Gasifier for refluxing and pyrolyzing tar

A technology of pyrolysis gasification and tar reflux, which is applied in the petroleum industry and the manufacture of combustible gas, etc., to achieve the effects of stable temperature, long combustion time and uniform air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

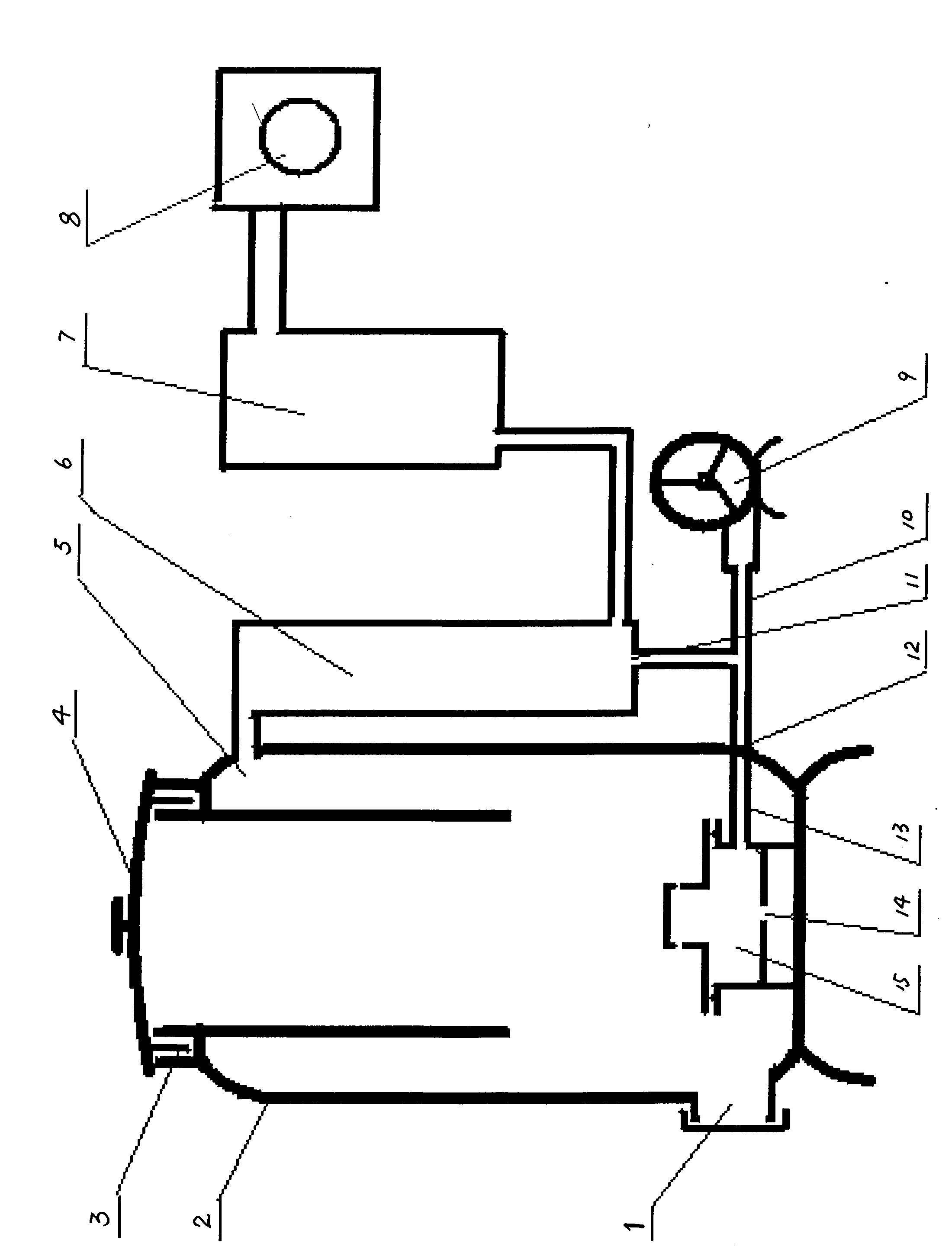

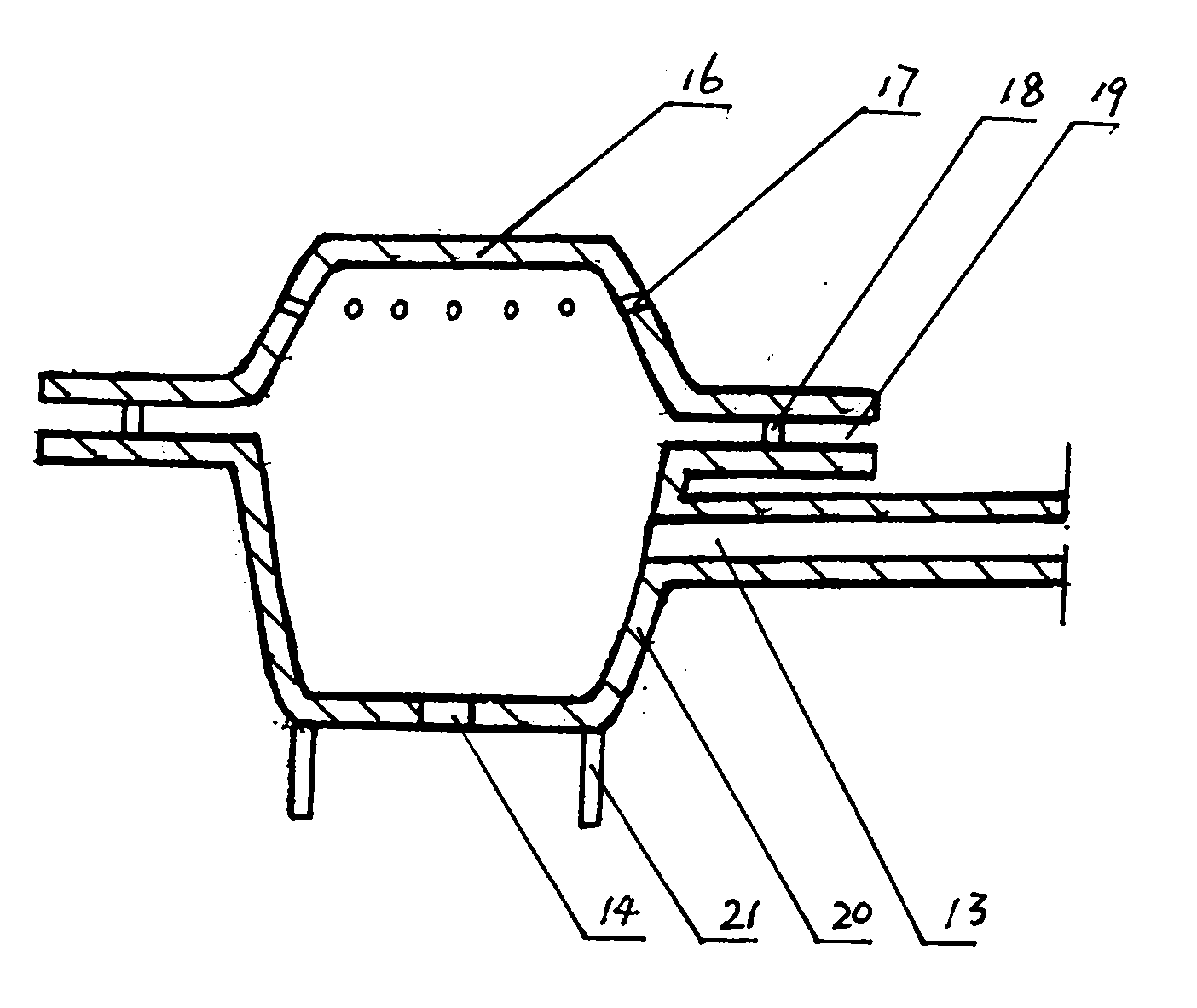

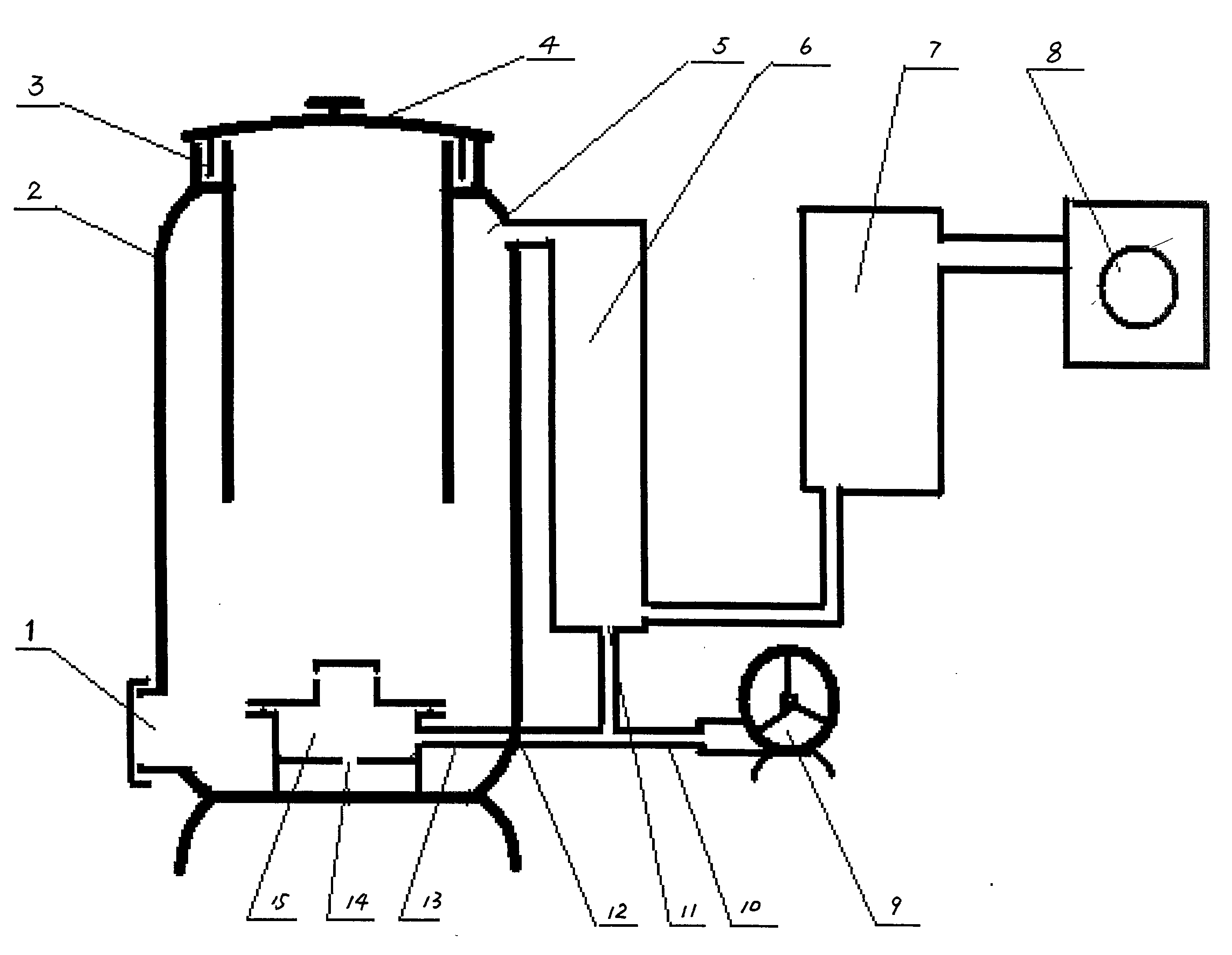

[0012] refer to figure 1 , figure 2 , The tar reflux pyrolysis gasification furnace includes a cylindrical furnace body 2 with a bottom, the upper part of the furnace body is open, and a U-shaped groove 3 is arranged on the top. After placement, a water seal structure is formed; the upper part of the furnace body is a sandwich structure with an air outlet 5, and the air outlet is connected to a water vapor separation device 6. The device is a closed box with an outlet 11 at the bottom. Serpentine condenser 7, serpentine condenser 7 is connected with cooking stove through pipeline; Furnace body bottom has air inlet hole 12, slag outlet hole 1, and air inlet hole 12 connects blower 9 externally through pipeline 10, and the outlet at the bottom of water vapor separation device 6 passes through The pipeline communicates with the air inlet hole 12. In order to facilitate the backflow of tar moisture, the position of the end of the pipeline near the air inlet is relatively low; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com