Water pressure cracking in-situ stress measurement wireless automatic well logging system

A technology of stress measurement and water pressure, which is applied in the fields of mechanical seal structure, automatic measurement, ultra-low power consumption electronic technology, and wireless bluetooth, can solve problems affecting work efficiency, inaccurate measurement, damage, etc. The effect of accurate pressure measurement and improved measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below by embodiment the present invention will be further described, and its purpose is only to understand research content of the present invention better but not limit protection scope of the present invention.

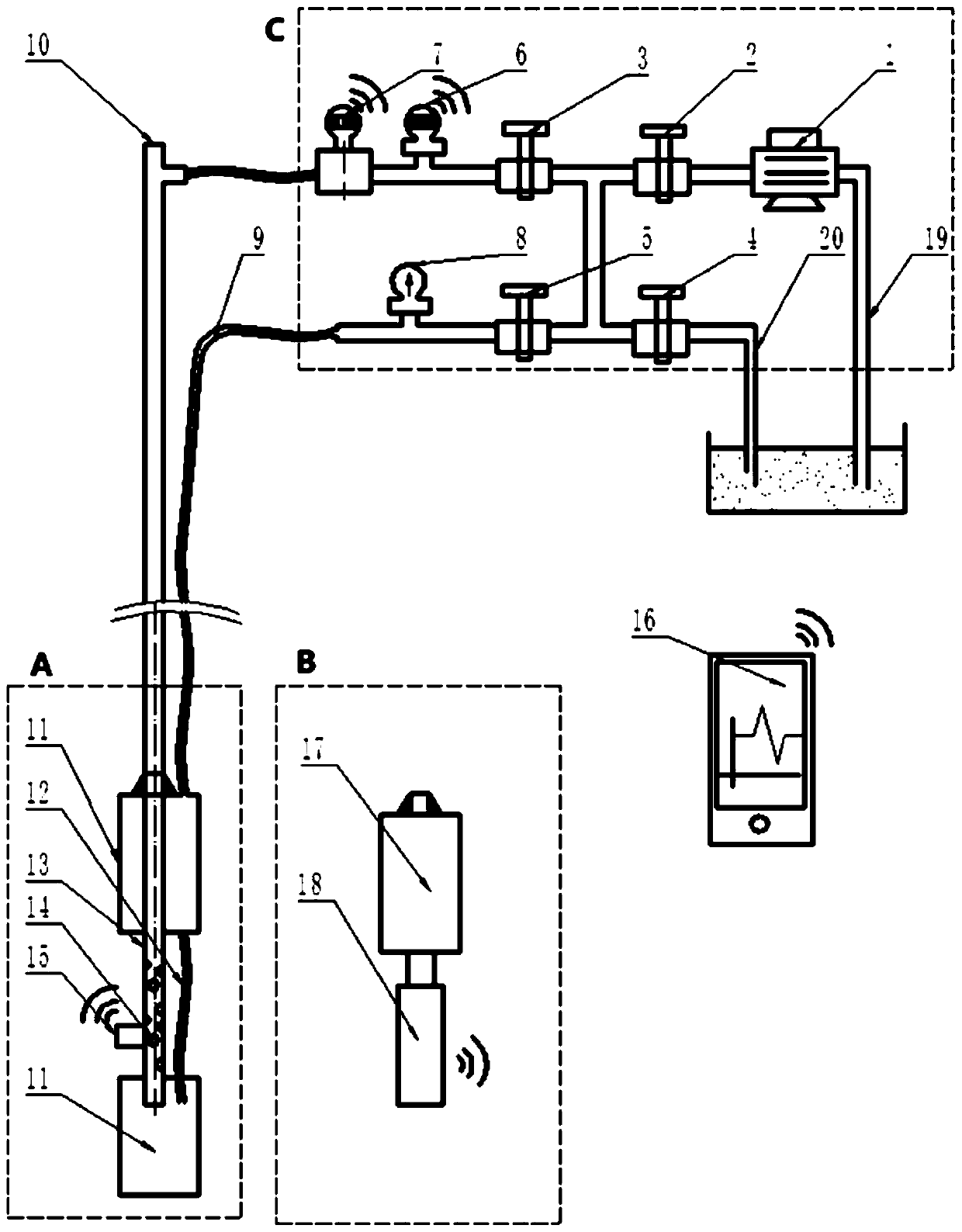

[0023] Such as figure 1 As shown, a wireless automatic logging system for hydraulic fracturing in-situ stress measurement according to an embodiment of the present invention includes: a stress measurement probe A, used for drilling fracturing, and recording the drilling fracturing section during fracturing the hydraulic pressure; the directional probe B is used to orient the fracture of the rock fracture in the borehole; the pressure flow sensing and control unit C is used to generate and send to the stress measurement probe A or to the directional probe B Provide water pressure; drill pipe (water source and pressure channel) 10 is arranged between the pressure flow sensing and control unit C and the stress measurement probe A or directional probe B, and is u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap