Backlight module and manufacturing method thereof

A backlight module and lithography technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of yellowing of the lamp board, low backlight display effect, abrasion and scratches of the packaging glue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments that the present application can be used to implement. The directional terms mentioned in this application, such as [top], [bottom], [front], [back], [left], [right], [inside], [outside], [side], etc., are for reference only The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the application, but not to limit the application. In the figures, structurally similar elements are denoted by the same reference numerals.

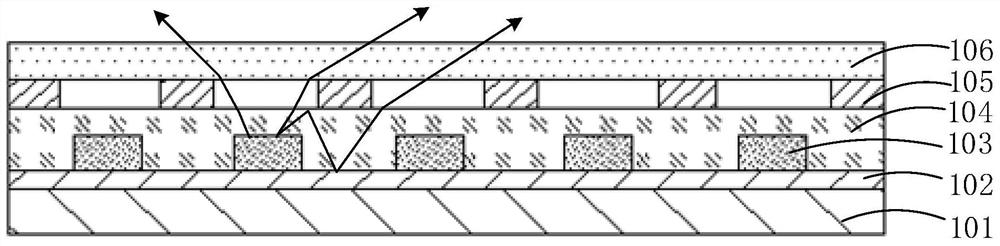

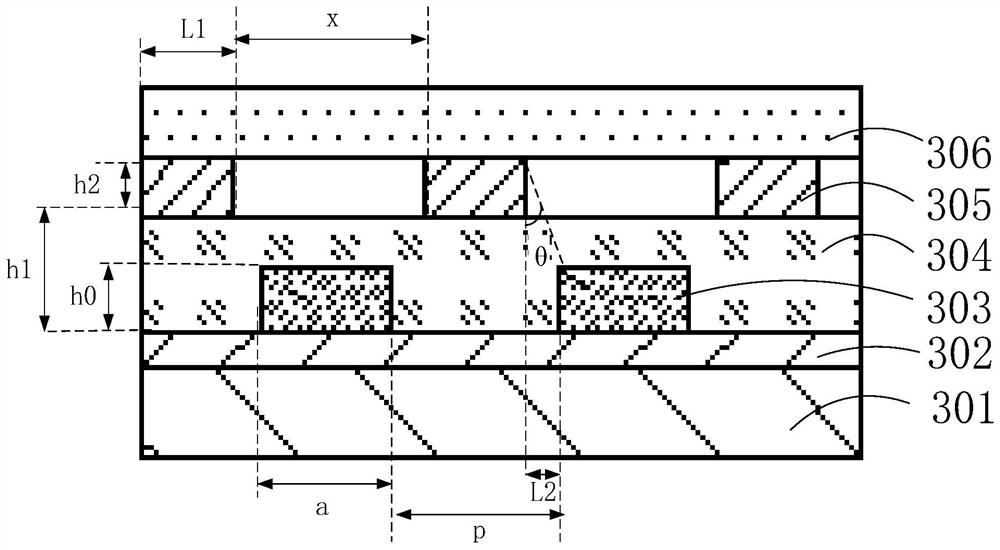

[0039] Such as figure 1 As shown, this figure is the first cross-sectional structure diagram of the backlight module provided by the embodiment of the present application. figure 1 Among them, the present application provides a backlight module, and the backlight module includes: a printed circuit board 101 and a paint layer 102 disposed on the printed circuit board 101;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| beam angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com