Method for changing a distribution between port fuel injection and direct injection in an internal combustion engine

A technology of an internal combustion engine and an intake pipe, applied in the field of computer programs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

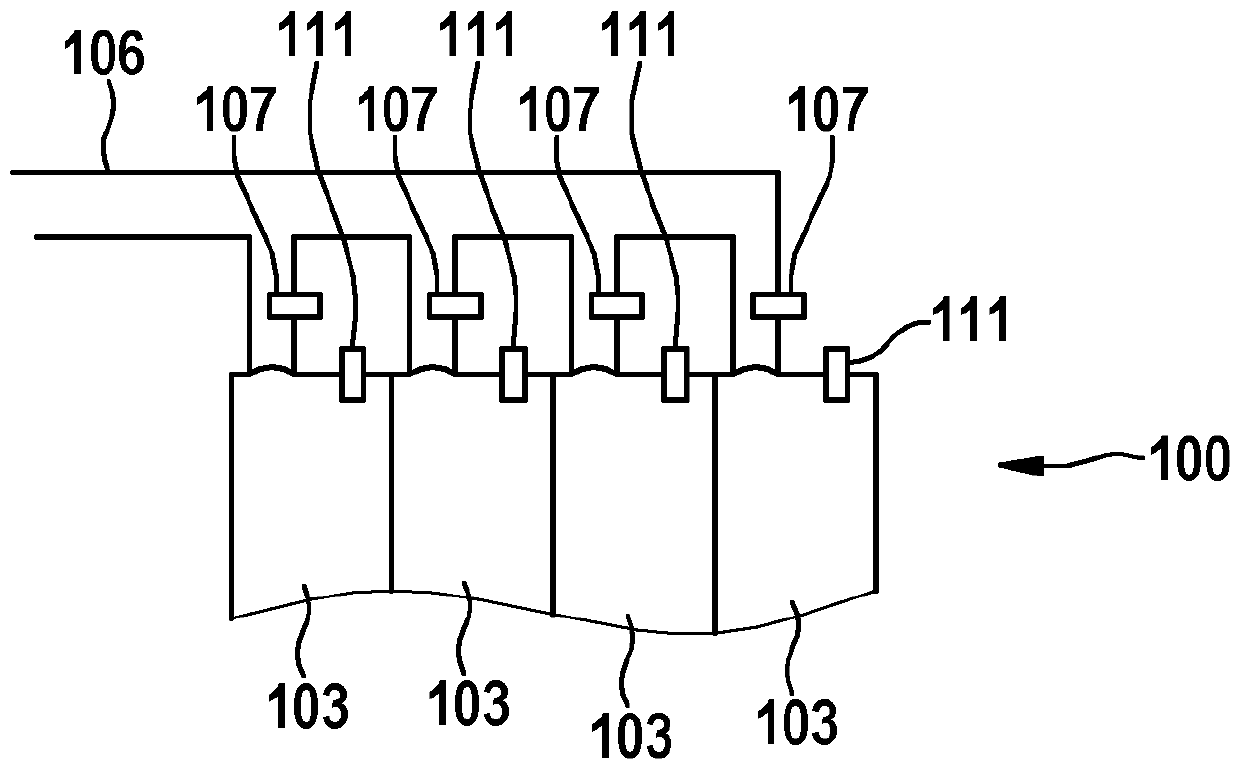

[0021] exist Figure 1a An internal combustion engine 100 is shown schematically and in simplified form, which can be used for the method according to the invention. The internal combustion engine 100 exemplarily has four combustion chambers 103 and an intake duct 106 connected to each of the combustion chambers 103 .

[0022] The intake manifold 106 here has, for each combustion chamber 103 , a fuel injector 107 which is arranged in the respective section of the intake manifold shortly before the combustion chambers. The fuel injector 107 is thus used for intake manifold injection. Furthermore, each combustion chamber 103 has a fuel injector 111 for direct injection.

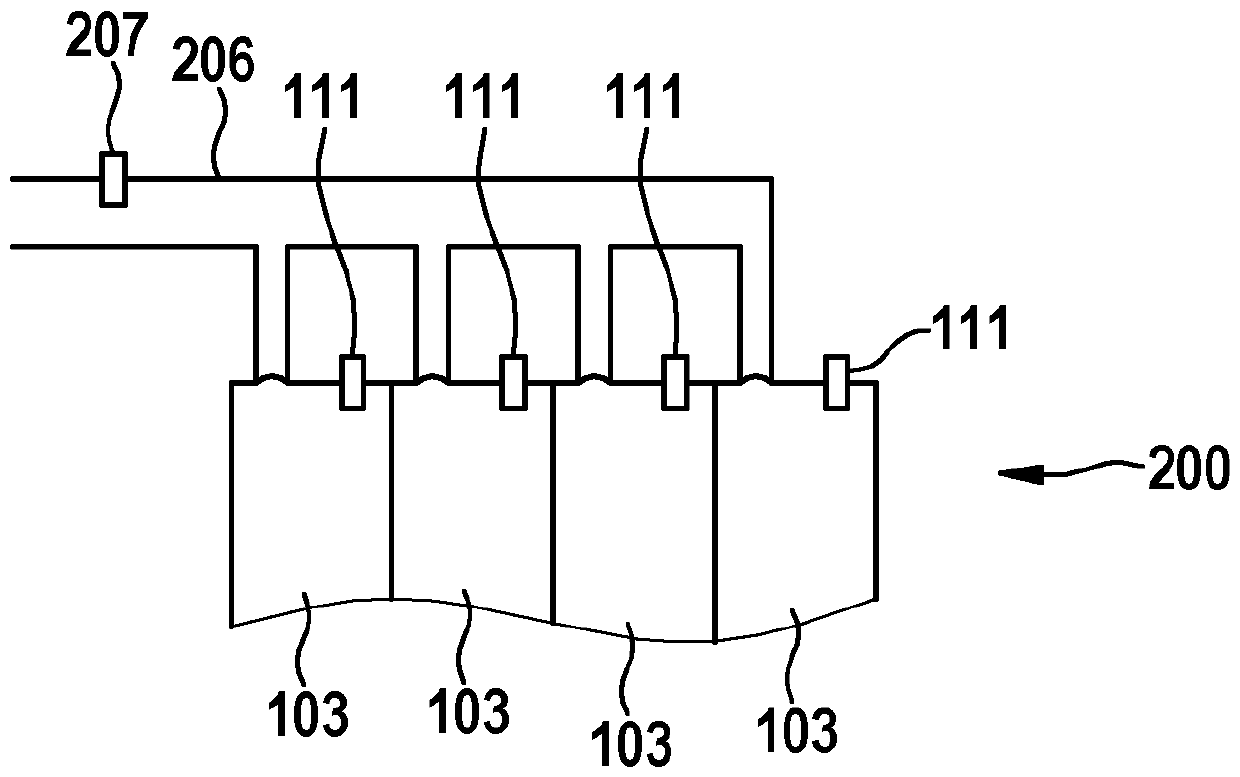

[0023] exist Figure 1b A further internal combustion engine 200 is shown schematically and in simplified form, which can be used for the method according to the invention. The internal combustion engine 100 exemplarily has four combustion chambers 103 and an intake duct 206 connected to each of the combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com