Moisture flow measuring method based on straight through type gas ultrasonic flowmeter

A technology of flow measurement and flowmeter, which is applied in the field of straight-through gas ultrasonic flowmeter to measure moisture, can solve the problems of incomparability, non-universality, and large differences in the form of false height correction formulas, so as to avoid workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0016] The moisture measuring method of the present invention is realized based on a monophonic through-type gas ultrasonic flowmeter.

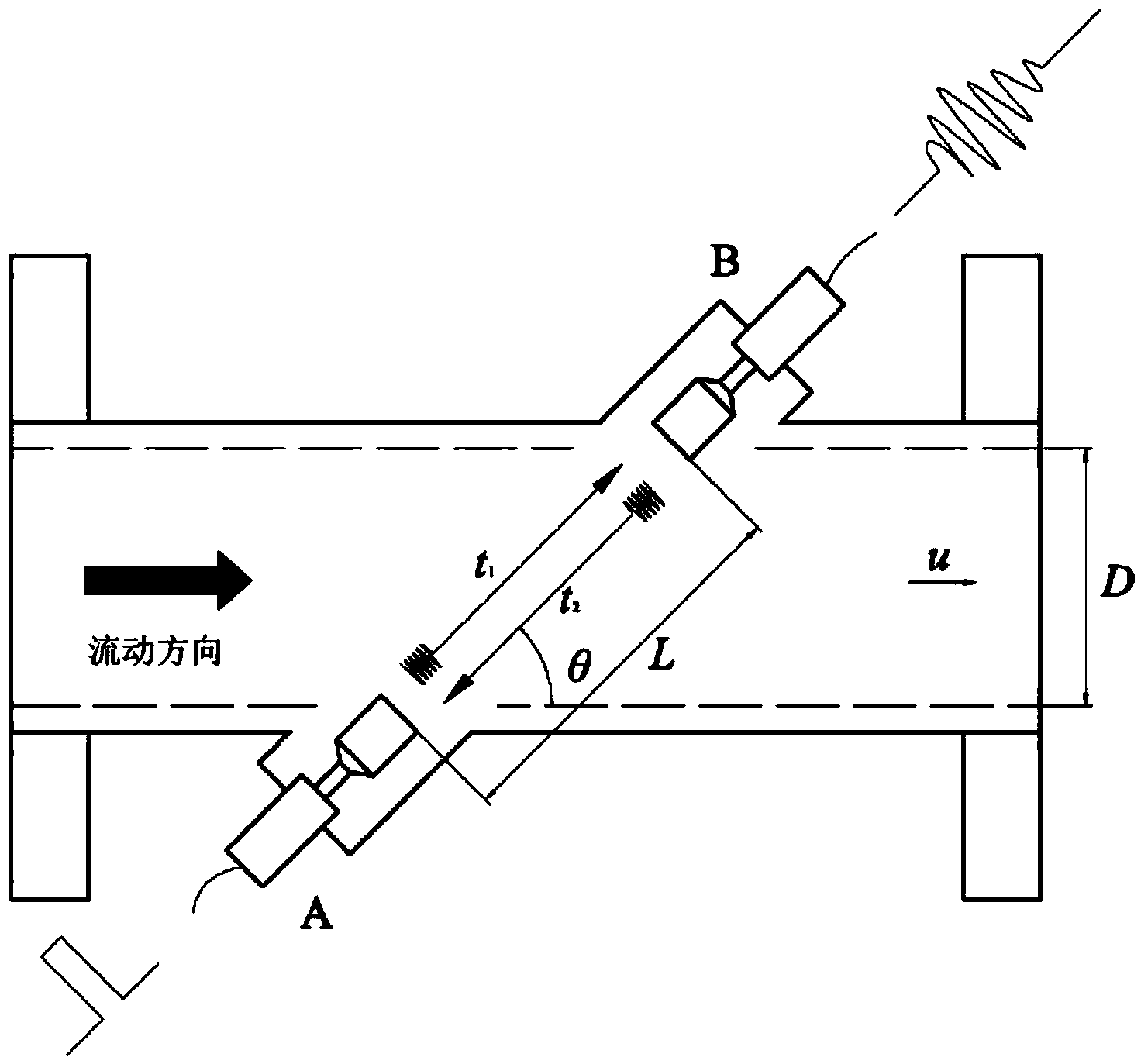

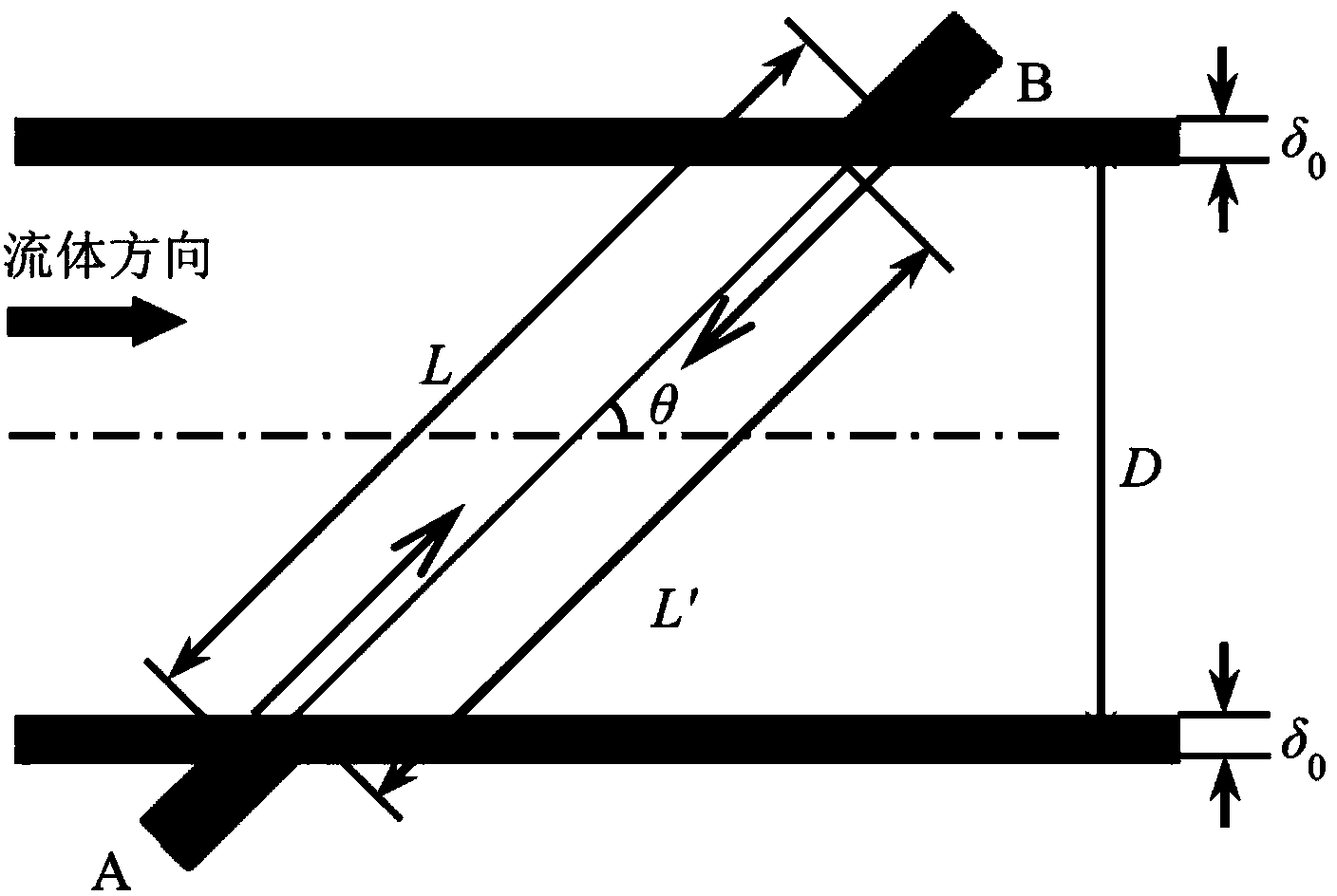

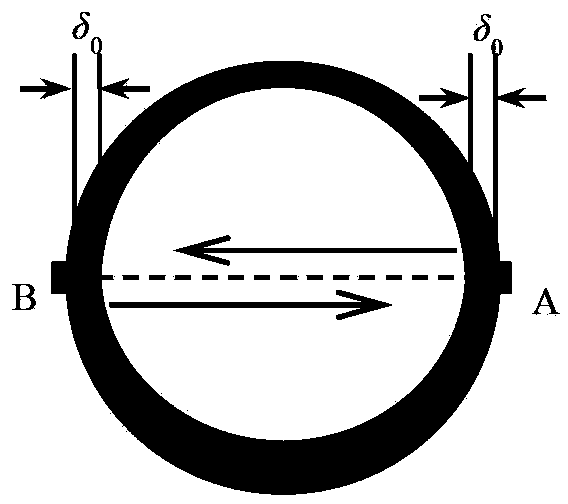

[0017] The structure of the mono channel straight-through gas ultrasonic flowmeter is as follows: figure 1 As shown, A and B are a pair of transducers. according to figure 1 In the flow direction of the fluid shown, the ultrasonic signal is transmitted by A and received by B in the downstream direction, and the propagation time is t 1 ; The ultrasonic signal is transmitted by B, received by A in the upstream direction, and the propagation time is t 2 . The mono channel straight-through gas ultrasonic flowmeter can obtain t by detecting the ultrasonic pulse signal passing through the fluid in the pipeline 1 and t 2 . Assume that the propagation distance of the ultrasonic signal between the transducers is L, the propagati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com