Filter pressing equipment for producing nano calcium carbonate

A nano-calcium carbonate and equipment technology, applied in the direction of filtration circuit, filtration separation, mobile filter element filter, etc., can solve problems such as laborious and troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

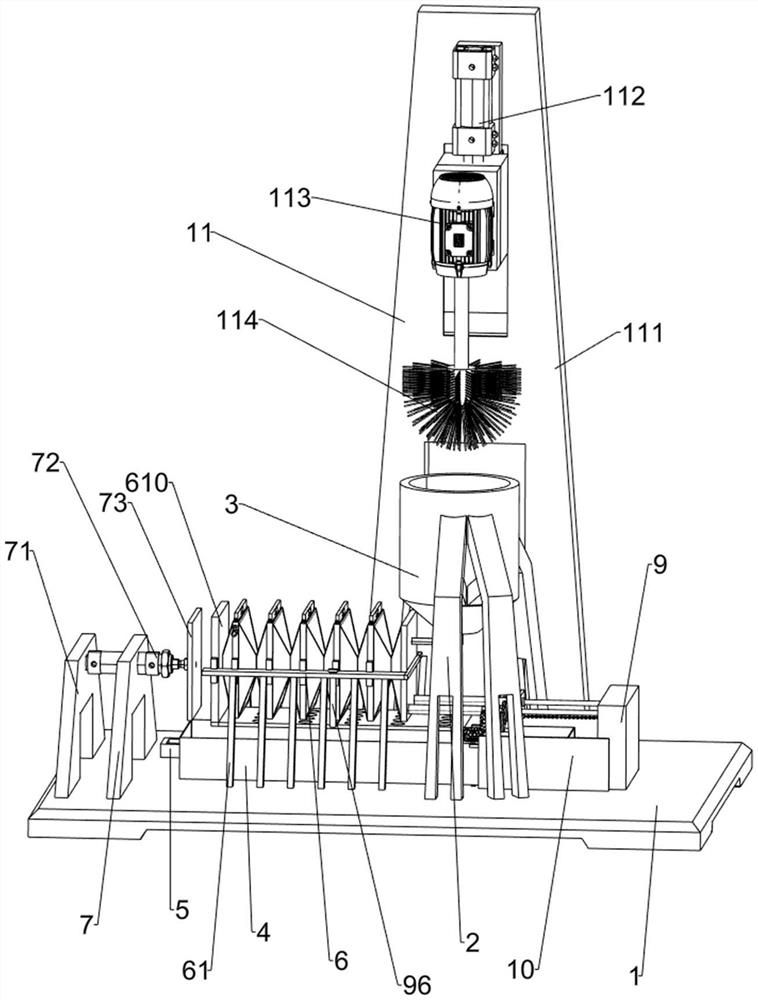

[0026] A kind of pressure filter equipment for the production of nanometer calcium carbonate, such as Figure 1-Figure 4 As shown, it includes a base 1, a first fixing bracket 2, an inlet barrel 3, a liquid storage tank 4, a handle 5, a filter mechanism 6 and an extruding device 7, and four first fixing brackets are fixed in the middle of the top right side of the base 1. Bracket 2, feed cylinder 3 is fixedly connected between the inner ends of the four first fixed brackets 2, a liquid storage tank 4 is placed in the middle of the top of the base 1, a handle 5 is fixedly connected to the middle part of the outer left side of the liquid storage tank 4, and the base 1 A filter mechanism 6 is provided on the top, and the filter mechanism 6 is connected and communicated with the discharge end of the feeding cylinder 3 . The left side of the top of the base 1 is provided with an extruding device 7 , and the extruding device 7 cooperates with the filter mechanism 6 .

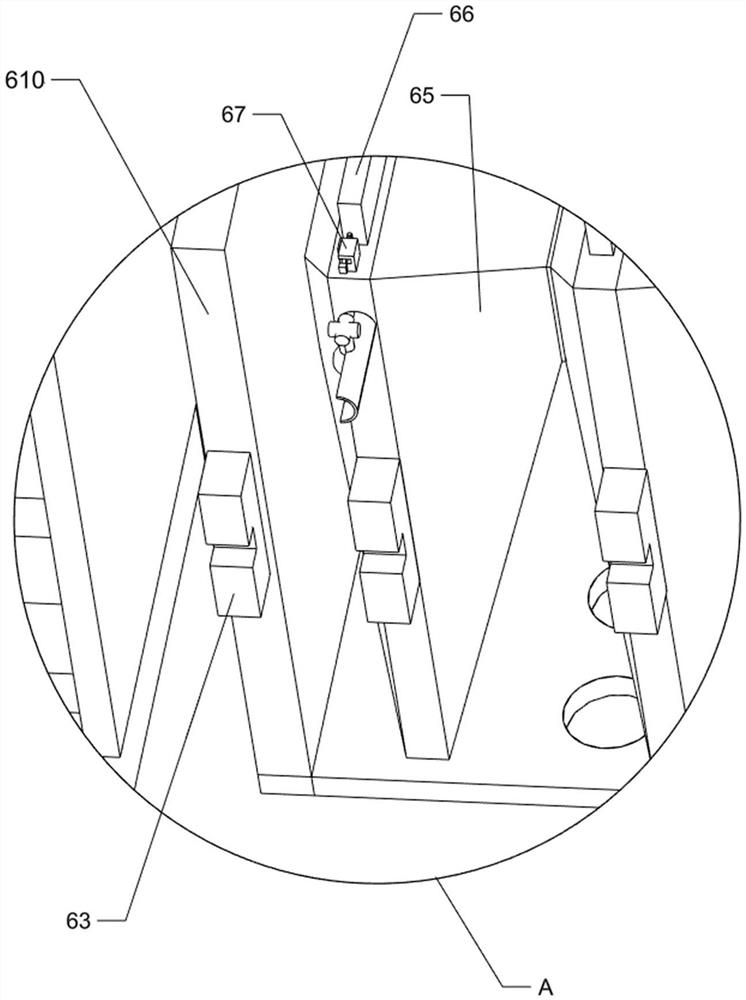

[0027] The fi...

Embodiment 2

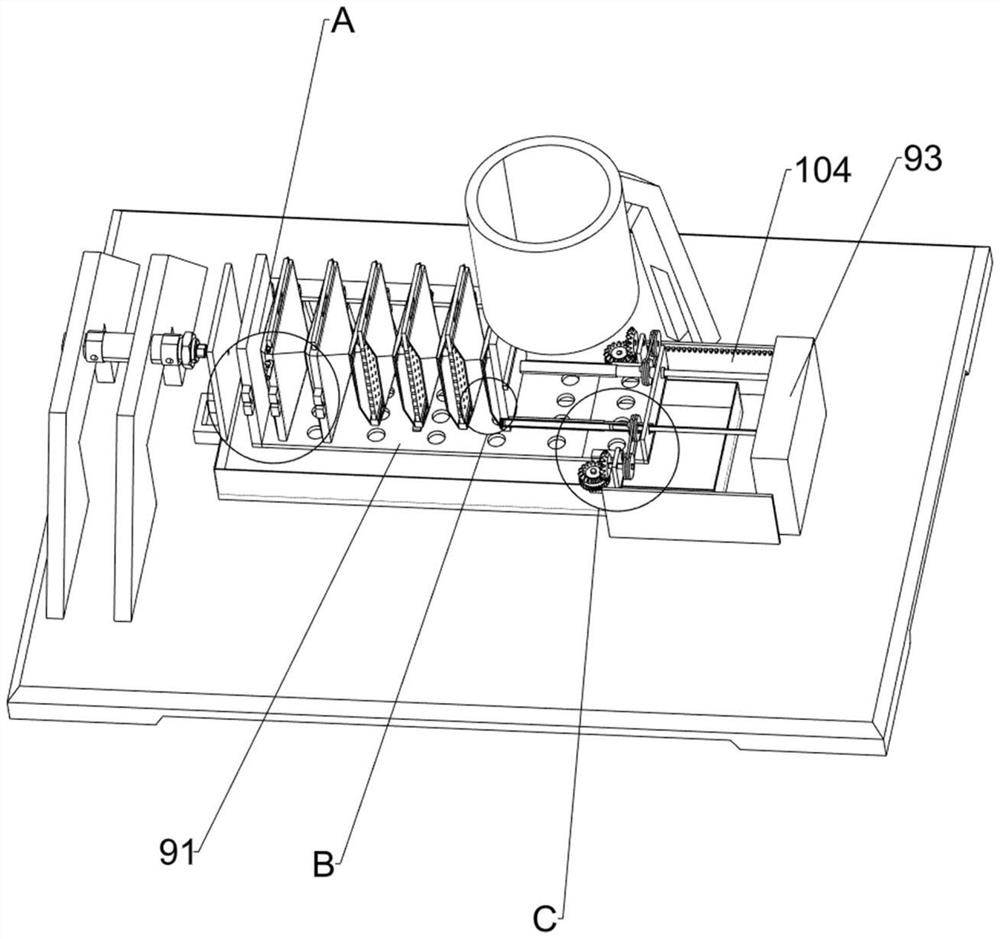

[0033] On the basis of Example 1, such as figure 1 , figure 2 with Figure 5 As shown, a cleaning mechanism 9 is also included, and the cleaning mechanism 9 includes a filter plate 91, a cleaning pipe 92, a fixed block 93, a fixed rod 94, a cleaning block 95 and a scraper 96, and the front and rear sides of the first fixed plate 62 are right A scraper 96 is fixedly connected between the parts, and a sliding cleaning pipe 92 is provided in the discharge pipe 68, and a filter plate 91 is fixedly connected between the outer right of the cleaning pipe 92 on the front and rear sides, and the outer bottom of the scraper 96 is connected to The inner bottom of the filter plate 91 is in contact with each other, the left side of the inner bottom of the filter plate 91 is fixedly connected with the bottom of the extruding plate 73, the middle of the right side of the top of the base 1 is fixed with a fixed block 93, and the upper left side of the fixed block 93 is symmetrically fixed w...

Embodiment 3

[0038] On the basis of embodiment 1 and embodiment 2, such as figure 1 with Figure 6 As shown, a cleaning mechanism 11 is also included. The cleaning mechanism 11 includes a sixth fixed plate 111, a second cylinder 112, a motor 113 and a hair brush 114. Six fixed plates 111 are provided with a sliding motor 113 on the upper front side of the front side, and the output shaft end of the motor 113 is fixedly connected with a hairbrush 114. The second air cylinder 112, the end of the telescopic rod of the second air cylinder 112 is fixedly connected with the top of the motor 113 .

[0039] It also includes a ball valve 12. The ball valve 12 includes a fixed pipe 121, a notched ball 122 and a rotary rod 123. The upper part of the front side of the leftmost second fixed plate 64 is fixedly connected with the fixed pipe 121 and communicated with it. A rotary rod 123 is passed through, and a notched ball 122 is fixedly connected to the bottom end of the rotary rod 123, and the notc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com