Die tipping vibrating table and tilting vibration method

A vibrating table and mold technology, applied in the field of concrete production lines, can solve the problems of poor product quality and uneven concrete distribution, and achieve the effects of improving product quality, compactness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

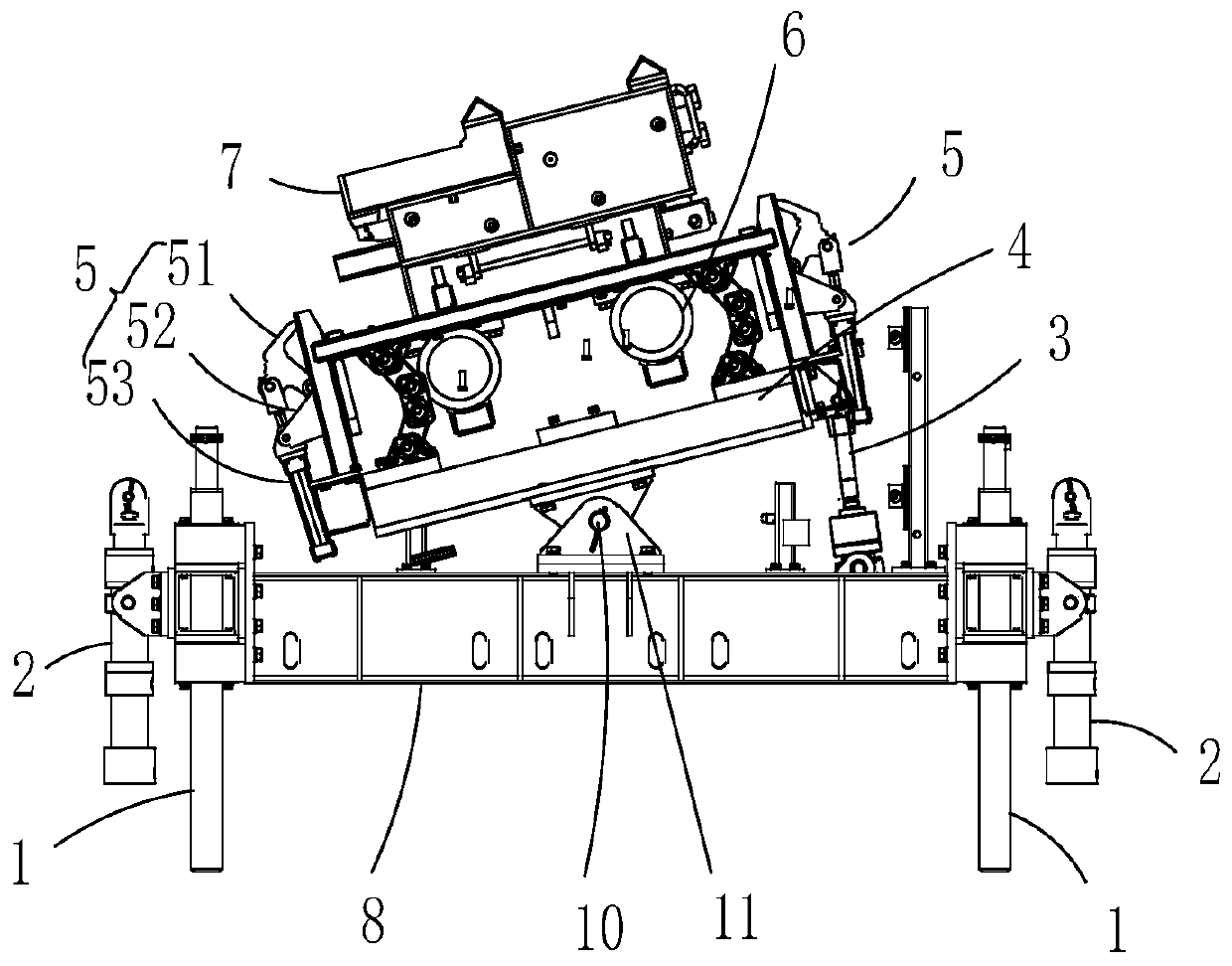

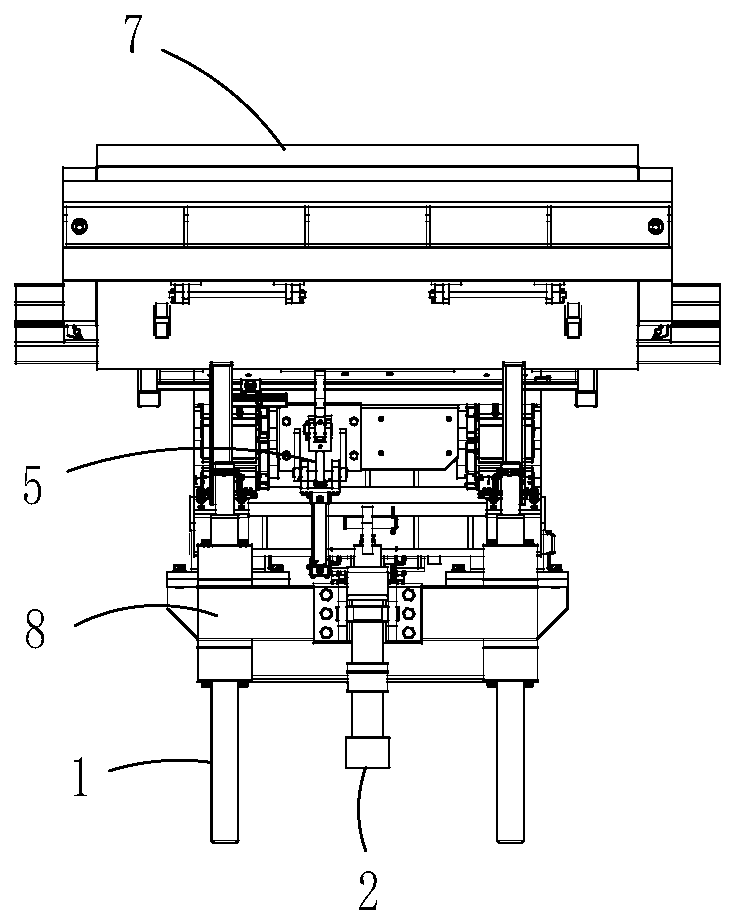

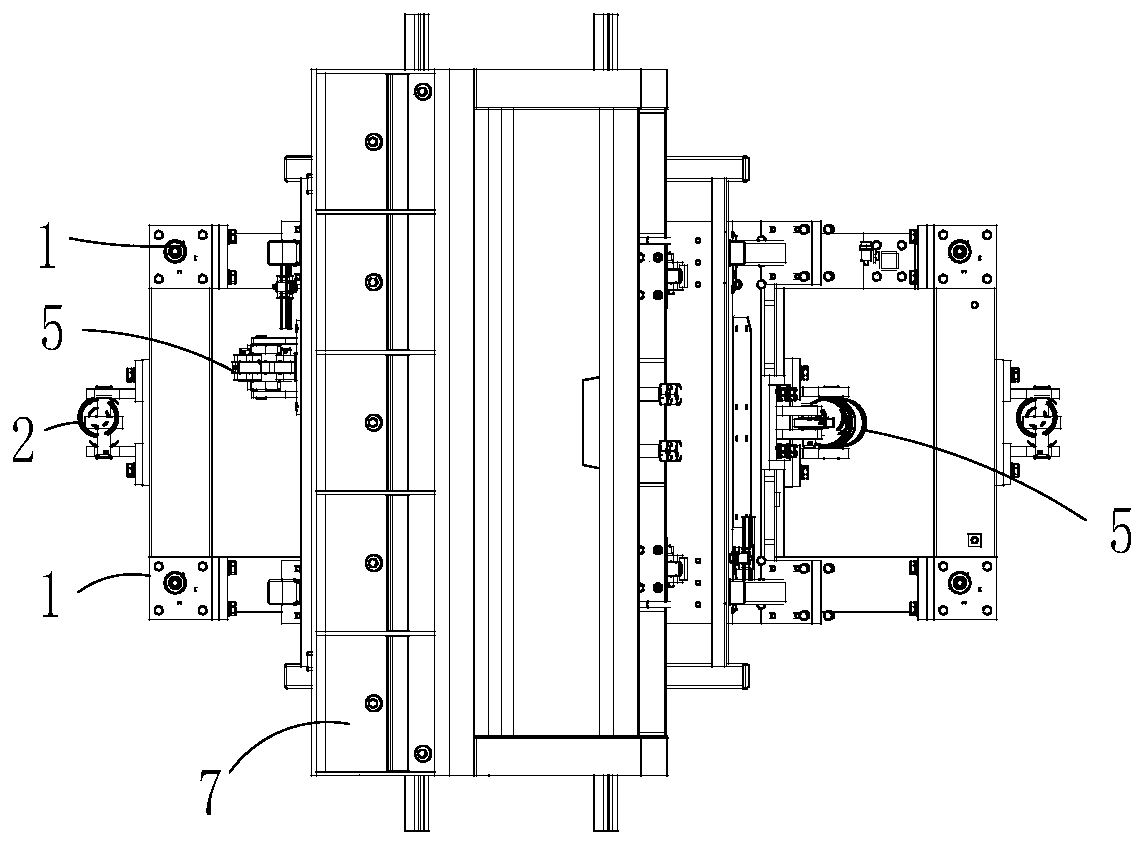

[0054] Please refer to Figure 1 to Figure 5 Now the mold tilting vibration table provided by the present invention will be described. The mold tilting vibrating table includes a vibrating base 8, a turning table body 4, a telescopic drive mechanism 3, a lifting conveying device 9 and at least two clamping and positioning devices 5; the turning table body 4 is connected to the vibrating table 8 by means of a pin 10 The hinge is used to provide vibration to the mold; one end of the telescopic drive mechanism 3 is hinged to the vibrating base 8 and the other end is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap