Tire apex turning device

A technology of apex rubber and flaps, which is applied in the field of tire production equipment, can solve problems such as poor process stability and complexity, and achieve the effects of high degree of automation, fast shaping speed, and precise stop position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

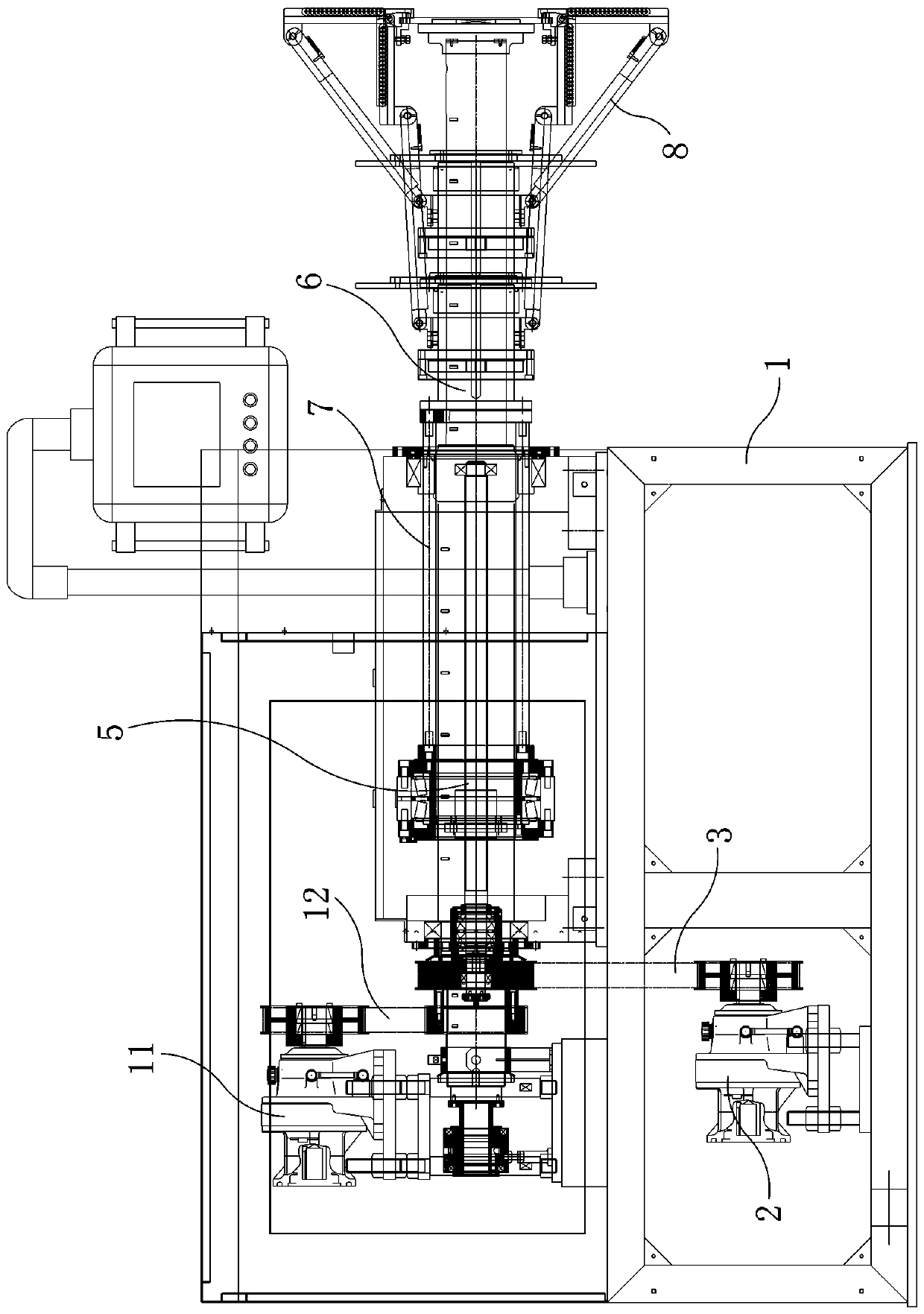

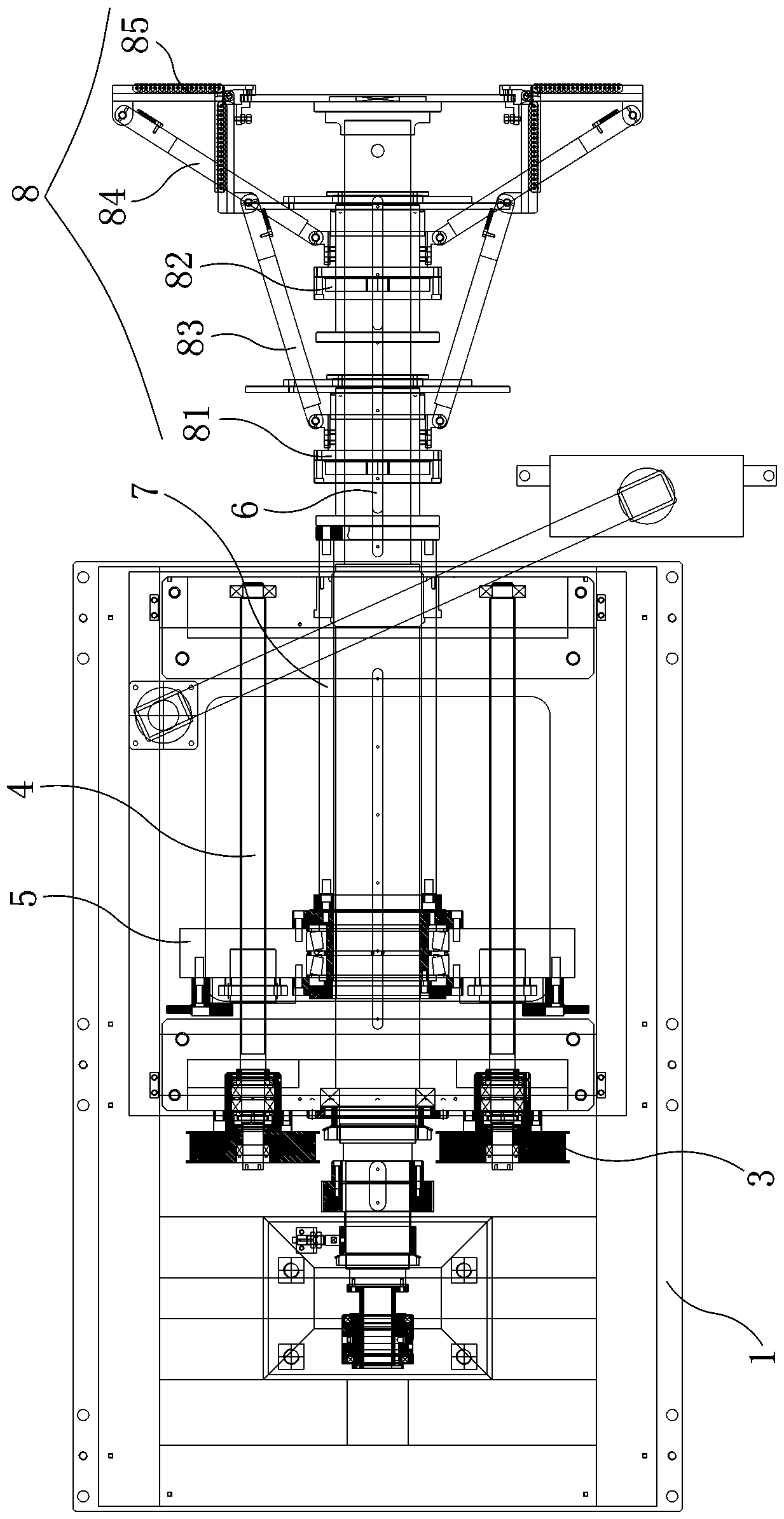

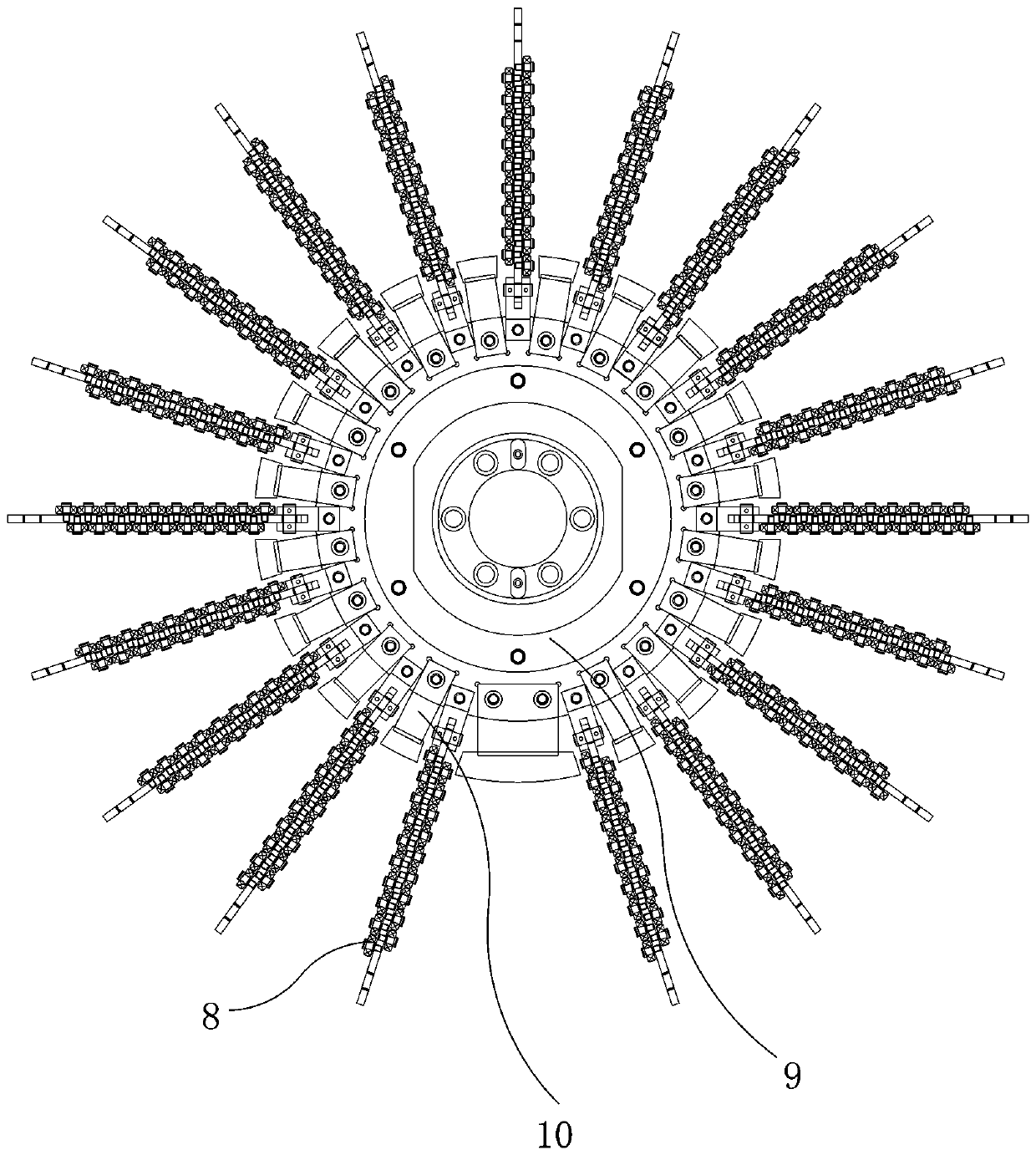

[0012] Such as Figure 1-Figure 3 As shown, the present invention is a tire apex turning device, and the apex molding drum includes a molding frame 1, a molding motor 2, a molding pulley mechanism 3, a molding screw 4, a screw seat 5, and a molding spindle 6. Push rod 7, forming link mechanism 8, suction cup seat 9, multiple suction cups 10, main shaft rotating motor 11, main shaft pulley mechanism 12.

[0013] The forming motor 2 is installed on the forming frame 1, the output shaft of the forming motor 2 is connected with one end of the forming screw 4 through the forming pulley mechanism 3, and the forming screw 4 is rotatably installed on the forming frame 1, forming The middle part of the screw mandrel 4 is screwed on the screw mandrel seat 5, and the middle part of the screw mandrel seat 5 is movably socketed on the forming main shaft 6 and can move back and forth along the forming main shaft 6. One end of the push rod 7 is fixed on the screw mandrel seat 5, and The oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com