A method for lifting a steel arch tower

A technology of steel arches and arch towers, applied in the field of bridge construction, can solve problems such as unsuitable lifting method, difficult bridge installation and construction, and complicated vertical rotation process, so as to avoid high-altitude welding operations, safe construction process, and simple principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

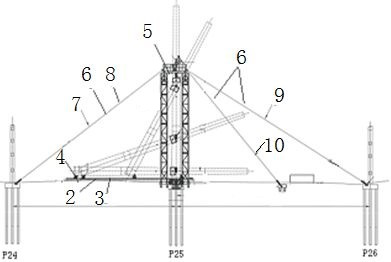

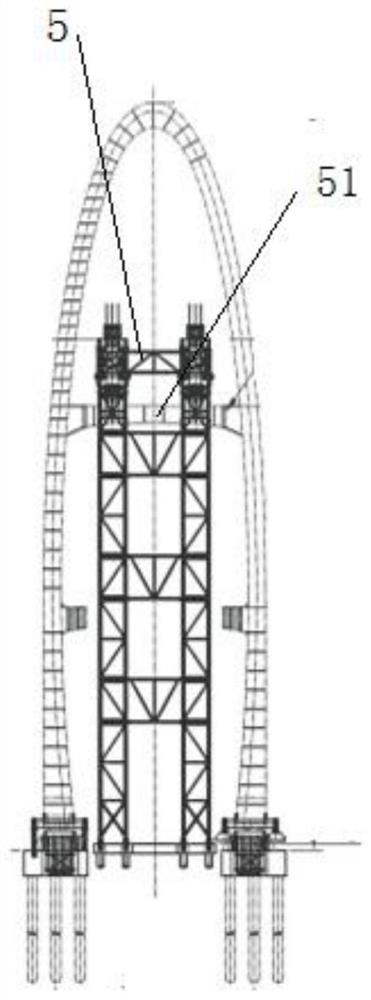

[0039] Embodiment 1: Taking a steel arch tower with a lifting weight of about 2100t as an example

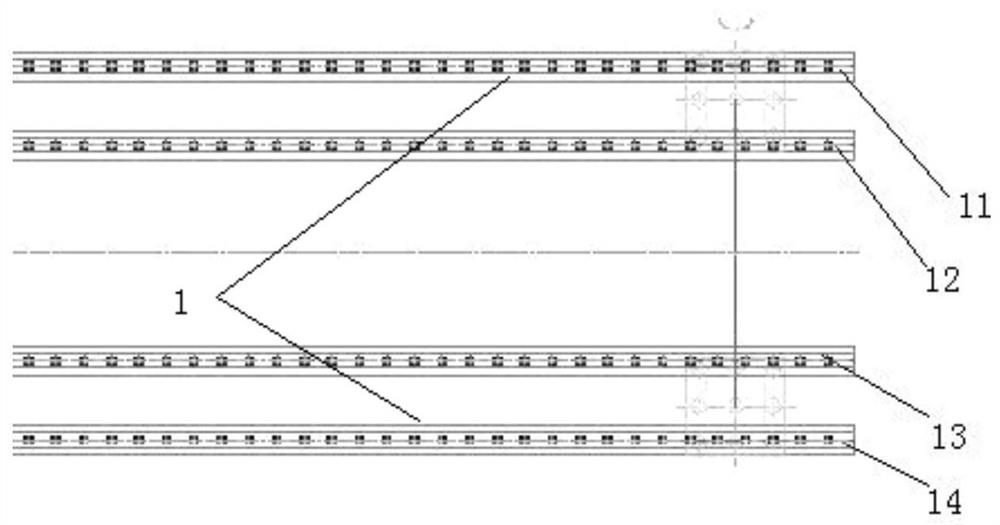

[0040] Step 1: Install the sliding structure: set four strip foundations 1 with the same length and parallel to each other on the ground. 1 In order respectively the first strip foundation 11, the second strip foundation 12, the third strip foundation 13 and the fourth strip foundation 14, the transverse central axis of the first strip foundation 11 and the second strip foundation 12 The distance between the transverse central axes is 8000mm, the distance between the transverse central axis of the second strip foundation 12 and the transverse central axis of the third strip foundation 13 is 21888mm; the embedded parts are installed on the strip foundation 1, and the A number of sliding rails 2 are laid on the embedded parts, and steel plates are laid on the sliding rails 2 to form a sliding surface 3. The number of the sliding rails 2 is 4. When the lifting load is 2100 tons, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap