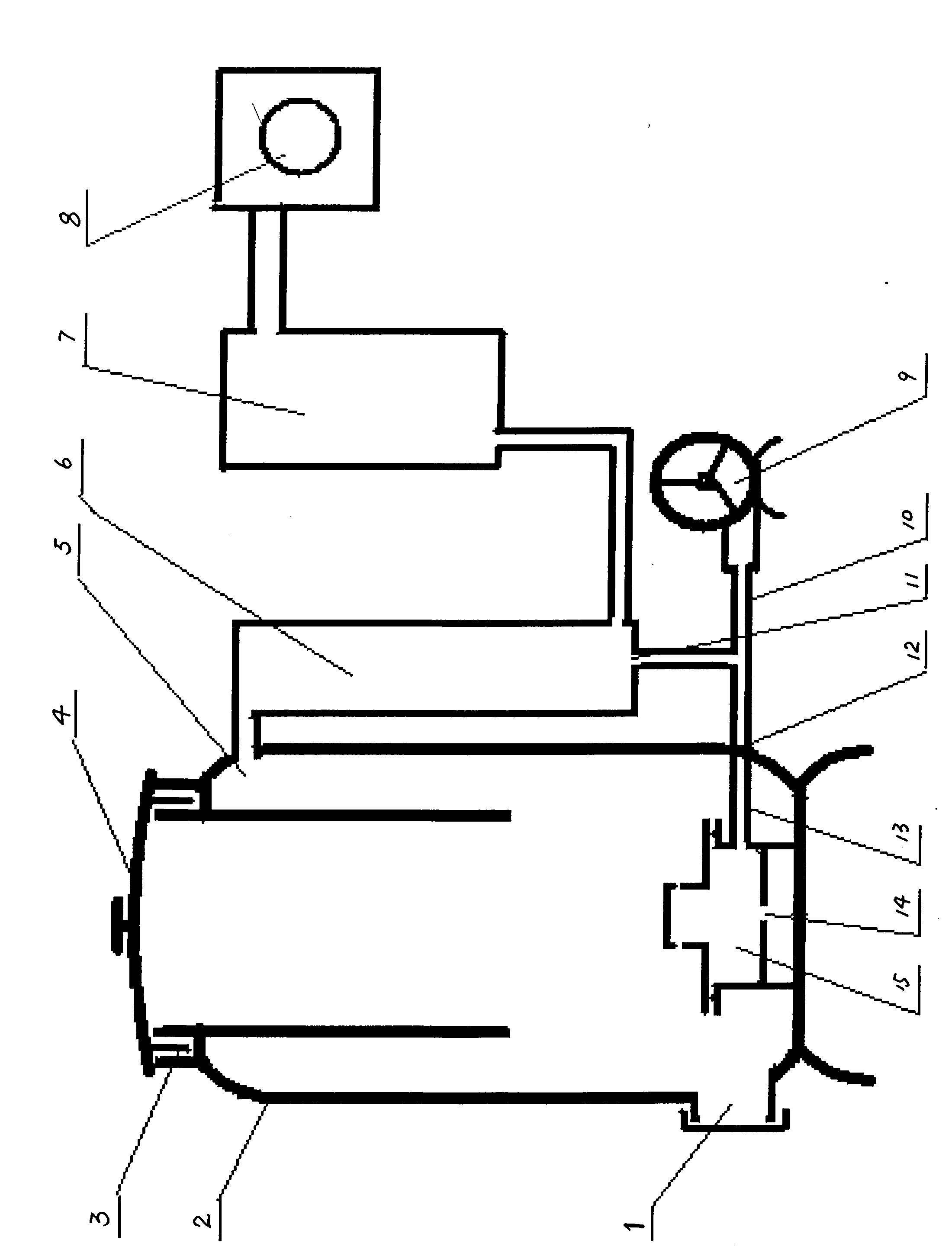

Analog flue gas mixing device based on high temperature humidity generator

ActiveCN103055732AAvoid human errorAvoid Humidity Measurement EffectsFlow mixersMixer accessoriesHigh humidityMixed flow

The invention belongs to the field of a flue gas monitoring and testing device, and particularly relates to an analog flue gas mixing device based on a high temperature humidity generator. The analog flue gas mixing device based on the high temperature humidity generator comprises a gas tank (2), a standard-gas flow meter (7), a moisture flow meter (8), a foam generator (10), a constant temperature water tank (11), a dry gas flow meter (15), a T-junction (16), a mixed moisture flow meter (17), a small testing case (20), a medium testing case (21), a mixed moisture pipeline (23), a standard-gas heating pipeline (24), a mixing gas tank (25), and a dew-point instrument (18). When the analog flue gas mixing device simulates flue gas mixture, the analog flue gas mixing device based on the high temperature humidity generator utilizes a mixed flow method to solve the problem that how to simulate a high temperature and high humidity state of the flue gas at first, and thus can simulate high temperature moisture with 0% to 30% volume occurred at the temperature of up to 165 degrees, and then adds the standard-gas with the high temperature moisture to achieve a higher gas composition and humidity accuracy based on the traceably calibrating function of the precision mirror surface dew-point instrument, so that an instrument calibration and other experiments can be achieved without being on the scene of the flue, and therefore the labor intensity of the staff is reduced and great convenience is brought for experimenters.

Owner:NANJING ASSEN ENVIRONMENT TECH

Roof vent

A vent for a building has a cover attached to a base. The base has an aperture permitting gas to pass. A moisture directing means on an underside of the cover directs moisture move under the influence of gravity to fall outside of the aperture. The cover may include a slanted side wall portion, with the aperture positioned with its center displaced from the center of the cover toward the slanted side. The base may include a pair of moisture deflecting features along at least a portion of one of the nonslope sides to prevent moisture flowing along the base from within an area on the base covered by the cover to outside of the covered area at the nonslope sides. The base may also include a water deflecting ridge on its underside positioned between a downslope edge and the aperture to deflect water away.

Owner:CANPLAS INDS

Waterproofing structure for electric junction box

ActiveCN1551436APrevent immersionCasings/cabinets/drawers detailsSubstation/switching arrangement casingsDouble wallEngineering

To provide the waterproof structure of an electric connection box which can raise waterproofness according to a simple structure. Since the moisture dropped to an external double wall 23U provided at the upper side of the electric connection box 10 in a using state flows through the outside of cover members 30f, 30r, the moisture can be prevented from being flooded into the electric connection box 10. If the moisture flows to a body 20 side along the cover members 30f, 30r to flood into the external double wall 23, ribs 32a protruding from the engaging edges 32f, 32r of the cover members 30f, 30r toward the inner surface 24a of the external double wall 23 prevent the moisture from being flooded, and the moisture can be prevented from being flooded into the electric connection box 10. (C)2005,JPO&NCIPI.

Owner:YAZAKI CORP +1

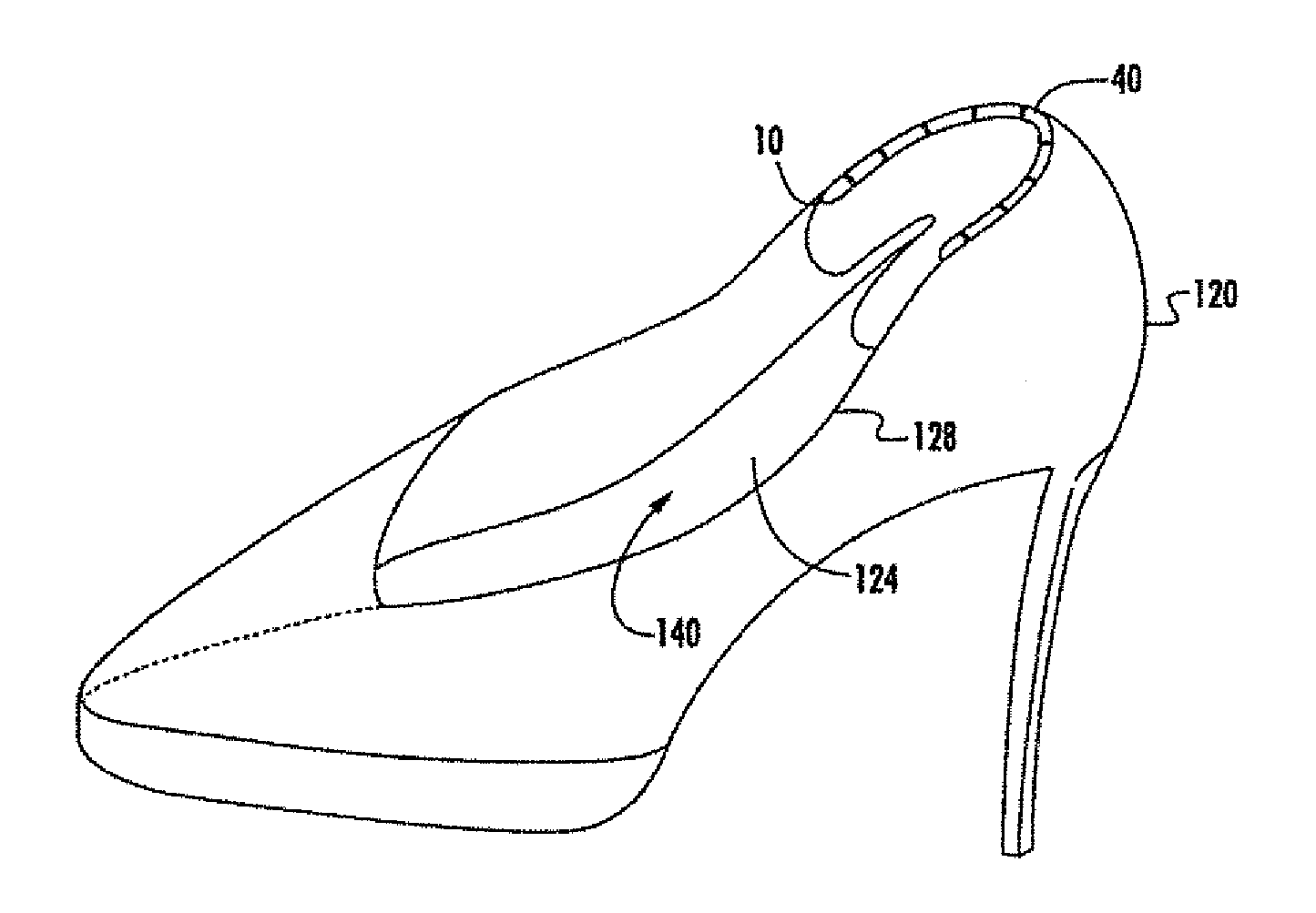

Shoe heel engagement support system

Provided is a shoe heel engagement system and method of using the same to secure a user-heel-shoe interface and prevent unintended slipping and discomfort. The heel engagement system includes an elastomeric molded system having a plurality of projecting bumpers and stress concentration geometry features. The geometry stress concentration features may be linear or curved and may have multiple profiles. The geometry stress concentration features are arranged at least transverse to a heel arrangement, and may optionally be aligned with a heel arrangement and in arcuate form relative to heel or a foot-heel curvature improved security and shoe comfort that allow for easy bending-without buckling to fit the inner shape of a shoe. The geometry stress concentration features allow for easy air flow, moisture flow, and easy installation and adaption to the foot-shoe geometry.

Owner:J M PROMOTIONS INC

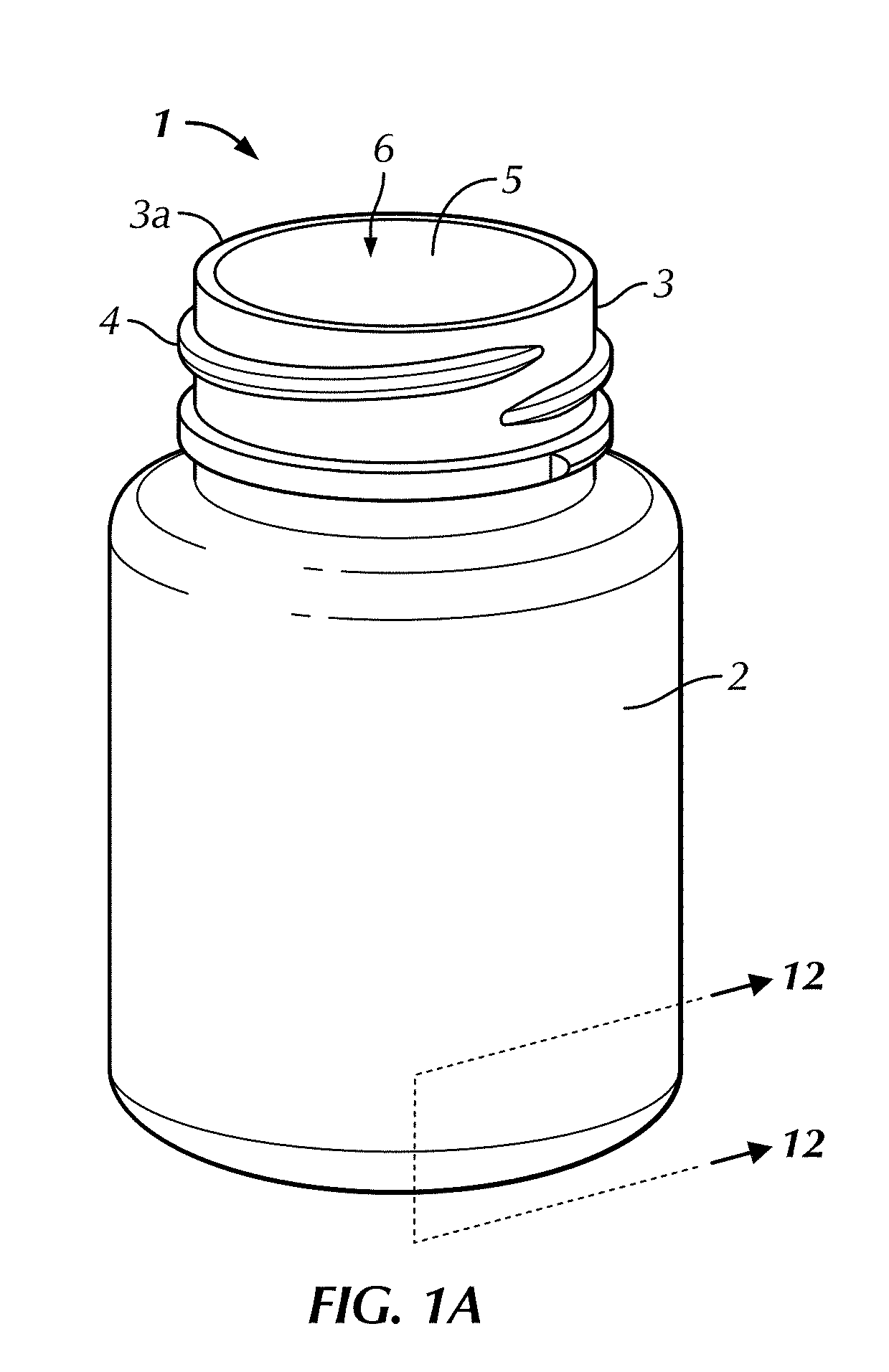

Container assembly and closure with predetermined humidity and related method

A container assembly configured to maintain a predetermined humidity for storing a product therein. The container assembly includes a container having a body with a body wall and a mouth opening into a storage cavity and a cap having a top wall. The cap is selectively mountable over the mouth of the container to substantially enclose the storage cavity in a mounted configuration. A sidewall extends substantially perpendicularly from one of the body wall and the top wall. The sidewall defines an opening and a compartment and has an opening edge adjacent the opening. A moisture control material is positioned within the compartment. A sealing membrane has a peripheral portion. The peripheral portion is secured to the sidewall proximate the opening edge. The sealing membrane is configured to allow moisture flow therethrough to maintain the predetermined humidity in the storage cavity.

Owner:DRUG PLASTIC & GLASS +1

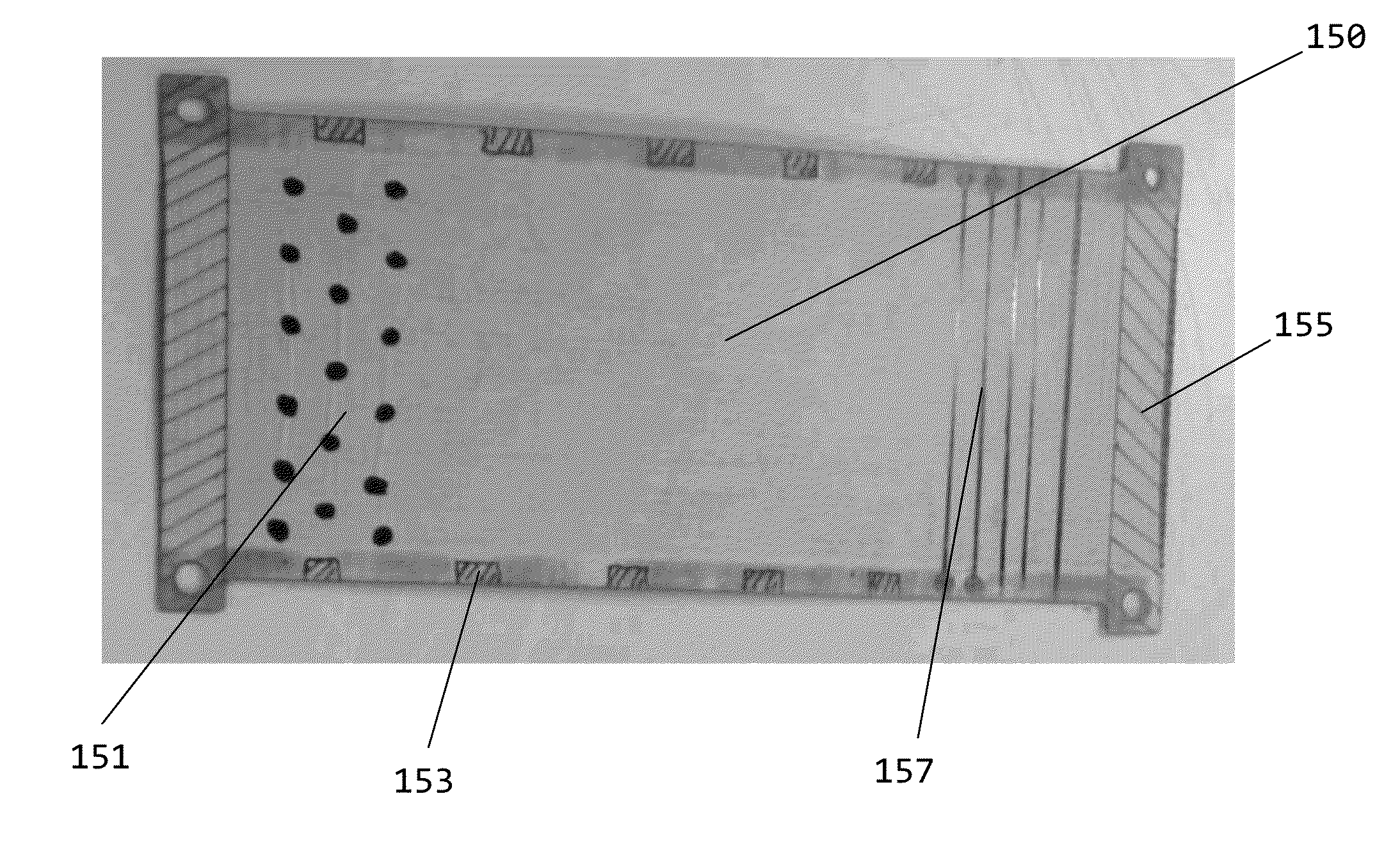

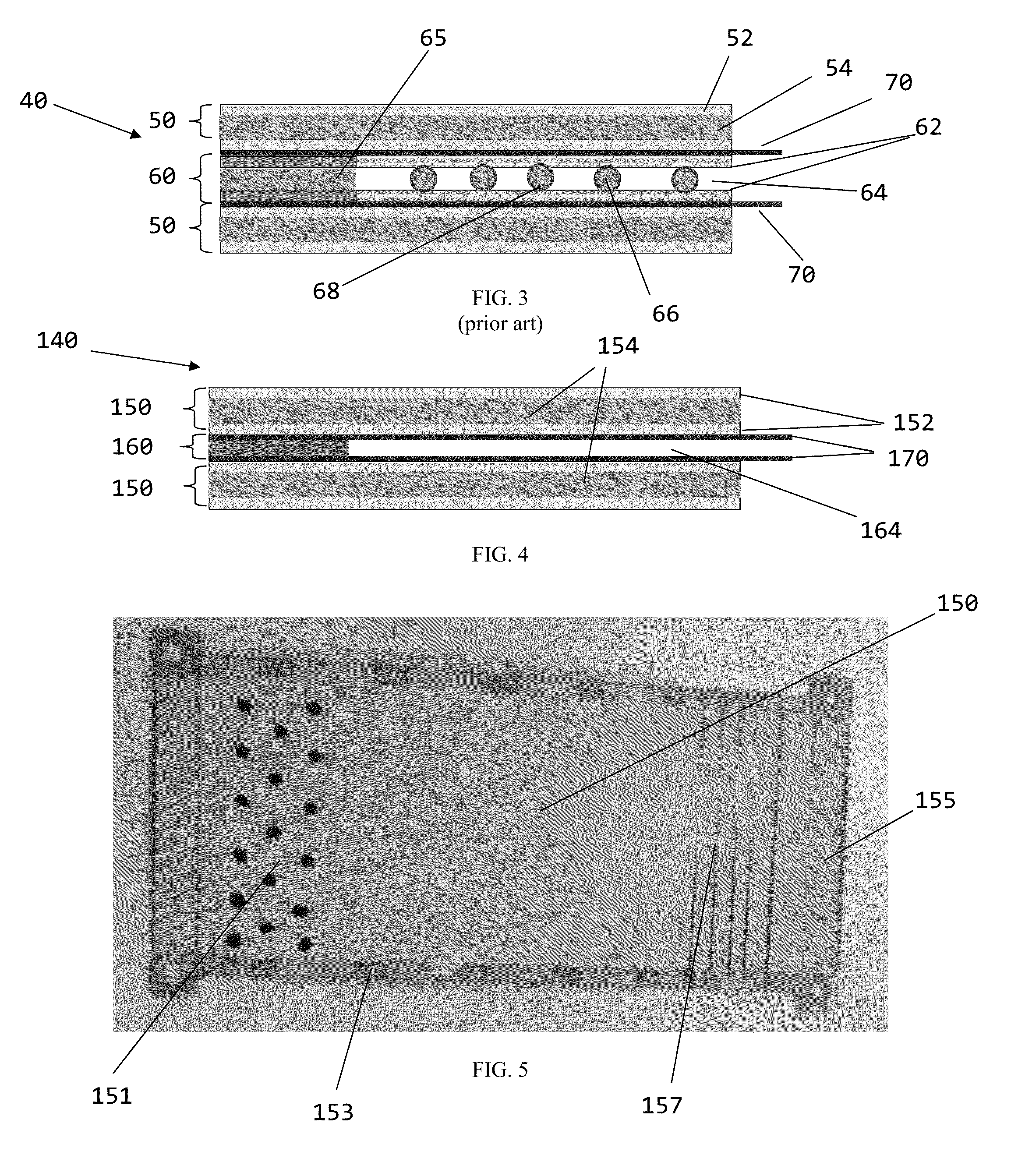

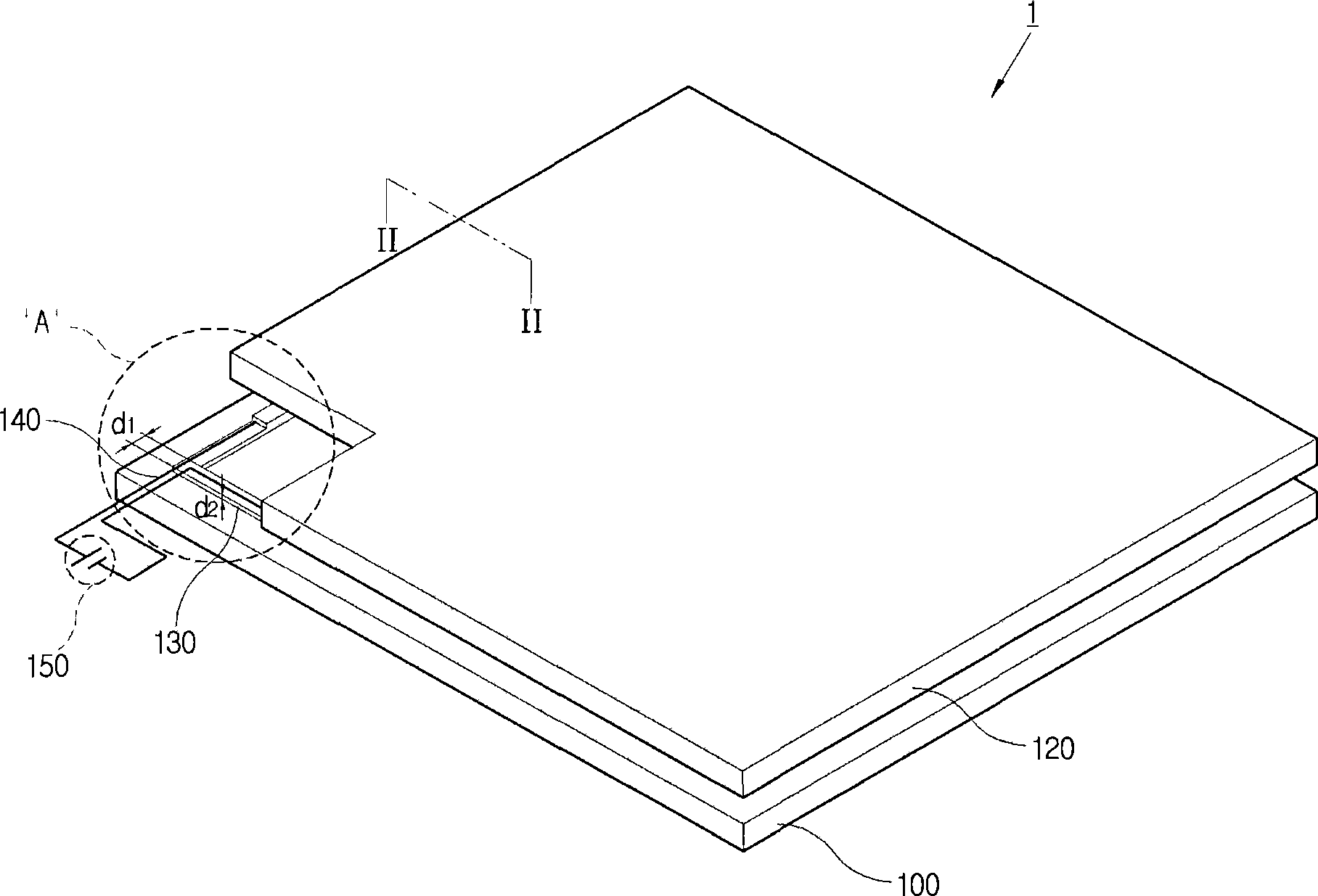

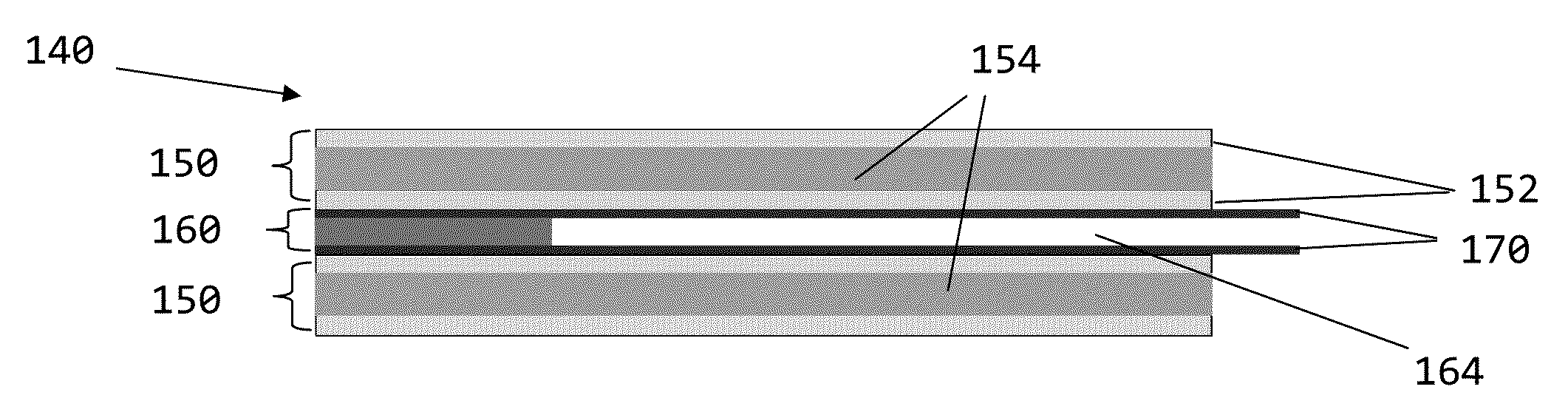

Discretely supported wet side plates

ActiveUS9203097B2Efficient transferIncrease in dry side flow channel thicknessMechanical working/deformationFuel cells groupingFuel cellsWater vapor

A water vapor transfer separator plate assembly and a method of making the same. In such an assembly made up of a stack of alternating wet side plates and dry side plates with a membrane disposed between them, a humid fluid such as that found in a fuel cell cathode exhaust flows against one side of each membrane such that at least some of its moisture content travels across the membrane to a lower humidity fluid on the opposite side of the membrane. The lower humidity fluid, such as that found in a fuel cell cathode entrance, experiences an increase in its humidity by the operation of the moisture flow across the membrane. At least a portion of the assembly may be made thinner by removing diffusion media and reinforcing structure of the dry side plates such that the overall assembly is simplified.

