Production assembly line for bead filler

A production line, apex technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of complexity and poor process stability, and achieve the effect of fast running speed, effective fit and accurate stop position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

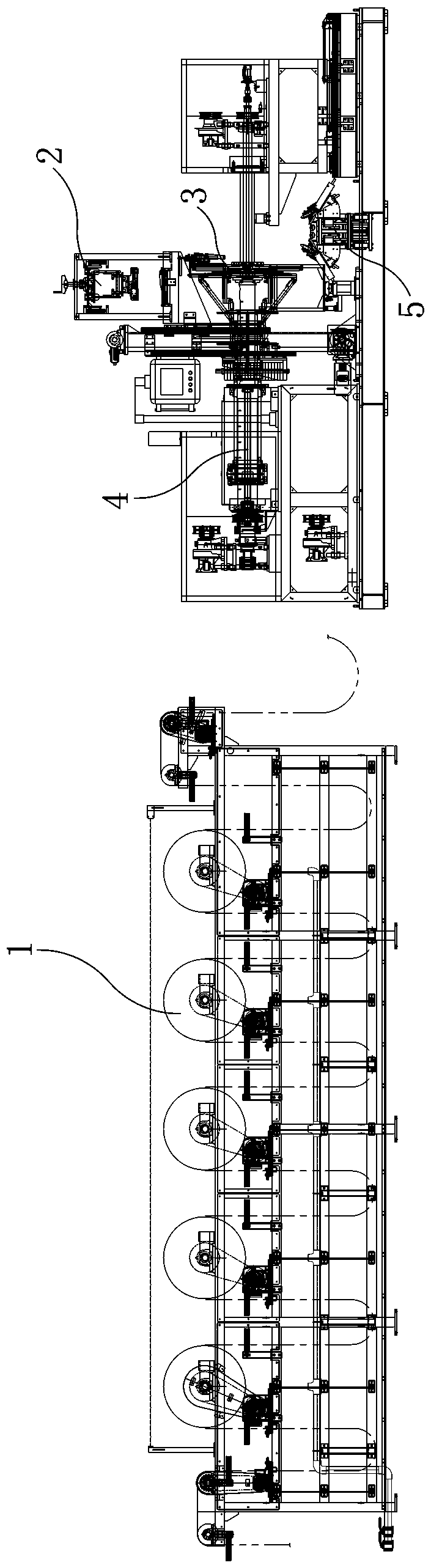

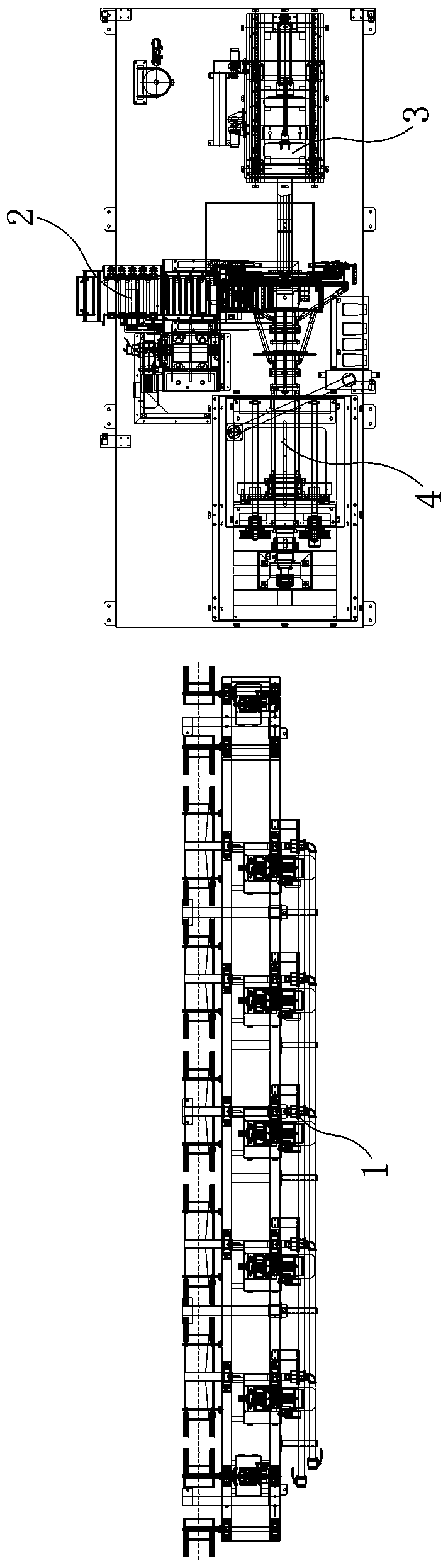

[0037] Such as figure 1 , figure 2 As shown, the present invention is an apex production line, which includes a cooling storage device 1, a feeding device 2, an apex forming drum 3, an apex bonding device 4, and an apex roller pressing device 5.

