New energy automobile tire abrasion resistance detection device

A new energy vehicle and detection device technology, applied in the direction of automobile tire testing, measuring device, testing wear resistance, etc., can solve the problems of imperfect structure, inconvenient tire wear, and inconvenience to detect the rapid fixation of tires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

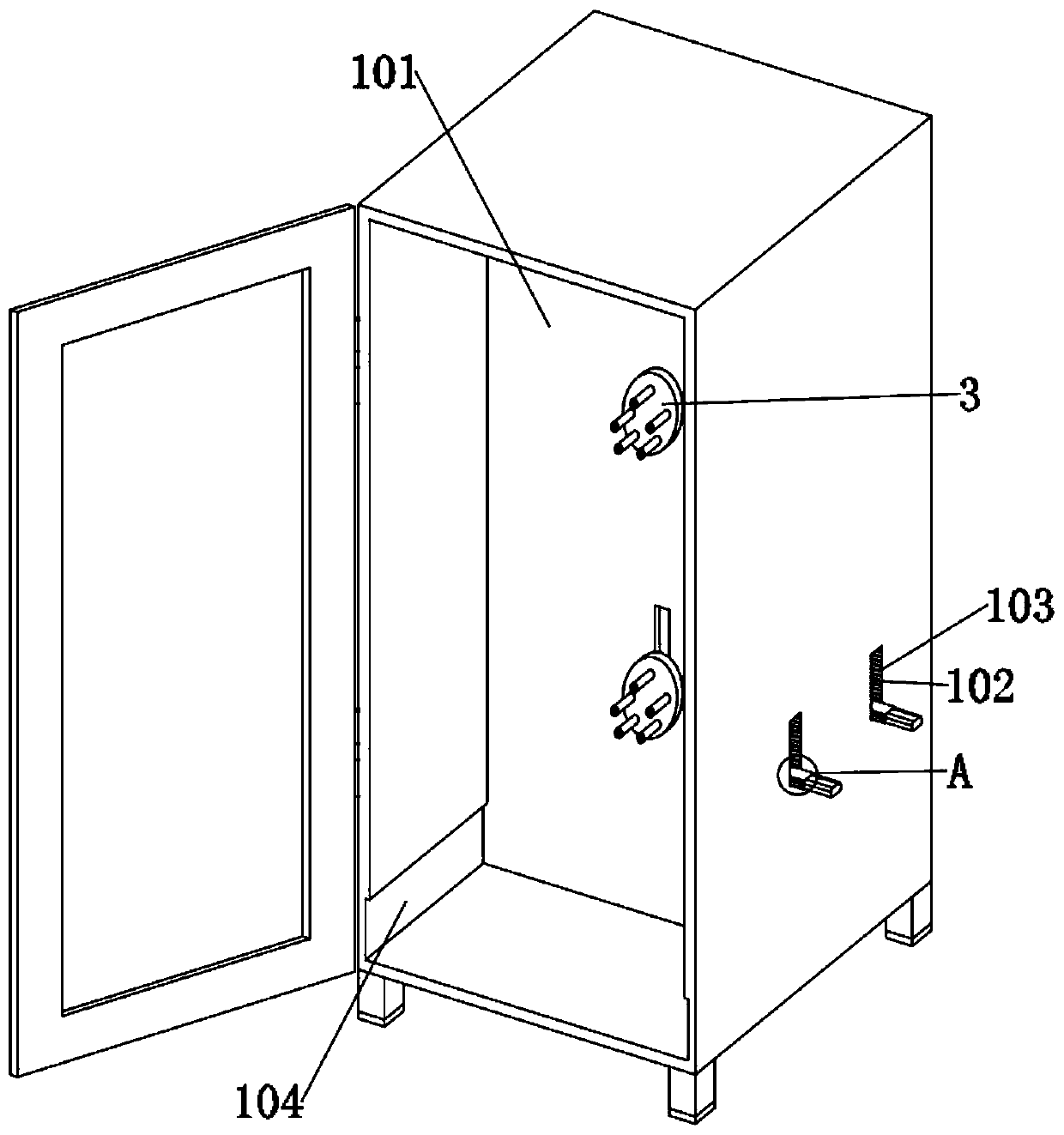

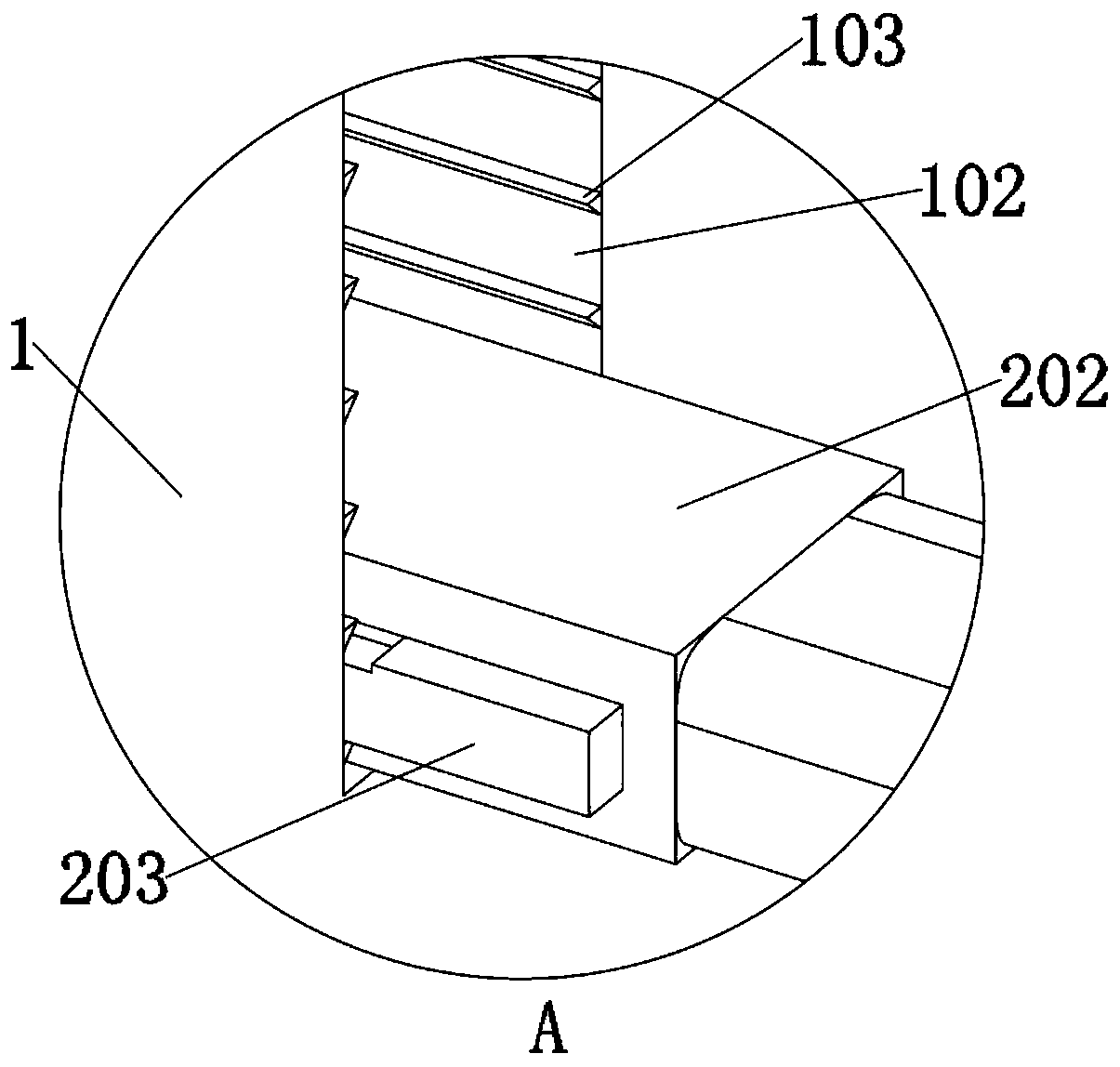

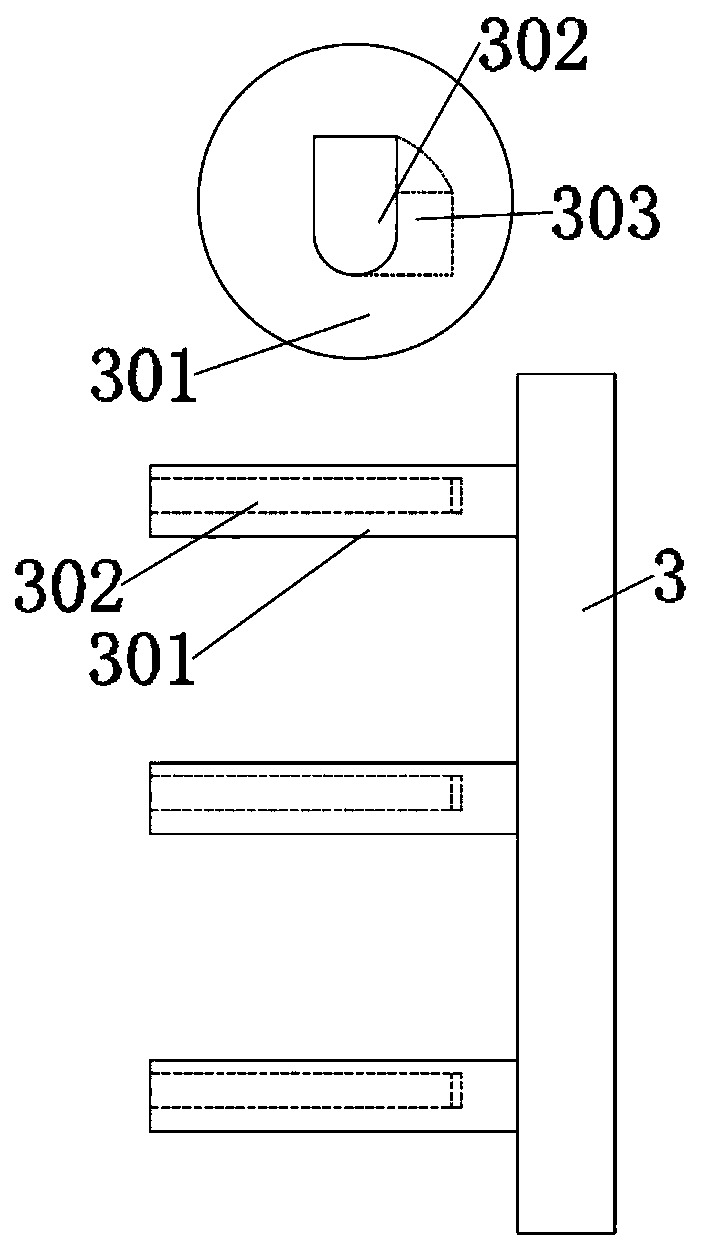

[0031] as attached figure 1 To attach Figure 7 Shown:

[0032] The invention provides a new energy automobile tire wear resistance detection device, which includes a main body 1, a partition 101, a side groove 102, a clip 103, a bottom groove 104, a collection bin 105, a pulling groove 106, a motor 2, a connecting piece 201, Connecting rod 202, block 203, connecting plate 3, inserting rod 301, slot 302, inner groove 303, fixed plate 4, rotating part 401, rotating rod 402, clamping plate 403, rotating part 5, connecting hole 501 and contact parts 502; the main body 1 is a rectangular internal hollow structure, the front end of the main body 1 is equipped with a sealing plate through a connecting shaft, moreover, the bottom corner of the main body 1 is provided with supports, and the inner middle of the main body 1 is provided with partitions Plate 101, and the middle position of the front end of the collection bin 105 is provided with a draw groove 106; the motor 2 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com