Fuel-operated vehicle heating device and method for operating a fuel-operated vehicle heating device

A technology for vehicle heaters and fuels, applied in the direction of combustion methods, fuel supply adjustment, vehicle components, etc., to achieve the effects of improving exhaust emission values, improving comfort, and improving odor interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

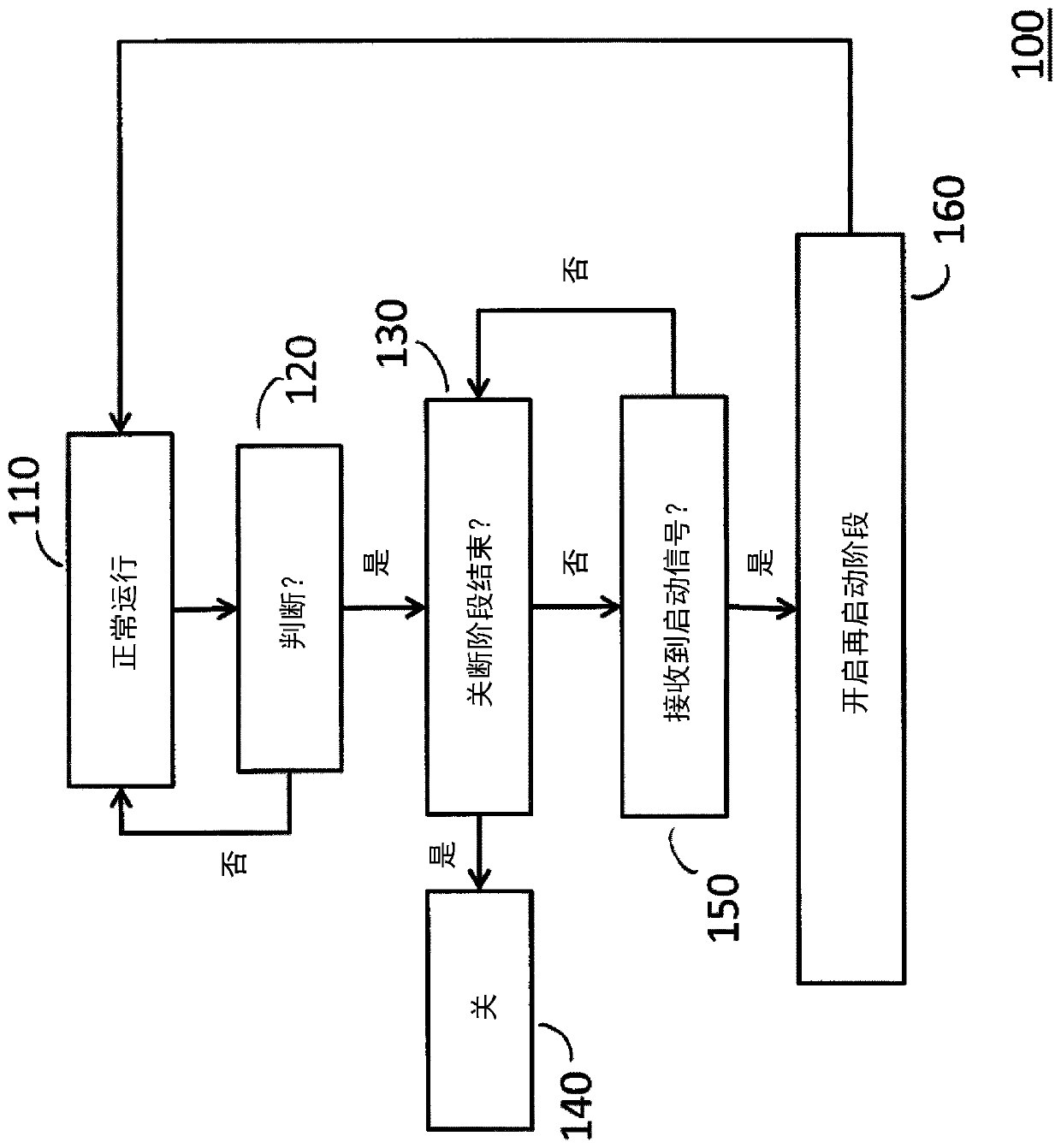

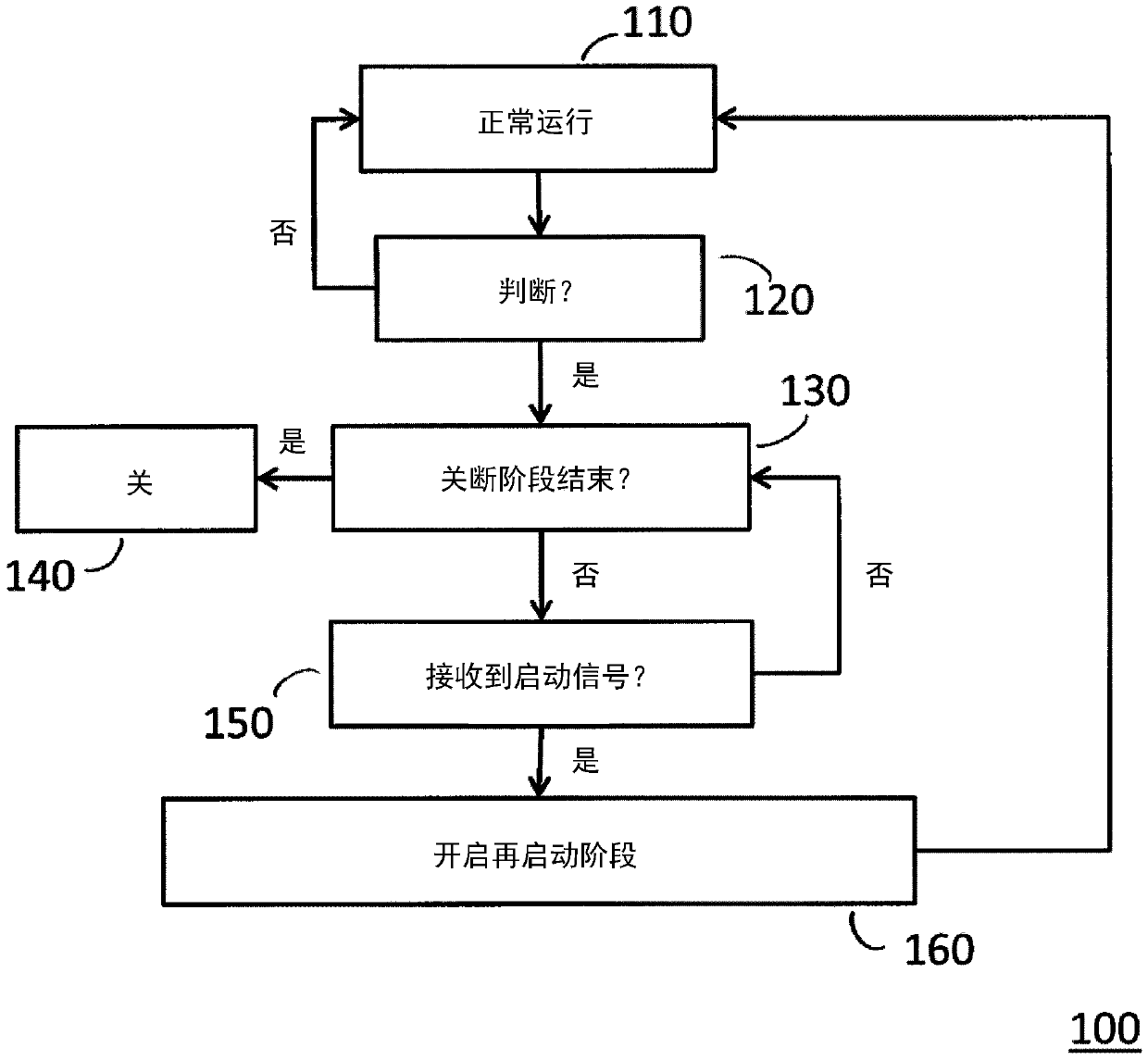

[0015] figure 1 A flow chart of a method 100 for operating a fuel-operated vehicle heater is shown. The illustrated method 100 starts, for example, in normal operation 110 . Proceeding from this, it is checked in step 120 whether a switch-off signal has been received. This can be done, for example, in a controller of a fuel-operated vehicle heater. If no shutdown signal is received, "No" in step 120, normal operation remains. Conversely, if a switch-off signal is received, step 120 "Yes", the switch-off phase is started, and in a subsequent step 130 it is checked whether the switch-off phase has ended. The shutdown phase can also be controlled by the controller. During the shut-off phase, the residual fuel still present in the burner of the fuel-operated vehicle heater, ie to be disposed of, can be burnt in a controlled manner. If the shutdown phase is over, step 130 is YES, then the fuel-operated vehicle heater is switched off in step 140 . Conversely, if the shutdown p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com