Owner:GM GLOBAL TECH OPERATIONS LLC

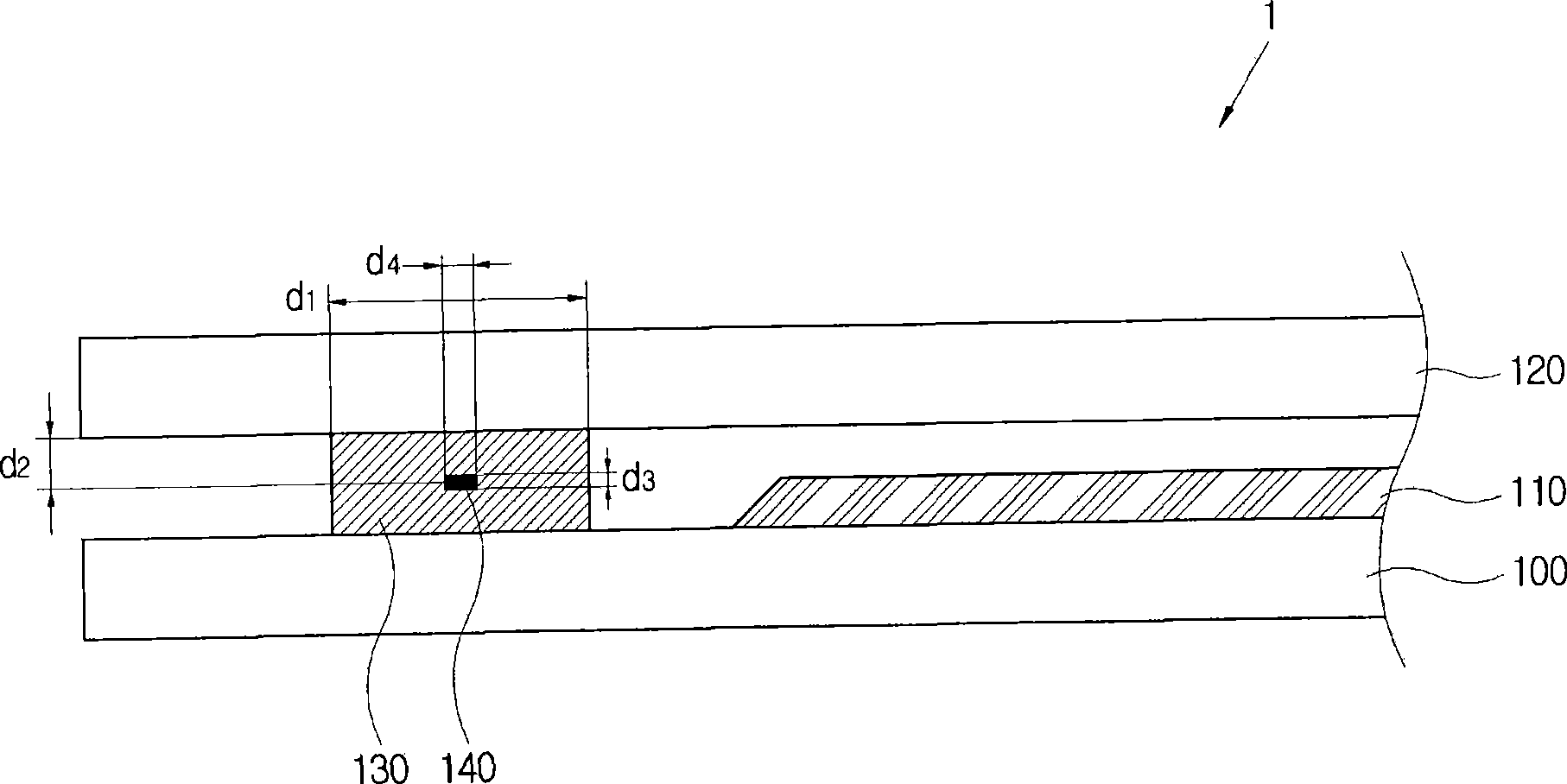

Flat panel display and manufacturing method thereof

ActiveCN101504951ASolid-state devicesSemiconductor/solid-state device manufacturingFritDisplay device

The present invention discloses a flat panel display which comprises the following components: an insulating substrate which is provided with a display element, a covering substrate which faces the insulating substrate and is connected with the insulating substrate, frit which is formed along the edge between the insulating substrate and the covering substrate, and filling material which is positioned between the insulating substrate and the covering substrate and connects the insulating substrate with the covering substrate. The filling material comprises a first part which is spaced from the frit and covers the display element, and a second part which is positioned between the frit and the insulation substrate. Therefore, the invention provides the flat panel display which can minimize the oxygen and moisture flowing from outside.

Owner:SAMSUNG DISPLAY CO LTD

Sulfur measuring system

InactiveCN104089916AReduce failure frequencyReduce moisturePreparing sample for investigationColor/spectral properties measurementsCombustionSulfur

The invention discloses a sulfur measuring system, comprising a combustion tube (3), a drying tube assembly (5) filled with a magnesium perchlorate drying agent and a pre-dewatering device (4) arranged between the combustion tube (3) and the drying tube assembly (5), wherein the pre-dewatering device (4) comprises a nafion tube (41) and a shell (42) covering outside the nafion tube (41), the nafion tube (41) is connected between the outlet end of the combustion tube (3) and the air inlet end of the drying tube assembly (5), and the shell (42) is provided with an exhaust port and an air inlet for introducing dry gas. According to the sulfur measuring system, the nafion tube is used in the pre-dewatering device, and the nafion material is only used for bringing away internal moisture through external drying, so that the moisture flowing into the drying tube assembly is effectively reduced, the failure frequency of the magnesium perchlorate drying agent in the drying tube assembly is reduced, and the test cost is reduced.

Owner:CHANGSHA KAIYUAN INSTR

Greening watering reminding system

InactiveCN103636465AEasy and Smart ConnectivityWatering devicesPressurised distribution of liquid fertiliserSoil scienceSpray nozzle

The invention belongs to the technical field of greening and particularly relates to a greening watering reminding system. The system comprises an earth surface humidity sensor, a deep stratum humidity sensor, a controller, a mineral ion detection unit, an ingredient controller, a flow controller and a spray nozzle. The earth surface humidity sensor and the deep stratum humidity sensor detects the humidity of soil of the earth surface and the land deep stratum and transmits humidity signals to the controller, the mineral ion detection unit detects soil mineral substances and inputs mineral substance content signals to the controller, and the controller adjusts the ingredient controller and the flow controller to adjust the water flow and ingredients and is connected with the spray nozzle.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Discretely supported wet side plates

ActiveUS20130022897A1Guaranteed normal transmissionIncrease the flow channelMechanical working/deformationLamination ancillary operationsFuel cellsWater vapor

A water vapor transfer separator plate assembly and a method of making the same. In such an assembly made up of a stack of alternating wet side plates and dry side plates with a membrane disposed between them, a humid fluid such as that found in a fuel cell cathode exhaust flows against one side of each membrane such that at least some of its moisture content travels across the membrane to a lower humidity fluid on the opposite side of the membrane. The lower humidity fluid, such as that found in a fuel cell cathode entrance, experiences an increase in its humidity by the operation of the moisture flow across the membrane. At least a portion of the assembly may be made thinner by removing diffusion media and reinforcing structure of the dry side plates such that the overall assembly is simplified.

Owner:GM GLOBAL TECH OPERATIONS LLC

Gasifier for refluxing and pyrolyzing tar

The invention discloses a gasifier for refluxing and pyrolyzing tar. The gasifier comprises a sealed furnace body, wherein the upper part of the furnace body can be opened and be provided with a cover and a gas outlet, the outside of the gas outlet is connected with the inlet of a steam separation device, the bottom of the steam separation device is provided with an outlet; the lower part of the furnace body is provided with an intake and a slag hole, the outside of the wind hole is connected with a blower; an air-jetting themolysis gasifier is arranged on the lower end of the inside of the furnace body, the upper part of the air-jetting themolysis gasifier is opened, an air-jetting shield is covered on the gasifier body, the gap between the gasifier body and the air-jetting shield is used as an integral air-jetting path, an air-jetting gasification pyrolyzer is connected with the intake through a blast pipe, and the bottom outlet of the steam separation device is communicated with the intake through a pipe. The inside of the gasifier of the invention is provided with the air-jetting themolysis gasifier, the themolysis device and circular air-jetting device are integrated in the device of the invention, the cooled tar and moisture flow back to the inside of the gasifier to gasify, pyrolyze and burn; and the uniform air-jetting and uniform burning of the gasifier can be realized and the problem that coarse can not be burned by the gasifier is solved.

Owner:杨修早 +1

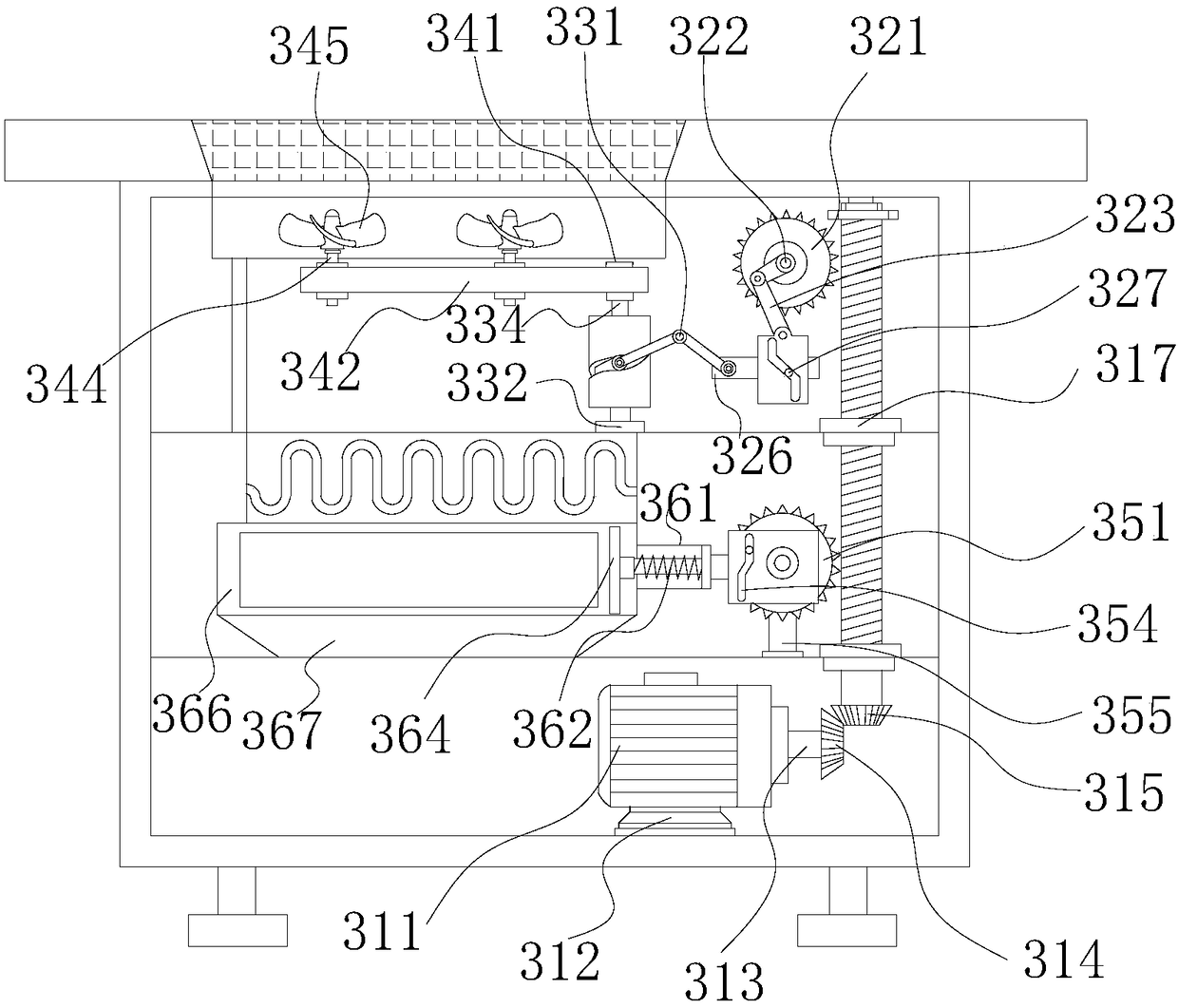

Machine for drying and sterilizing towels in bathroom by extrusion and dehydration

InactiveCN108577635ADry fastShorten drying timeDomestic applicationsRadiationHydraulic cylinderPulp and paper industry

The invention discloses a machine for drying and sterilizing towels in a bathroom by extrusion and dehydration. The machine comprises a box body, a hydraulic cylinder and an air heater, wherein a horizontal rotating plate is embedded in the top center of the box body, the lower lateral surface of a pressure plate is covered with water absorbing sponge, and a horizontal extruding screen is arrangedbelow the water absorbing sponge; a hanging rod for hanging a towel is fixedly mounted in a hanging rod groove; and a downward-sunken embedded groove is formed in the upper surface of a support plate, a plurality of drainage holes penetrating through the support plate of the box body are formed in the bottom of the embedded groove, and a horizontal support screen is fixedly mounted in the embedded groove. The extruding screen which can move up and down, and the support screen below the extruding screen can be used for extruding the towel between the extruding screen and the support screen toextrude the moisture in the towel, wherein a part of moisture is absorbed through the water absorbing sponge on the upper surface, and the other part of moisture flows into a collecting tank at the lower side, thereby quickly reducing the moisture in the towel, being convenient for quickly drying the towel by hot air and shortening the drying time of the towel.

Owner:王书铭

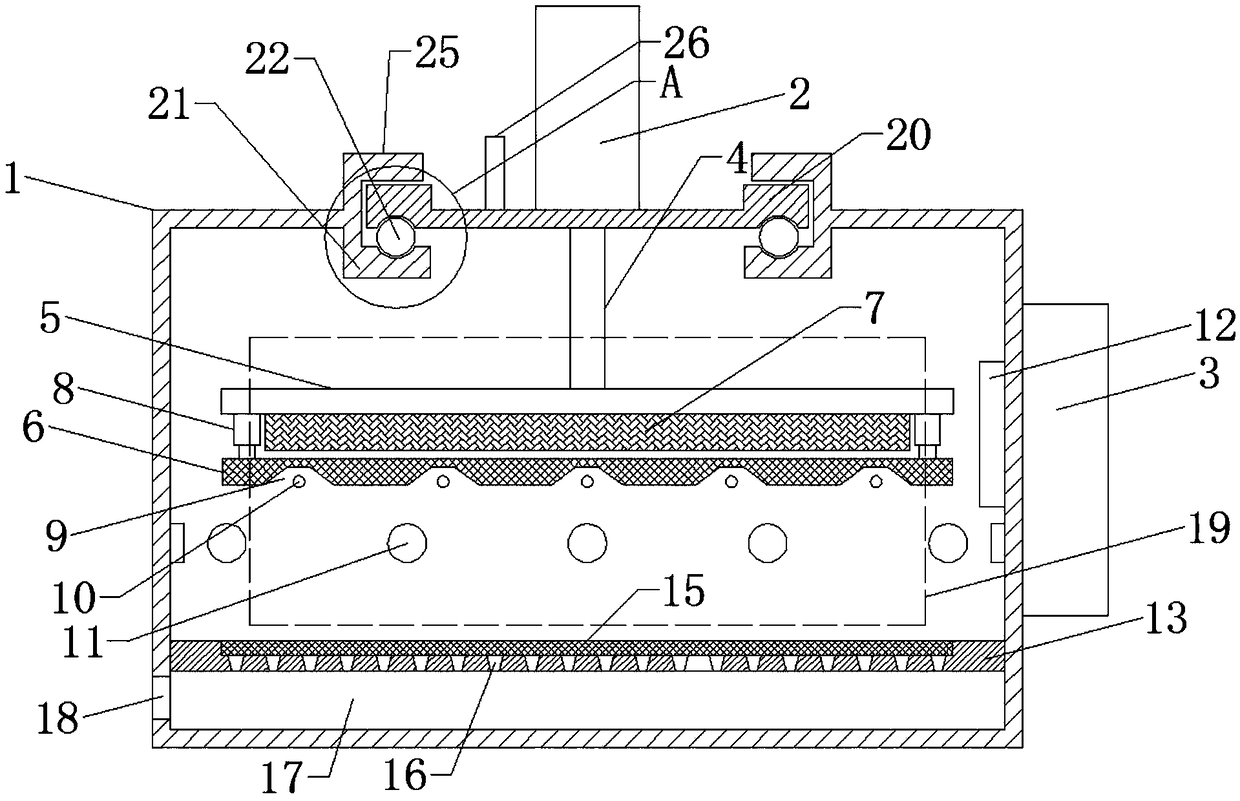

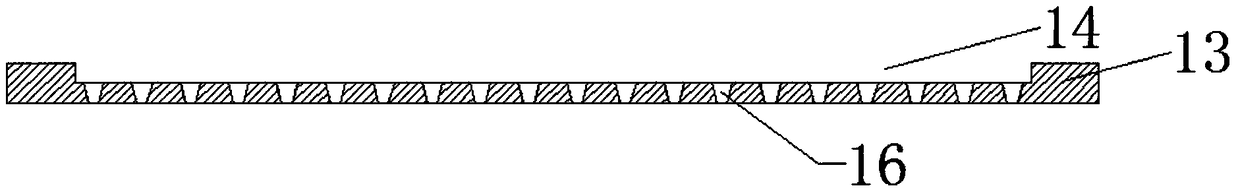

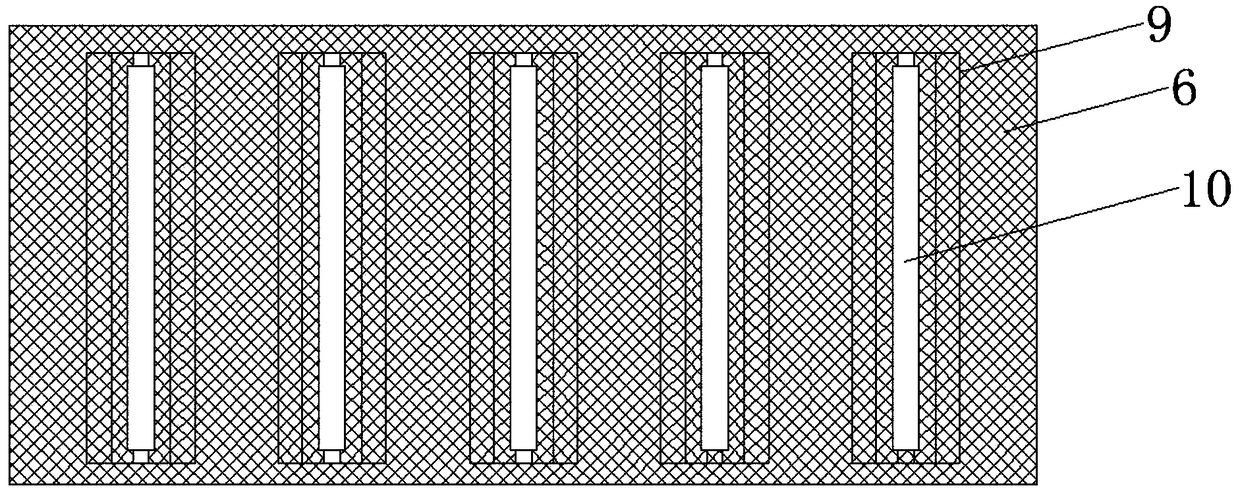

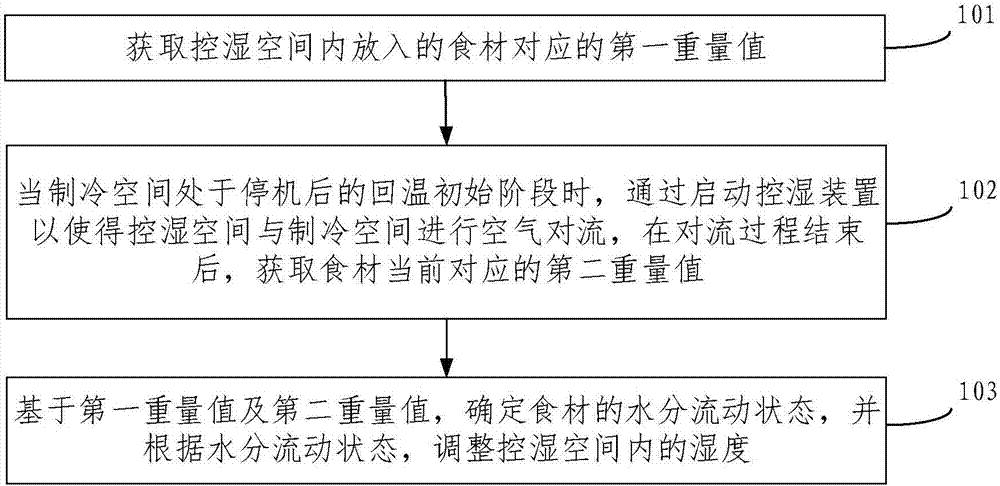

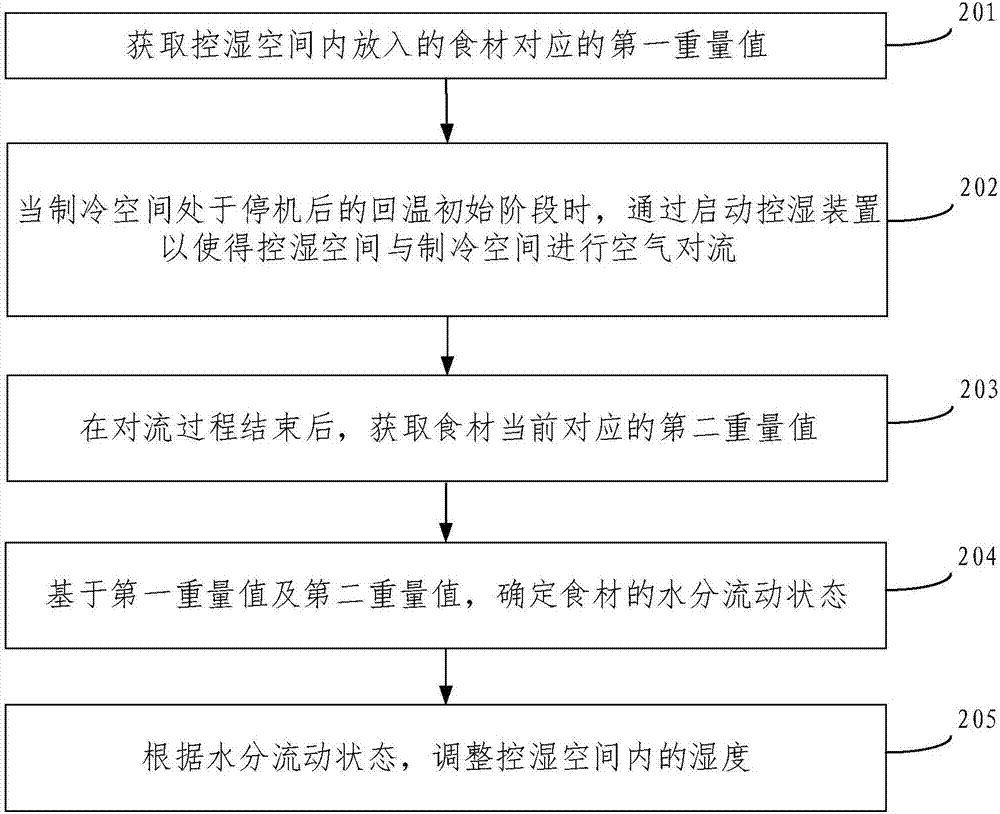

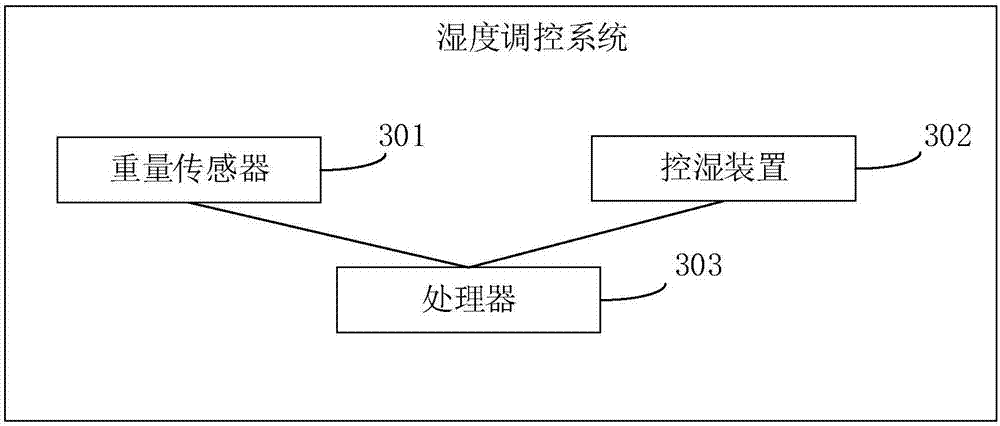

Humidity regulating method and system

ActiveCN107477944APrecise Humidity ControlLow costLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention provides a humidity regulating method and system, and belongs to the technical field of household electrical appliances. The method comprises the steps that a first weight value corresponding to food materials put in a humidity control space is acquired; when a refrigeration space is in a warming initial stage after halt, a humidity control device is started, the humidity control space and the refrigeration space are in air convection, and a current second weight value corresponding to the food materials is acquired after convection; the moisture flowing state of the food materials is confirmed based on the first weight value and the second weight value, and humidity in the humidity control space is regulated according to the moisture flowing state. According to the humidity regulating method, the storage humidity environment required by the food materials is judged through detecting weight change of the food materials, humidity in the humidity control space is correspondingly regulated, the situation that the proper storage humidity required by the food materials cannot be accurately judged as the food materials block one another is avoided, humidity can be accurately regulated, and a better fresh-keeping effect can be achieved.

Owner:HEFEI HUALING CO LTD +2

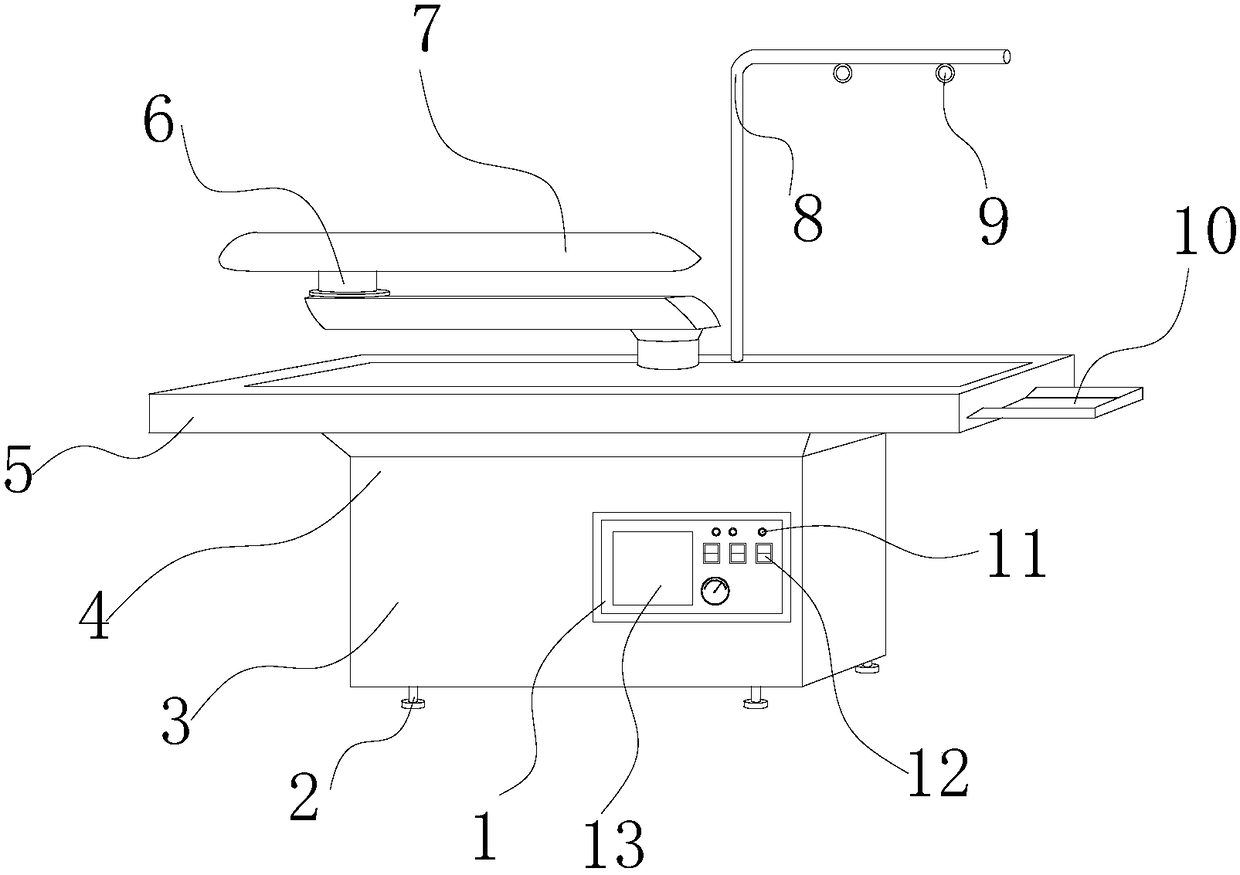

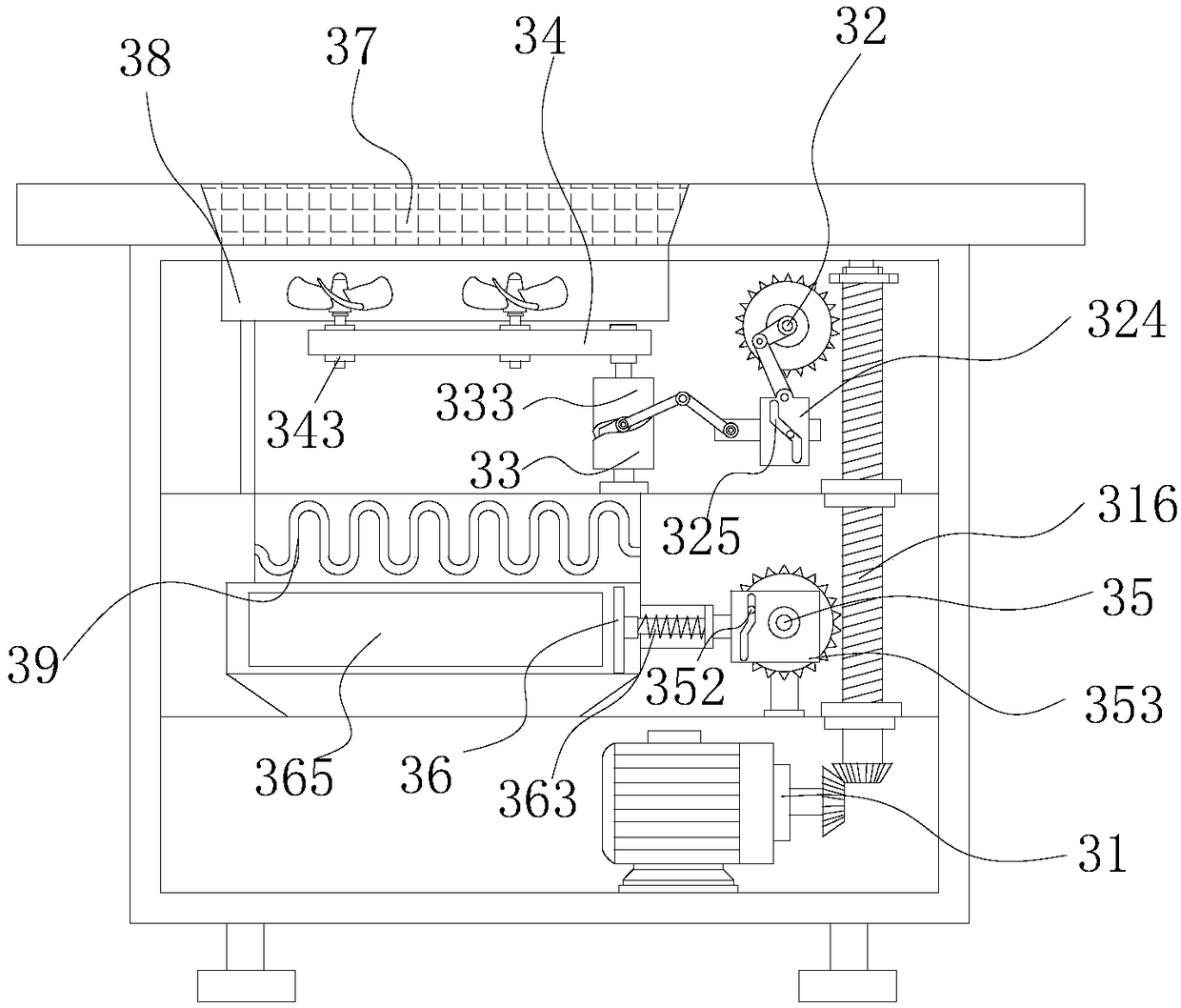

Wind-suction ironing table with good drying and dehumidifying effects

InactiveCN108517673APrevent backflowImprove drying effectIroning boardsTextiles and paperEngineeringFan blade

The invention discloses a wind-suction ironing table with good drying and dehumidifying effects. The wind-suction ironing table structurally comprises a control panel, supporting leg cups, a main bodydevice, a table body, a worktable, a rotating bracket, an ironing arm, a support frame, fixed rings, an auxiliary support frame, an indication lamp, an operation button and a display screen, whereinthe main body device comprises a driving mechanism, a worm wheel transmission mechanism, a scored pulley transmission mechanism, a fan blade transmission mechanism, a driven wheel transmission mechanism, a water suction transmission mechanism, a intercepting net, a wind suction hole and an electric heating wire. According to the wind-suction ironing table, the problems that relatively wet cloth cannot be rapidly dehydrated by virtue of an electric heating wire of a traditional wind-suction ironing table, moisture flows back, and the dehydration effect is poor are solved, the rapid drying and dehydration can be realized, the drying effect is improved, and the practicability is strong.

Owner:HUZHOU ZHUOHAO SILK CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com