Novel spring set automatic positioning combined mechanism and positioning method thereof

A technology of automatic positioning and combination mechanism, which is used in positioning devices, metal processing mechanical parts, clamping and other directions, can solve the problems that the direction cannot be satisfied, cannot be guaranteed, cannot meet the positioning requirements, etc., achieve fast and accurate positioning, and ensure coaxiality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

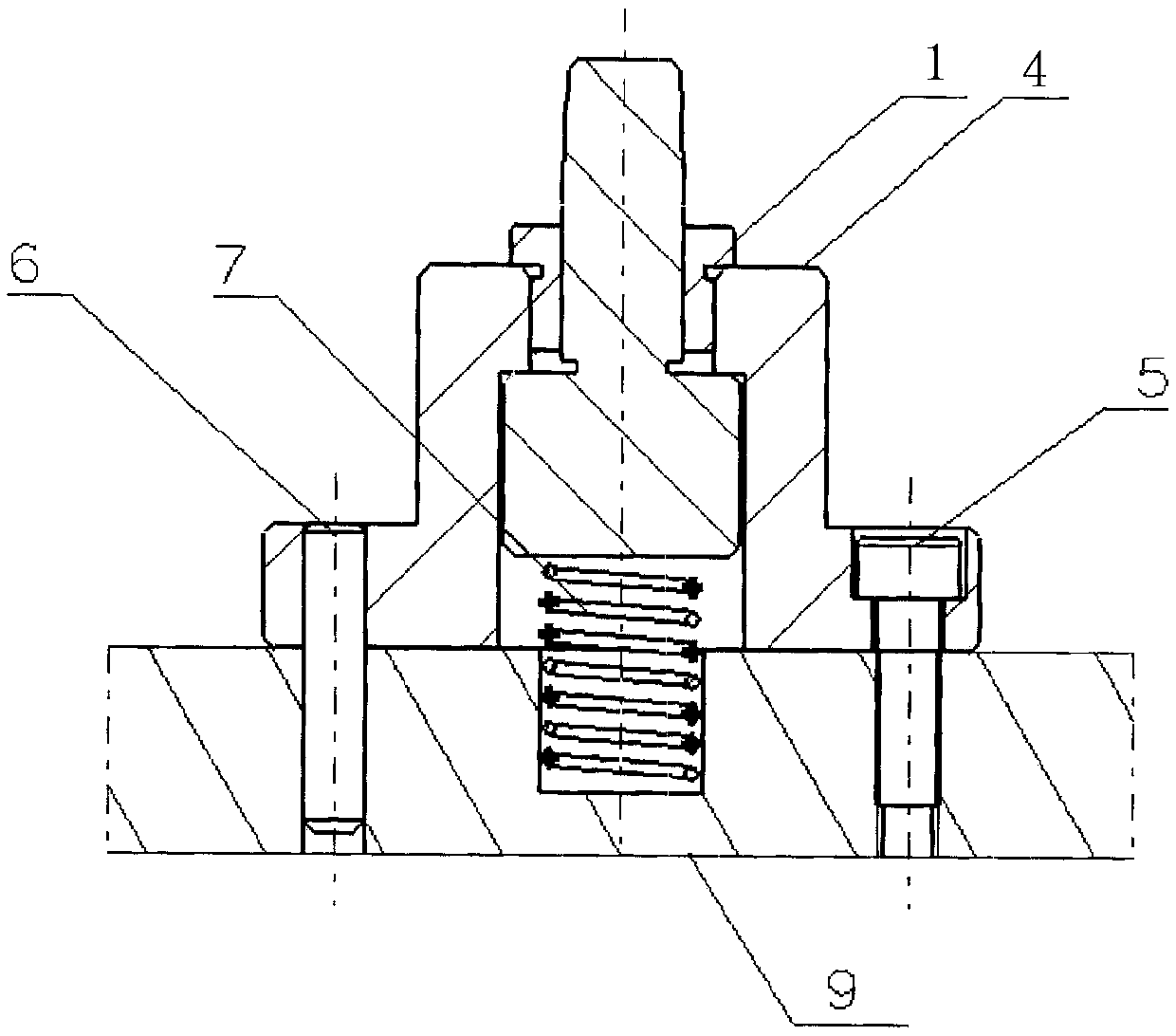

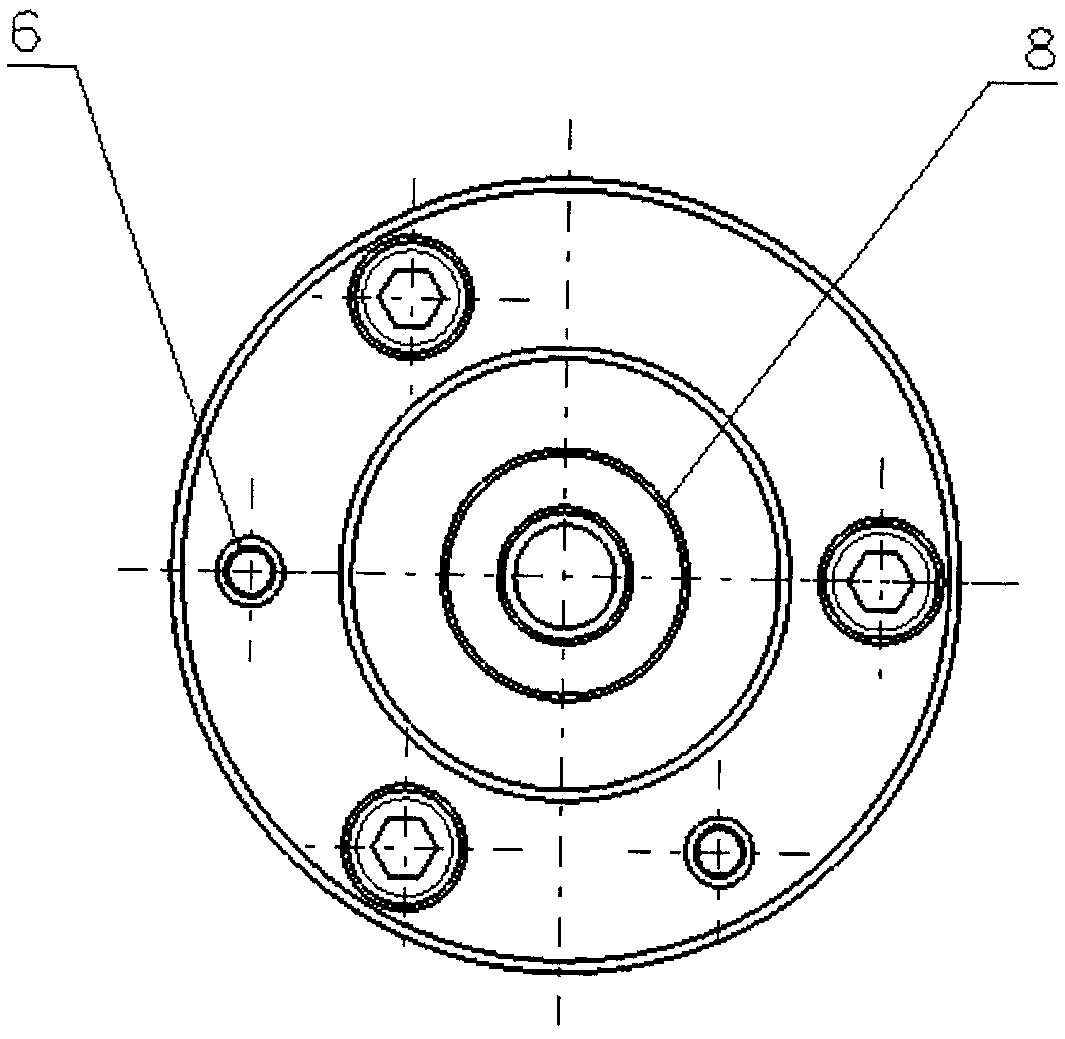

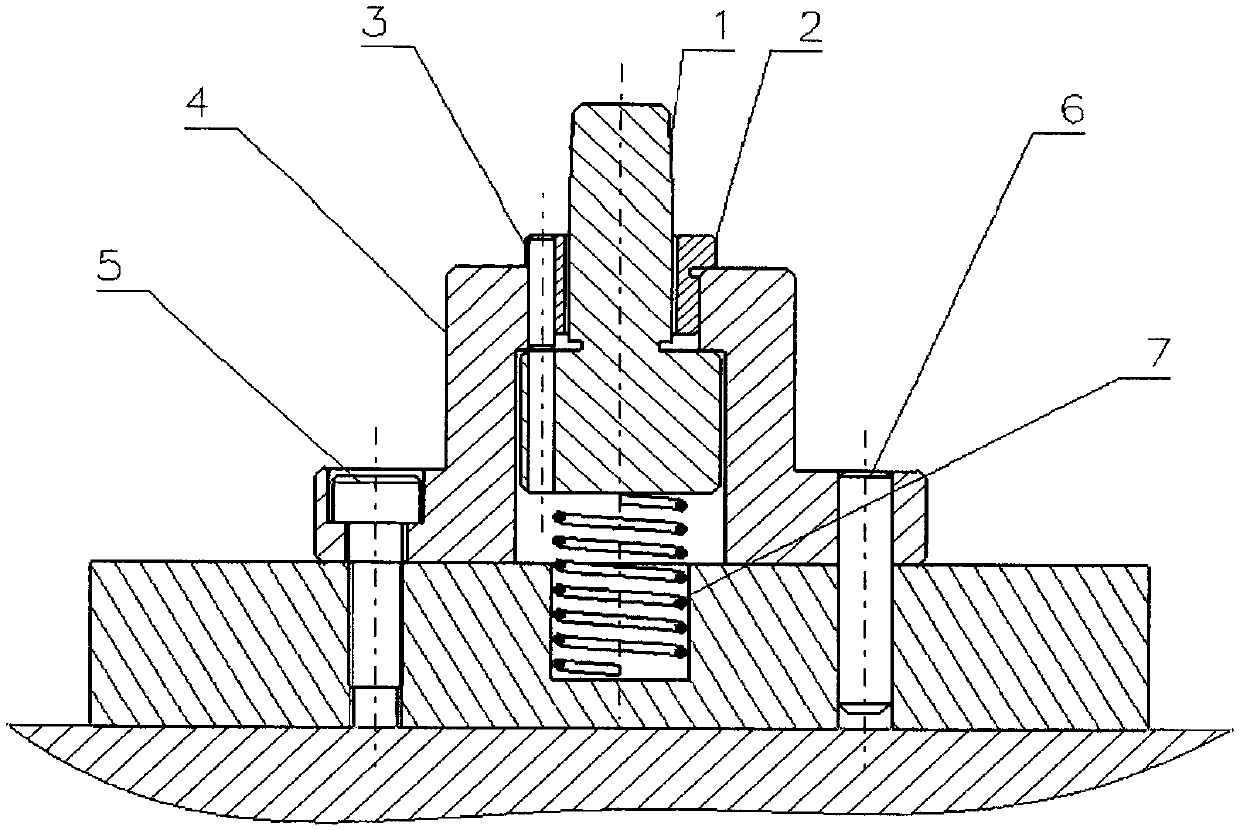

[0020] Such as figure 1 with figure 2 As shown, a new group spring automatic positioning combination mechanism is provided with a base 9 on the support surface of the clamp body, and the circular support 4 is positioned on the base 9 through two connecting