a cleaning tool

A cleaning tool and cleaning department technology, applied in cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problems of complicated operation of peripheral pedals, insufficient squeezing, laborious squeezing, etc., to achieve optimized user experience and smooth squeezing , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

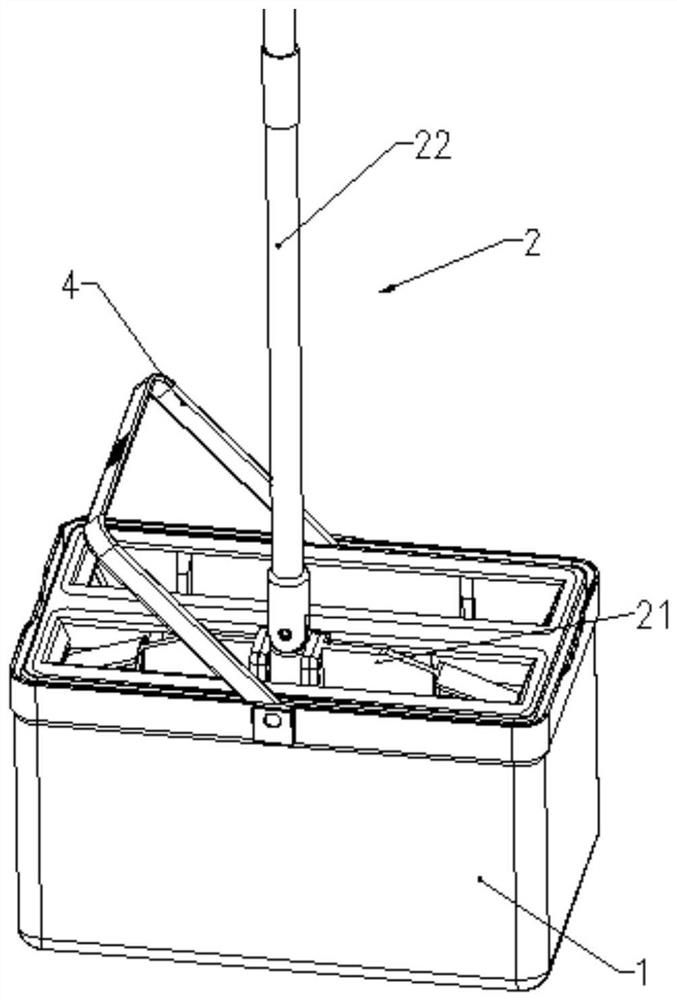

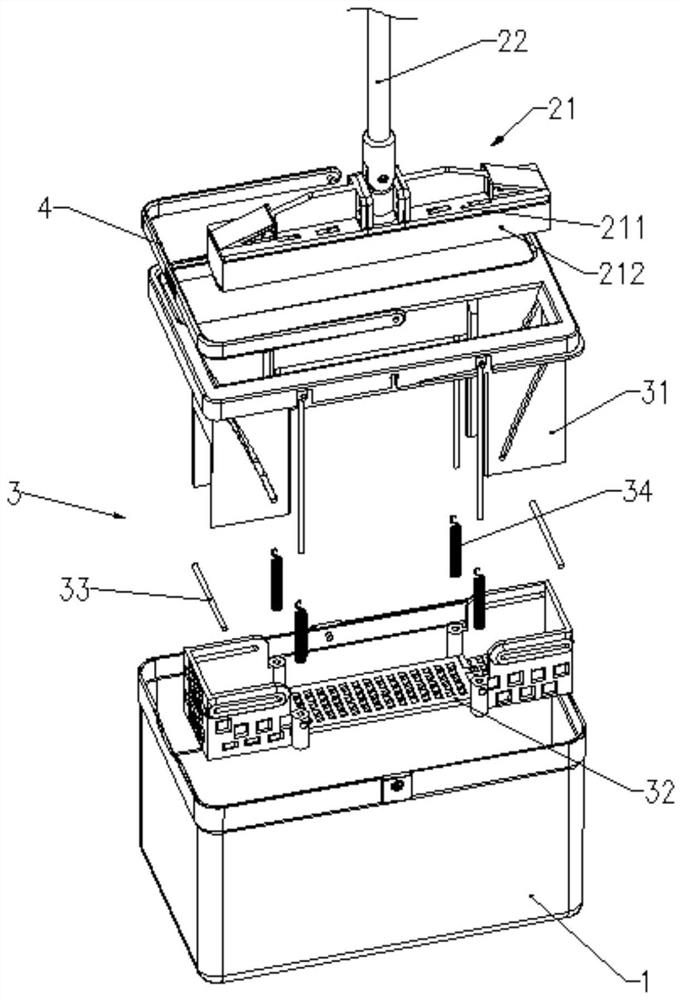

[0067] see Figures 1 to 8 As shown, this embodiment provides a cleaning tool that can squeeze a mop for dehydration, including a mop, the mop includes a mop bar 22 and a mop head 21 connected to the mop bar 22, the mop head 21 includes a mop plate 211, and a mop mounted on the mop The cleaning part 212 on the plate, the cleaning part 212 can be deformed after dehydration. The cleaning part 212 can be made of materials such as some materials that expand after absorbing water, shrink after dehydration, and can be deformed to different degrees, such as foamed cotton tips, colloidal cotton tips, sponge tips, or the like.

[0068] The mop board 211 is generally in the shape of a strip or plate, and has a longer length direction and a shorter width direction. The mop bar 22 and the mop head 21 are rotatably connected. The mop rod 22 can be rotated relative to the mop head 21 in a plane perpendicular to the length direction of the mop plate 211, and the rotation range is 0-180°. I...

Embodiment 2

[0099] The difference between this embodiment and Embodiment 1 is as follows: the guide portion 2111 is a guide groove 2111b formed at both ends of the mop plate 211, and the mop rod 22 is pressed down, and a pair of extruders 33 symmetrically arranged on both sides of the mop head 21 can be Sliding in the guide groove 2111b, during the sliding process, the collodion is squeezed to dehydrate.

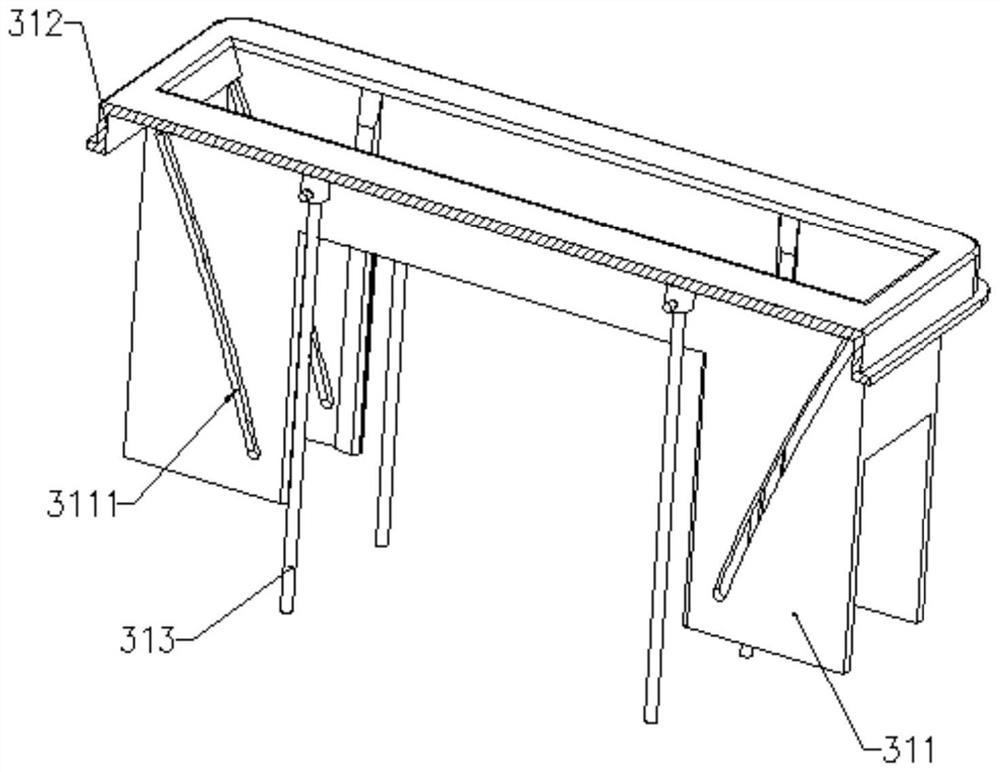

[0100] combine Figure 9 As shown, the upper end of the first movable slot 3111 is located inside the lower end. The length of the mop head 21 is greater than the length of the batt; the guide groove 2111b is located outside the length of the batt. The outer side of the guide groove 2111b is high and the inner side is low. In the initial state, the distance between the upper surface of the pressing plate 321 and the lower end of the pressing member 33 is not less than the distance between the lower end of the rubber cotton and the lower end of the guide groove 2111b, and the upper sur...

Embodiment 3

[0102] The difference between this embodiment and Embodiment 1 is as follows: the guide portion 2111 is a guide rail 2111c formed at both ends of the mop plate 211, and the mop rod 22 is pressed down. The guide rail 2111c slides, and in the process of sliding, the collodion is squeezed to dehydrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com