A submersible pump diversion shell blade coated sand sand mold and its manufacturing method

A technology of a diversion shell and a submersible pump, which is applied in the directions of casting molds, cores, casting mold components, etc., can solve the problems of material energy waste, low production efficiency, and high scrap rate, and achieve low cost, reasonable structure, and clever design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

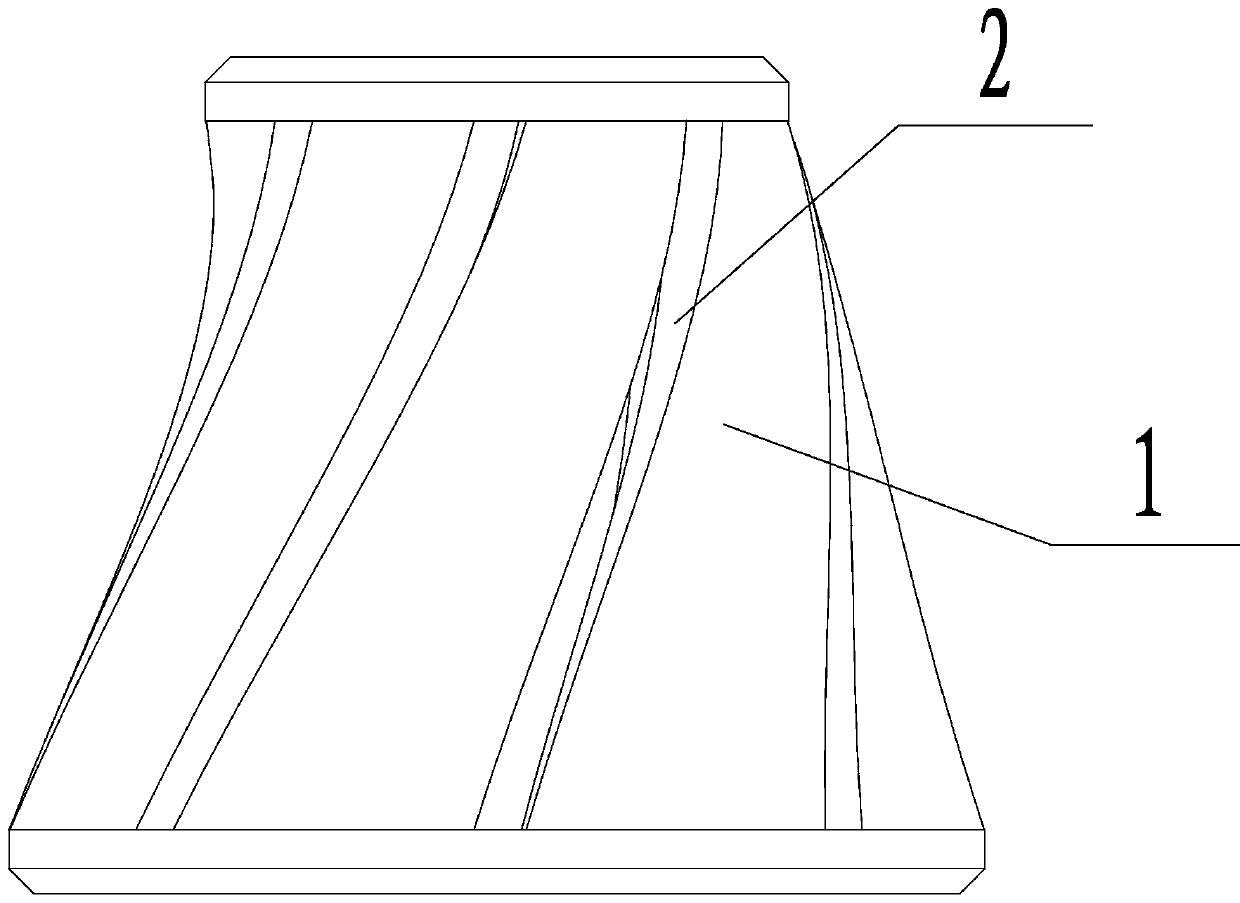

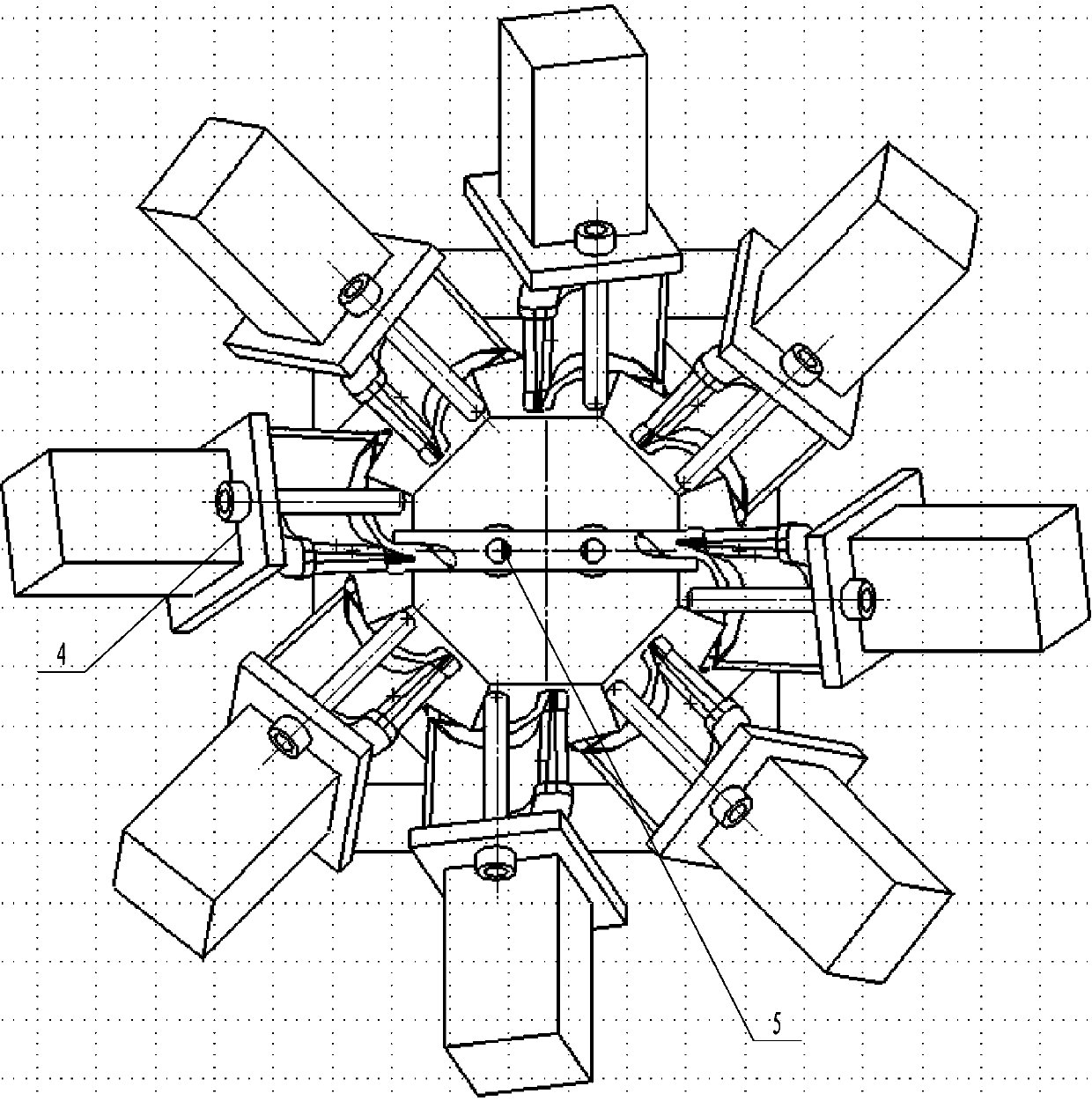

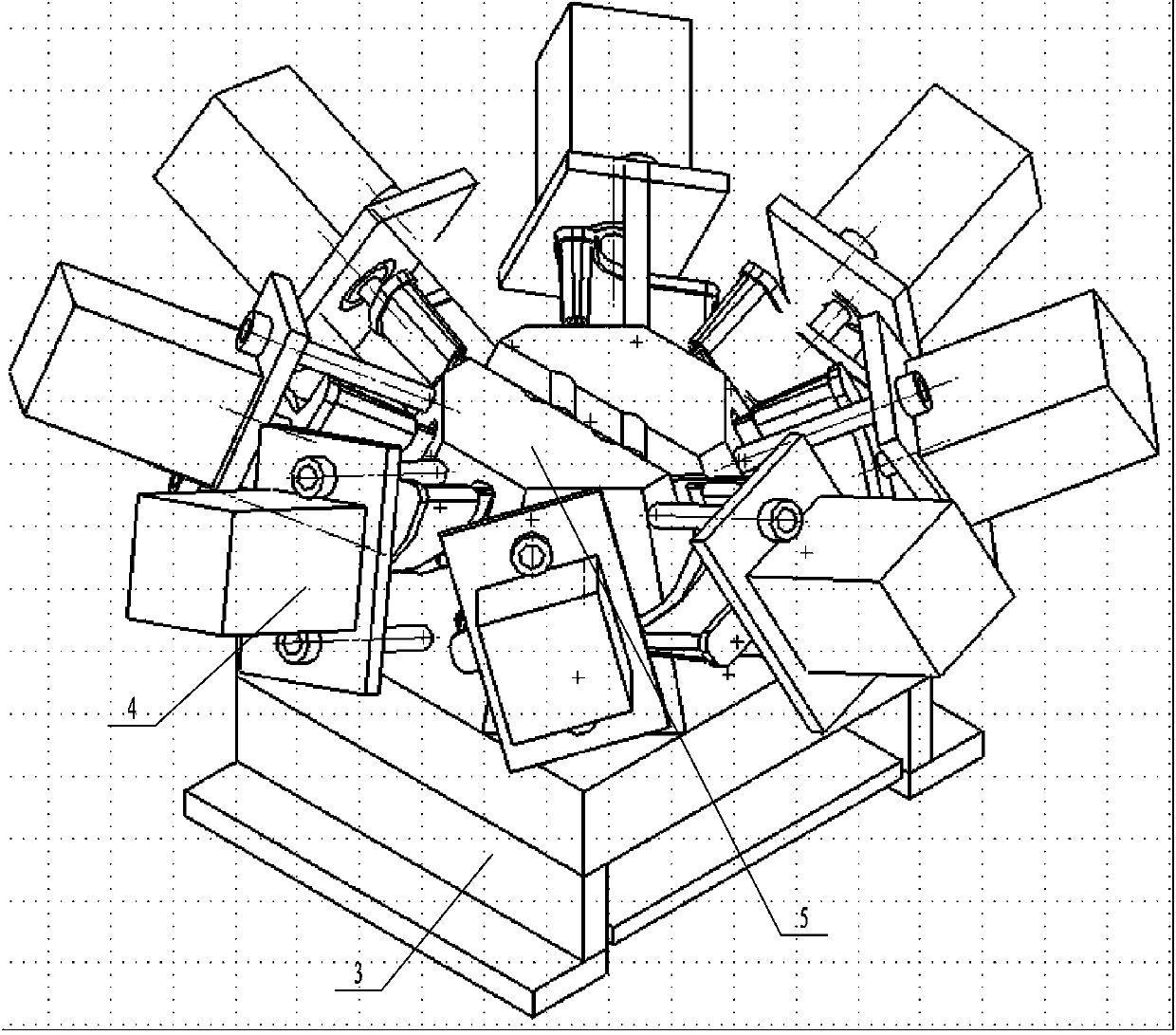

[0024] Such as Figure 1-3 As shown, the present invention includes a shell core sand mold 1 that is compatible with the inner cavity of the submersible pump diversion shell, at least two blade passages 2 that are arranged on the shell core sand mold 1 and are adapted to the blades, and corresponding to the blade passages 2 The blade mould, the blade channels 2 are arranged in a circular array based on the axis line of the shell core sand mold 1.

[0025] Further, the riser is arranged on the lower end surface of the shell core sand mold 1, so as to optimize the process and facilitate casting.

[0026] Furthermore, the median line of the shell core sand mold 1 is the parting line, thereby optimizing the process and facilitating box closing and unpacking.

[0027] Such as figure 2 , 3 As shown, the auxiliary tooling used to manufacture the present invention includes an upper mold 5 arranged on the sand injection machine 3 and corresponding to the shell core sand mold 1, a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com