A socket automatic assembly equipment

An automatic assembly and equipment technology, applied in metal processing equipment, assembly machines, metal processing, etc., can solve problems such as inability to sort, achieve the effects of improving production efficiency, ensuring product quality, and stable and controllable production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

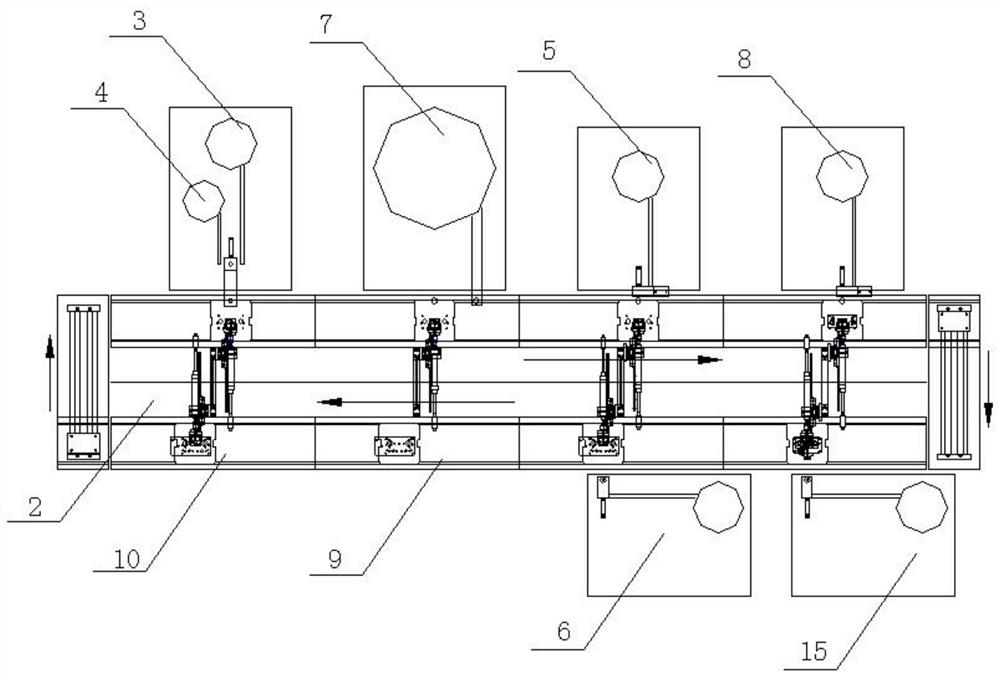

[0026]Such asFigure 1 to Figure 4As shown, an automatic socket assembly equipment includes a workbench 1, a horizontal conveyor belt 2, and the horizontal conveyor belt 2 is assembled on the upper part of the workbench 1. The horizontal conveyor belt 2 is connected end to end and arranged along a rectangular track. A rivet feeding mechanism is provided on the periphery of the horizontal conveyor belt 2. 3. Porcelain seat feeding mechanism 4. Negative insert feeding mechanism 5. Positive insert feeding mechanism 6, Inner cylinder feeding mechanism 7, Insulating gasket feeding mechanism 8, Positive insert feeding mechanism 6, Elastic gasket feeding mechanism 15, Riveting Mechanism 9 and feeding mechanism 10; rivet feeding mechanism 3, porcelain base feeding mechanism 4, negative electrode insert feeding mechanism 5, positive electrode insert feeding mechanism 6, inner cylinder feeding mechanism 7, insulating gasket feeding mechanism 8 and positive electrode insert feeding mechanism Th...

Embodiment 2

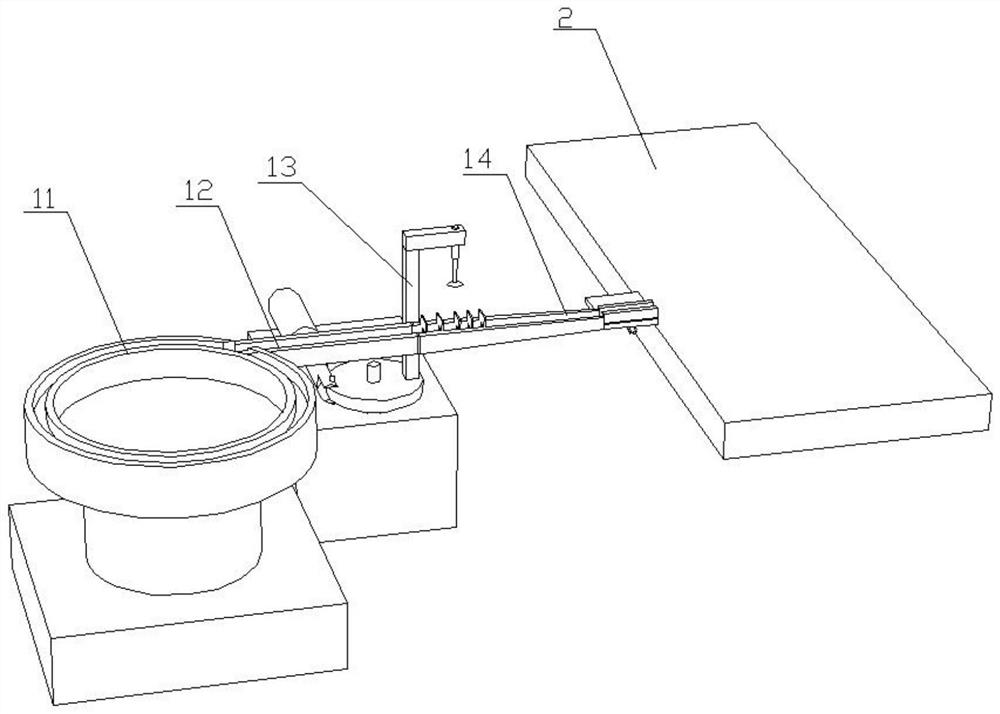

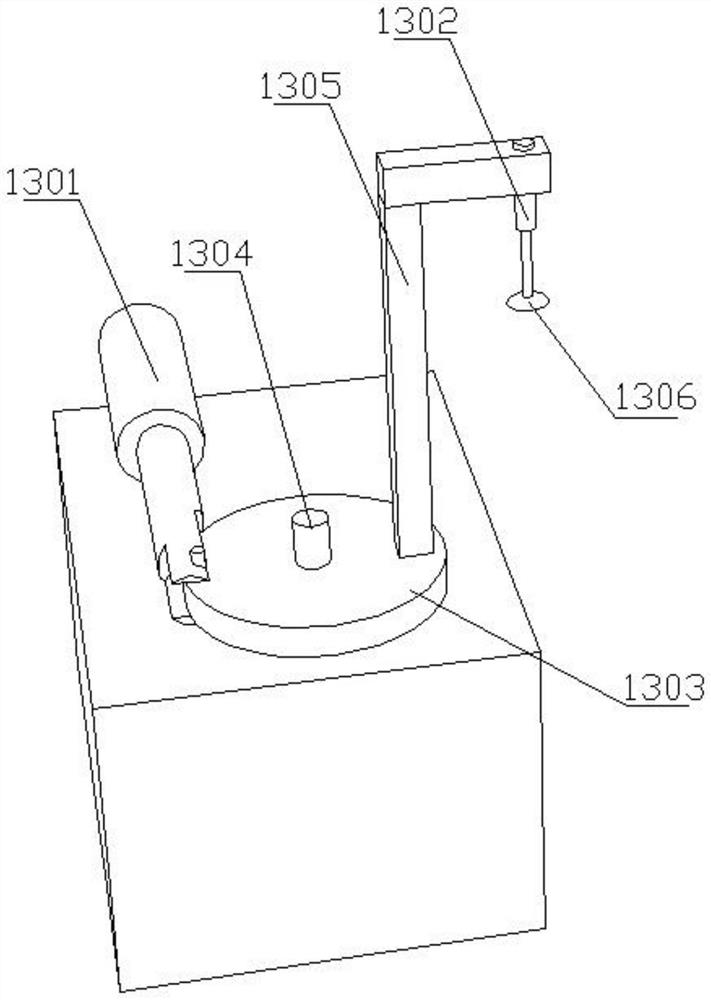

[0029]Such asFigure 5 As shown, the sorting mechanism 13 also includes an infrared transmitter, an infrared receiver and a controller. The infrared receiver and the infrared receiver are respectively arranged on both sides of the horizontal channel 1402. Between every two adjacent sieve plates 1401, the infrared receiver The first cylinder 1301 and the second cylinder 1302 are provided with solenoid valves, and the controller is connected with the solenoid valves of the first cylinder 1301 and the second cylinder 1302.

[0030]The arrangement mechanism 14 is arranged between the horizontal conveyor belt 2 and the vibrating feeding tray 11, and is fixedly connected to the horizontal conveyor belt 2; the sieve plates 1401 are arranged according to the size of the through holes 1403 from large to small, and the sieve plate 1401 near the horizontal conveyor belt 2 has the smallest through hole 1403 area .

[0031]The length of the through holes 1403 of the sieve plate 1401 corresponds to the ...

Embodiment 3

[0034]Such asImage 6 As shown, one end of the horizontal passage 1402 connected to the horizontal conveyor belt 2 is provided with a stay area. The stay area is provided with a stop 1404, a motor 1405 and a push block 1406. The stop 1404 is provided on the side of the horizontal passage 1402, the push block 1406 and the motor 1405 is set on the other side, the lower surface of the push block 1406 is provided with a nut 1407, the motor 1405 shaft is coaxially connected with a threaded rod 1408, and the nut 1407 is threaded with the threaded rod 1408; the horizontal channel 1402 is provided with a through groove 1409 on the surface of the push block 1406 and a nut 1407 are respectively located on the upper and lower surfaces of the horizontal channel 1402, the push block 1406 and the nut 1407 are connected to each other through the through slot 1409, and the motor 1405 is connected to the lower surface of the stay area.

[0035]There are infrared transmitters and infrared receivers on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com