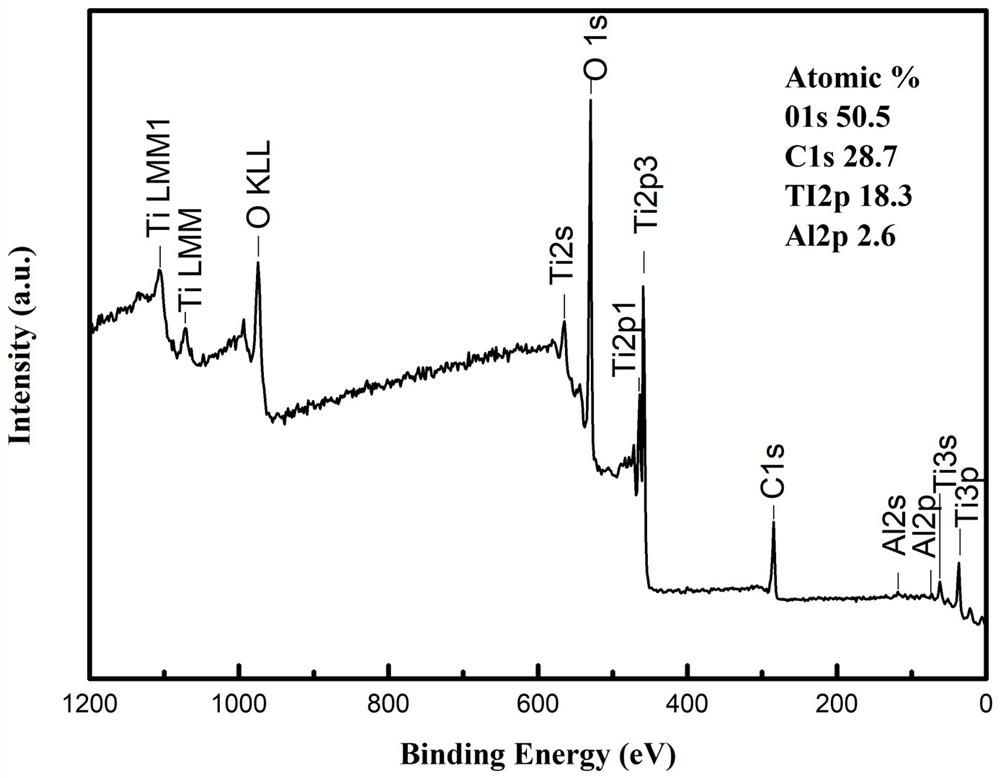

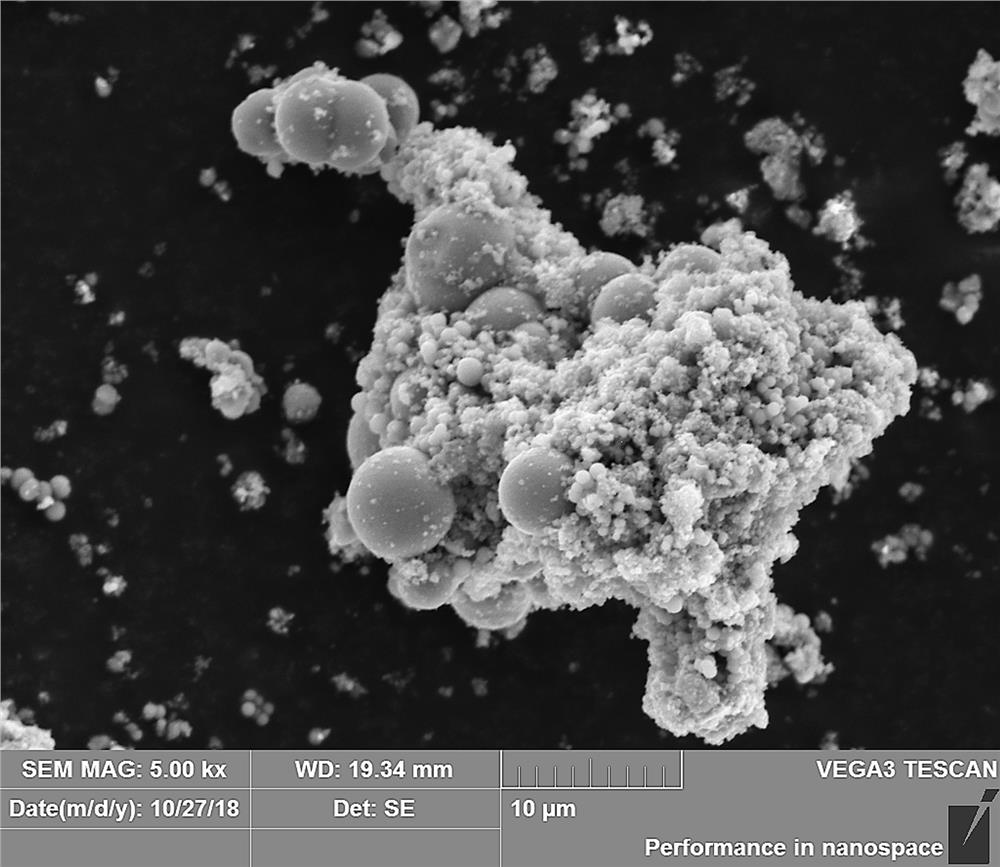

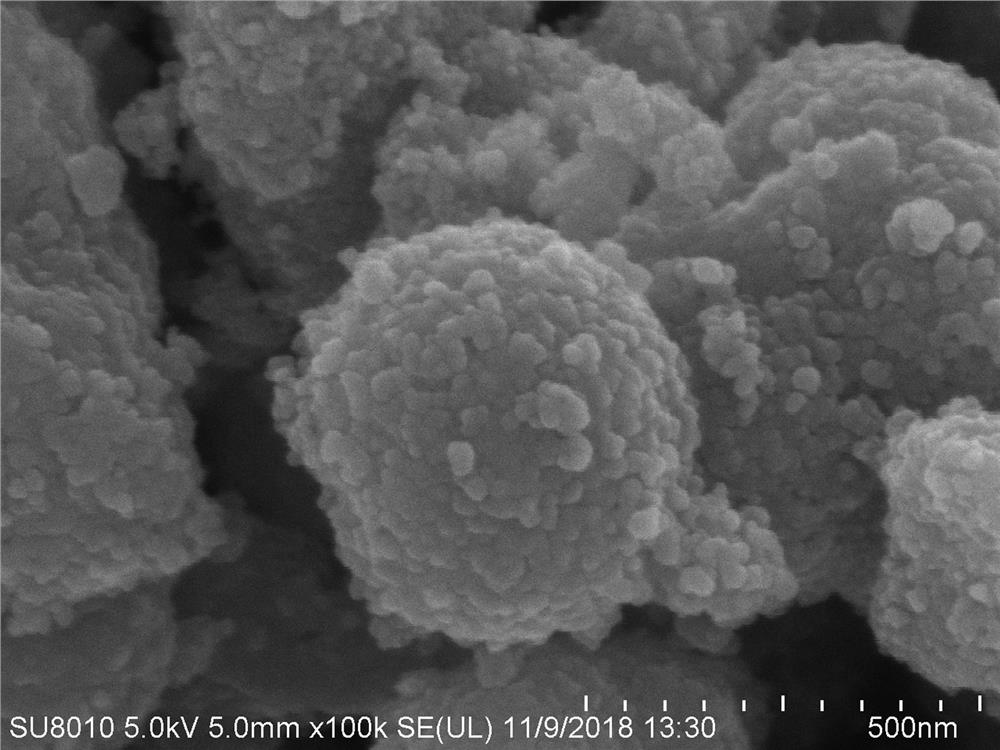

Preparation method of nano-titanium dioxide/γ-alumina composite powder

A technology of nano-titanium dioxide and composite materials, applied in the field of nano-material preparation, can solve the problems of mass production limitations of composite materials, poor mixing of two materials, and uncontrollable particle size, etc., to achieve excellent photocatalytic performance and process controllable , equipment cost and raw material cost are low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of TiO 2 / γ-Al 2 o 3 The preparation method of nanocomposite material powder, comprises the following steps:

[0036] Step 1. After taking aluminum nitrate and adding it into distilled water and fully stirring, adding absolute ethanol to continue stirring, and then adding ammonium citrate and stirring vigorously to obtain the raw material of the reaction solution, which is set aside;

[0037] In this step, the volume ratio of distilled water and absolute ethanol is 1:1. The γ-AlOOH nanoparticles produced by hydrothermal treatment have the best sphericity. Finally, ammonium citrate is added and fully mixed at a speed of 1200r / min. Aluminum nitrate and lemon The molar ratio of ammonium acid is (3~4):1, and the pore distribution of γ-AlOOH microspheres generated under this ratio is more uniform.

[0038] Step 2. Transfer the raw materials of the reaction solution obtained in step 1 into a stainless steel hydrothermal kettle with a polytetrafluoroethylene lining. ...

Embodiment 1

[0050] A kind of nano TiO 2 / γ-Al 2 o 3 The preparation method of composite material powder, comprises the following steps:

[0051] Step 1: After taking 2mmol of aluminum nitrate and adding 20ml of distilled water to fully stir, add 20ml of absolute ethanol to continue stirring, then add 0.5mmol of ammonium citrate, and mix and stir at a stirring speed of 1200r / min for 12min to obtain a pretreatment solution for later use ;

[0052] Step 2. Transfer the pretreatment solution obtained in step 1 to a stainless steel hydrothermal kettle lined with polytetrafluoroethylene. After that, put the hydrothermal kettle into a drying oven, and control the drying oven at a temperature of 3° C. / min. The heating rate was raised to 200 °C, and the hydrothermal reaction was carried out for 24 hours to obtain the hydrothermal product, which was set aside;

[0053] Step 3. Stir and suction filter the hydrothermal product obtained in step 2, take the filter residue, and then wash the obtaine...

Embodiment 2

[0061] A kind of nano TiO 2 / γ-Al 2 o 3 The preparation method of composite material powder, comprises the following steps:

[0062] Step 1: After taking 2mmol of aluminum nitrate and adding 20ml of distilled water to fully stir, add 20ml of absolute ethanol and continue to stir, then add 0.66mmol of ammonium citrate, and mix and stir at a stirring speed of 1000r / min for 15min to obtain a pretreatment solution for later use ;

[0063] Step 2. Transfer the pretreatment solution obtained in step 1 to a stainless steel hydrothermal kettle with polytetrafluoroethylene lining. After that, put the hydrothermal kettle into a drying oven, and control the drying oven at a temperature of 5 °C / min. The heating rate is raised to 150°C, and the hydrothermal reaction is carried out for 15 hours to obtain the hydrothermal product, which is set aside;

[0064] Step 3. Stir and suction filter the hydrothermal product obtained in step 2, take the filter residue, and then wash the obtained f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com