Engineering mixed structural body assembling mold

A structure and engineering technology, which is applied in the field of assembly molds for engineering mixed structures, can solve the problems of frame body cord wear, difficult assembly quality assurance, low efficiency, etc., to achieve the effect of convenient installation and positioning, and improve assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

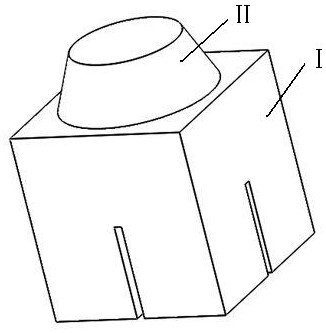

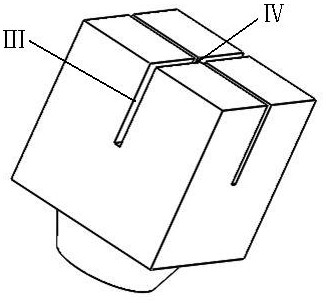

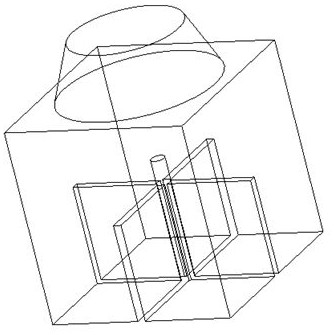

[0024] Refer to attached Figure 4 , 5 , 6, 7, during assembly and use, according to the shape of the assembly frame, select a main mold body and multiple auxiliary mold bodies that can be spliced with the main mold body. In this embodiment, the assembly mold consists of a main mold body 1 and an isosceles The trapezoidal first secondary mold body 2, the second secondary mold body 3, the third secondary mold body 4, and the fourth secondary mold body 5 are spliced together. The main mold body 1 is a rectangular plate with a fixed thickness; on the main mold body Circular holes 6 regularly arranged in rows are vertically opened. The number and arrangement order of the circular holes correspond to the installation position of the assembled hybrid structure. A fixed groove with a rectangular cross section is horizontally opened on the upper part of the circular holes arranged in rows regularly. 7. The fixed groove runs through the plate of the main mold body horizontally, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com