[0038] The feeding device 2 is installed at the discharge end of the cooling storage device 1, the apex forming drum 3 and the apex bonding device 4 are oppositely arranged, and the joint surface of the two is the discharge end of the feeding device 2. The apex roller pressing device 5 is installed below the apex bonding device 4.

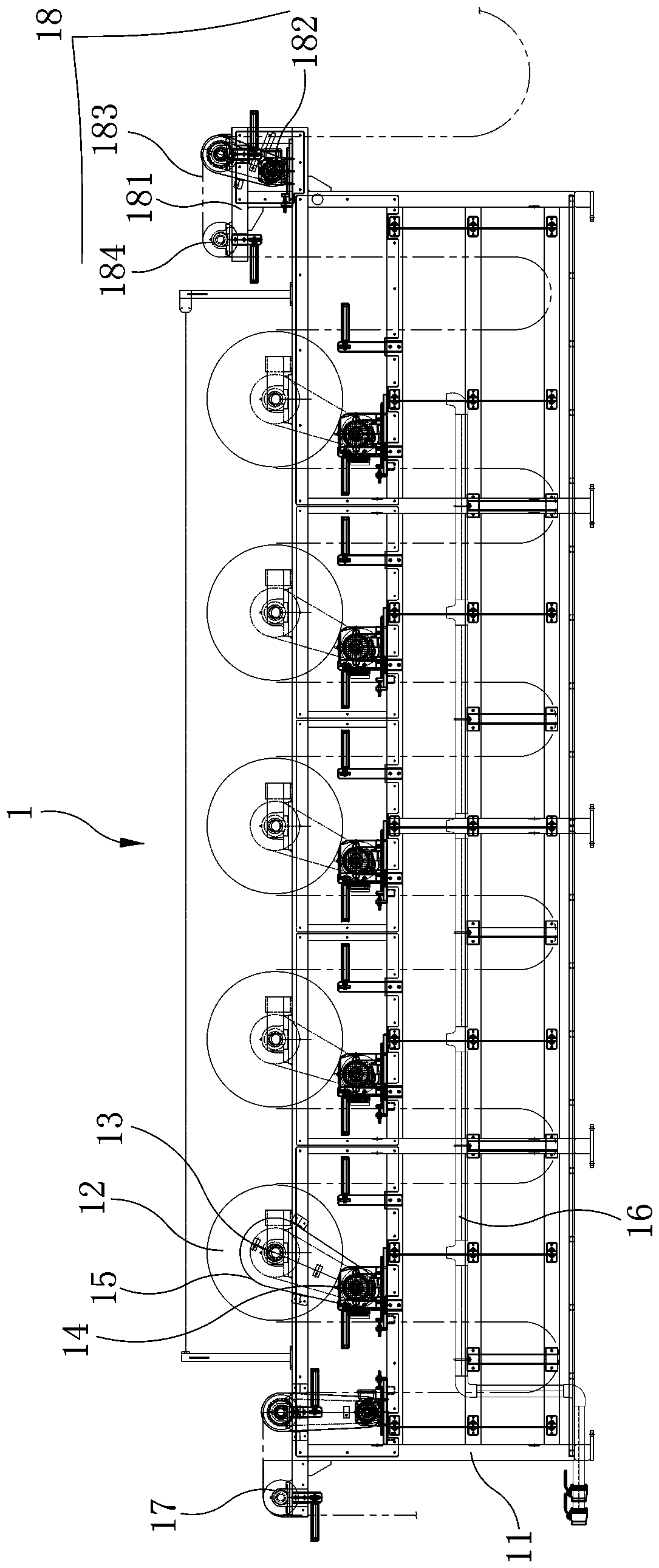

[0039] Such as Figure 3-Figure 6 As shown, the cooling storage device 1 includes a cooling frame 11, a plurality of cooling drums 12, a plurality of drum shafts 13, a plurality of drum motors 14, a plurality of drum pulley transmission mechanisms 15, a cooling water pipe 16, and a front guide wheel Group 17, rear guide wheel group 18, multiple groups of induction photoelectric 19; the multiple roller motors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com