Collodion mop of cleaning tool

A technology for cleaning tools and cotton mops, which is applied to cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problem of twisting caused by cleaning and placing the cotton mop, difficult folding and squeezing of the cotton head assembly, and the cotton head Water can not be squeezed out and other problems, to achieve the effect of reducing height, good squeezing effect, reducing packaging cost and transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] Detailed Description of the Invention: The present invention will be further described by way of embodiments with reference to the accompanying drawings.

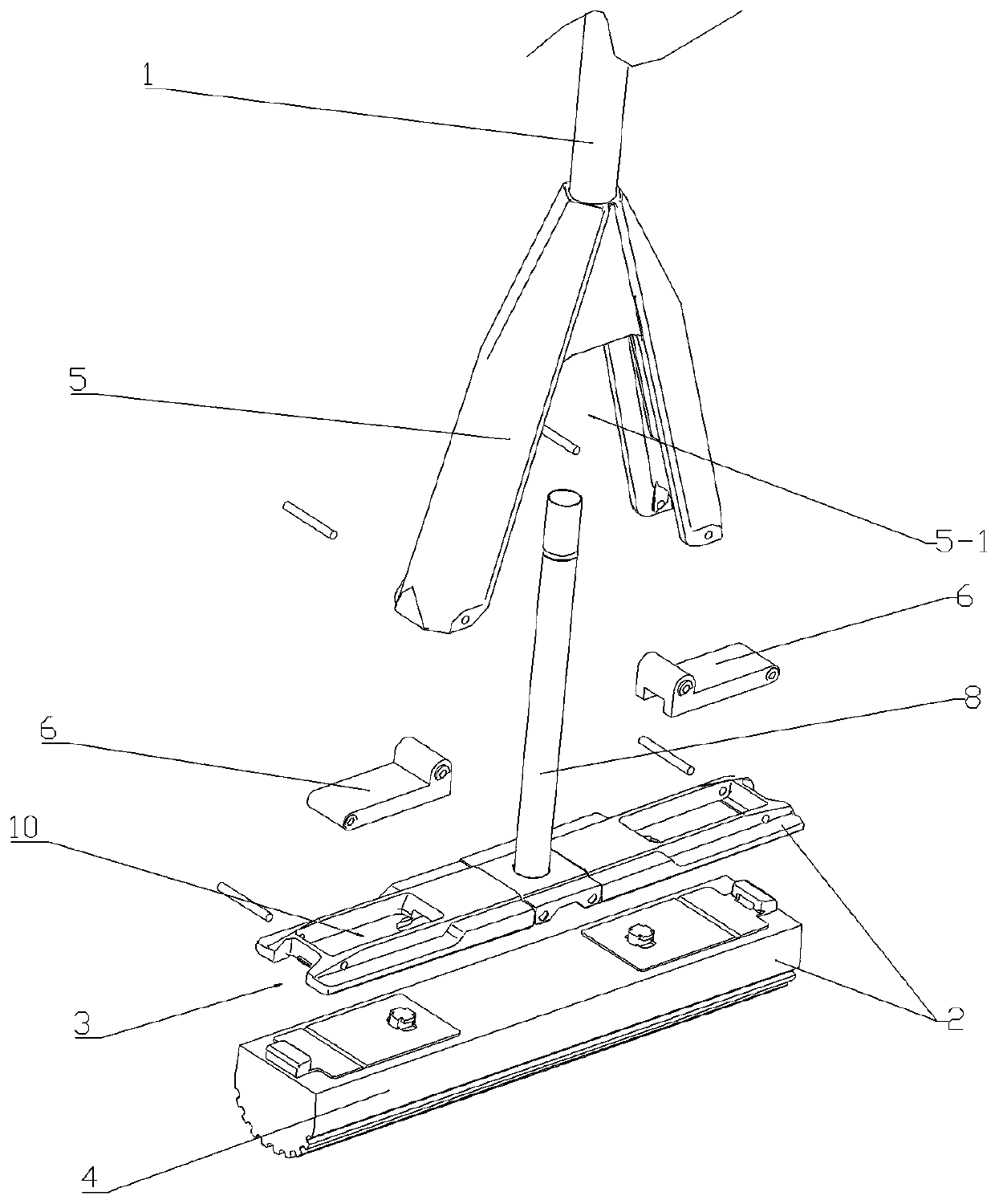

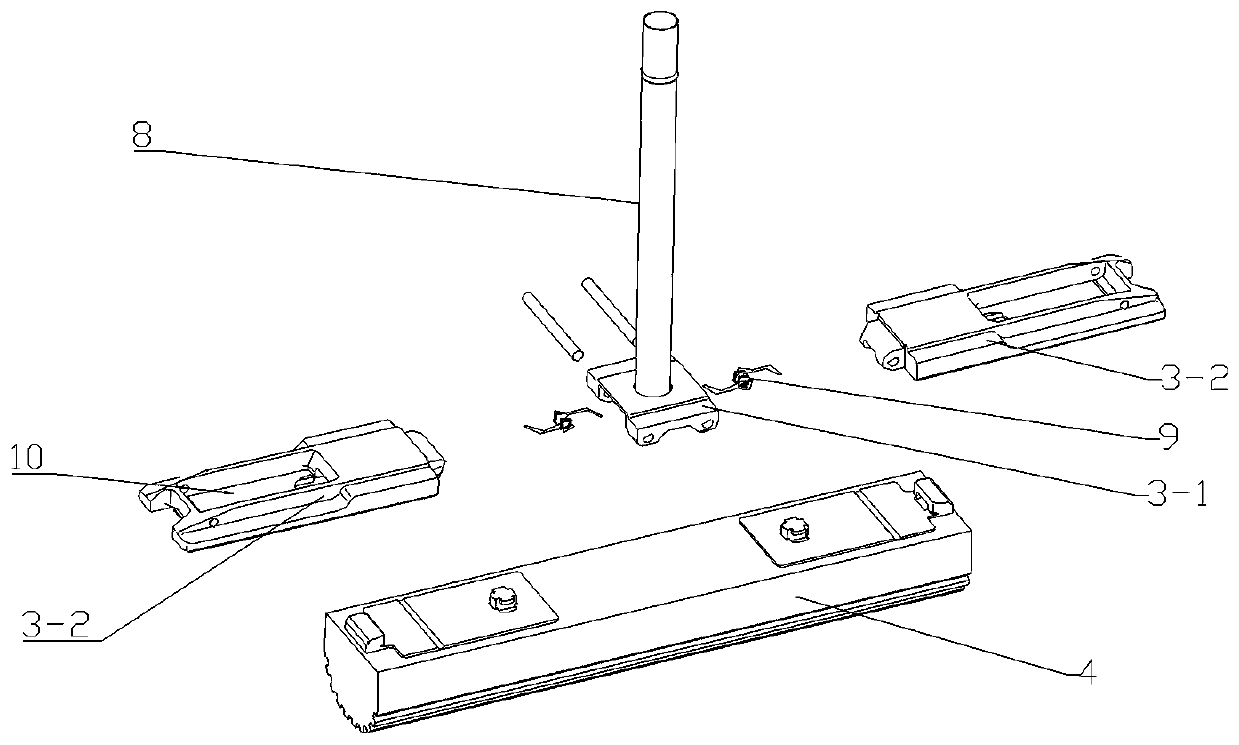

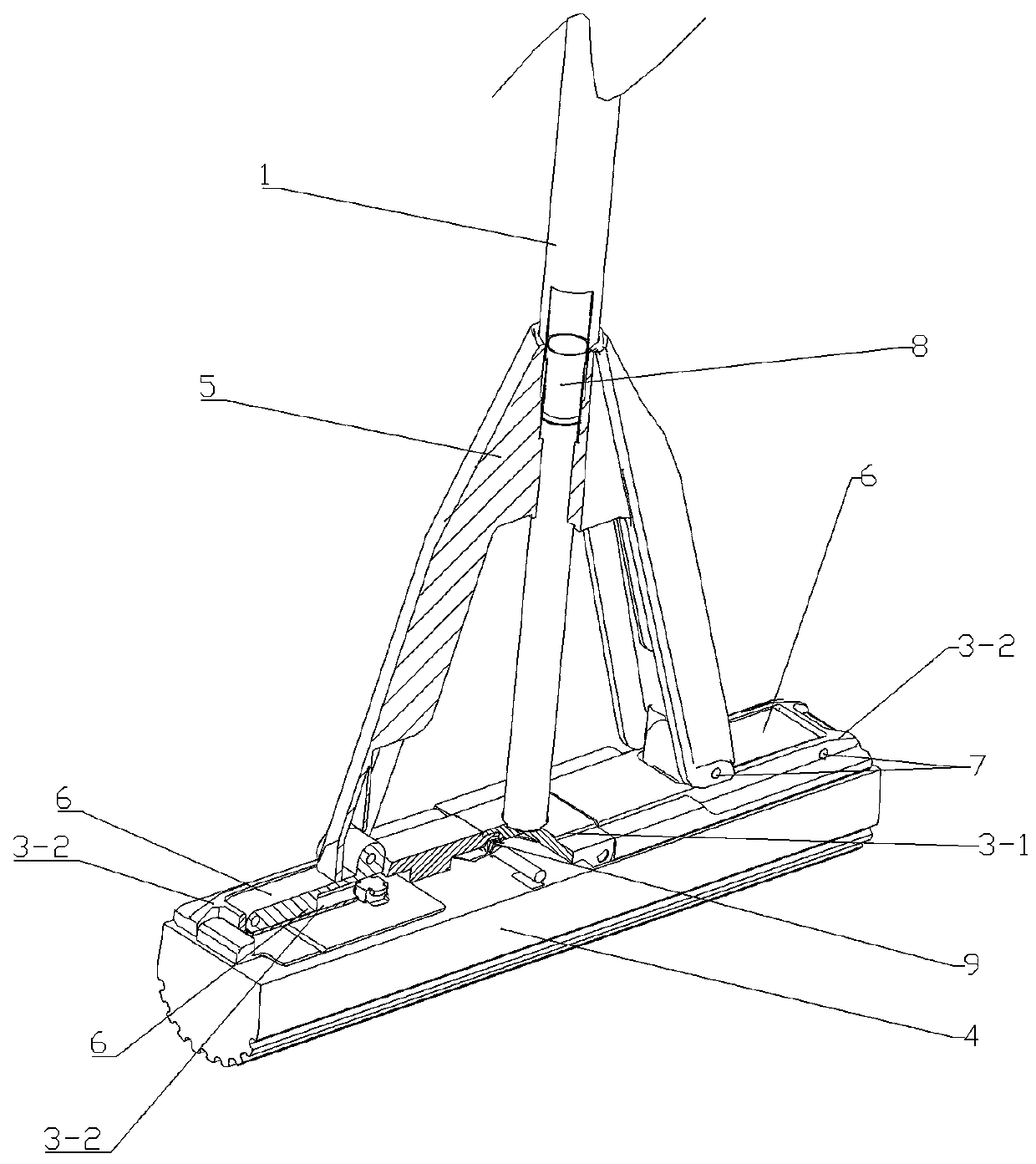

[0025] refer to Figure 1 to Figure 5 Shown: a collodion mop of a cleaning tool of the present invention, comprising a mop rod 1, an extruding device and a collodion head assembly 2; Cotton head 4; the extruding plate includes a middle plate 3-1, side plates 3-2 are respectively hinged on both sides of the middle plate, and the side plates can be folded relative to the middle plate so that the extruding plate 3 can drive the collodion head for 4 folds Receive; described extruding device comprises extruding frame 5, extruding frame one end is connected with mop rod 1, extruding frame other end is provided with extruding port 5-1, and described collodion head assembly 2 is located at extruding port 5-1 below, the extrusion port can form extrusion for the collodion head assembly 2 that moves and folds relative to it; i...

example 2

[0032] In the embodiment, there are many ways to connect the extruded plate and the collodion head, such as Example 1: Patent No.: CN201520286894.5 The upper end surface of the collodion head is bonded and fixed to the adhesion plate, and on the adhesion plate A lock head is provided, and a lock hole corresponding to the lock head is provided on the connecting plate. The adhesive plate is connected to the connecting plate through the cooperation between the lock head and the lock hole. The connection method between the collodion head and the extruded plate in this patent; example 2: Patent No.: CN201621389590.2 A clamping device for replacing the collodion mop head; example 3: the upper end surface of the collodion head and the adhesion plate Adhesive and fixed, an elastic hook is provided around the adhesive plate, and a hook position is provided on the extrusion plate to cooperate with the hook. buckle connection.

[0033]In the embodiment, the cleaning tool also includes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com