cylindrical pins 6, and the circular support 4 It is connected with the base 9 through the screw 5; a cavity is provided in the circular support 4, a groove is provided at the position of the cavity corresponding to the base 9, a spring 7 is arranged in the groove, and the upper surface of the spring supports the conical column positioning pin 1 , the upper end of the conical column positioning pin 1 is a conical surface, and protrudes from the top of the circular support 4, and a bushing 2 is arranged between the conical surface of the conical column positioning pin 1 and the circular support 4, the lining The upper end of the sleeve 2 is provided with a boss, and is seated on the upper surface of the circular support 4, ...

Embodiment 2

[0022] On the basis of the structure of Embodiment 1, the middle through hole of the bush 2 is processed into an oblong hole. It coincides with the axis of symmetry of the oblong hole in the length direction; the bottom of the circular support 4 is also provided with an oblong through groove, and the guide pins 3 are connected together in the two oblong through grooves 10 .

[0023] The method of positioning a part with two holes and one side by using a group of new group spring automatic positioning combination mechanism includes the following steps:

[0024] 1) Set the centers of the two bases 9 on the two positioning points specified by the technical requirements respectively, and install the circular support 4 and its internal spring 7 and conical column positioning pin 1 through the connecting cylindrical pin 6 and screw 5 , the positioning combination mechanism of one of the positioning points is the structure of embodiment one, and the positioning combination mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com