Patents

Literature

51results about How to "Squeeze water well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

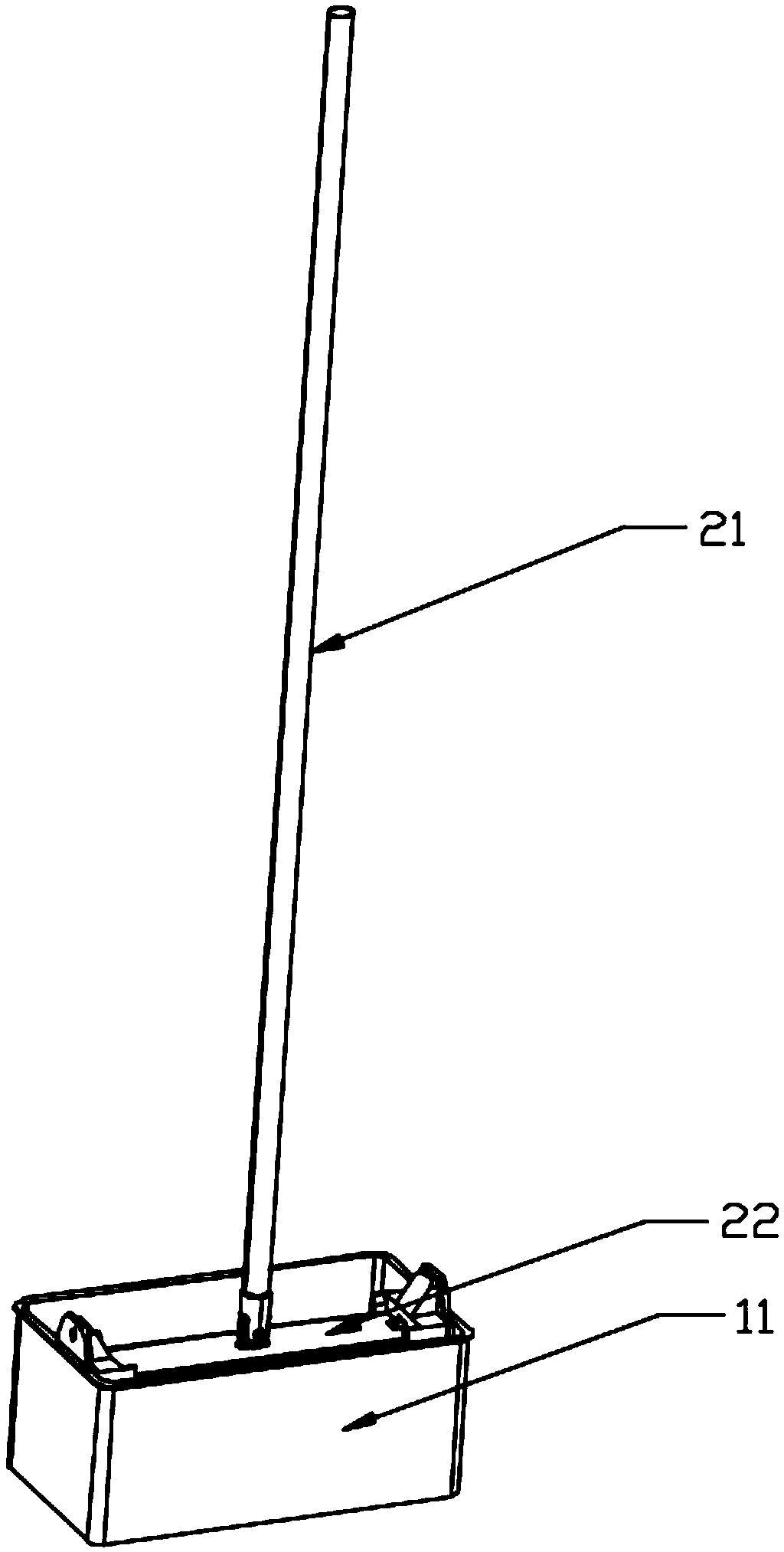

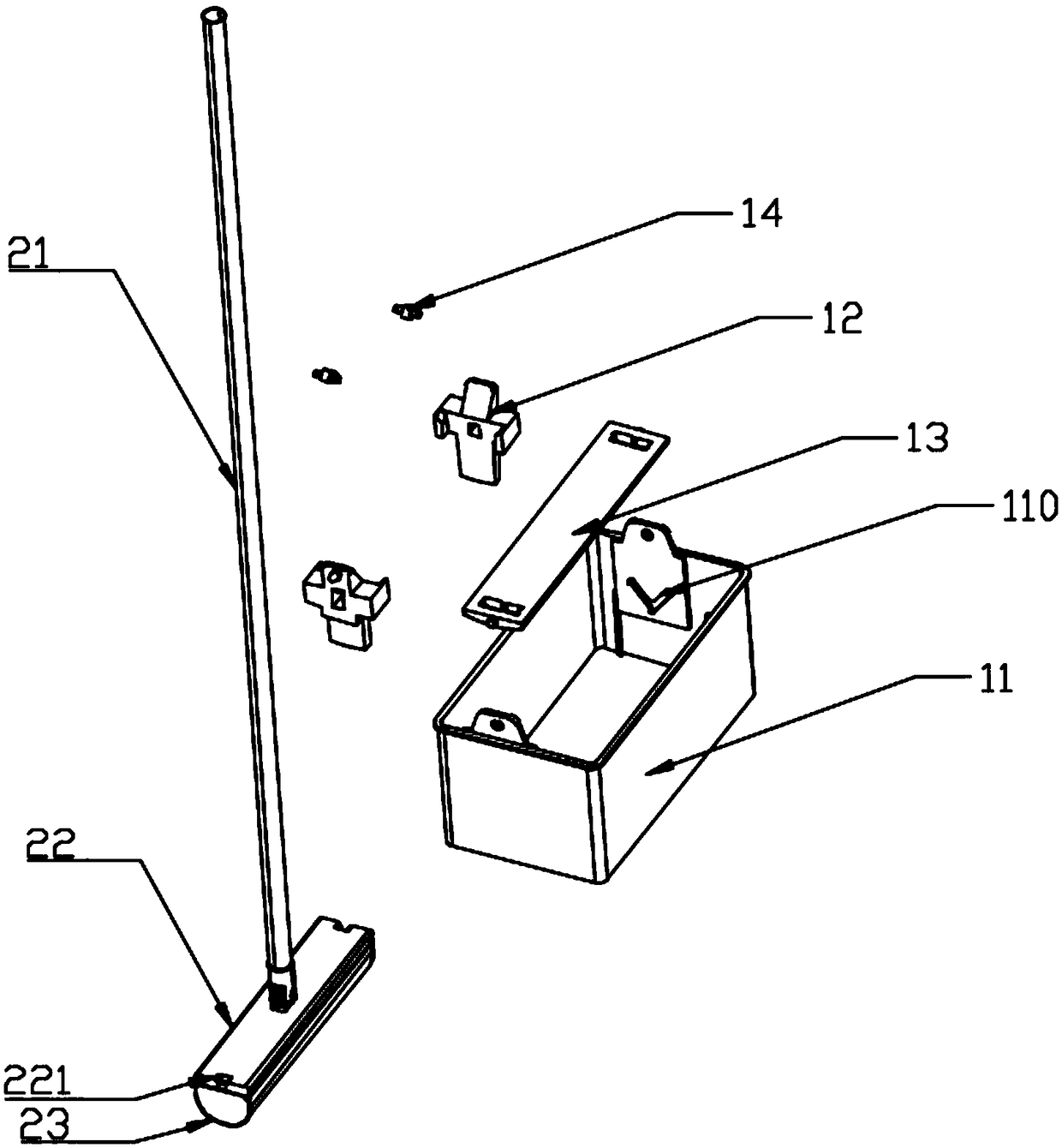

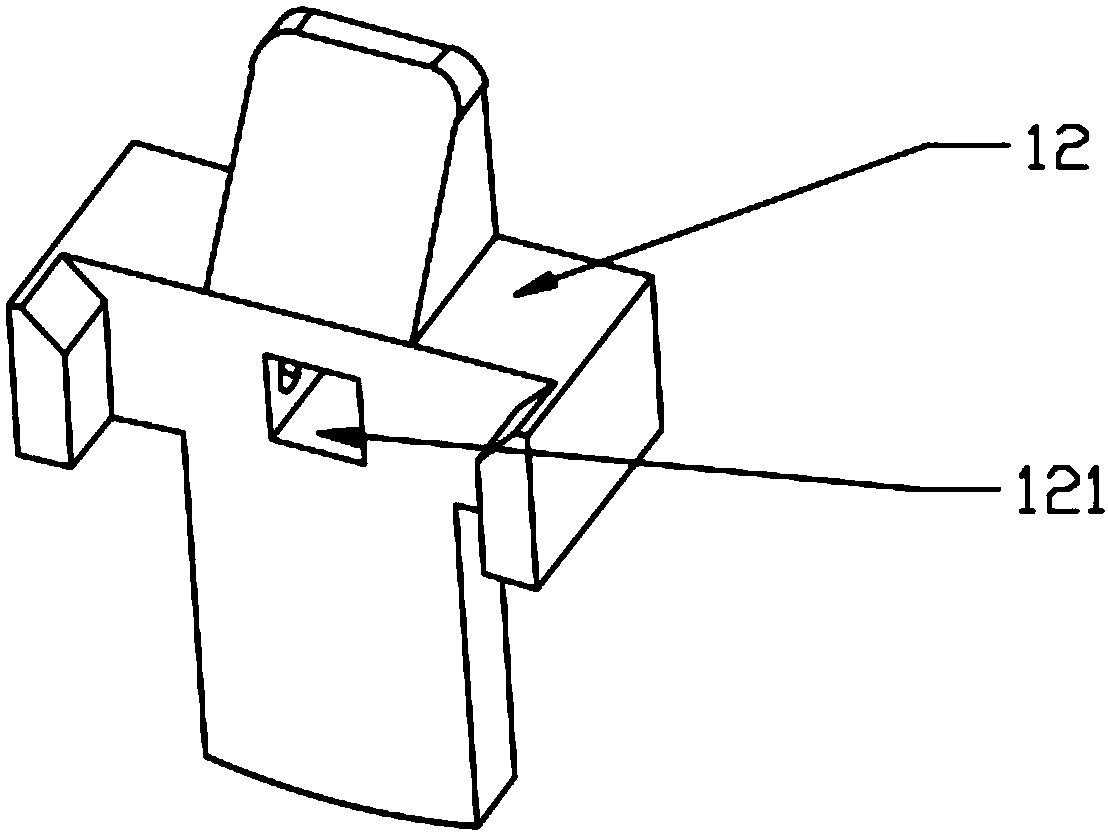

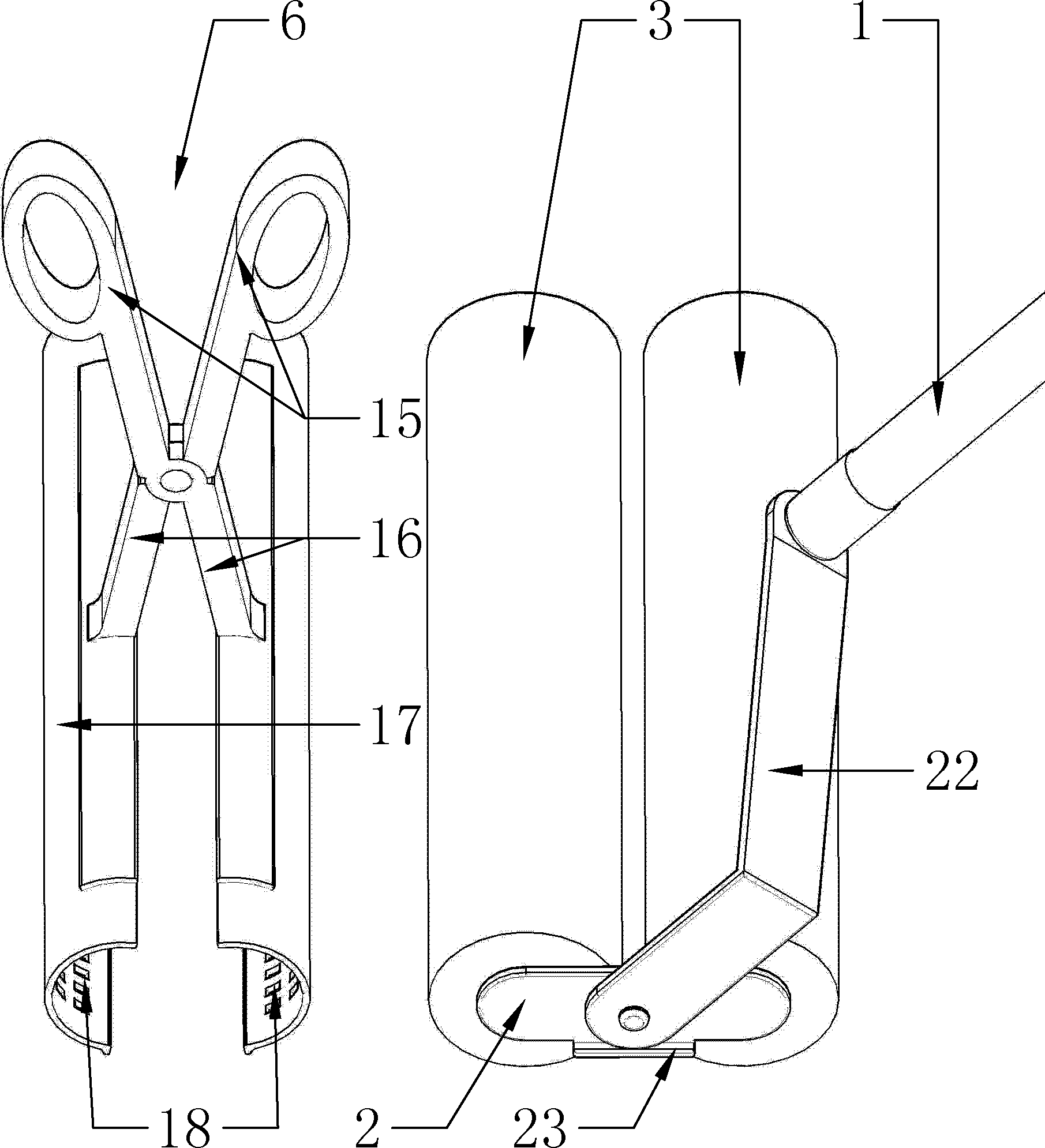

Mop

ActiveCN103070651ASimple structureAvoid damageCarpet cleanersFloor cleanersEngineeringMechanical engineering

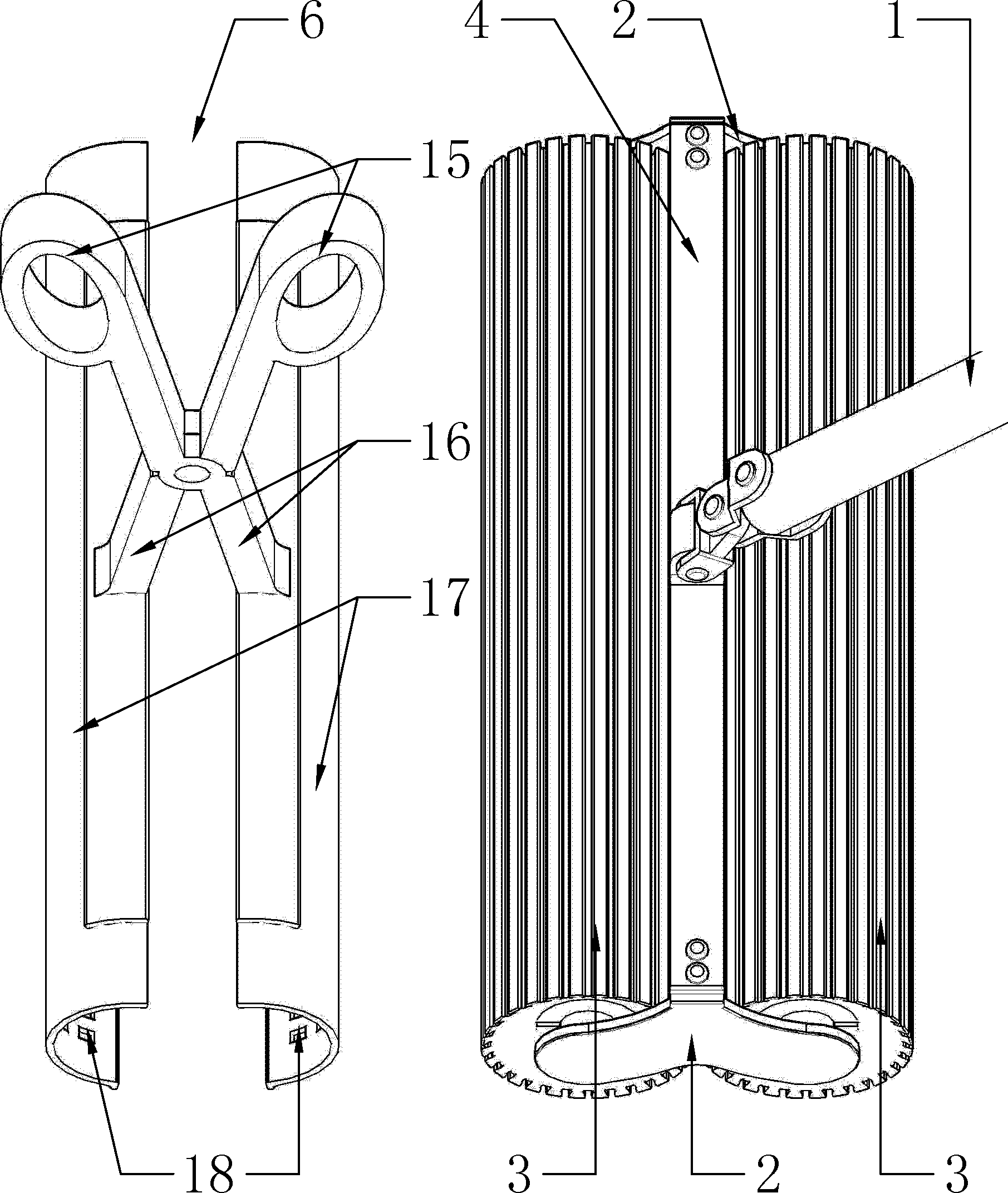

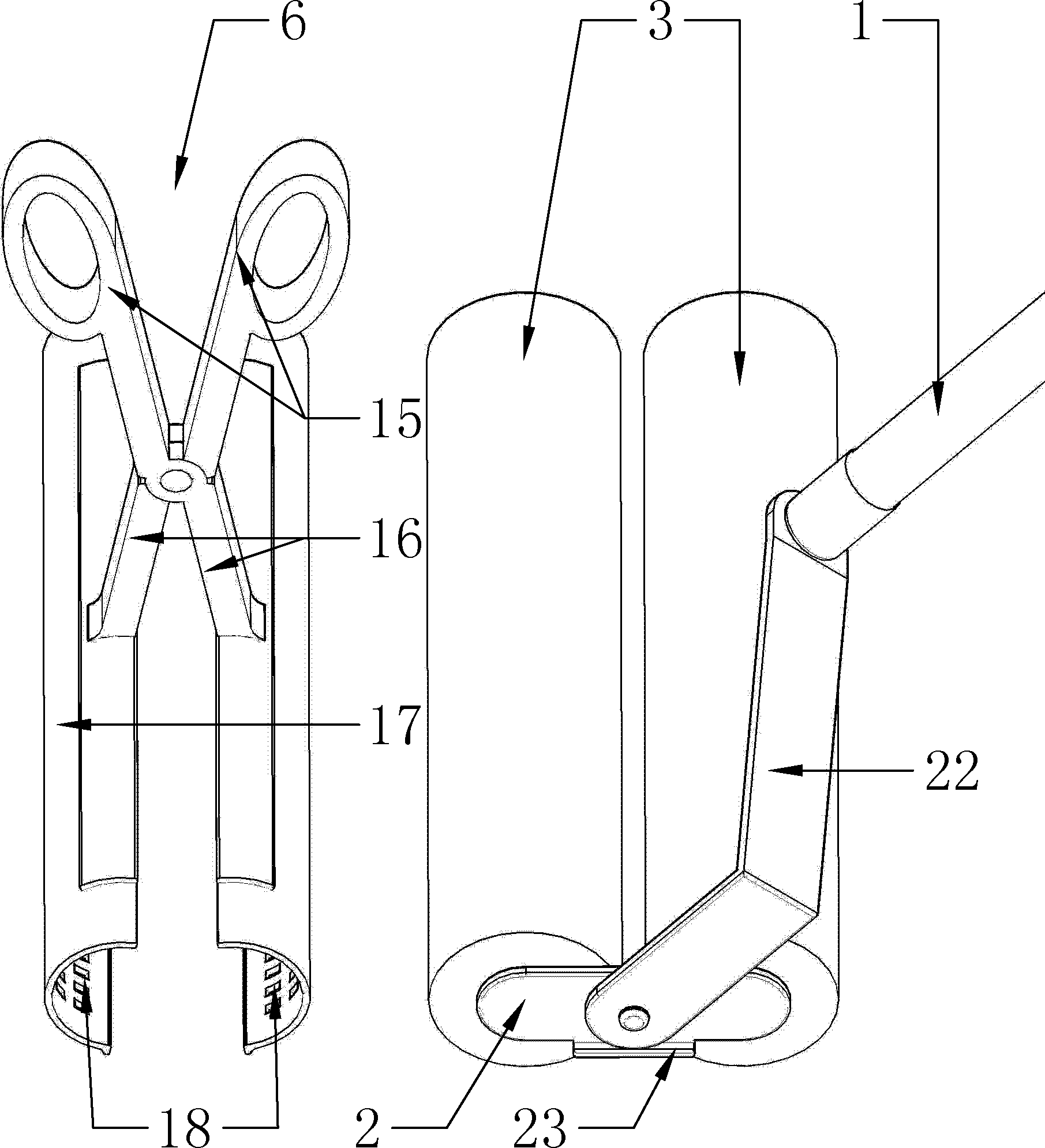

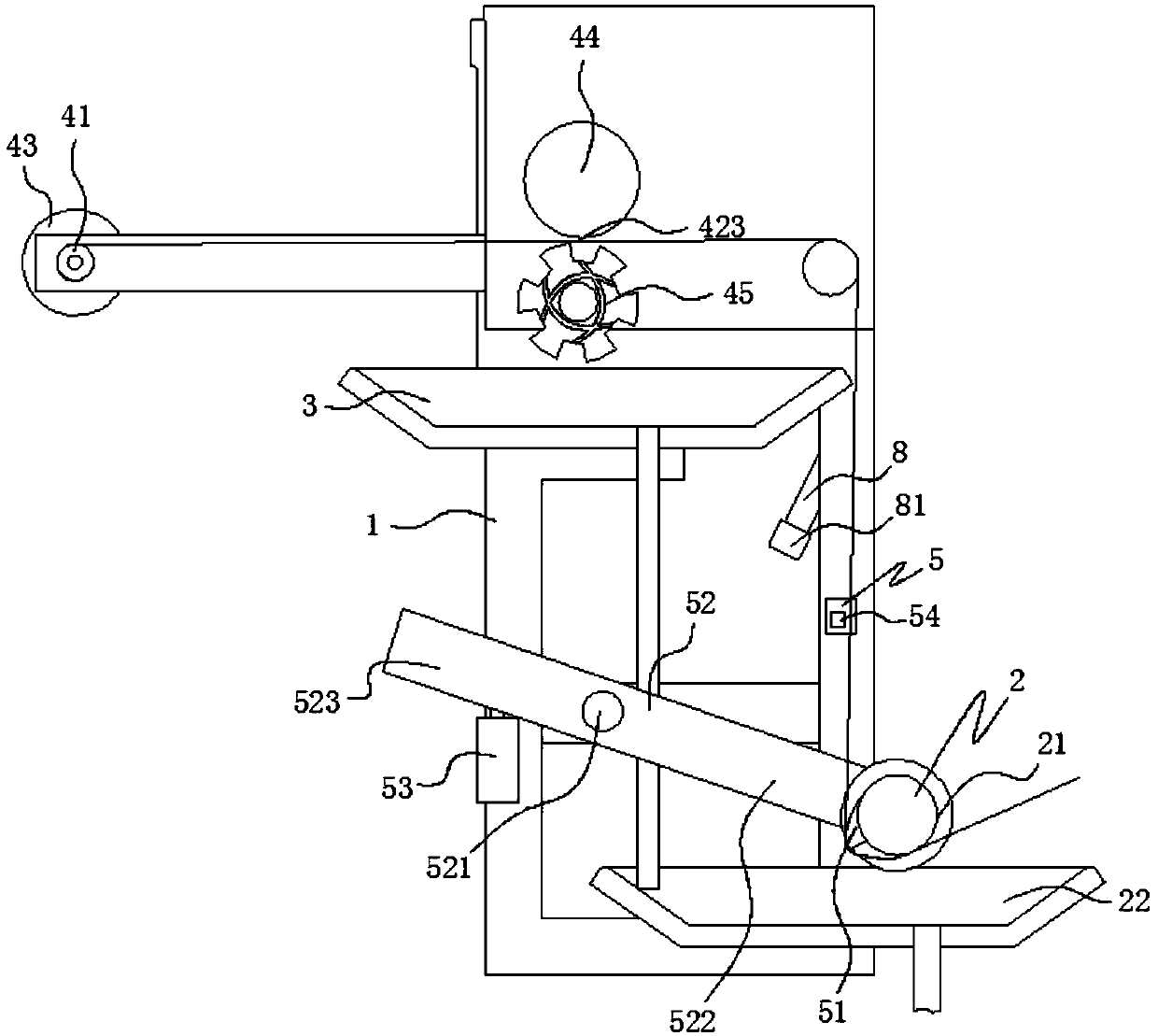

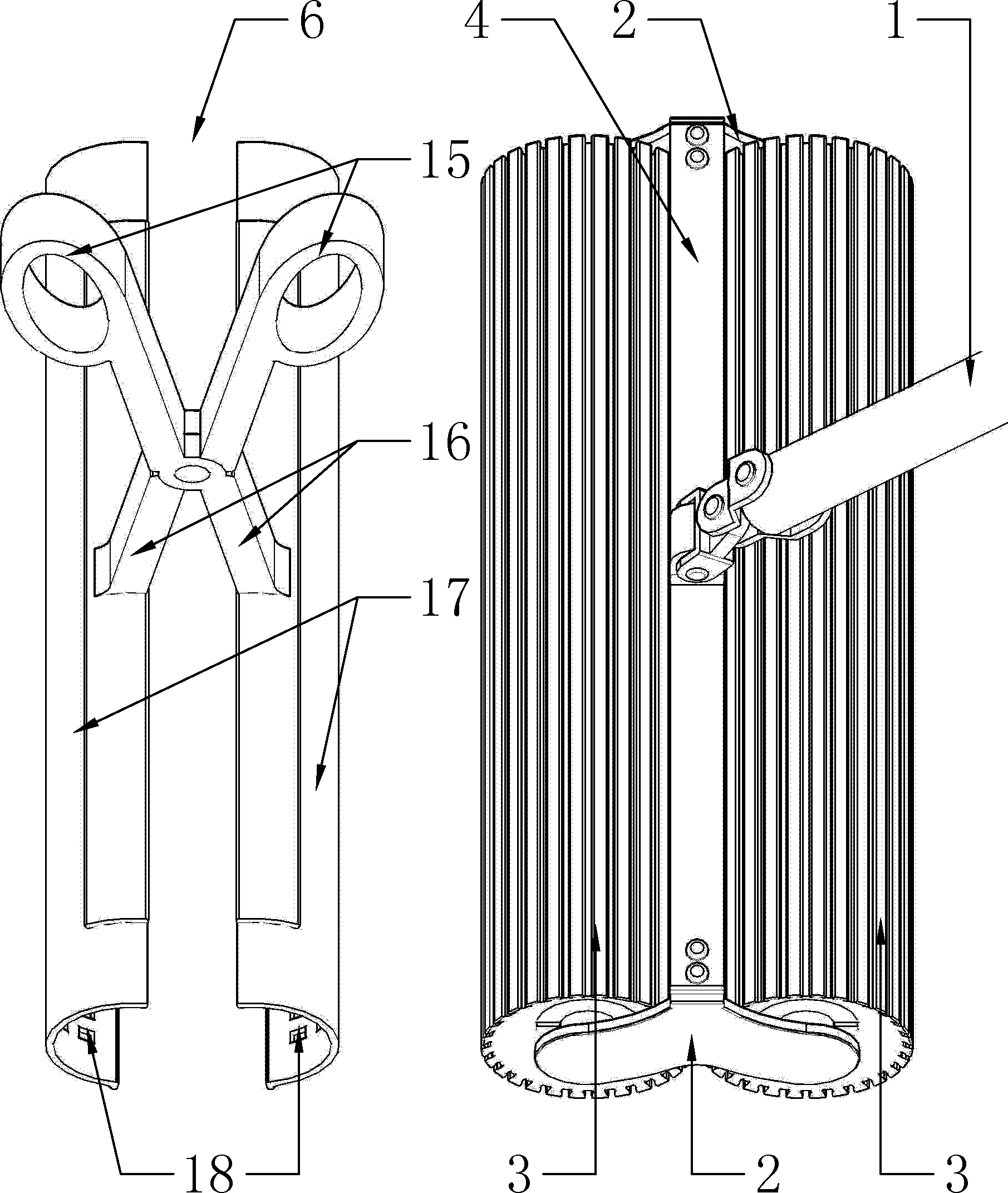

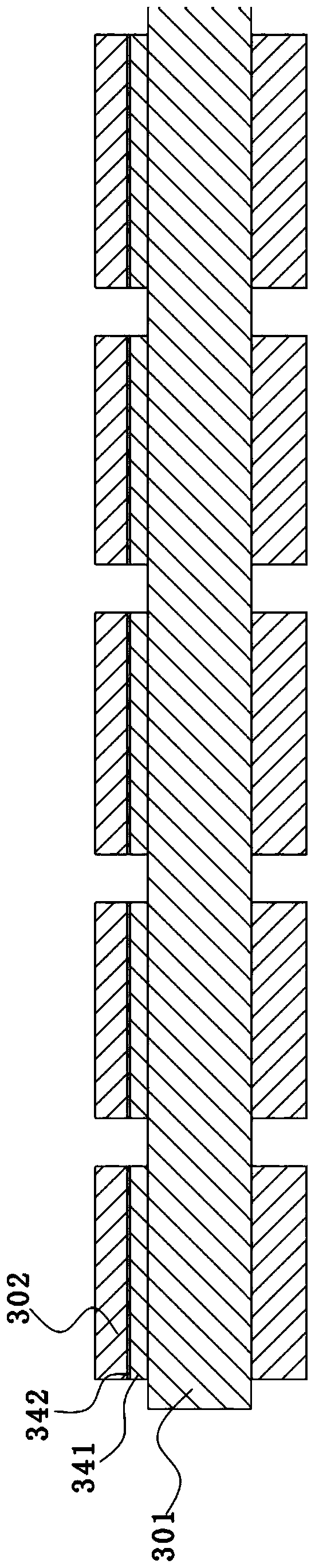

The invention discloses a mop which comprises a holding rod, a bracket connected to the lower end of the holding rod, and two rows of wiping rollers, wherein the two rows of wiping rollers are arranged on the bracket in parallel back and forth and can unidirectionally rotate; non-return directions of the wiping rollers in front and back rows are opposite; when the mop pushes forwards, the roller in the front row rolls forwards to wet the ground, and the roller in the back row stops for wiping the ground; and when the mop is pulled backwards, the roller in the back row backwards rolls to wet the ground, and the roller in the front row stops to wipe the ground. In the mopping process, the surfaces of the wiping rollers can be fully utilized; even if the rollers are dirt, falling dirt in the rolling process can be collected by the roller in a stopping state and is limited between two rows of rollers, so that the phenomena that the dirt and stain are distributed along the movement of the mop can be reduced or avoided, and the times of cleaning the mop in the mopping process can be reduced. The mop further comprises a wringer arranged in a separating manner. The wringer is of a tong-shaped structure with a simple structure; when the wringer is operated, the damage of the wringer to the rollers is little; when the wringer is damaged or lost, the wringer is only needed to be independently replaced; and the wringer can be also used for clamping solid waste on the ground.

Owner:阳珉

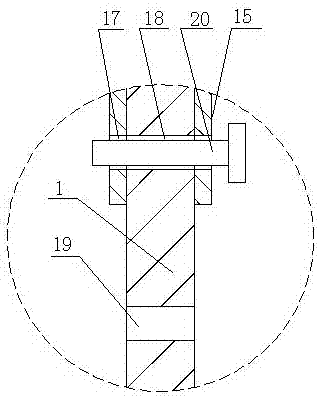

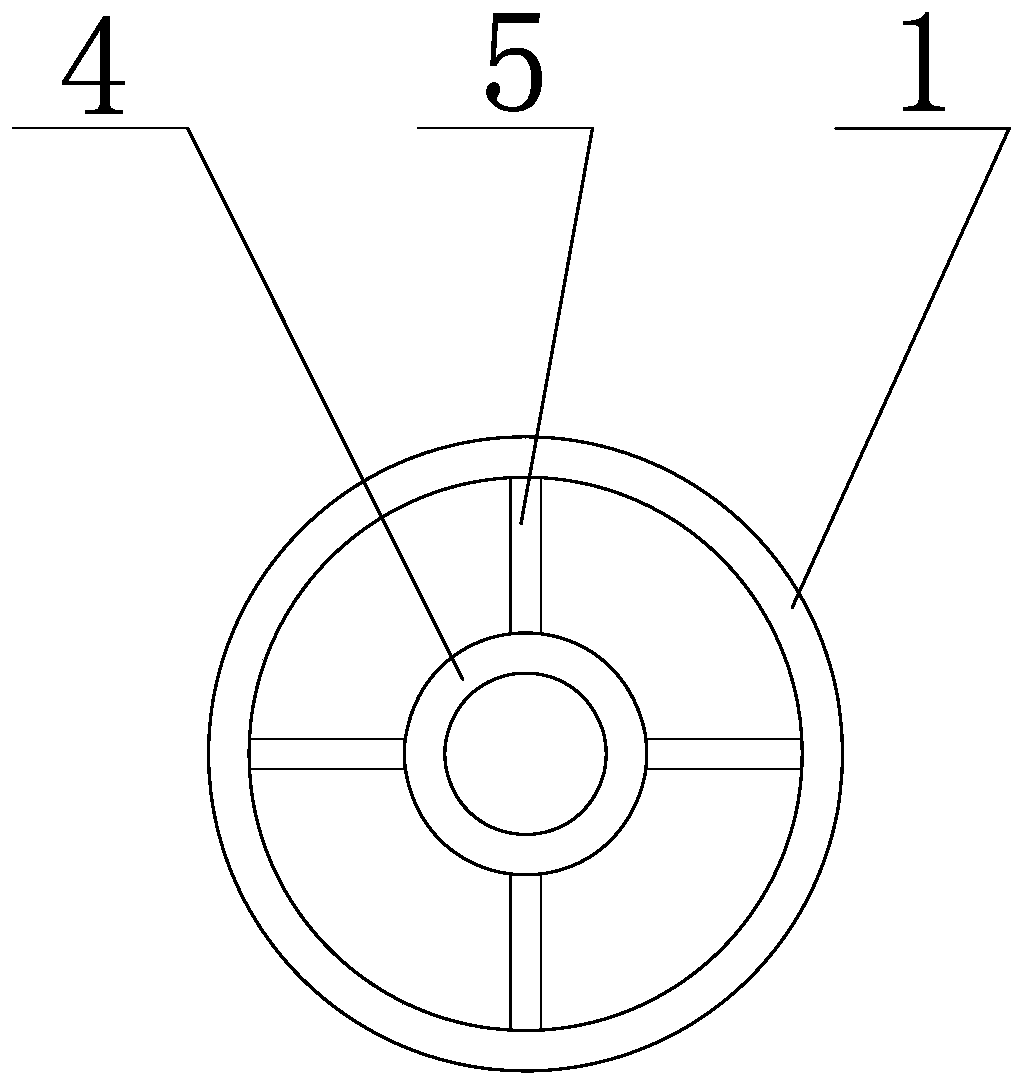

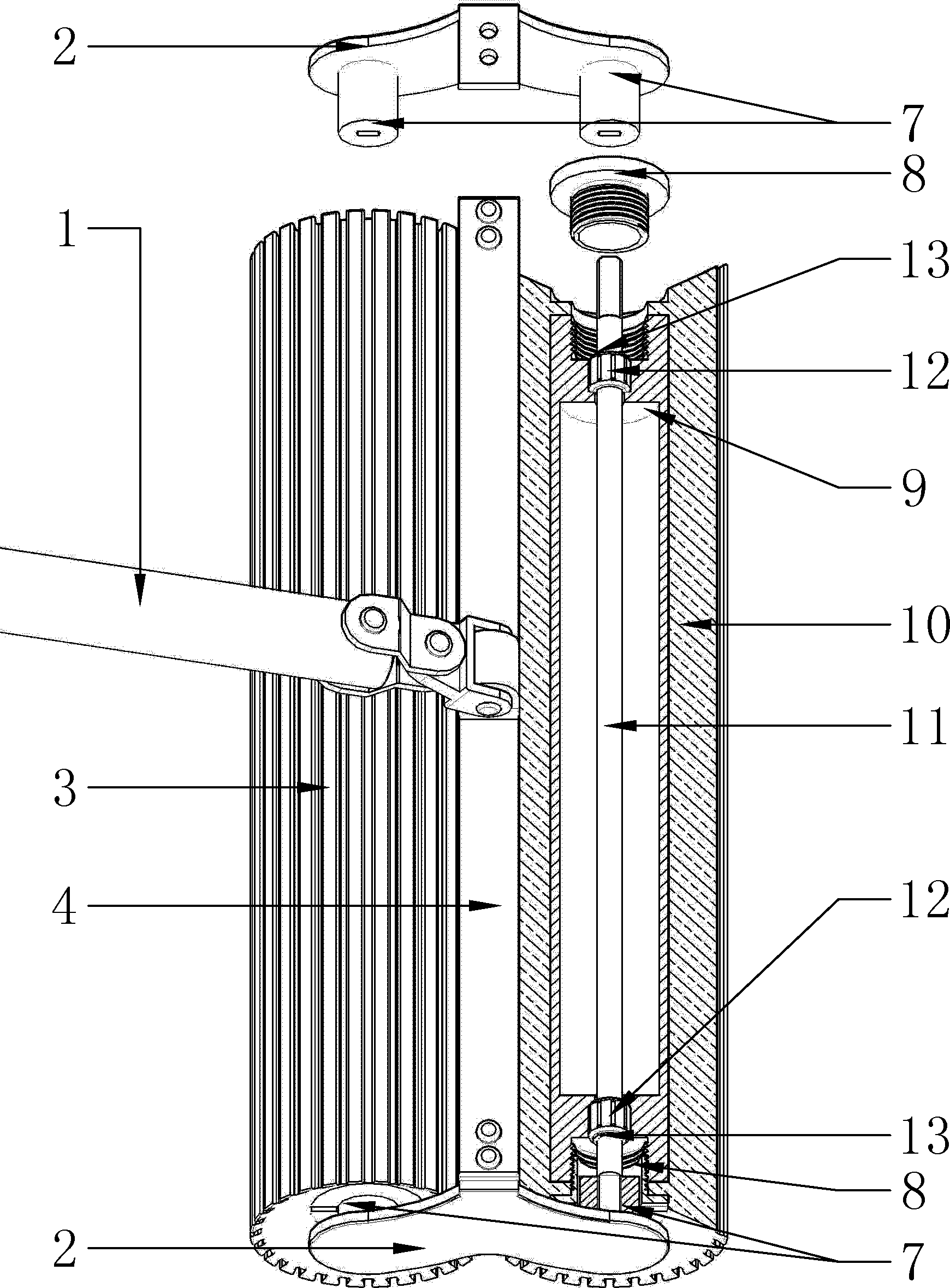

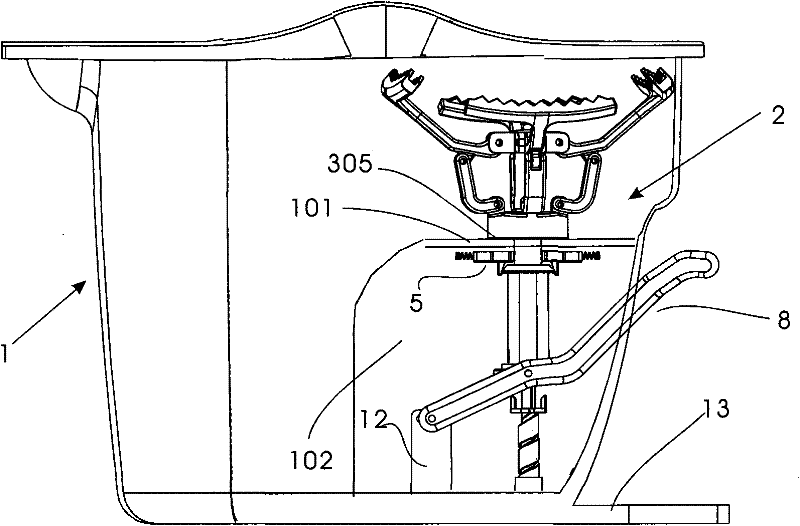

Mop water twisting barrel

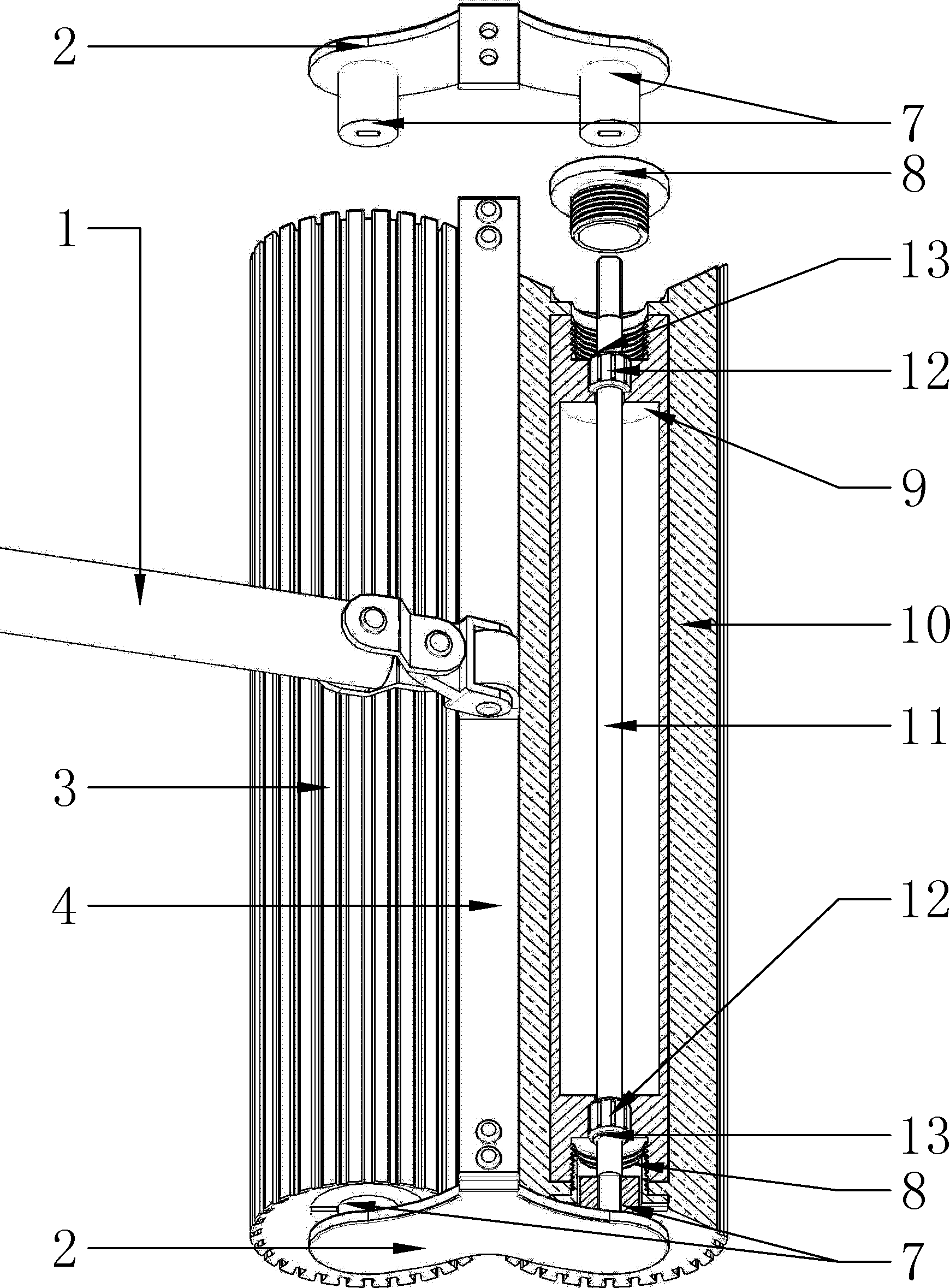

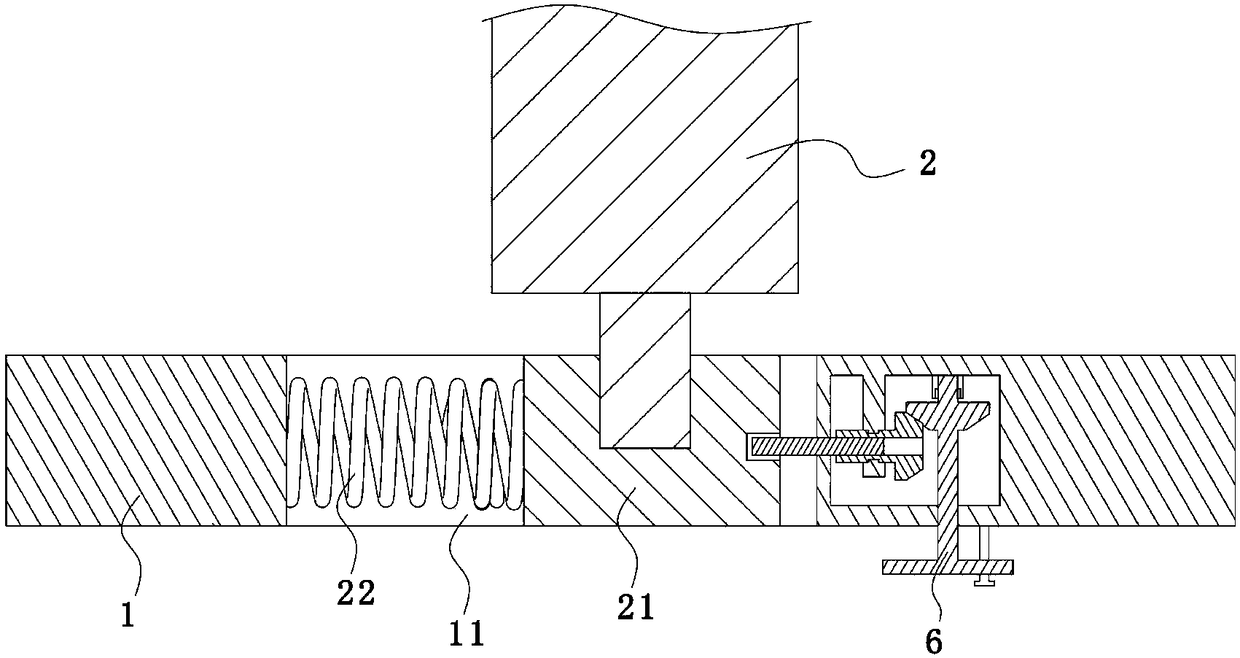

The invention relates to a mop water twisting barrel, which comprises a barrel body. The invention is characterized in that a mop water twisting device is arranged in the barrel body, and the mop water twisting device comprises a rotating shaft, a guide tube and a threaded guide post, wherein the upper part of the rotating shaft is connected with a mop tight grasping assembly, the guide tube is connected with a pedaling element, the lower part of the rotating shaft is arranged in the guide tube in a penetrating way, and the threaded guide post, which drives the guide tube to rotate, is arranged at the lower part of the guide tube. The invention has the advantages of clean dewatering effect on mop cloth and convenient use.

Owner:HUIZHOU QIANGLI DAILY NECESSITIES

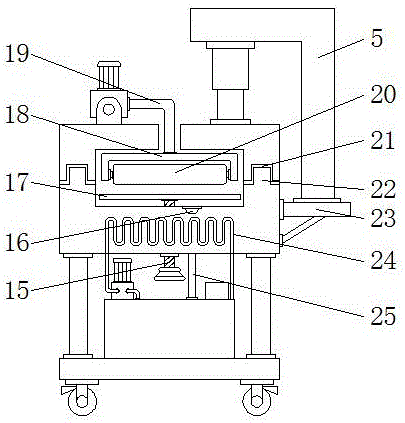

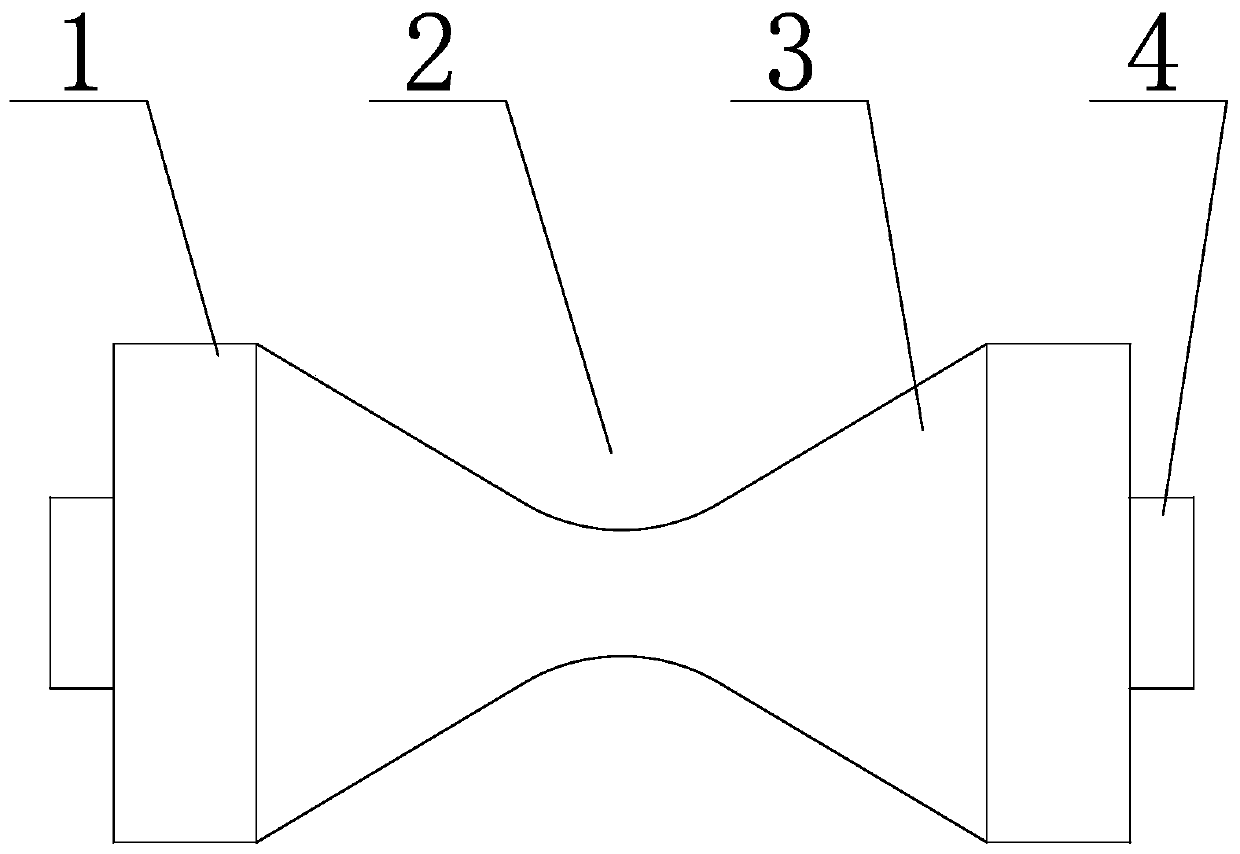

Water squeezing stretching machine

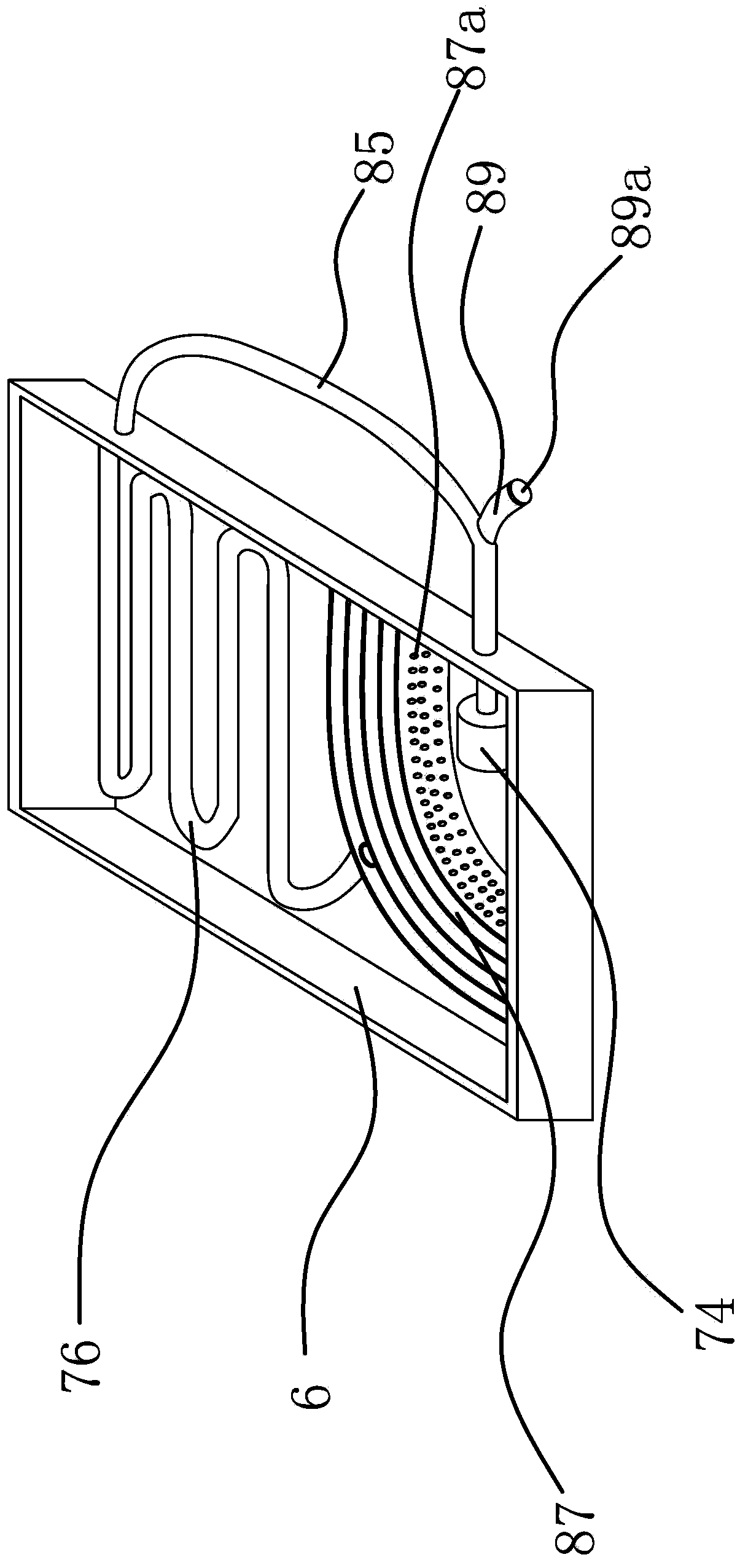

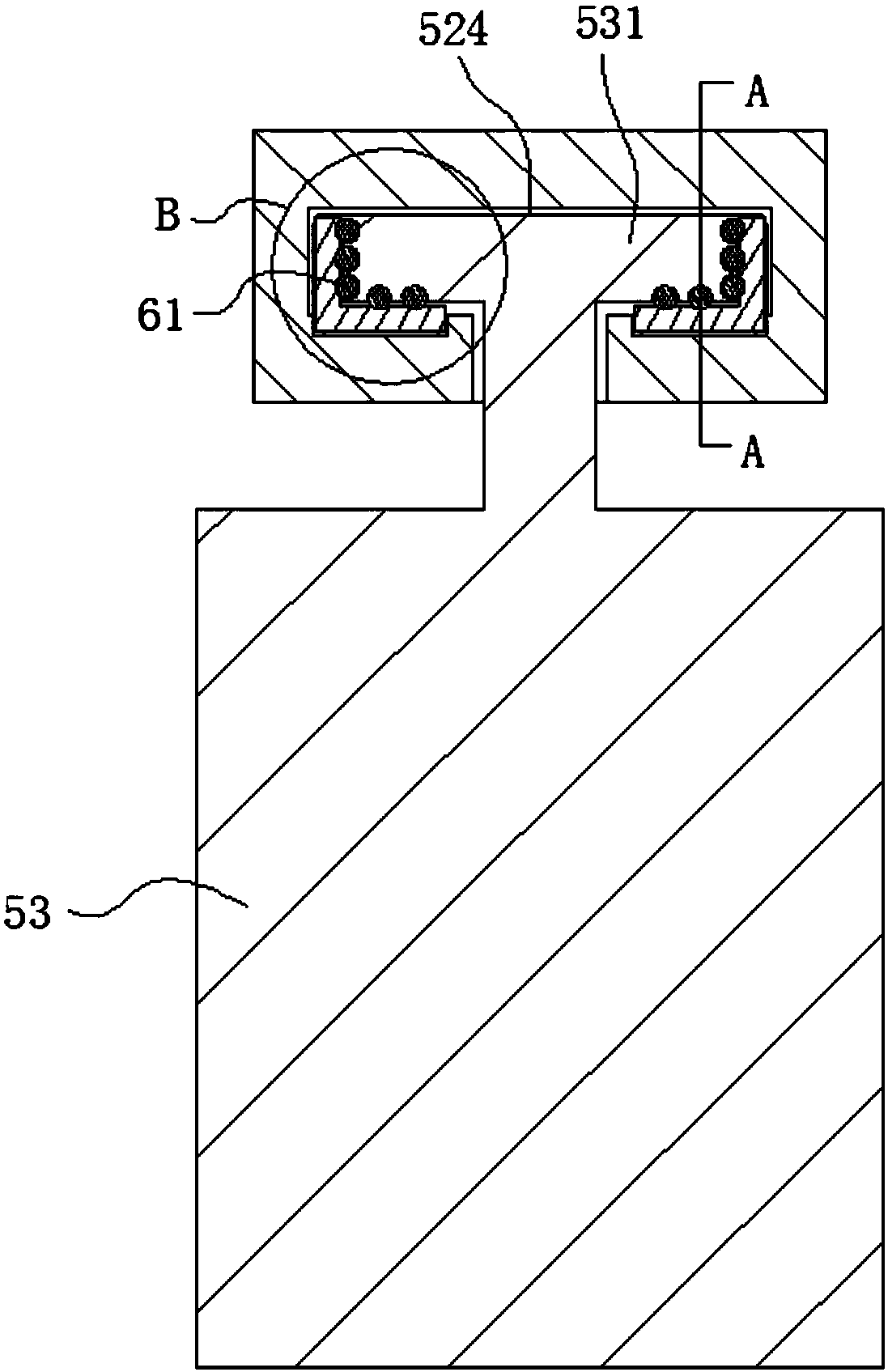

ActiveCN103388036AGood vertical stretchUniform thicknessLeather manufacturingSkins/hides/leather/fur manufacturing apparatusMotor drivePulp and paper industry

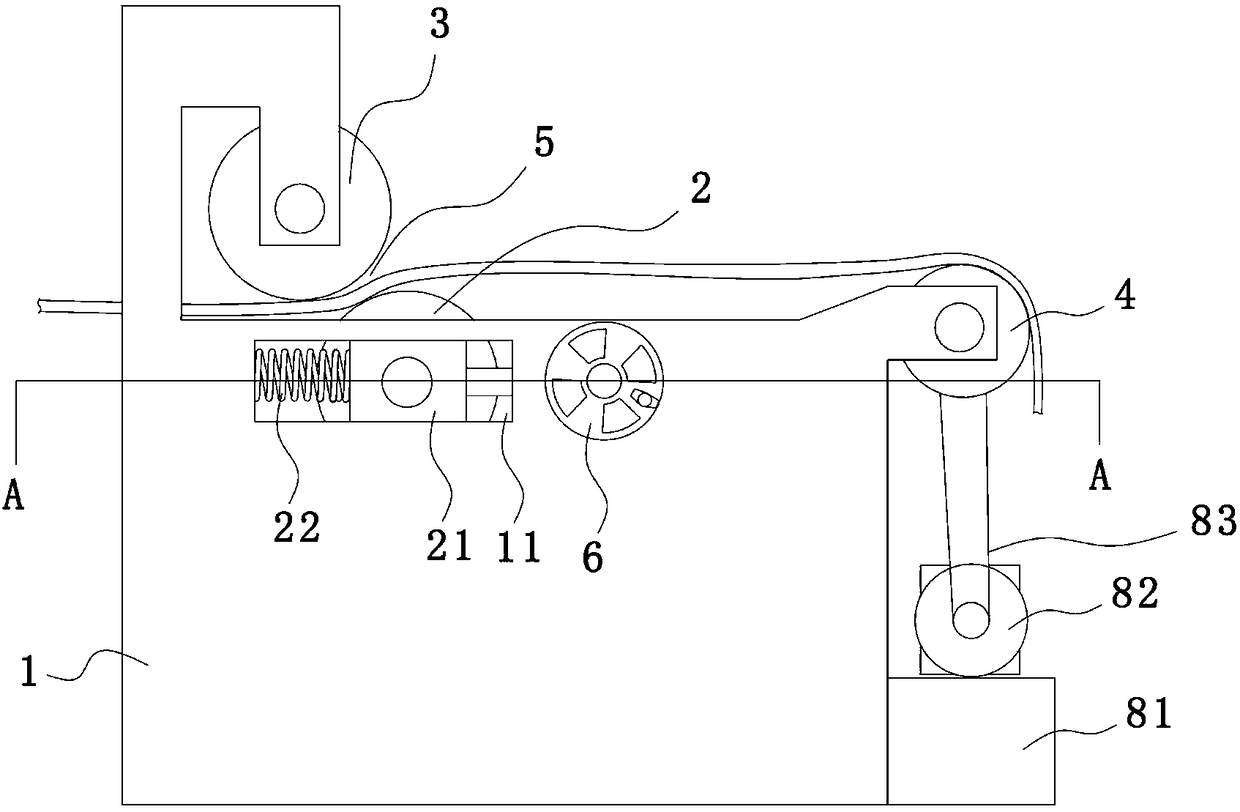

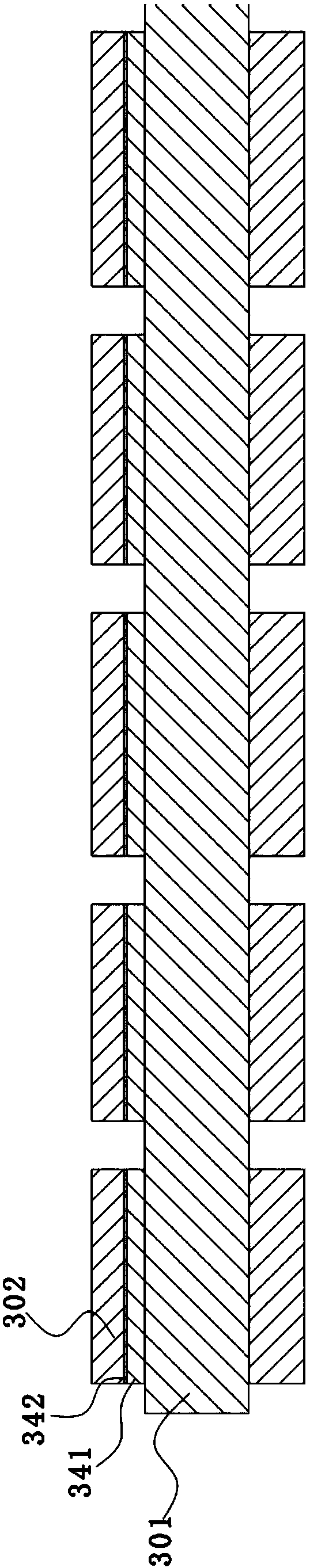

The invention provides a water squeezing stretching machine, belongs to the technical field of leather production equipment, and solves the technical problems that the production efficiency of the existing water squeezing stretching machine is low, the stretching effect is poor and the like. The water squeezing stretching machine comprises a driving roller and a driven roller which can freely rotate, wherein the driving roller is provided with a servo motor drive, and a conveyor belt is connected between the driving roller and the driven roller; the conveyor belt is provided with a longitudinal stretching roller and a water squeezing roller in a leaning manner, and a transmission mechanism is capable of enabling the revolving speed of the driving roller, the revolving speed of the water squeezing roller and the revolving speed of longitudinal stretching roller to successively increase, and the water squeezing stretching machine also comprises a box body the upper end of which is provided with an opening; the driving roller, the driven roller, the longitudinal stretching roller and the water squeezing roller are all connected with a plurality of supporting pillars fixedly arranged on the bottom of the box body, and a horizontal stretching roller is capable of being pressed on a leather and is arranged above a supporting network. The water squeezing stretching machine provided by the invention has advantages that the production efficiency is improved, the stretching effect is good and the like.

Owner:海宁长安皮革有限公司

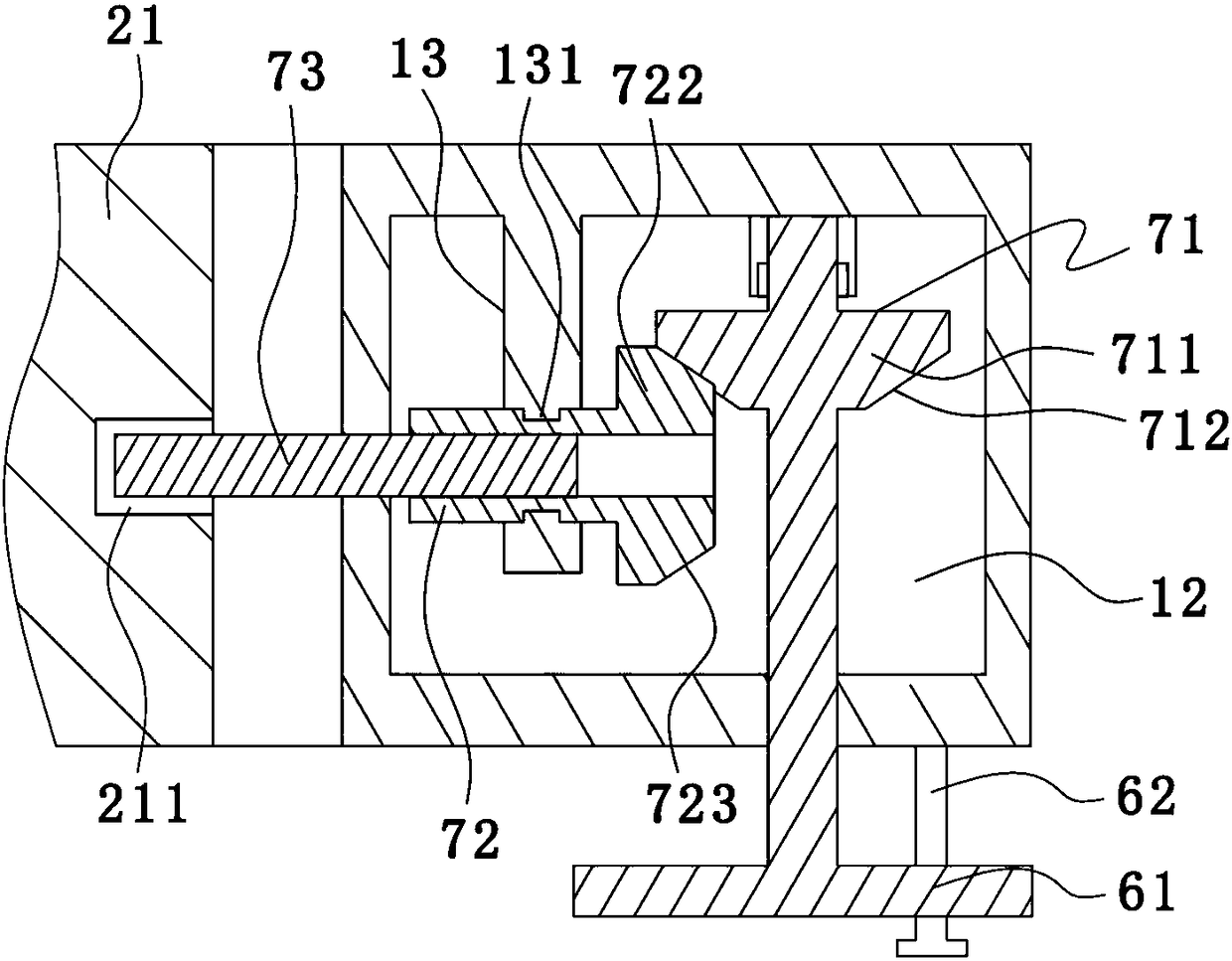

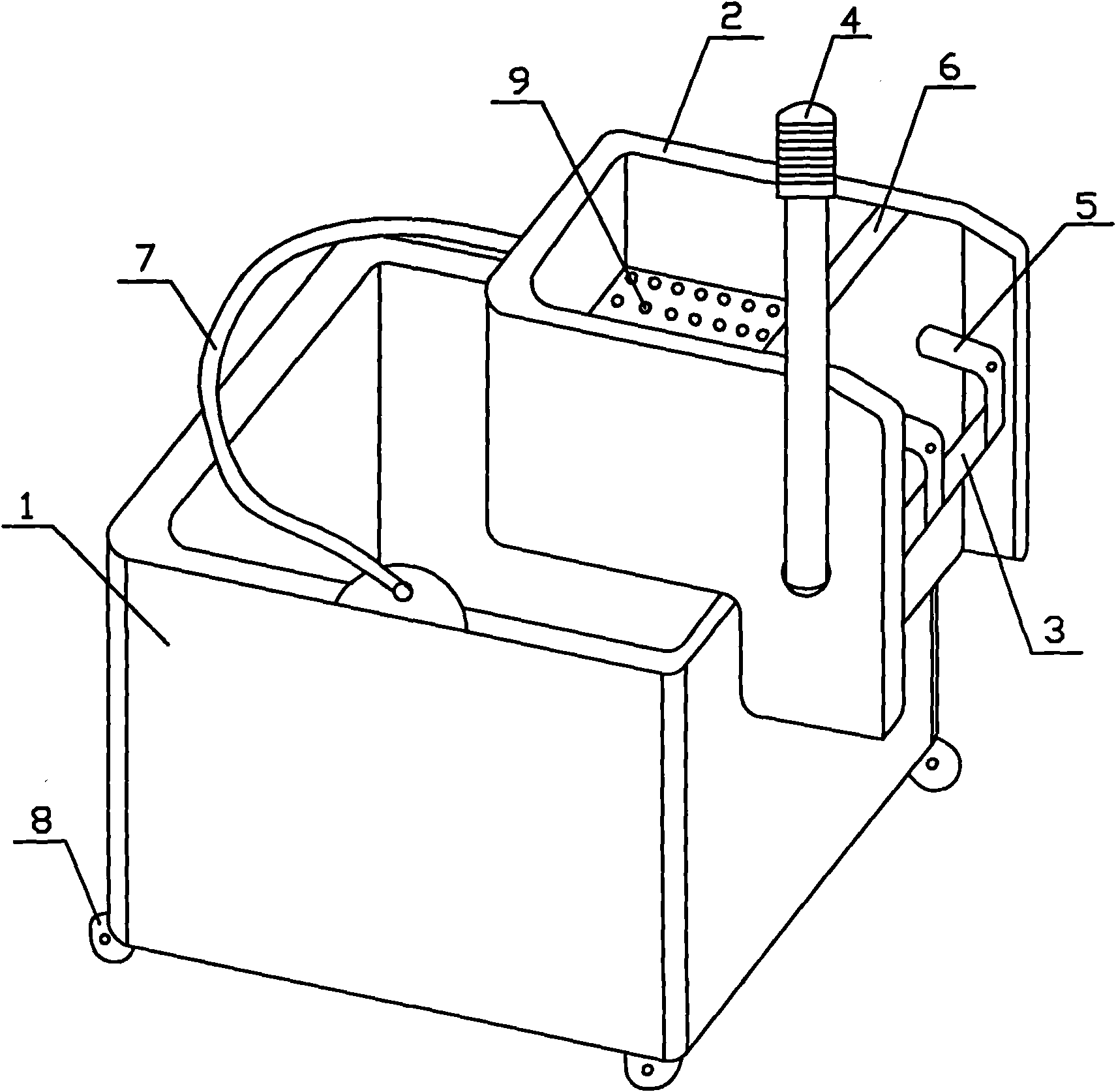

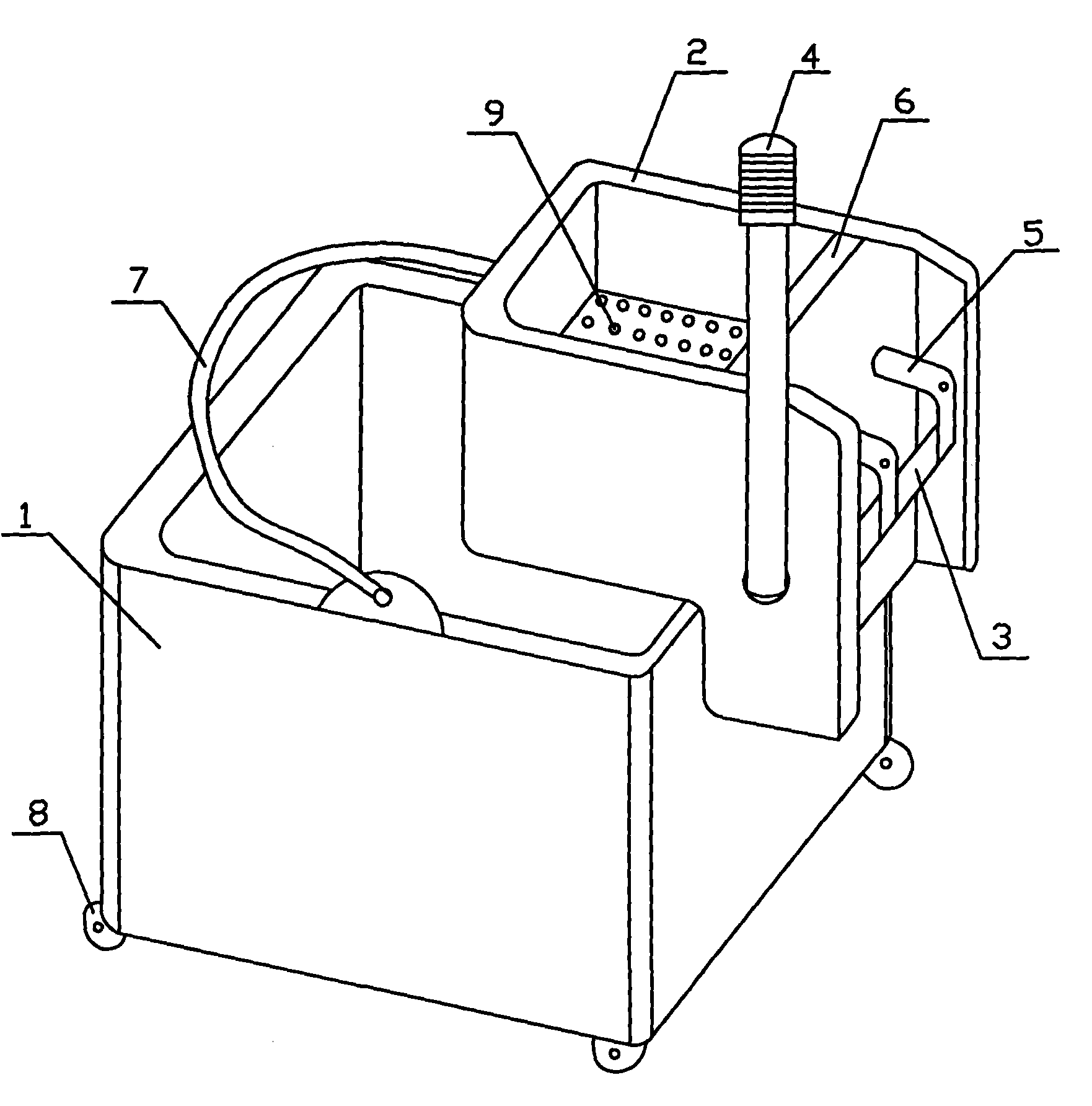

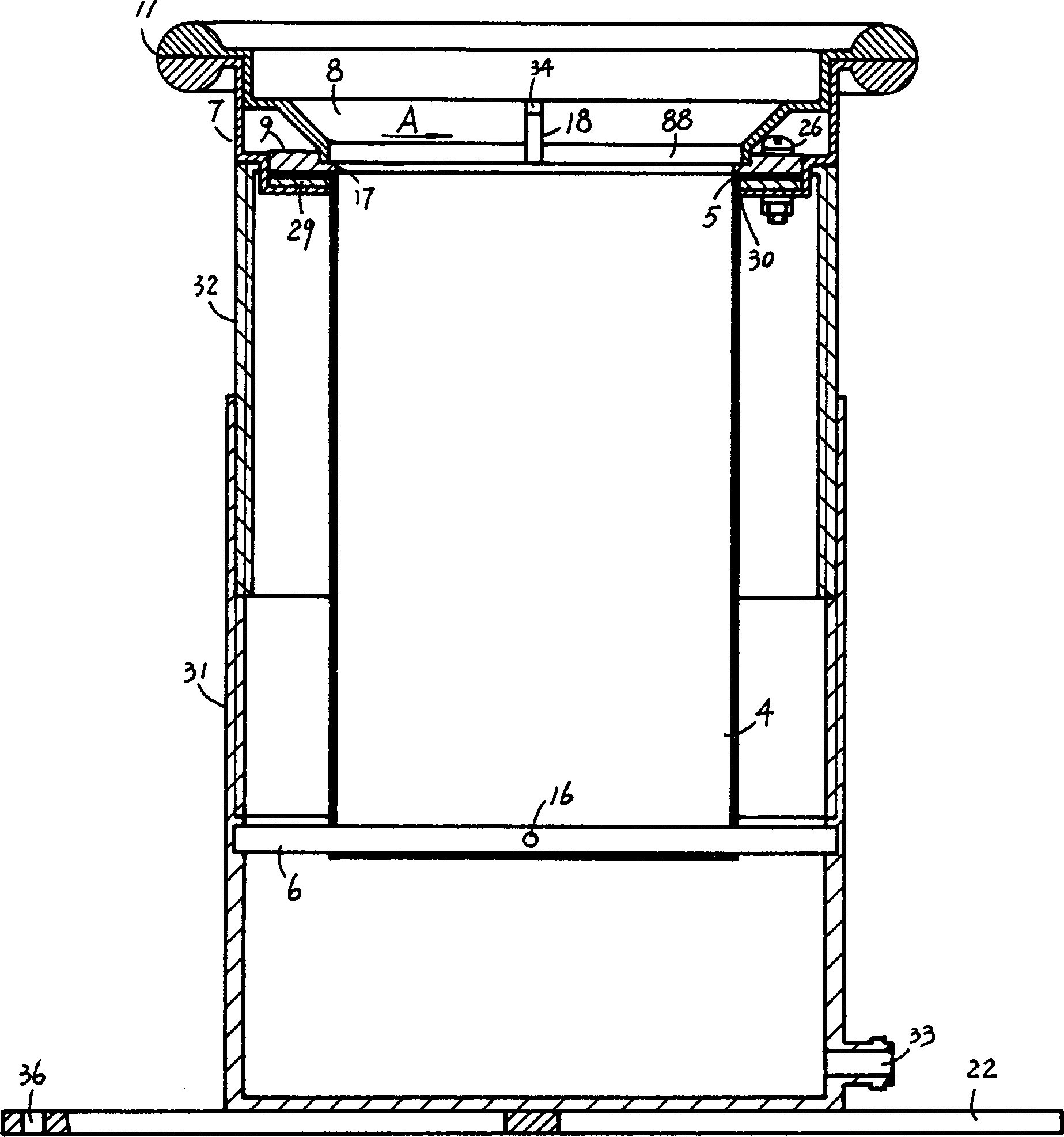

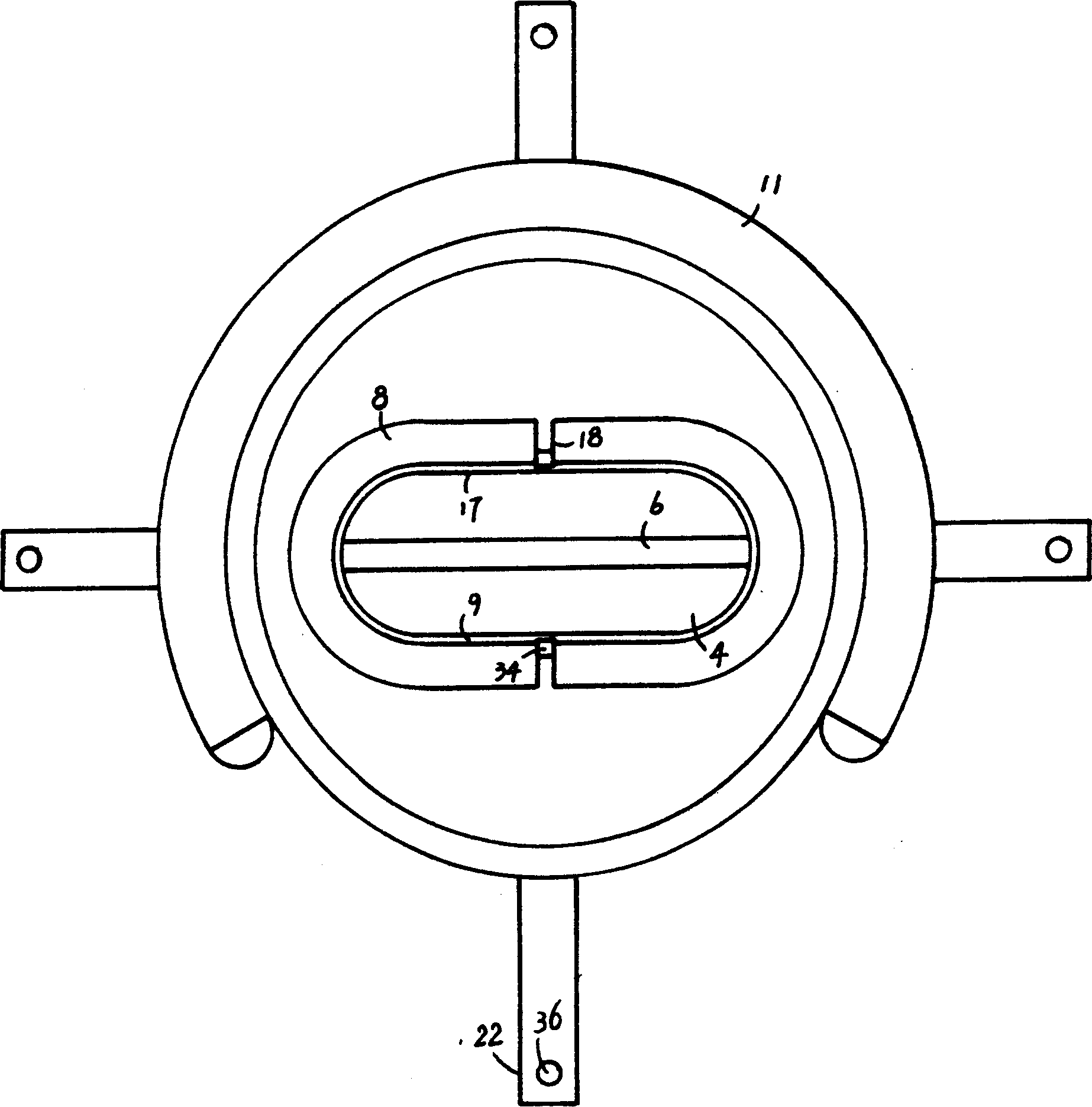

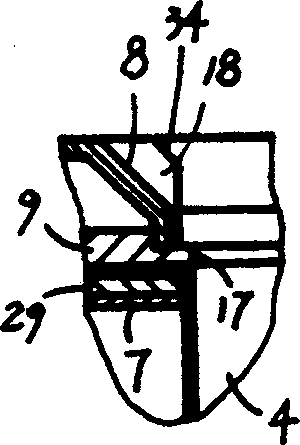

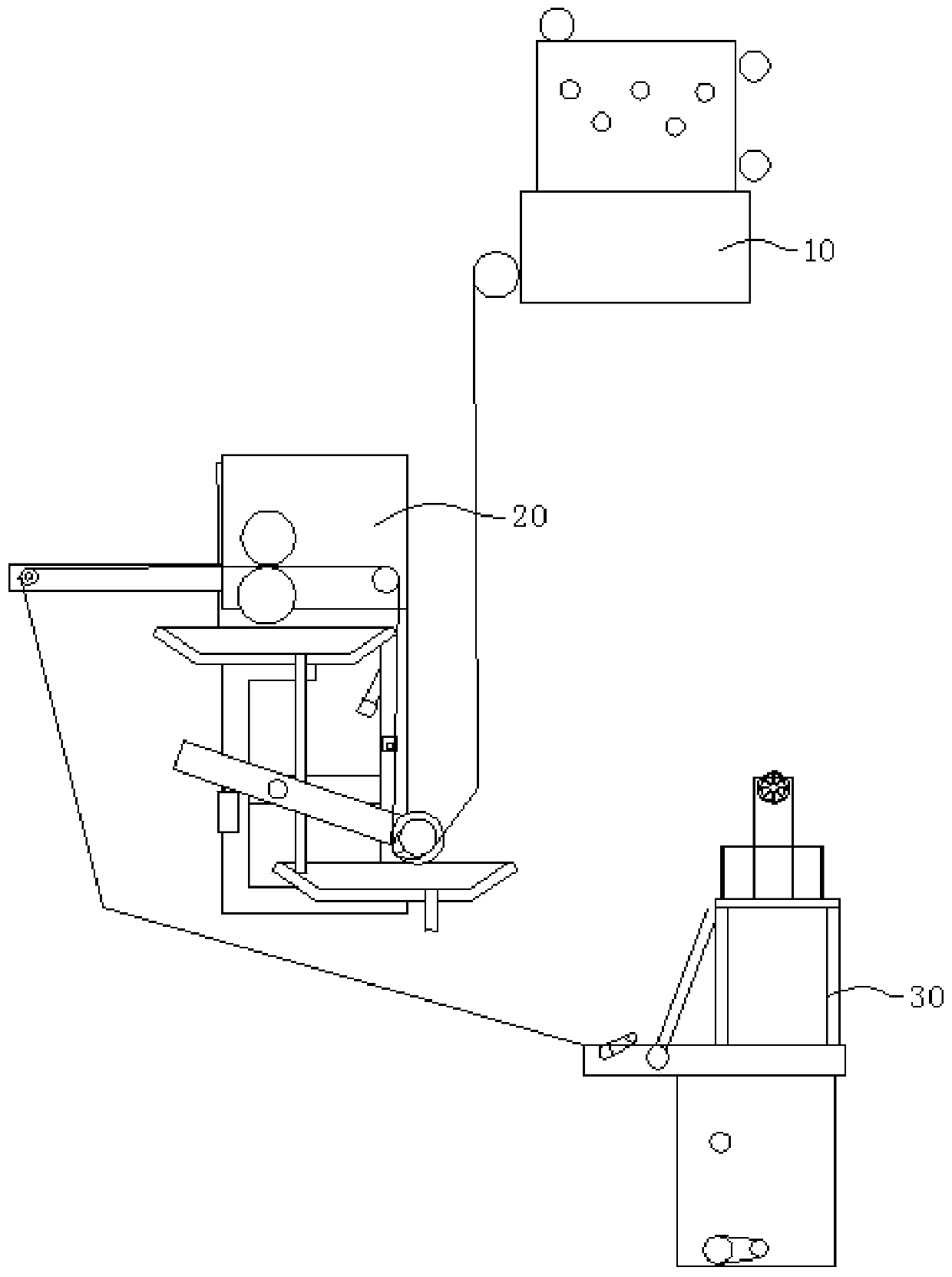

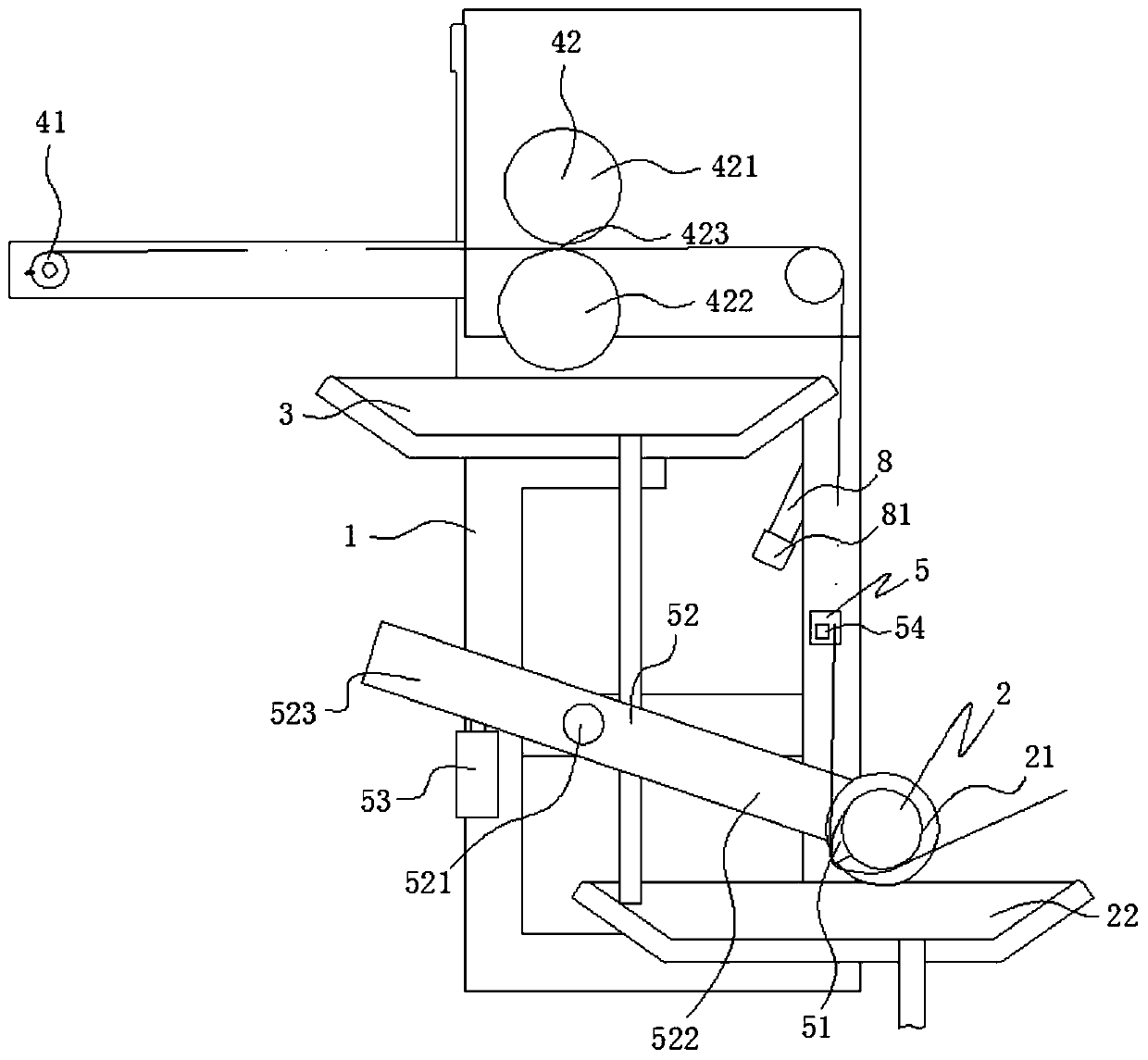

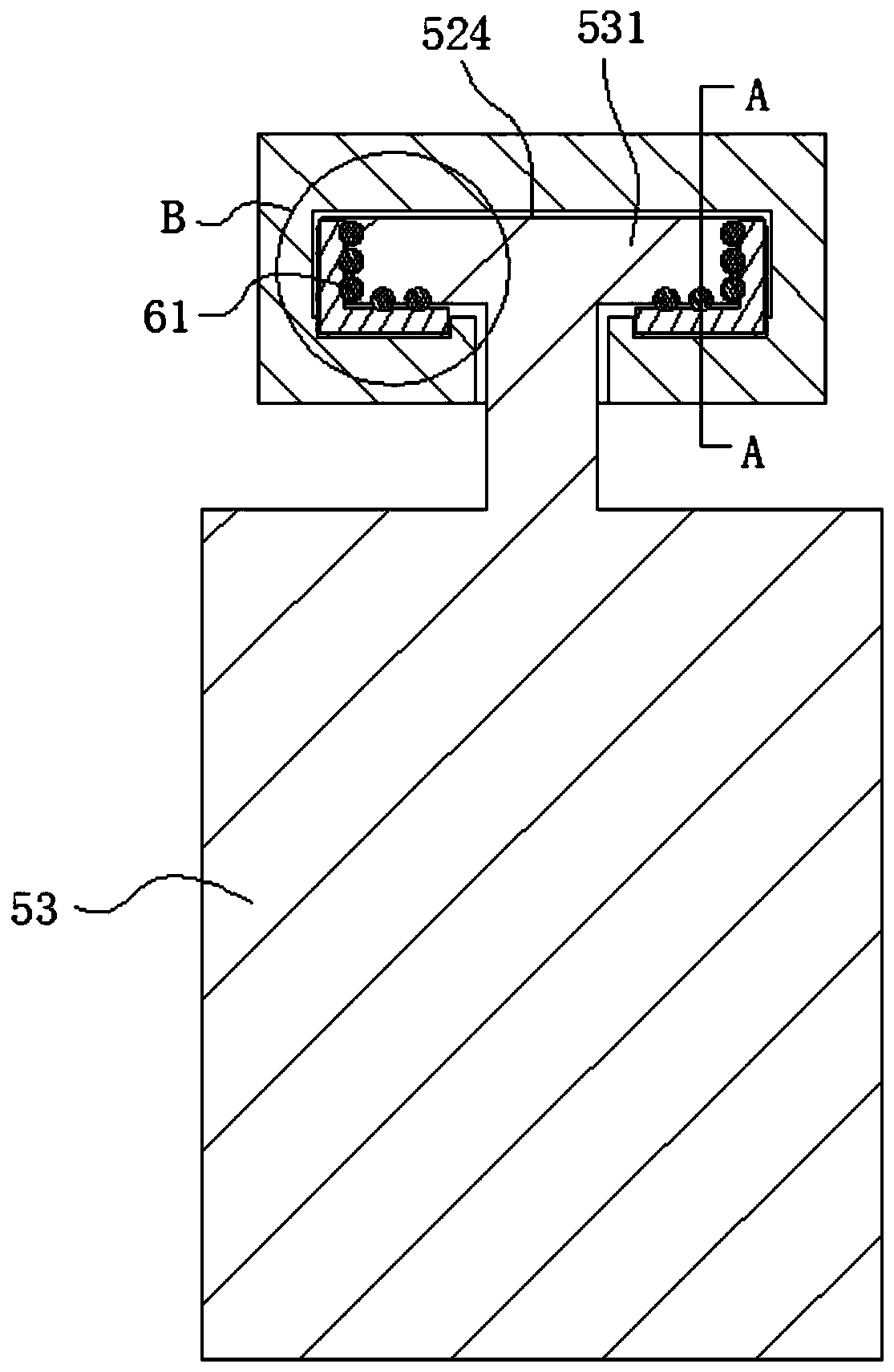

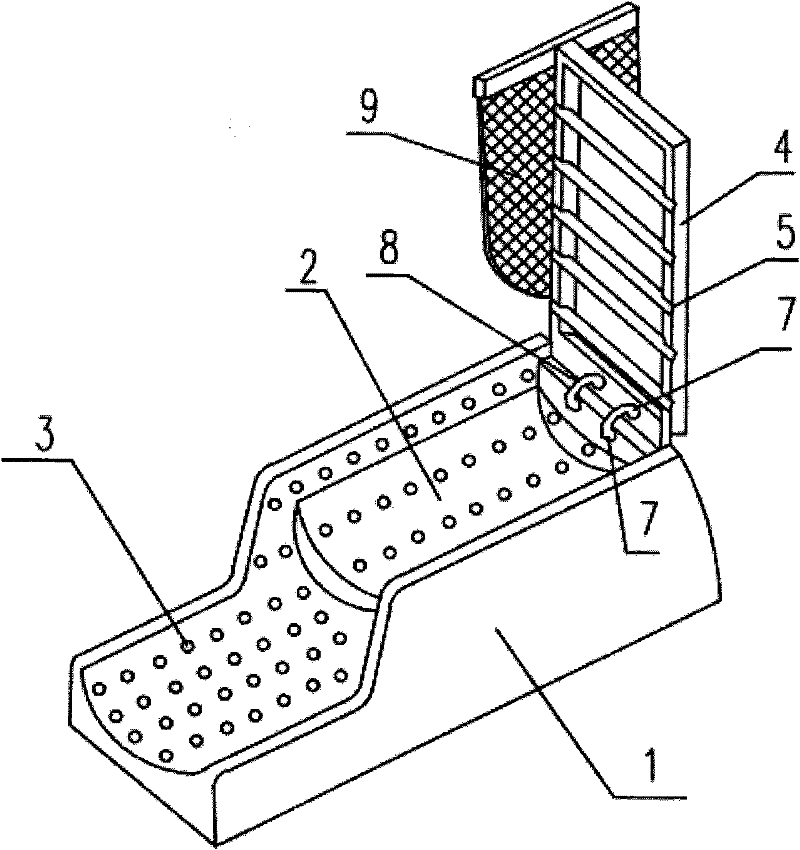

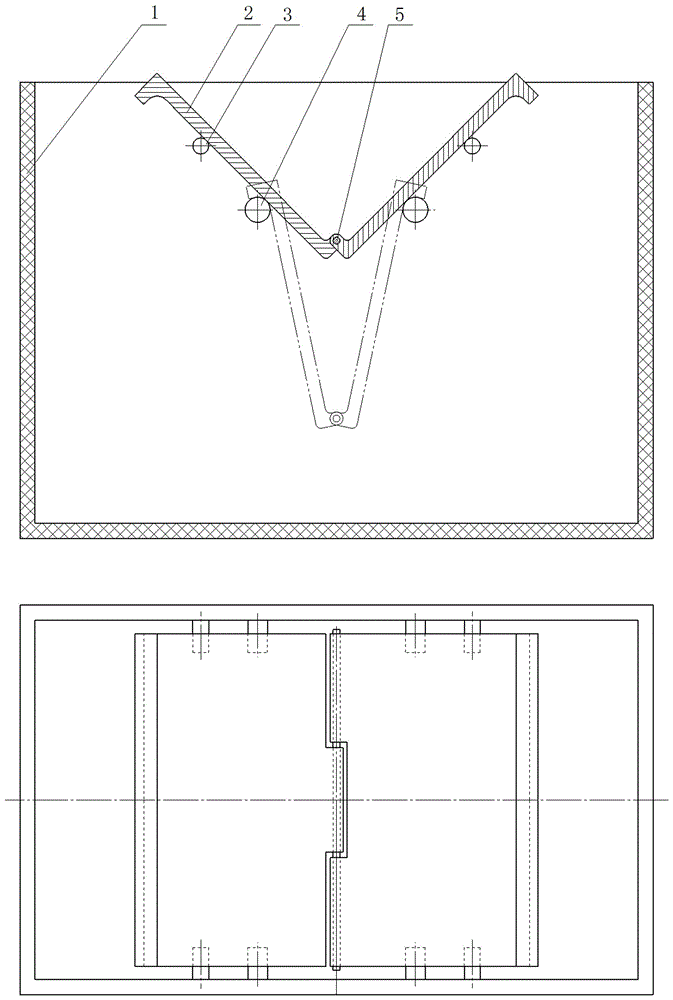

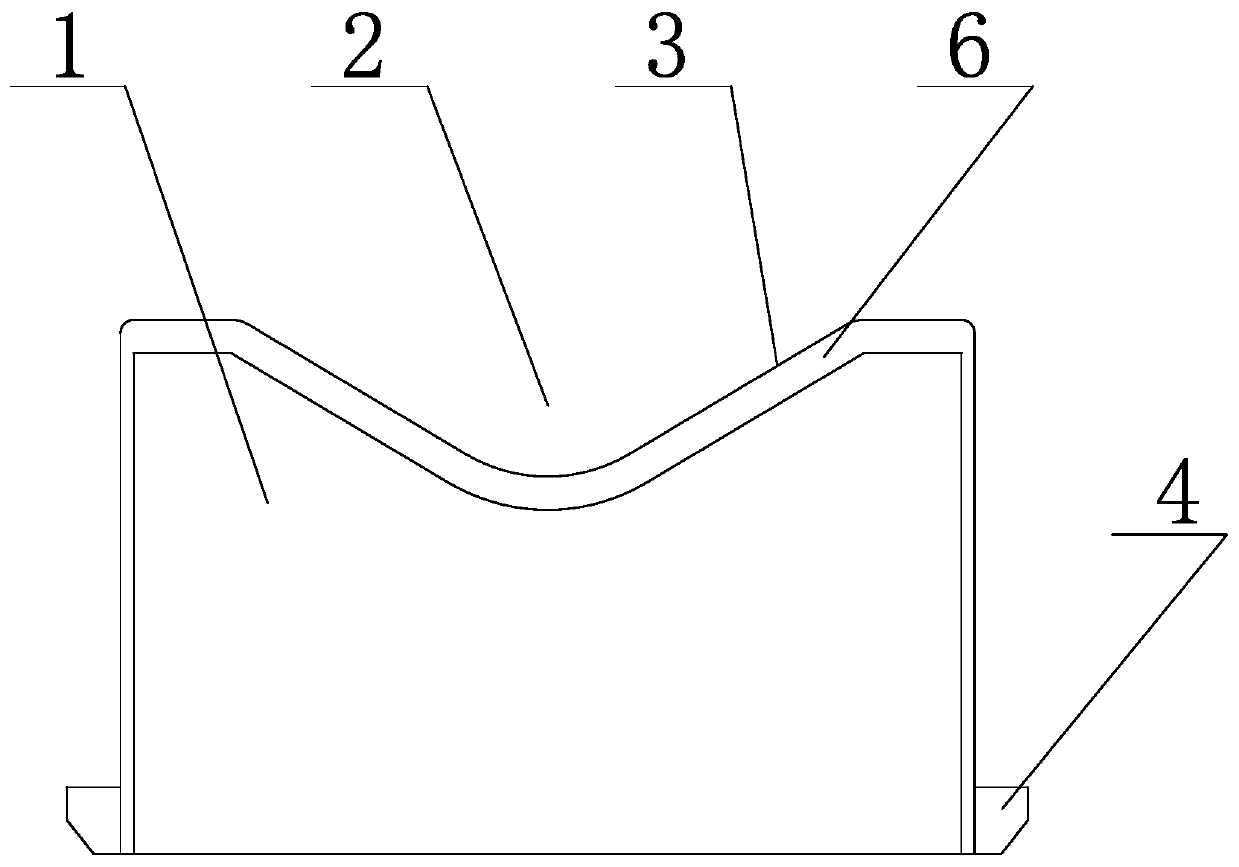

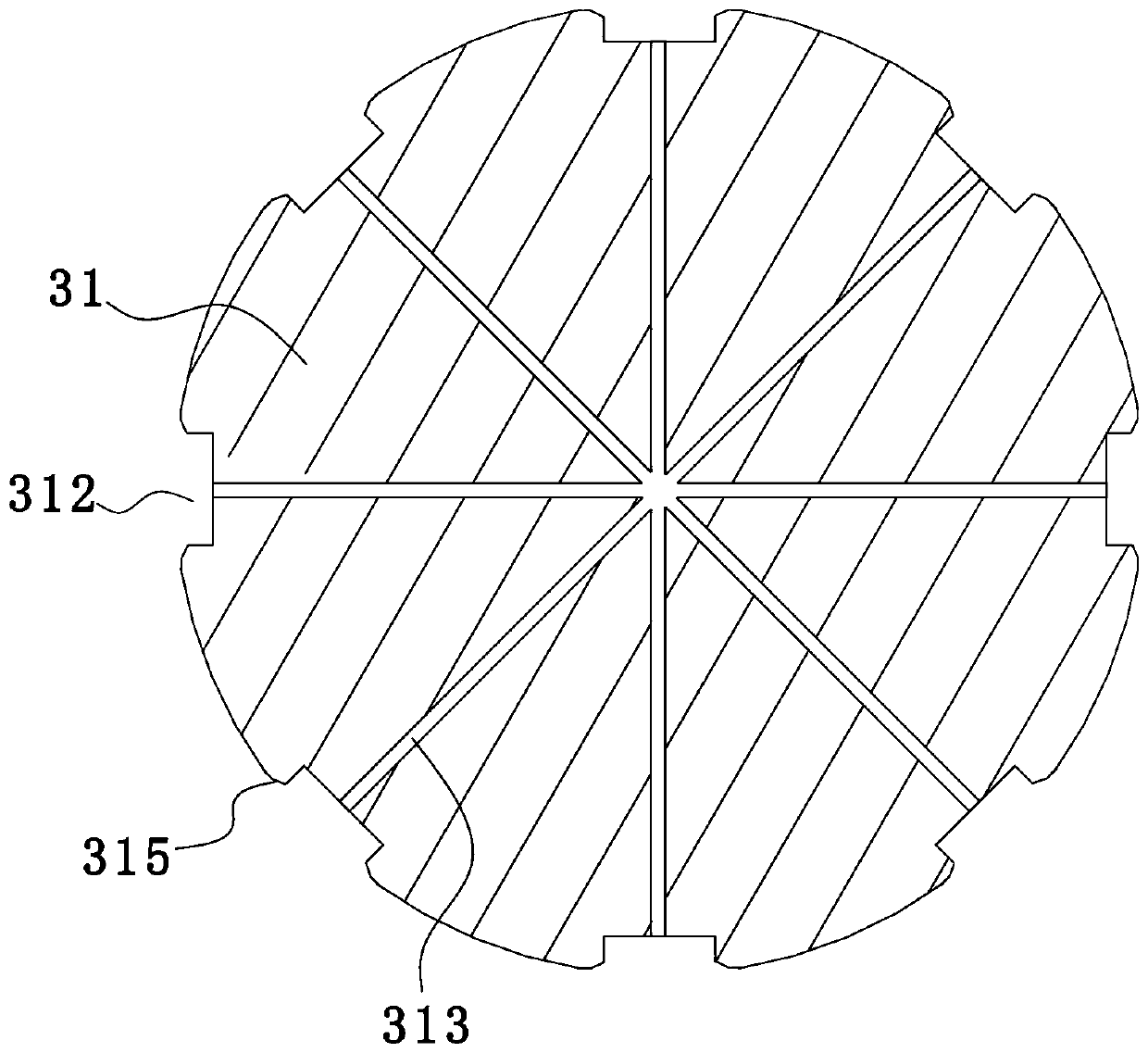

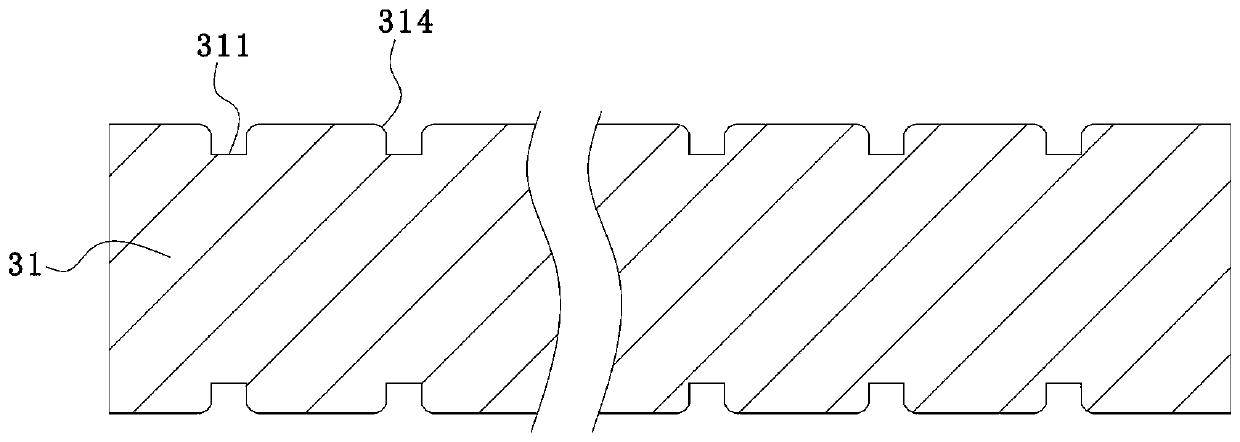

Squeeze bucket for collodion mop

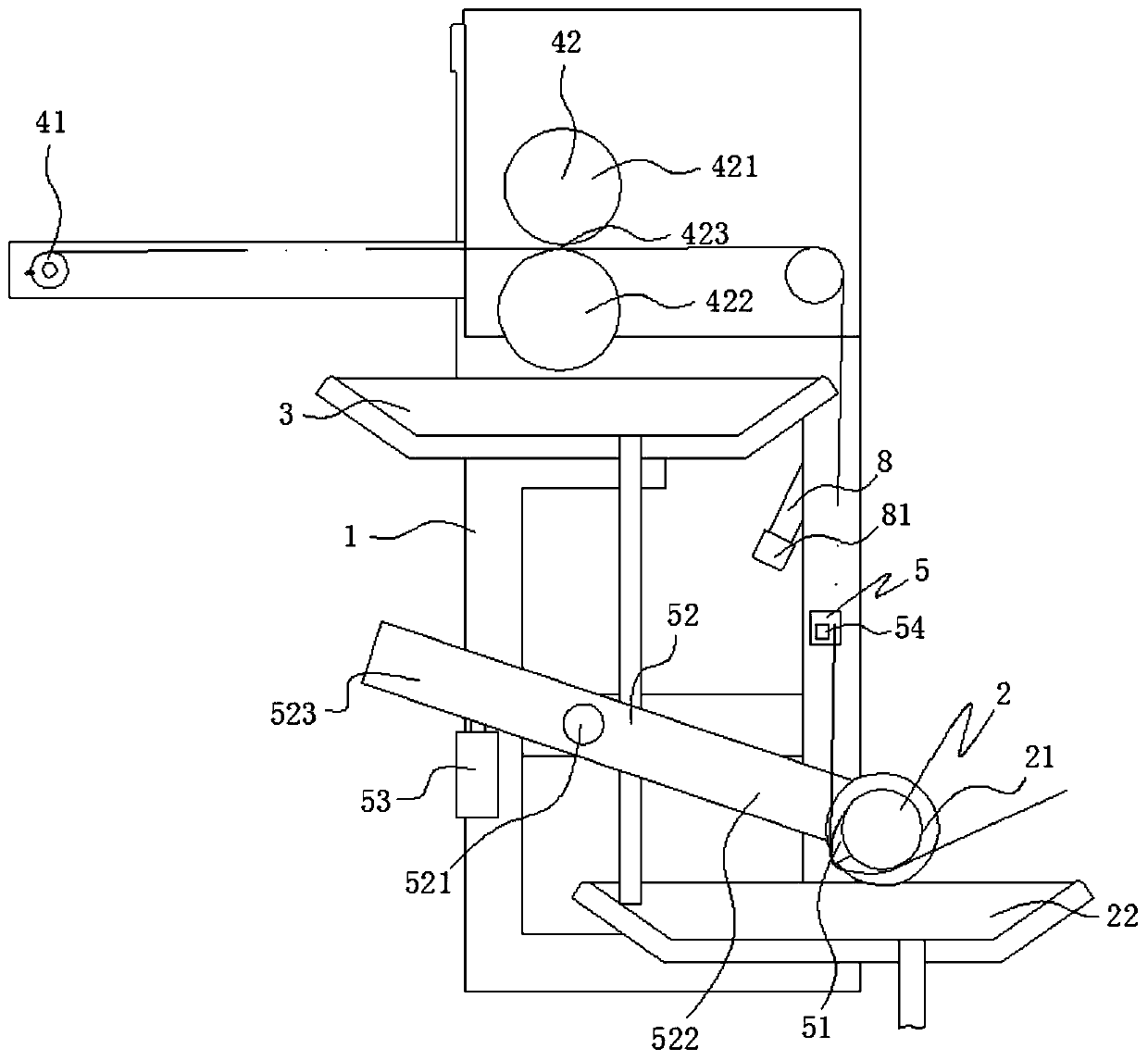

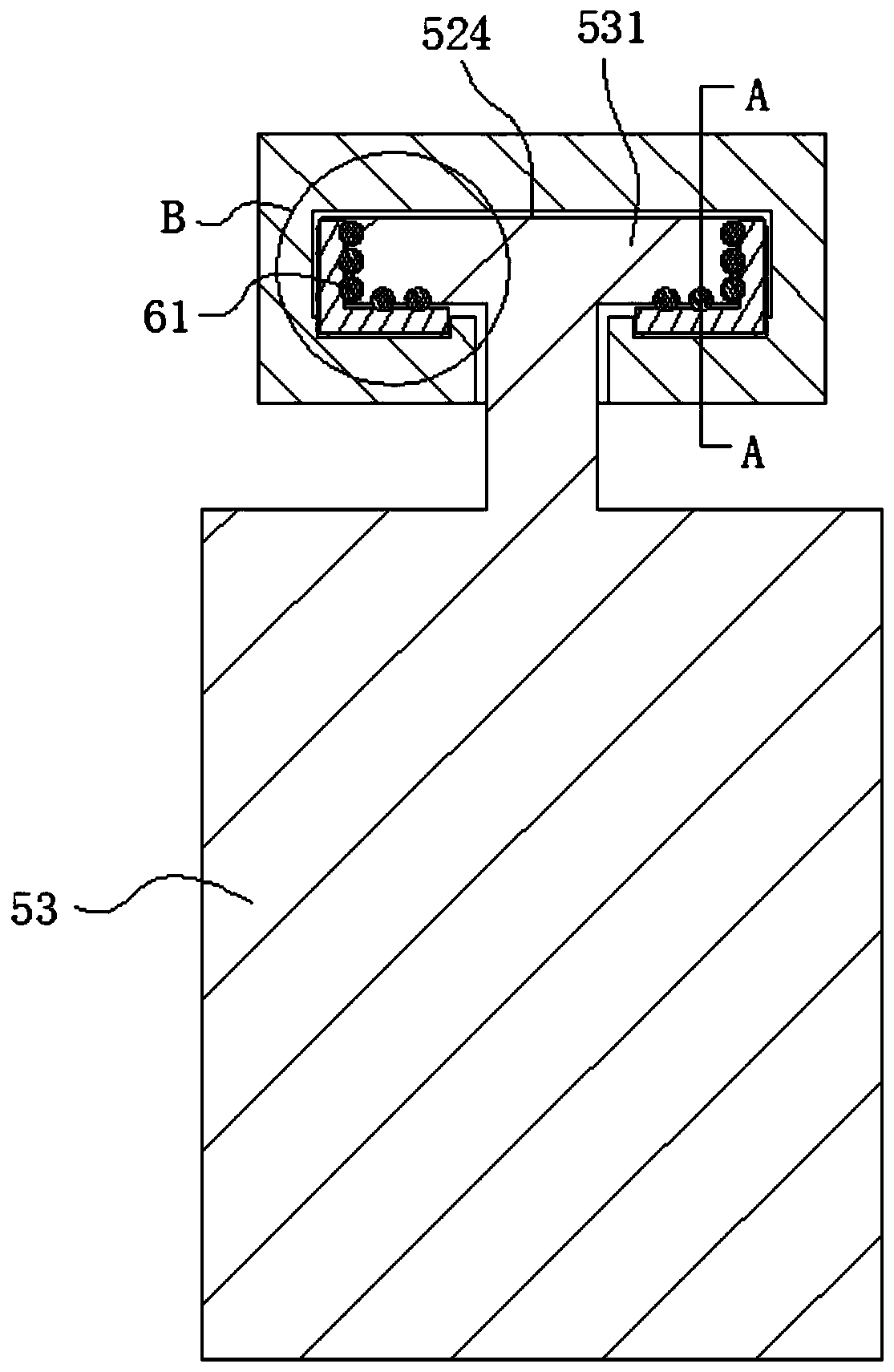

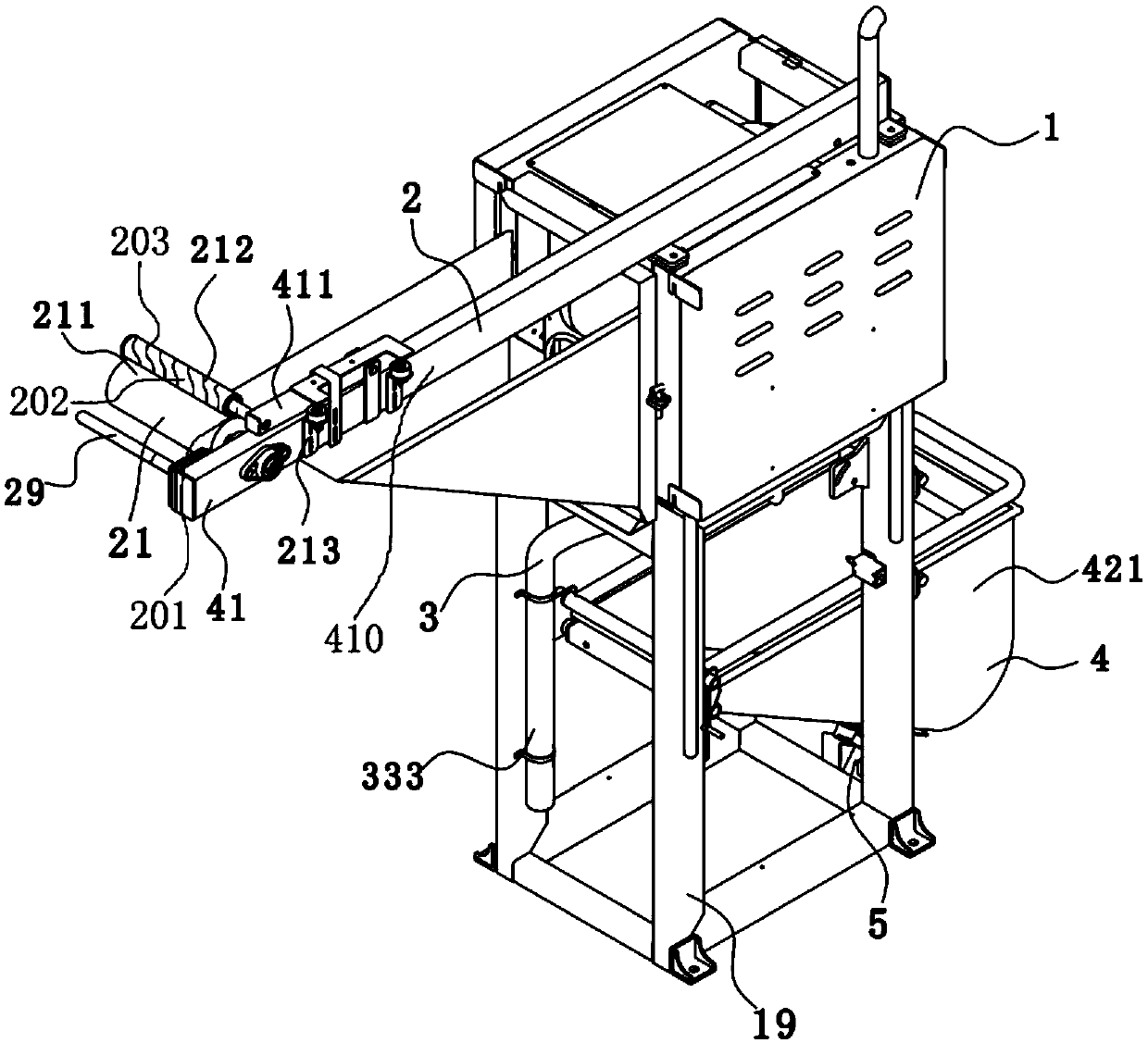

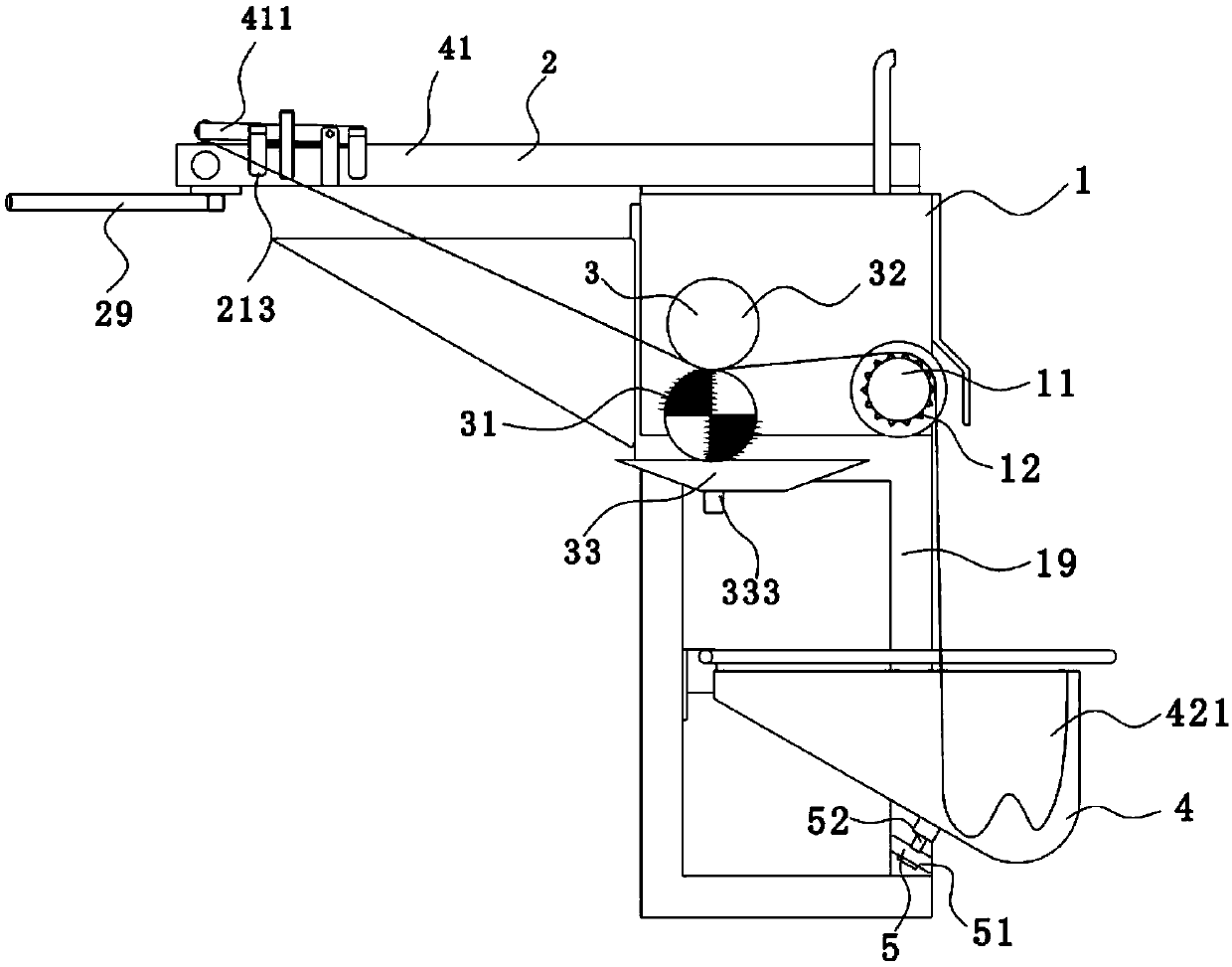

PendingCN109394106ASimple structureSqueeze water wellCarpet cleanersFloor cleanersEngineeringMechanical engineering

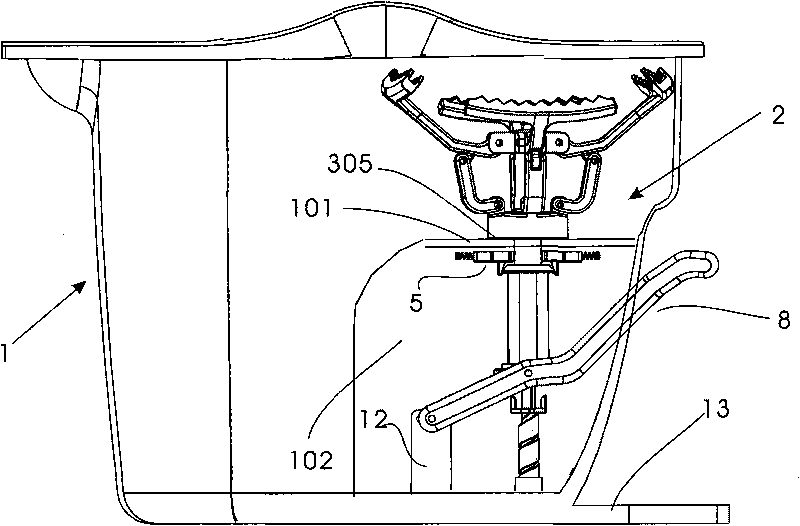

The invention relates to the field of mops, in particular to a squeeze bucket for a collodion mop. The squeeze bucket further comprises a pair of swing frames with the upper portions being hinged to the upper portions of a bucket body, a squeeze plate slidingly connected with the lower portions of the swing frames and counter-force supporting parts arranged at the upper portions of the swing frames; the bucket body is further provided with a guide part which cooperates with the squeeze plate and is used for guiding the squeeze plate to extrude a collodion head during the rotation of the swingframes. A user can drive the swing frames to rotate through a mop rod, and the squeeze plate is guided by the guide part to squeeze the collodion head along with the rotation of the swing frames to complete the squeeze. The length of the mop rod is long, so that only very little force is required for the user to drive the swing frames to rotate.

Owner:夏冬全

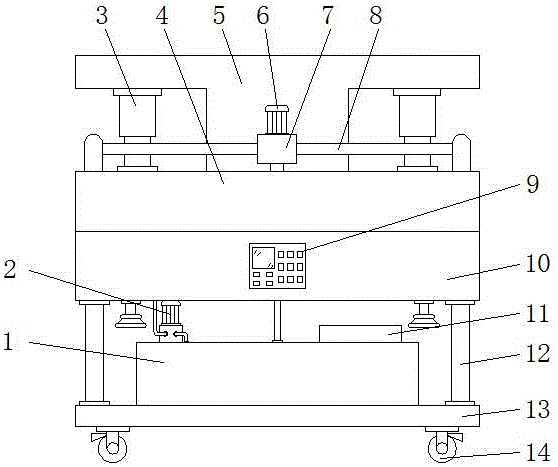

Dehydration device of garment fabric

ActiveCN108385312AAdjustable widthSmall residual moistureLiquid/gas/vapor removal by squeezing rollersTextile treatment carriersPulp and paper industryDehydration

The invention discloses a dehydration device of garment fabric. The dehydration device of the garment fabric comprises a machine frame, a first water squeezing roller, a water squeezing roller, a cloth guide roller and a driving part, wherein the first water squeezing roller and the second water squeezing roller are arranged on the machine frame; the cloth guide roller is matched with the fabric;the driving part is used for driving the cloth guide roller to rotate to drive the fabric to move; a water squeezing gap for the fabric to pass through is formed between the first water squeezing roller and the second water squeezing roller; a rotating piece and a transmission part are arranged on the machine frame; the transmission part is matched with the first water squeezing roller; and when the rotating piece rotates, the first water squeezing roller can be driven by the transmission part to move, so that the width of the water squeezing gap is adjusted. The width of the water squeezing gap can be adjusted, so that a water squeezing device adapts to water squeezing and process of the fabric with different thickness, materials and water-absorbing conditions without controlling the width of the water squeezing gap, the phenomenon of damage to the fabric caused by excessive squeezing is avoided, the water squeezing effect is good, the drying speed at the later stage is high and the processing efficiency is effectively improved.

Owner:中亨(绍兴)科技有限责任公司

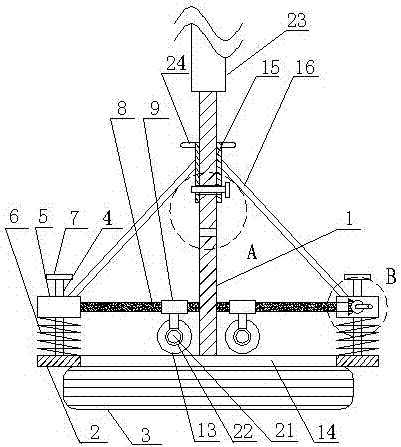

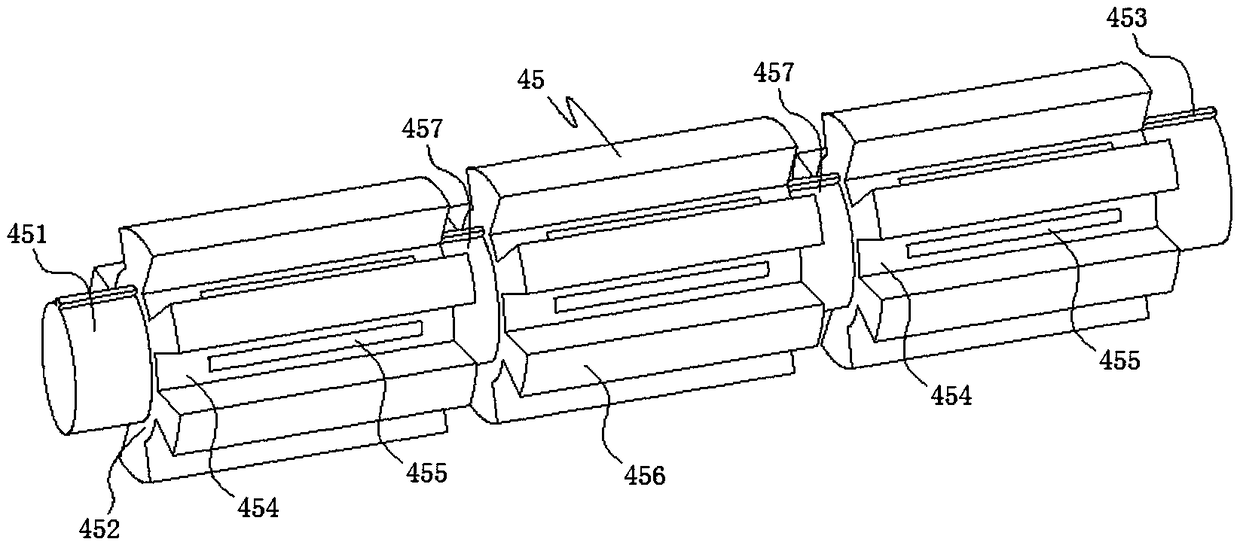

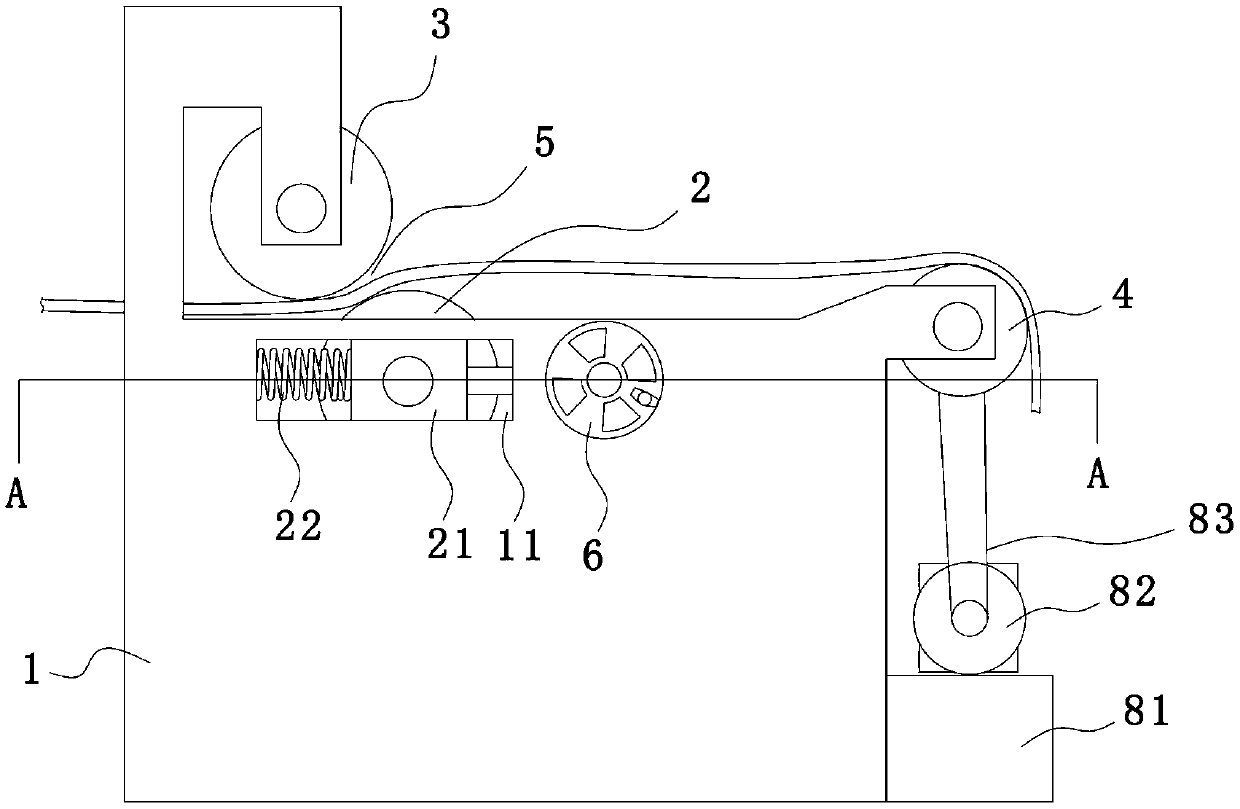

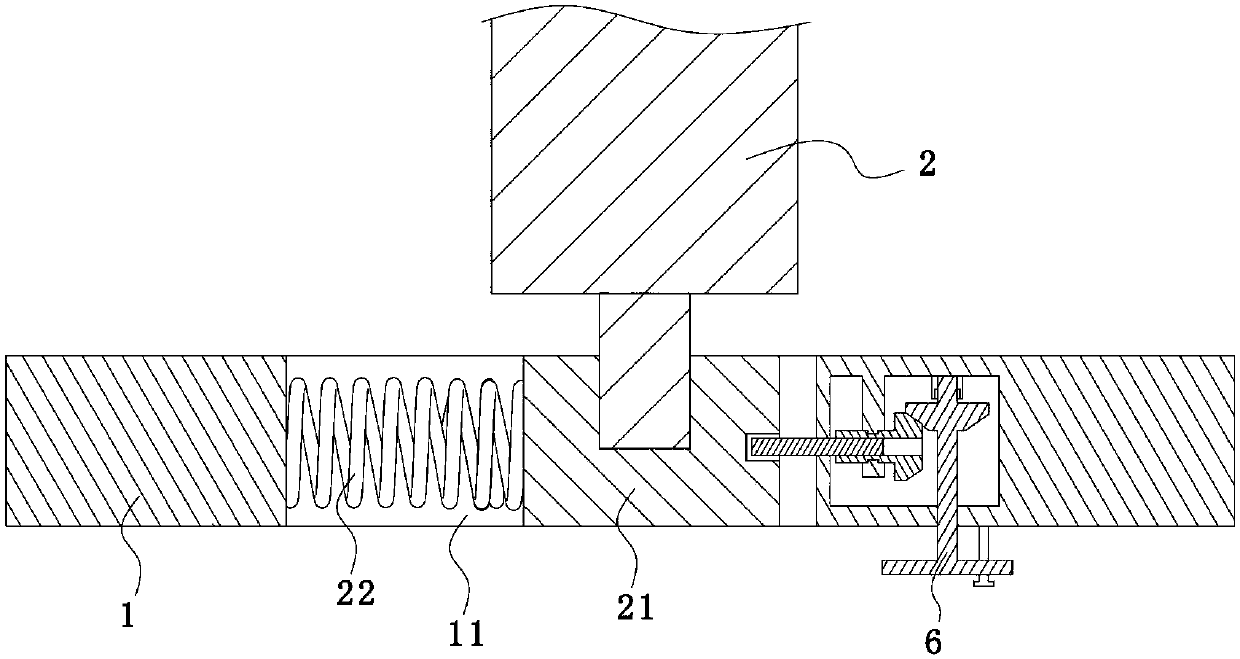

Hand-shaken water-squeezing collodion cotton mop

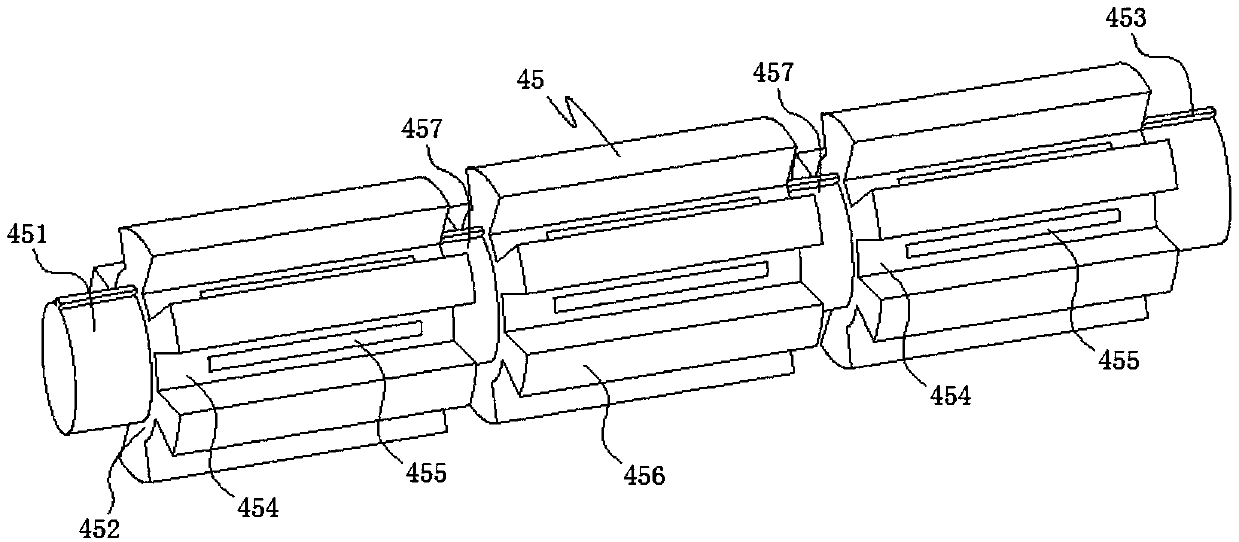

InactiveCN107510421ASqueeze water wellEasy to operateCarpet cleanersFloor cleanersAgricultural engineeringCollodion Cotton

The invention discloses a hand-cranked water-squeezing collodion mop, which comprises a mop rod, a fixed plate and a collodion mop head, the bottom end of the mop rod is connected to the fixed plate, the bottom of the fixed plate is provided with a collodion mop head, and both sides of the top of the fixed plate are Both guide rods are provided with sliders slidingly connected to the guide rods. A spring is provided between the sliders and the fixed plate. A limit block is provided at the top of the guide rods. A rotating shaft is connected between the sliders on the two guide rods. There are two moving blocks threadedly connected, and the two moving blocks are respectively located on both sides of the mop rod, and are opposite to the threaded direction of the rotating shaft. One end of the rotating shaft is connected with a tapered tooth A, and the corresponding slider at the end of the rotating shaft is equipped with a tapered tooth. B, the conical tooth A and the conical tooth B are meshed with each other, the conical tooth B is connected with the rocker on the outside of the slider through the connecting rod, the bottom of the two moving blocks is connected with the pressure wheel, and the fixed plate is equipped with the pressure wheel There are pressure grooves that cooperate with each other, and a slide block lifting adjustment mechanism is arranged above the mop rod.

Owner:SUQIAN JIAHE PLASTIC METAL PROD

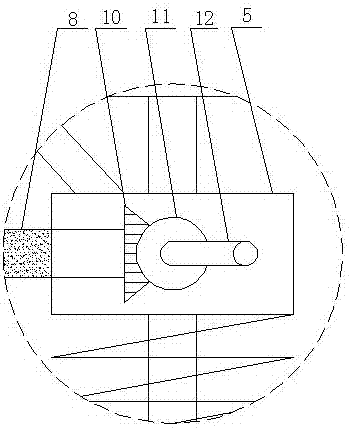

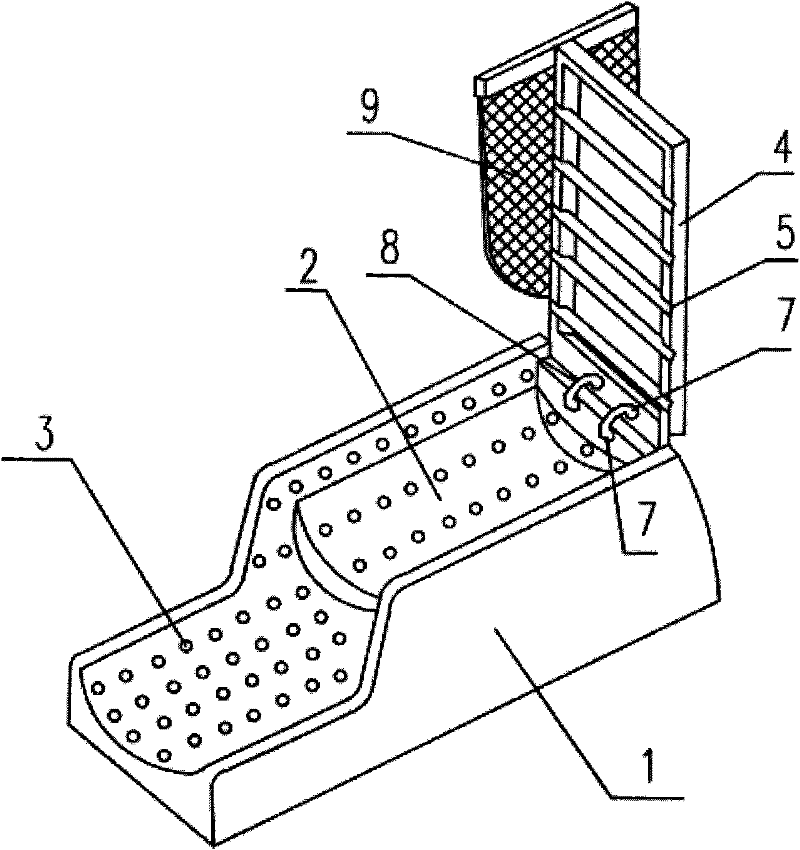

Mop wringing device

InactiveCN101999873ATo achieve the purpose of not getting wetSqueeze water wellCarpet cleanersFloor cleanersEngineering

The invention discloses a mop wringing device, which comprises a water barrel, wherein a wringing barrel is connected with the outer surface on one side of the water barrel; the wringing barrel is arranged above the water barrel; a plurality of drain holes are formed at the bottom of the wringing barrel; the outside wall of the wringing barrel is moveably connected with a rocker consisting of a transverse shaft and a vertical handle; the transverse shaft of the rocker is penetrated through one outside wall of the wringing barrel and moveably connected with another outside wall of the wringing barrel; the transverse shaft is fixedly connected with a propelling device which is connected with a push plate for squeezing a mop; and the push plate is placed in the wringing barrel. The mop wringing device has the advantages of simple structure, convenience, cleanness and sanitation.

Owner:NANTONG ZHONGLIAN S&T SERVICE

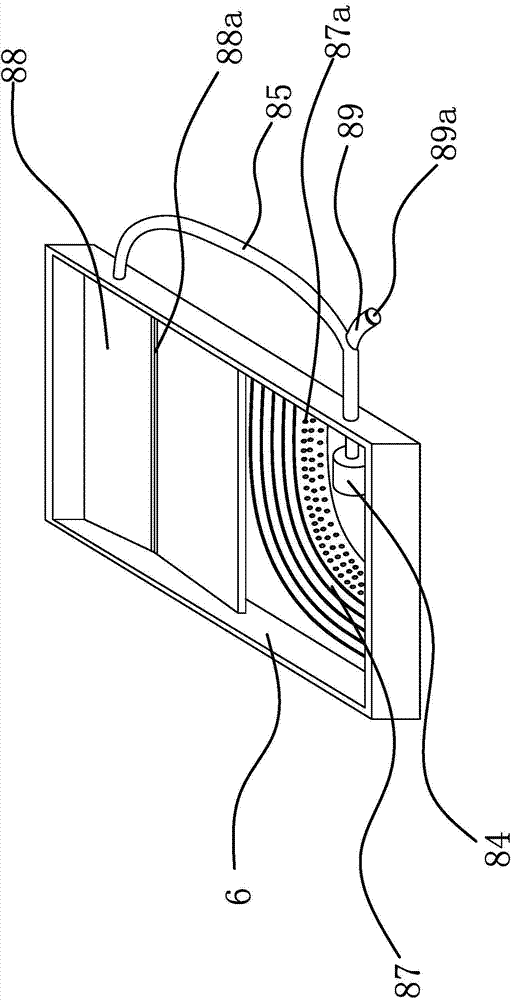

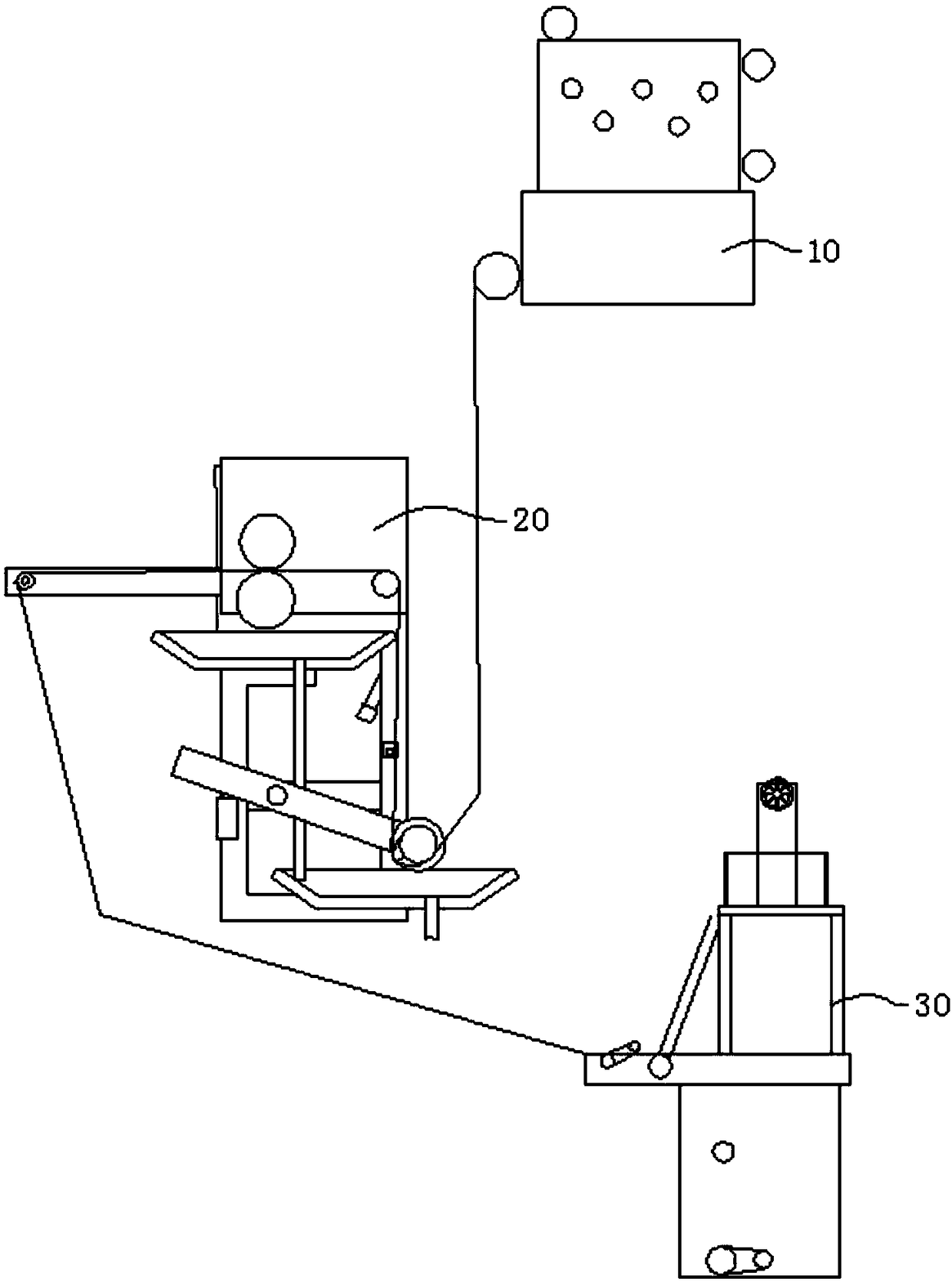

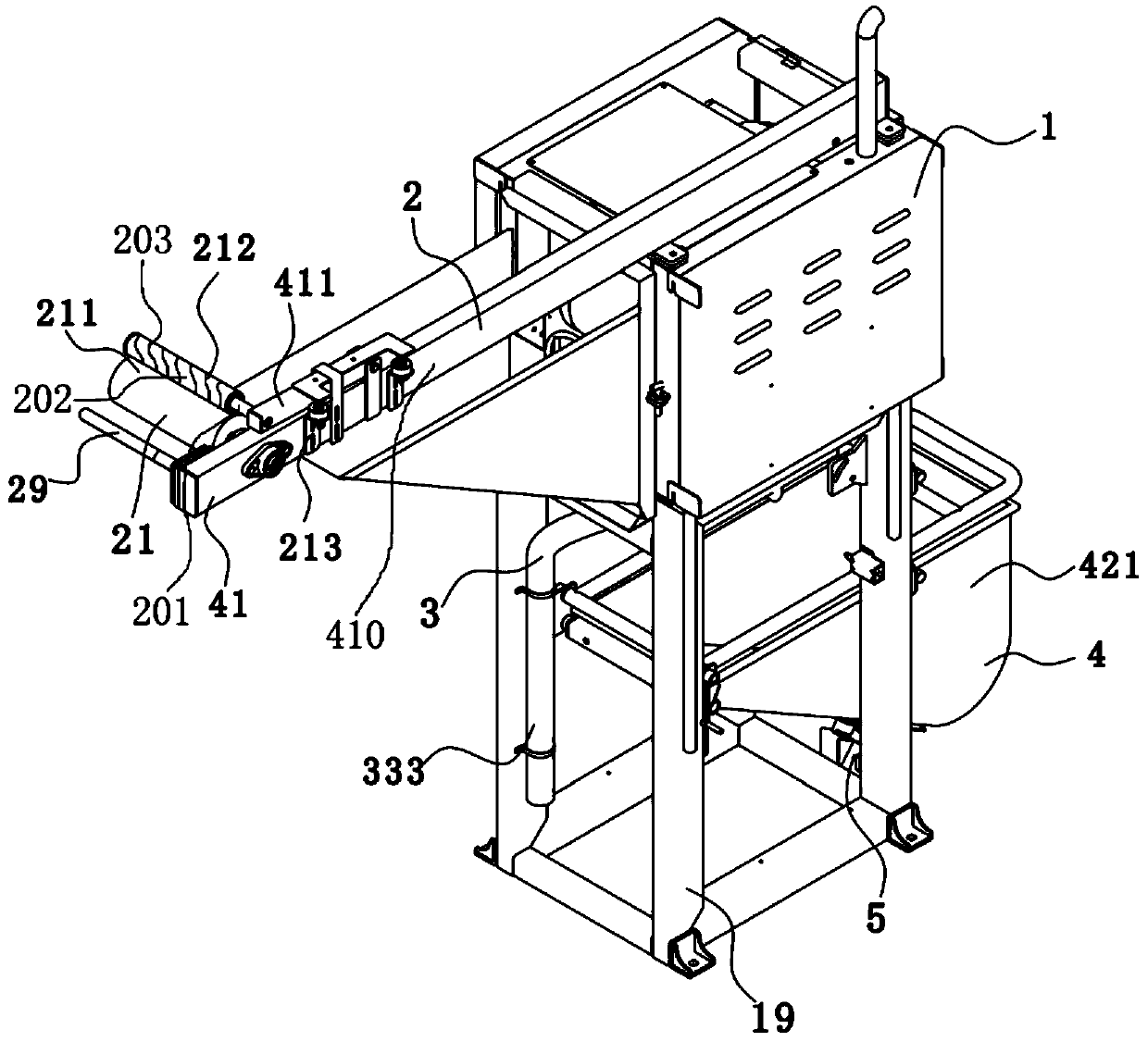

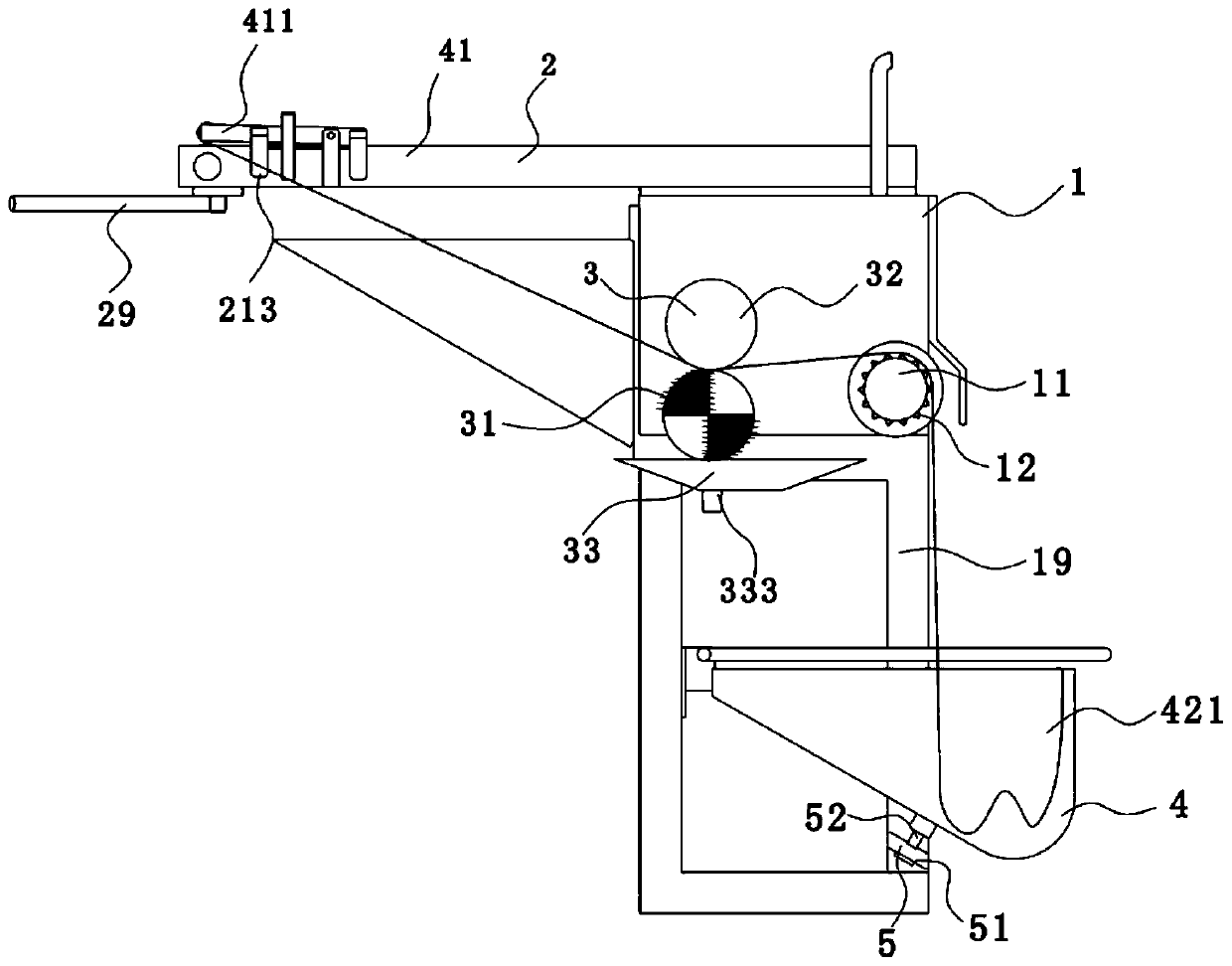

Printing and dyeing cloth water squeezing device

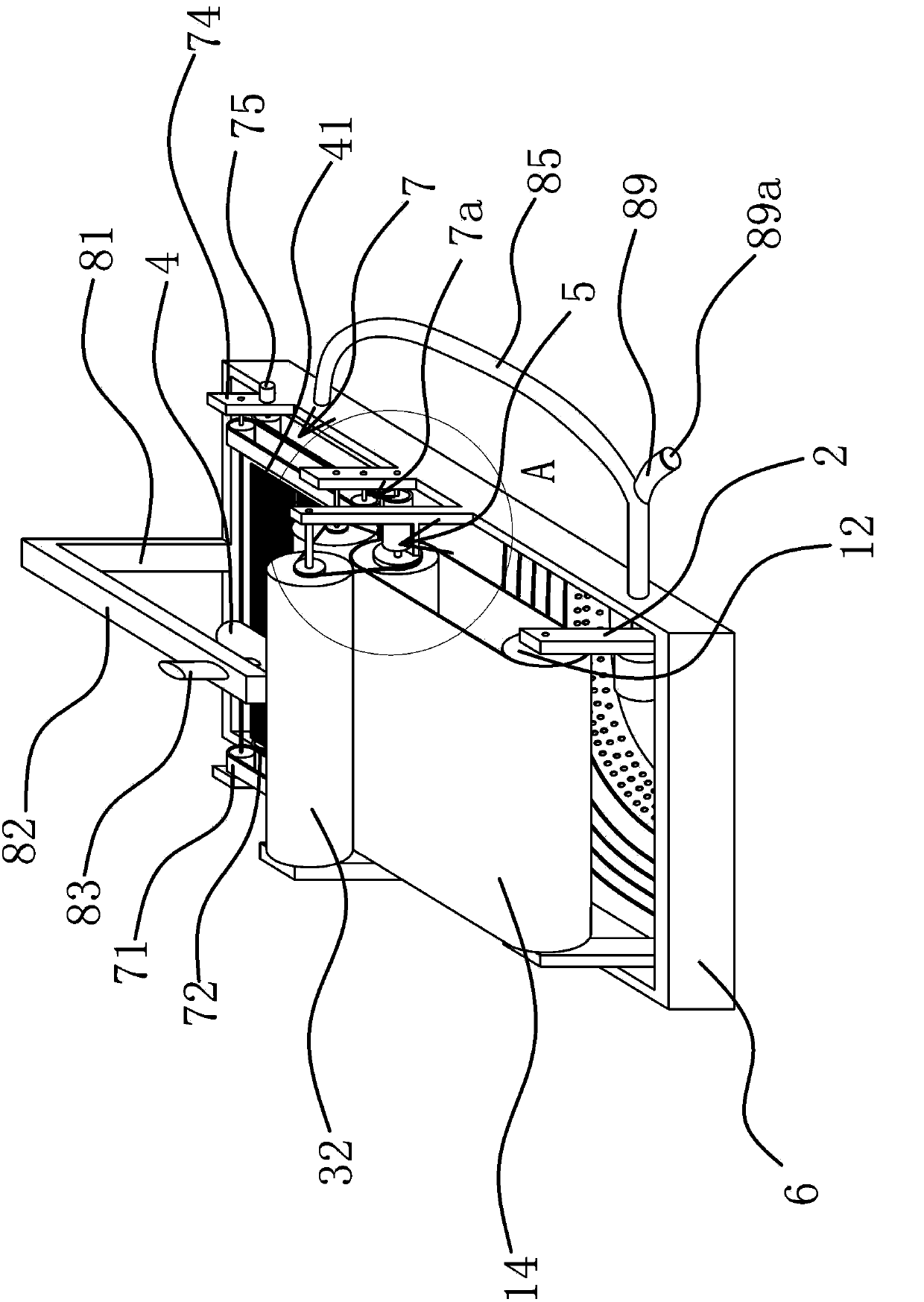

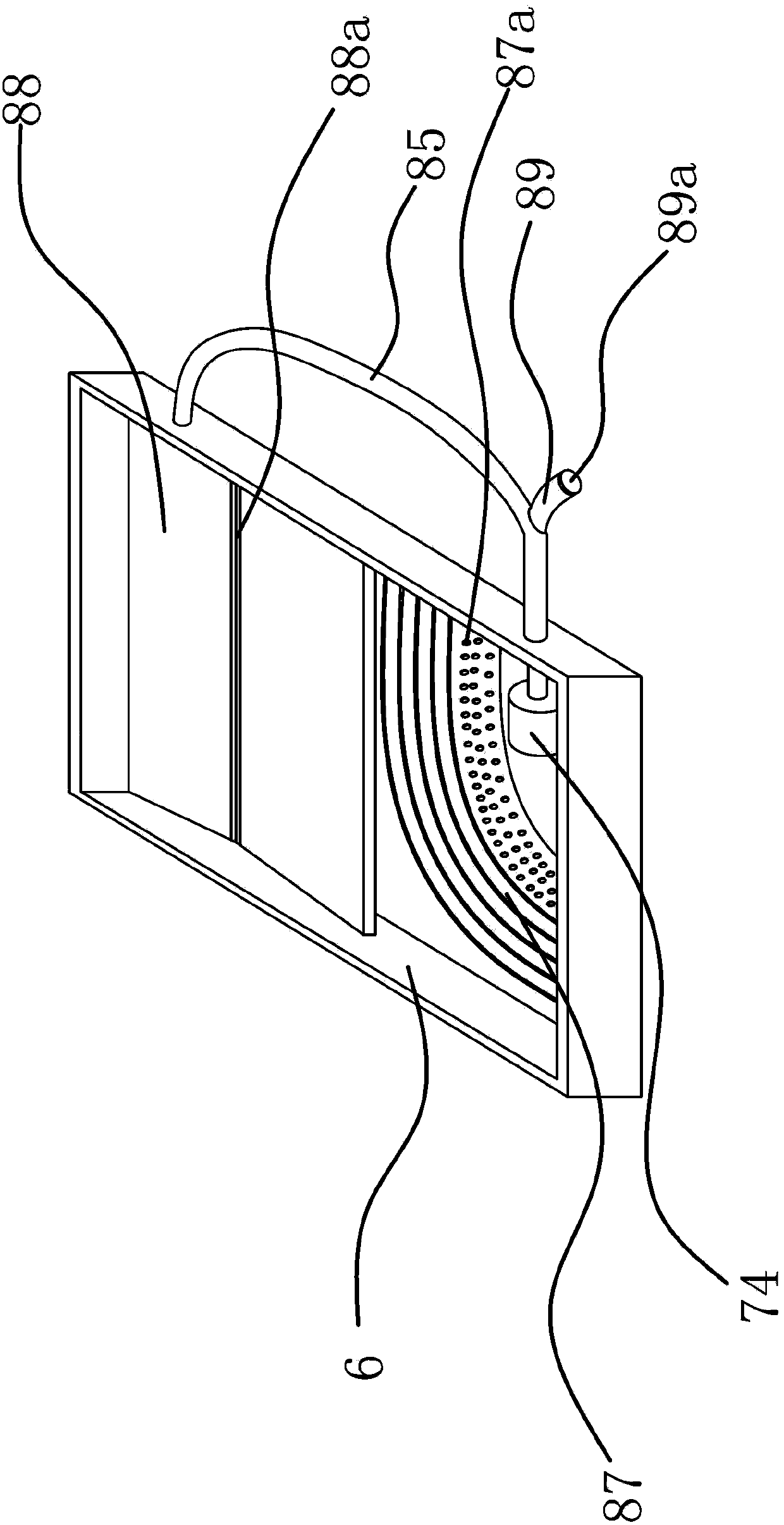

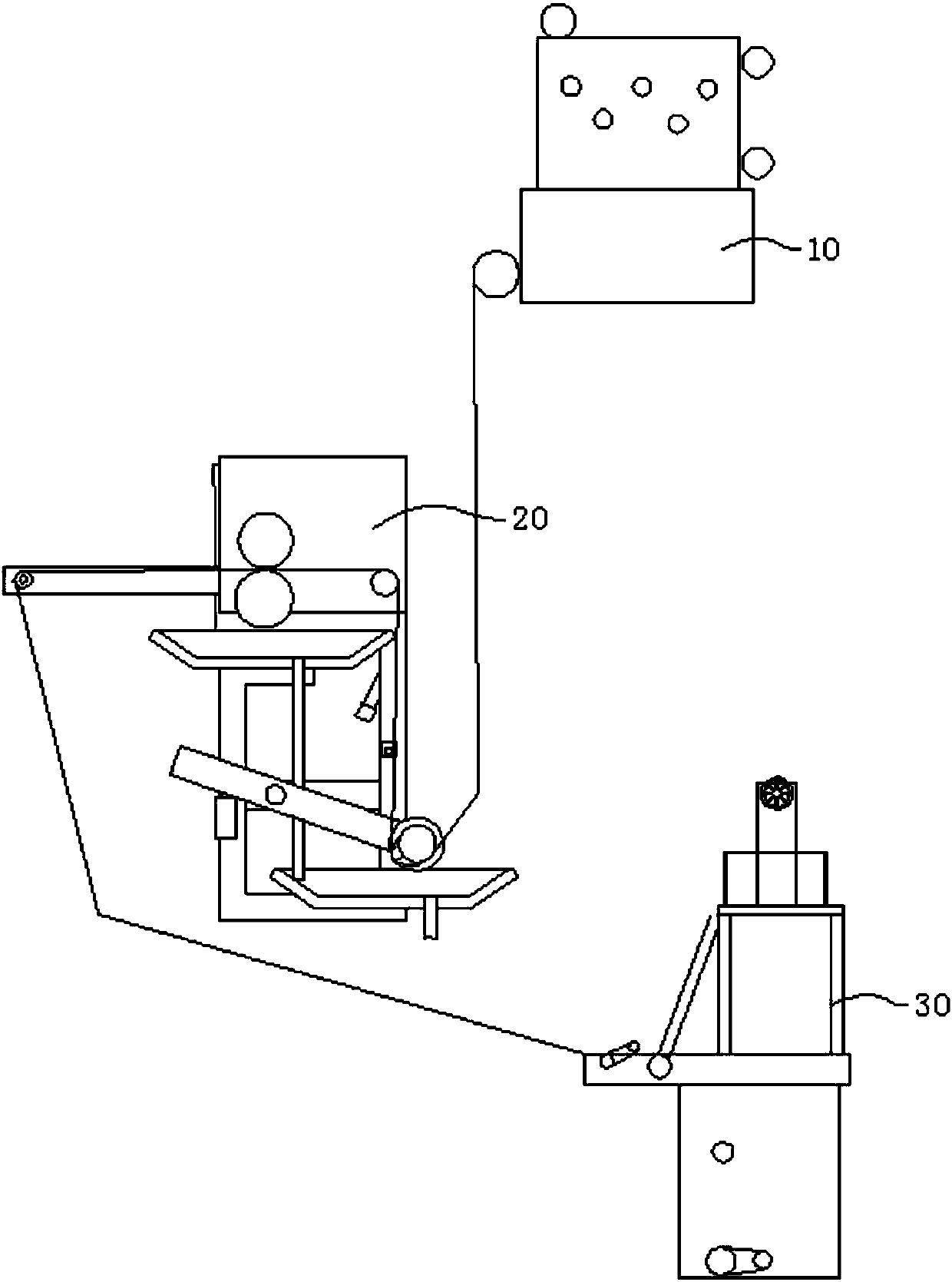

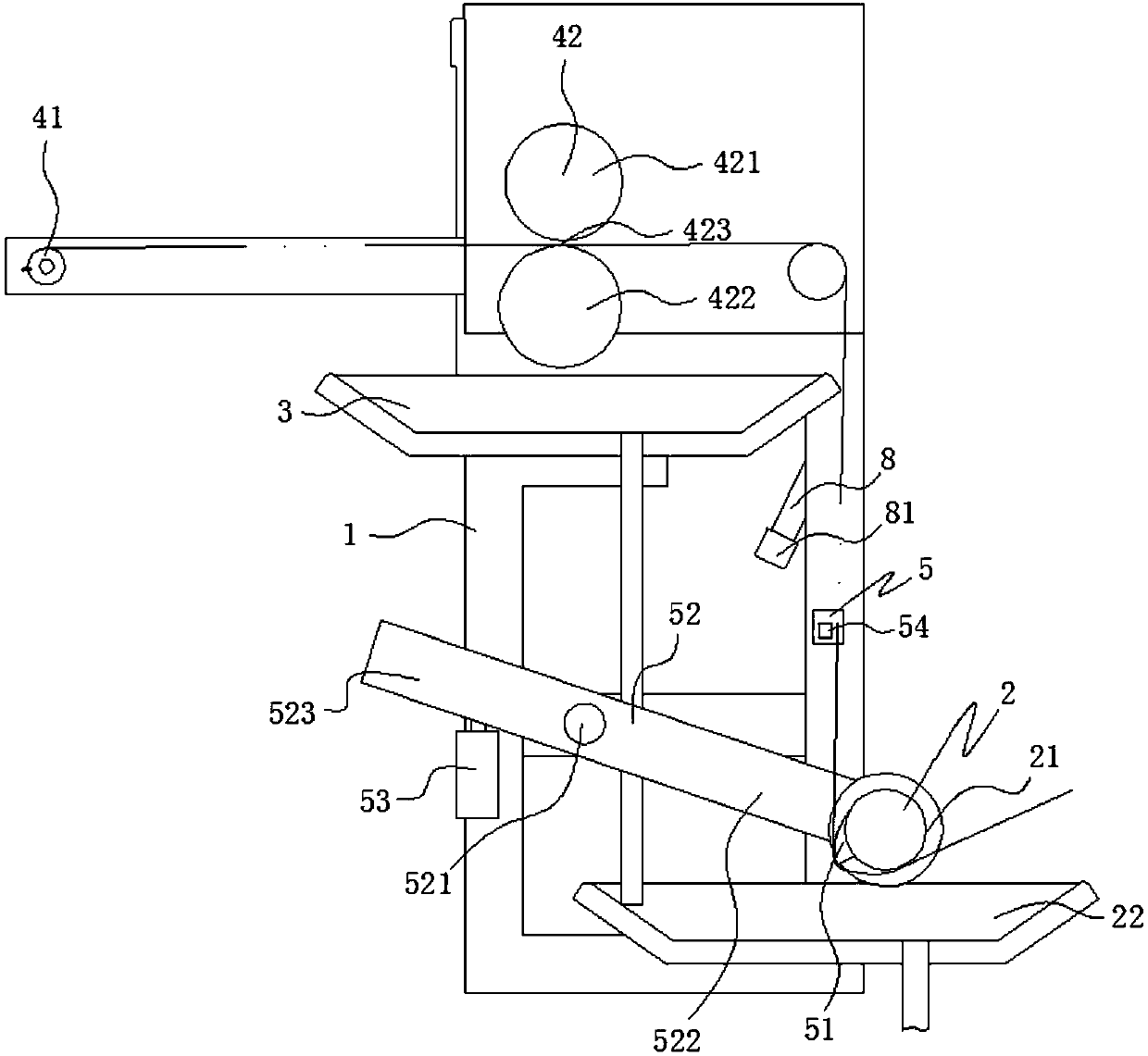

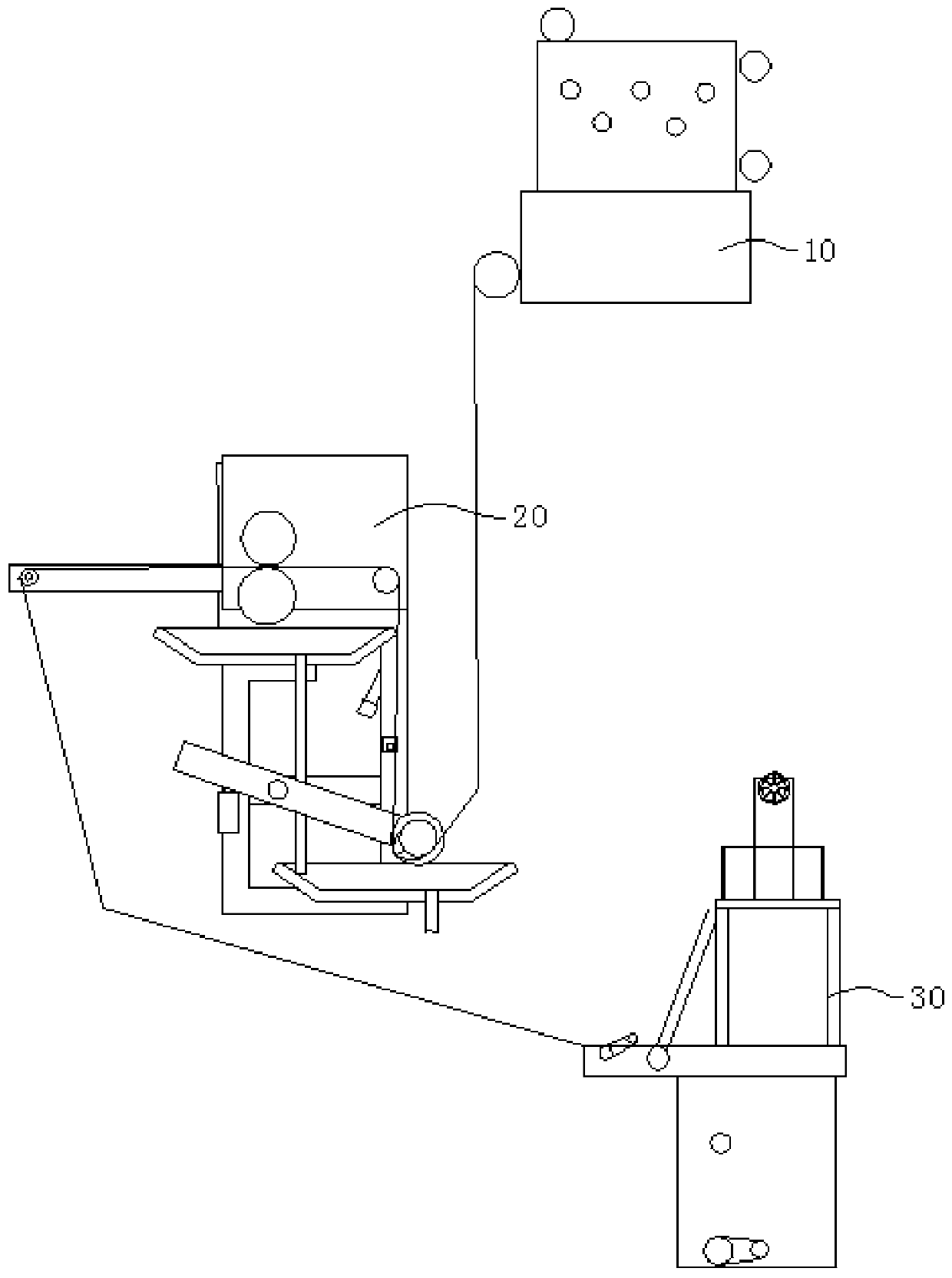

ActiveCN108221233AAdjustable squeeze effectGuaranteed smoothLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsEngineeringMechanical engineering

The invention discloses a printing and dyeing cloth water squeezing device. The device comprises a supporting frame, a first cloth pressing mechanism and a second cloth pressing mechanism; the first cloth pressing mechanism comprises a cloth feeding assembly for initially squeezing water from cloth and a cloth expanding assembly which cooperates with the cloth feeding assembly; the second cloth pressing mechanism includes a drive roller assembly, a driven roller assembly and a driving member for driving rotation of the drive roller assembly, and the drive roller assembly and the driven rollerassembly cooperate to each other for squeezing water from the cloth for the second time.

Owner:佛山市南海永其祥织染有限公司

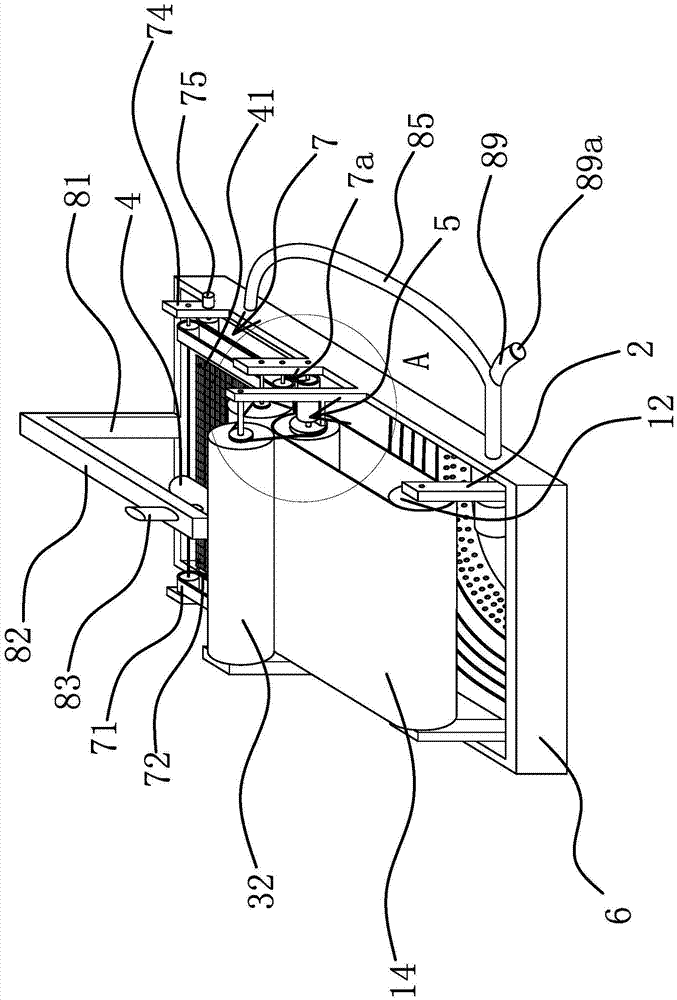

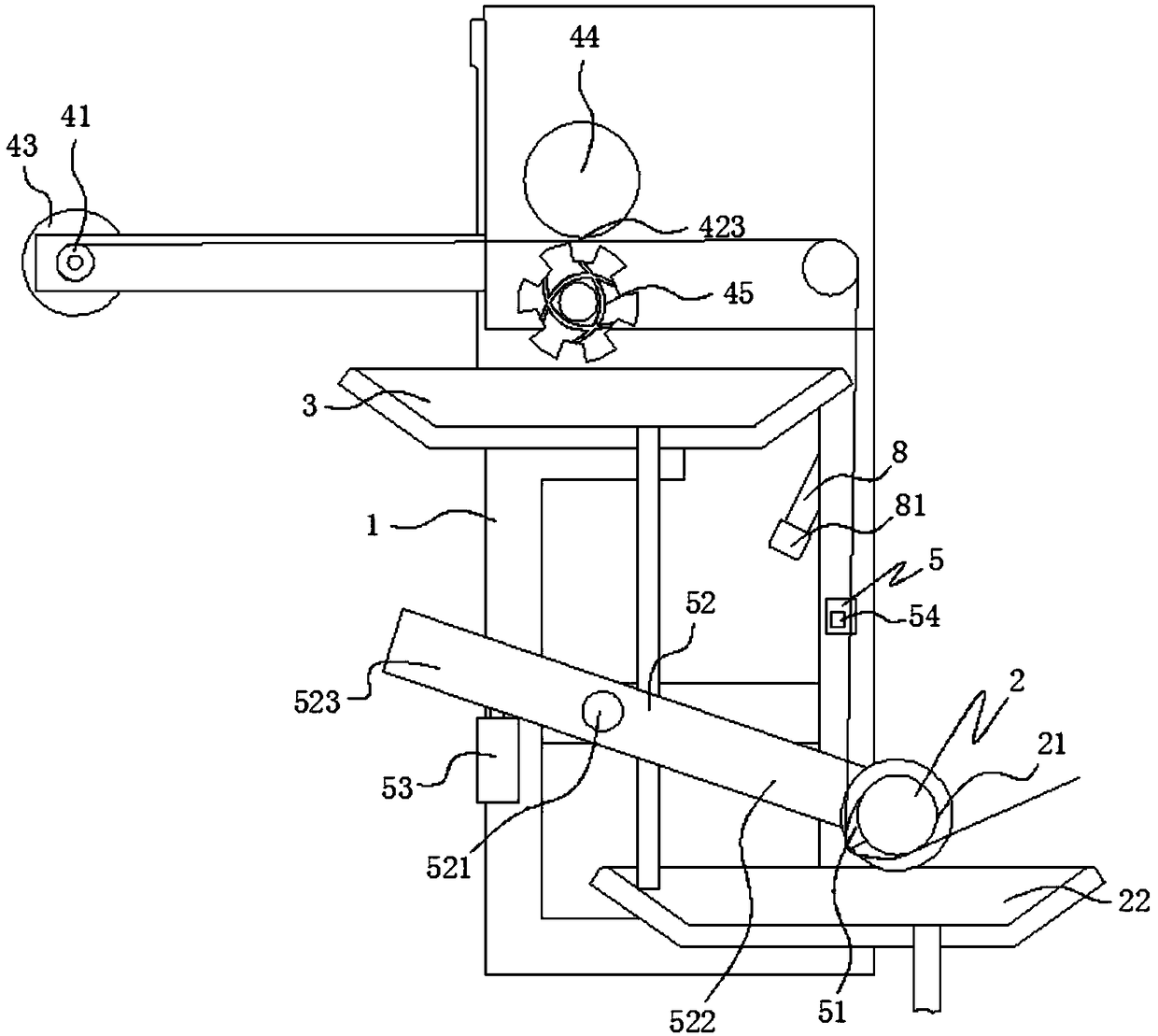

A system for fabric printing and dyeing

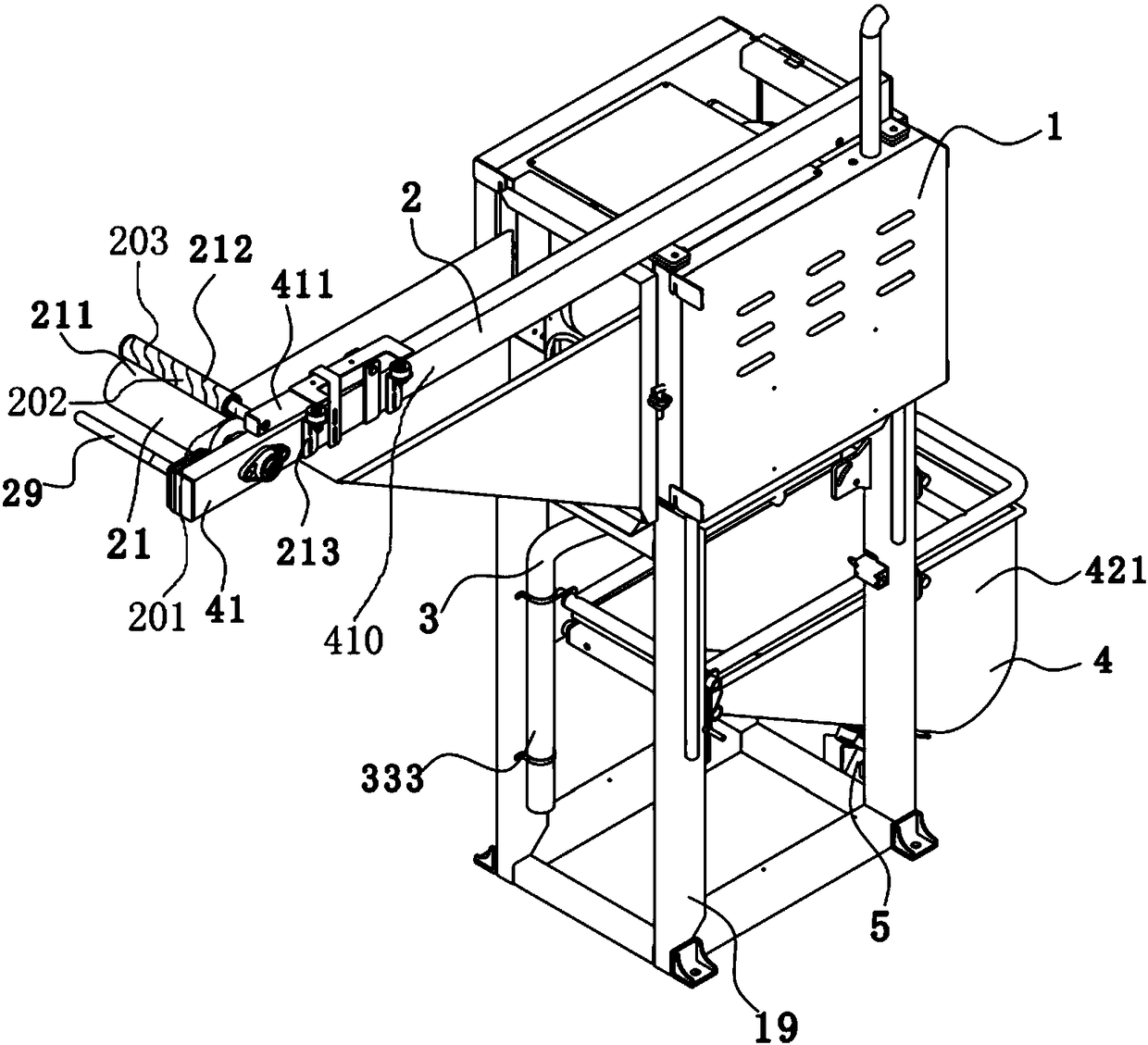

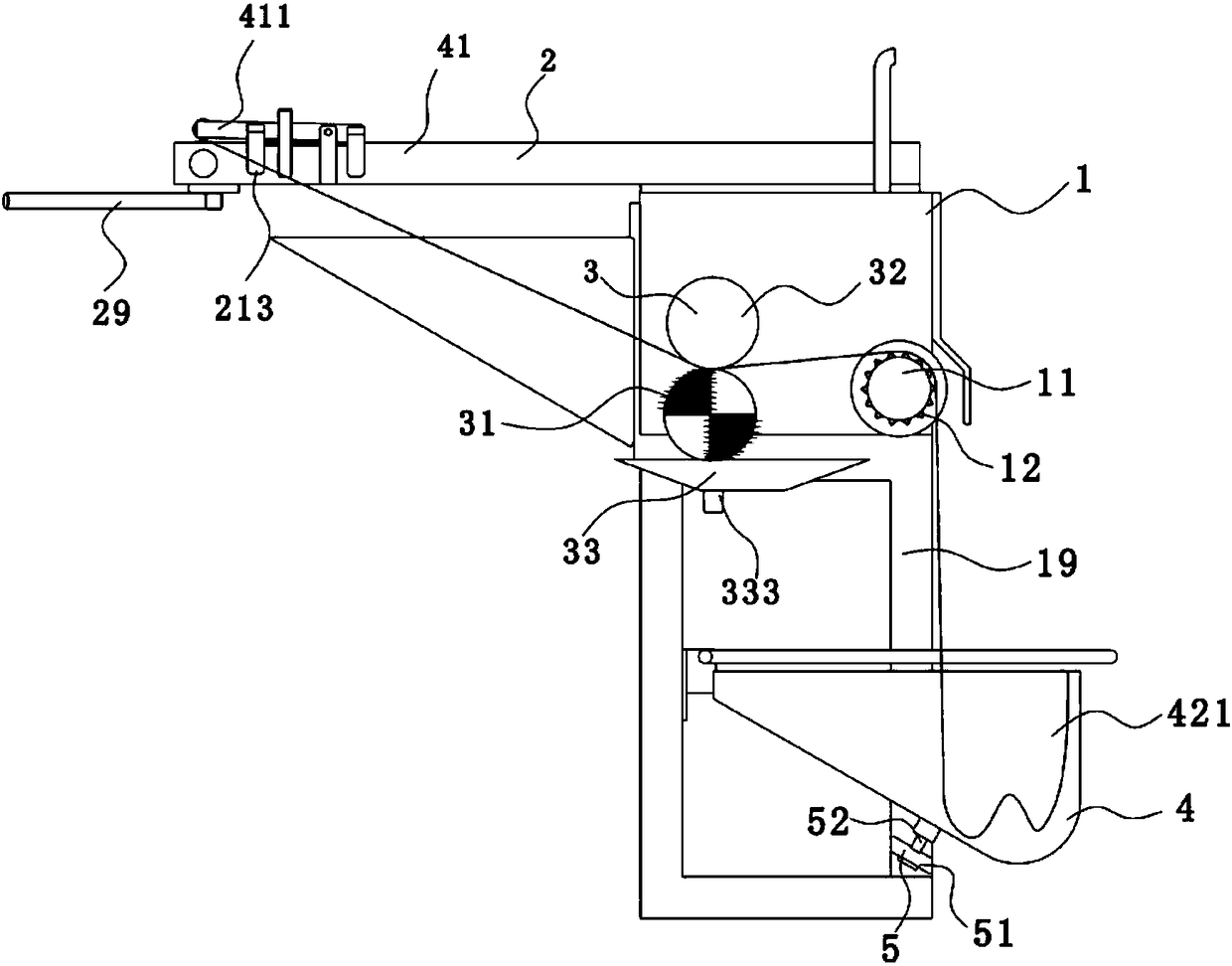

ActiveCN108035098BAvoid unexpandableAvoid drippingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsActive componentPulp and paper industry

The invention discloses a system used for printing and dyeing fabric. The system include a dyeing unit, a dewatering unit and a scutching unit which are arrayed in sequence; the dewatering unit includes a frame body, a dewatering device arranged on the frame body, a cloth tensioning device and a water containing device matched with the dewatering device; the dewatering device includes an active component, a dewatering component and a driving component used for driving the active component to rotate; the dewatering component comprises an upper dewatering roller and a lower dewatering roller, and a dewatering gap is formed between the upper and lower dewatering rollers; a cloth knotting detection device is arranged on the frame body and can control the driving component to stop running whenconveyed cloth is knotted or twined. Through the dewatering device, the printed and dyed cloth is extruded and dewatered, and the situation that water drops all around the place during scutching can be avoided.

Owner:绍兴圣苗针纺有限公司

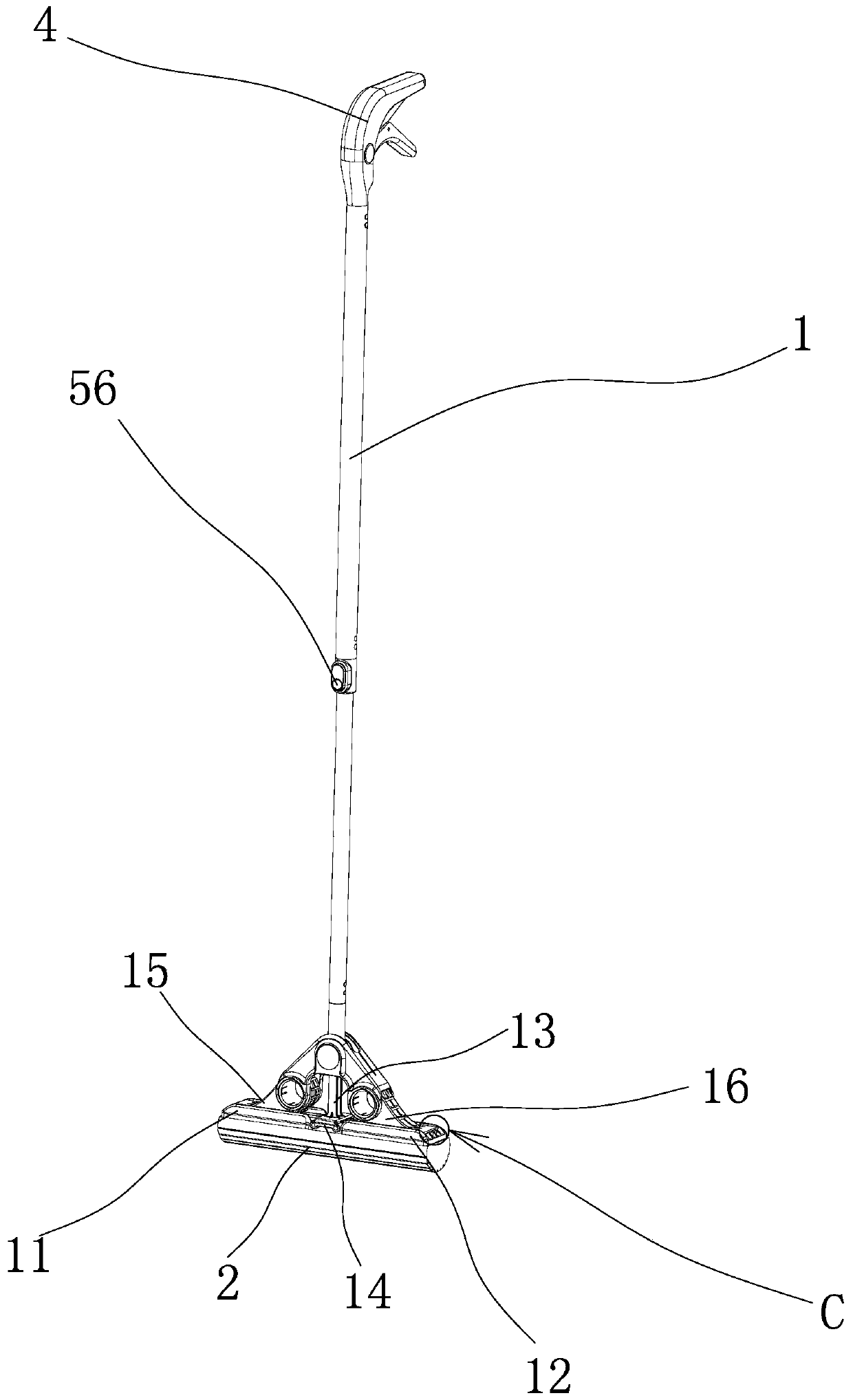

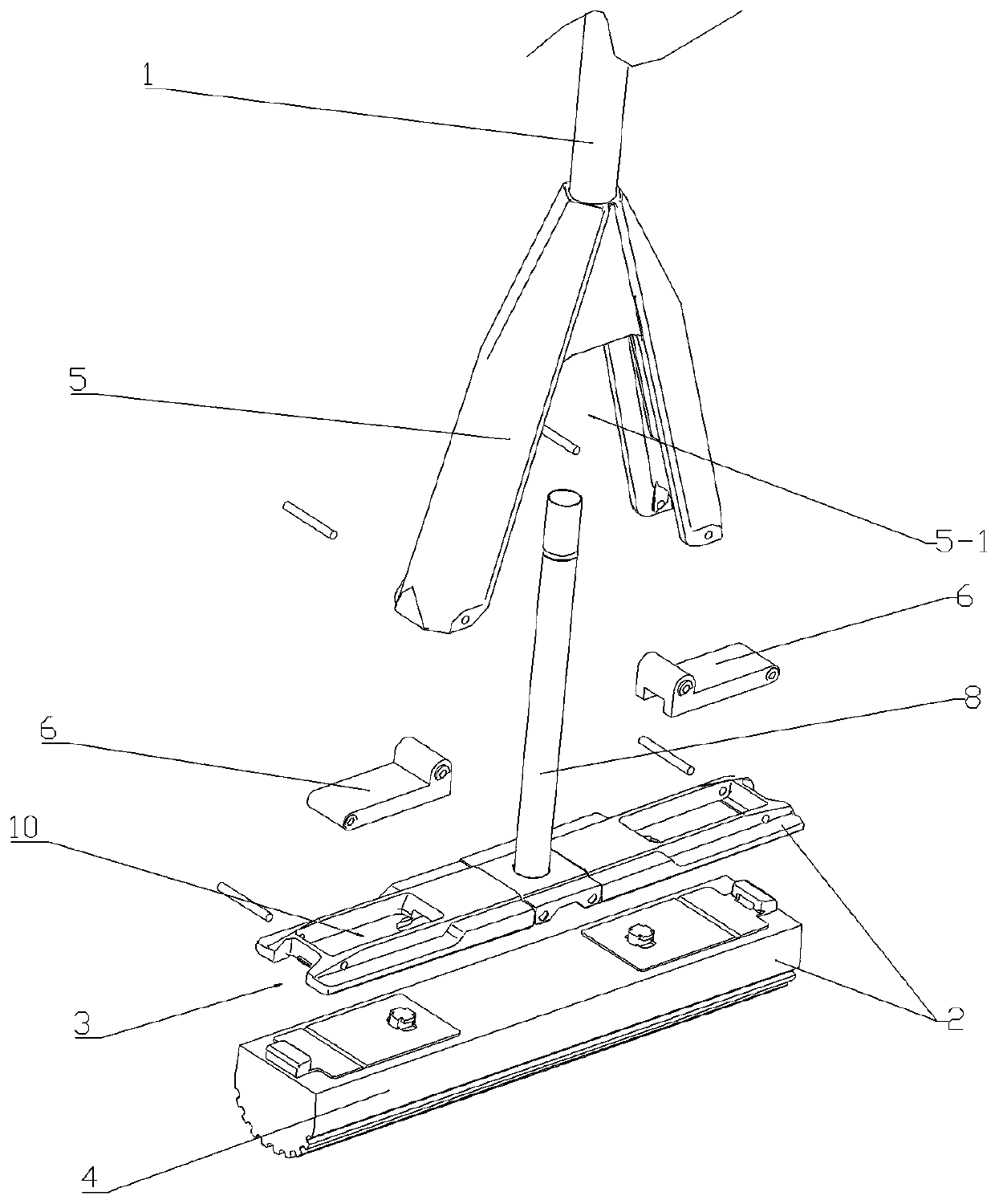

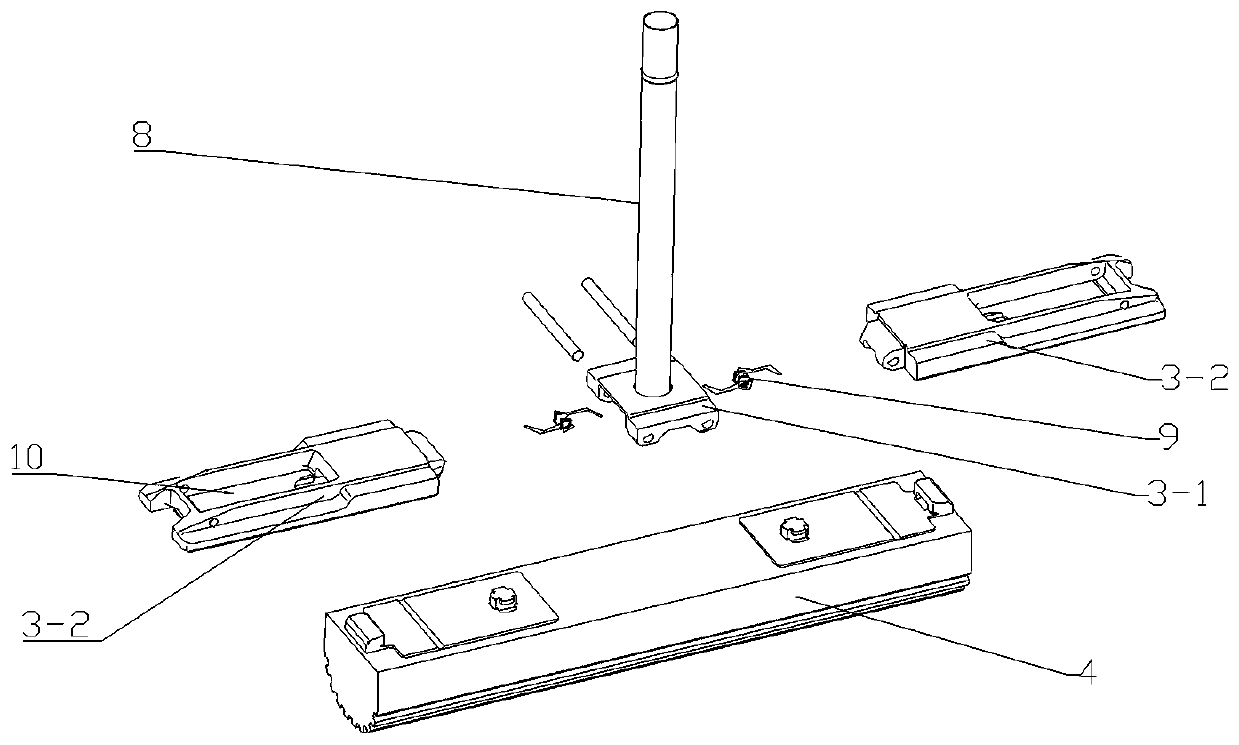

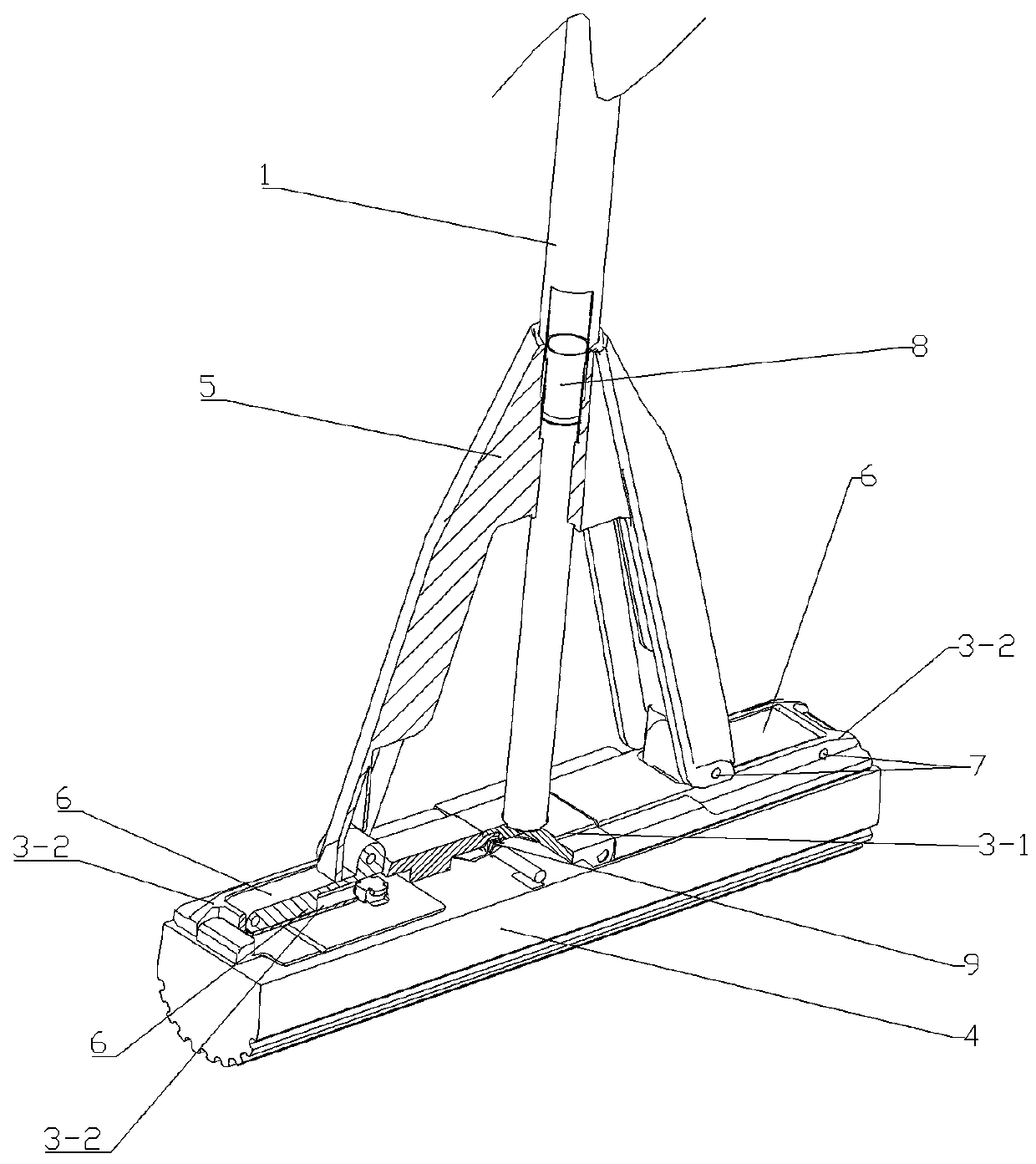

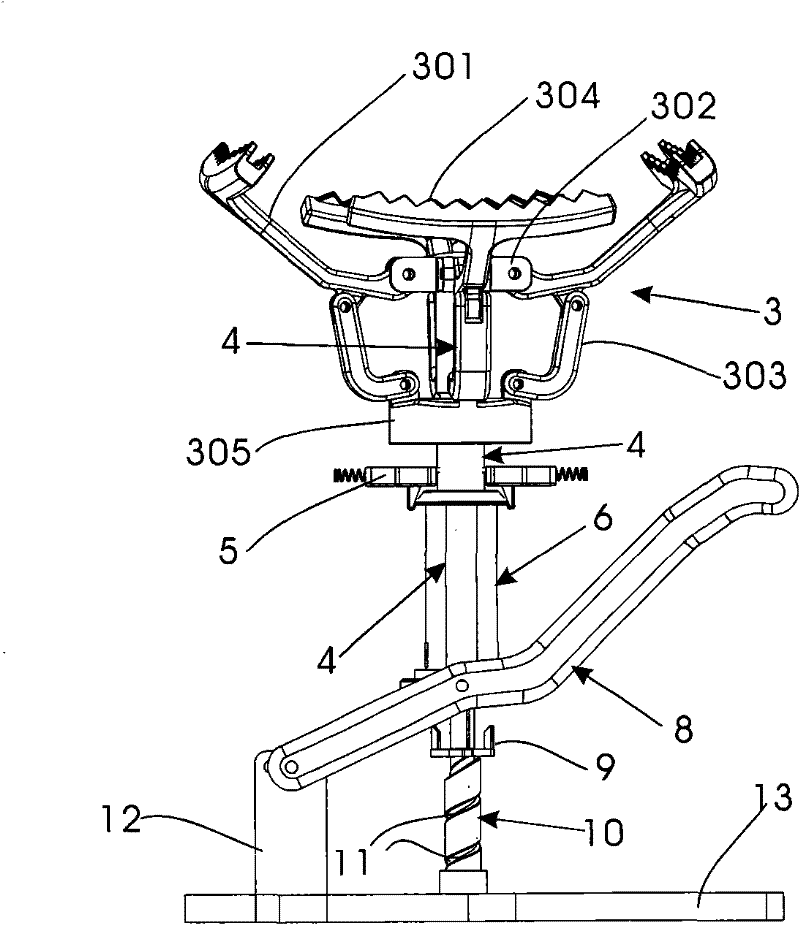

Telescopic folding wringing collodion mop

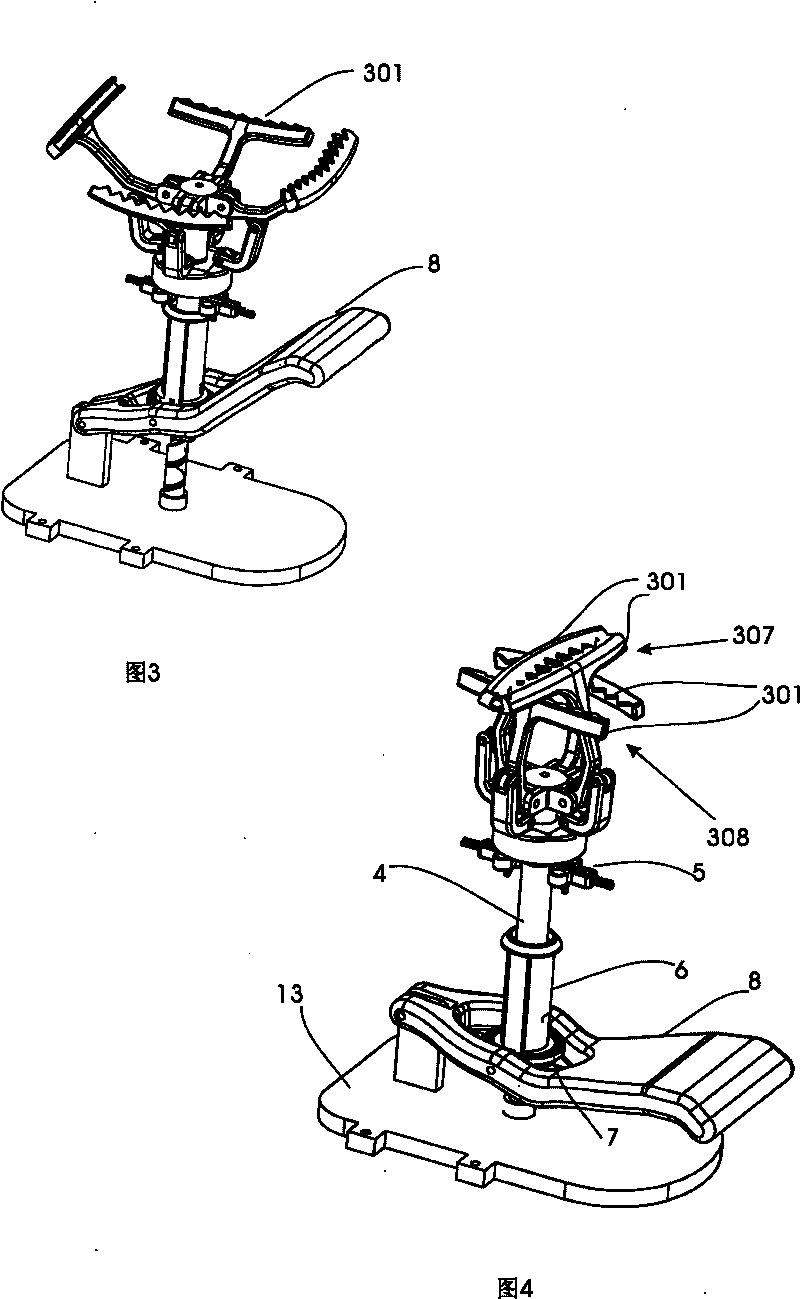

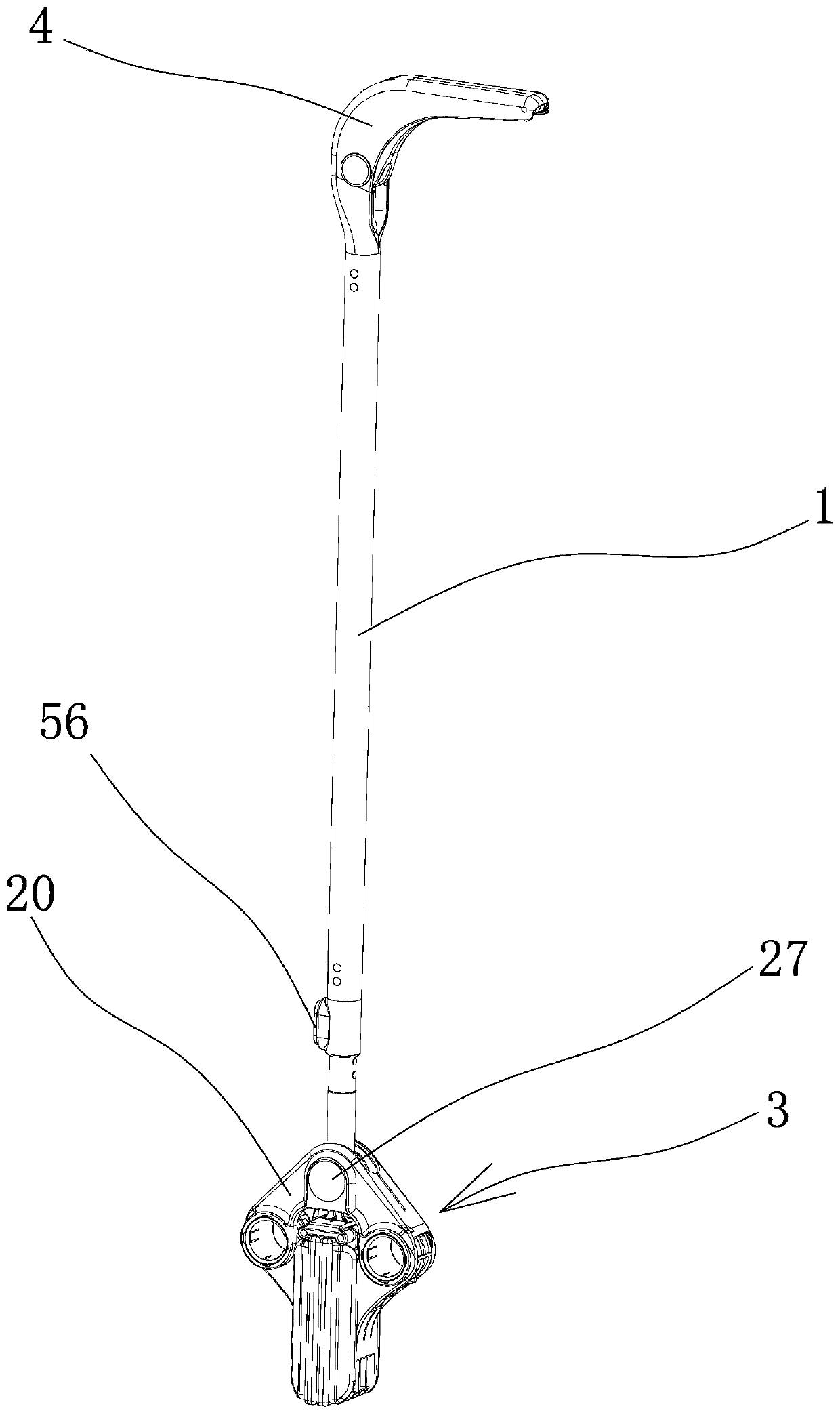

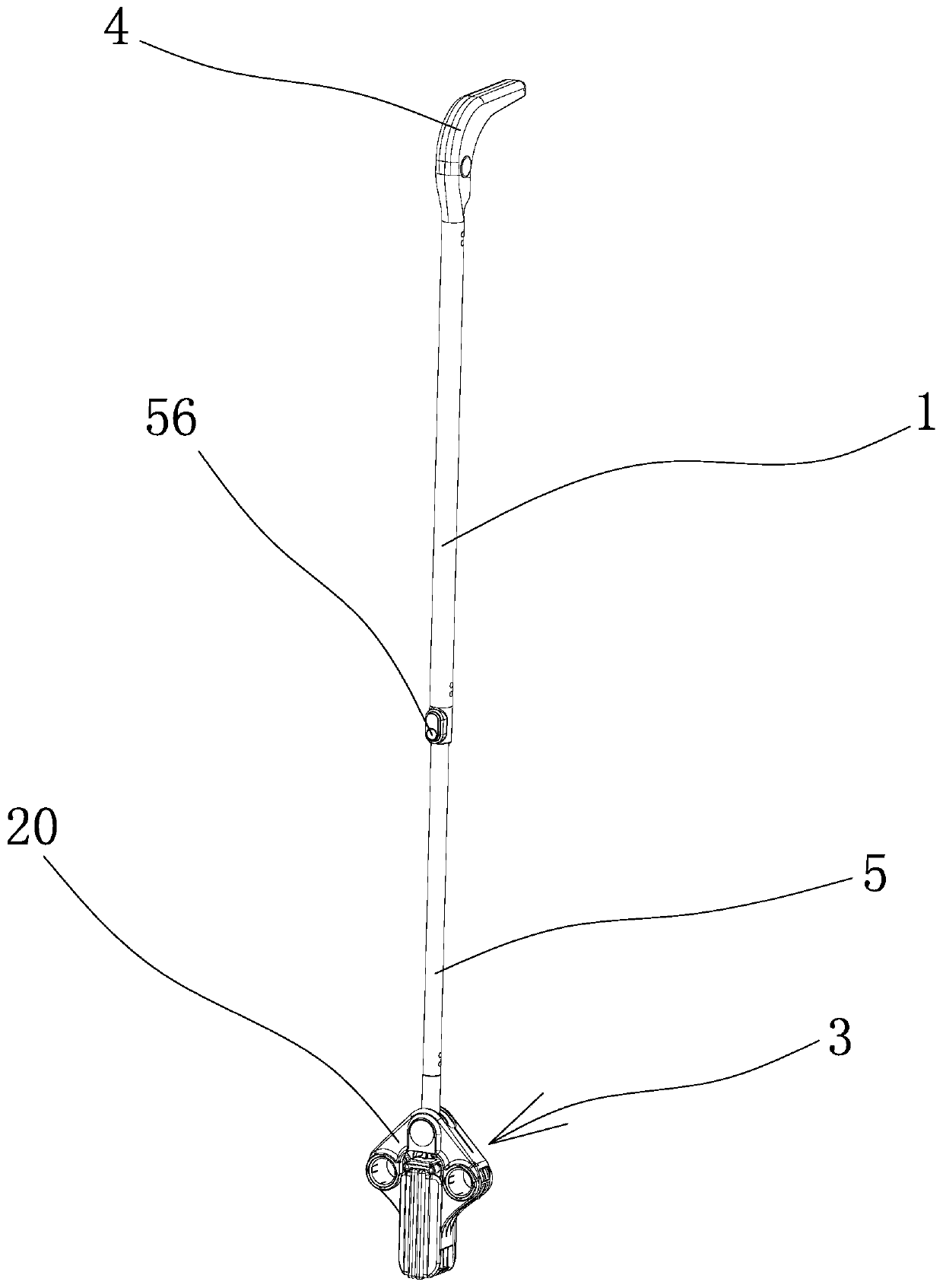

InactiveCN111084591AIncreased versatilityReduce the overall heightCarpet cleanersFloor cleanersEngineeringCollodion

The invention provides a telescopic folding wringing collodion mop, and belongs to the technical field of mops. The mop solves the problems that an existing mop is poor in wringing effect, inconvenient to wring and single in using scene. The telescopic folding wringing collodion mop comprises a mop rod capable of moving in the axial direction, a mop head provided with collodion and a rotatable handrail handle, wherein the rotatable handrail handle is arranged at the top of the mop rod and can drive the mop rod to move in the axial direction; the mop rod is connected with the mop head through aconnecting rod; a fixed rod with one end extending into the mop rod and the other end extending into the mop head is arranged in the connecting rod, a movable rod with one end extending into the handrail handle and the other end allowing the fixed rod to extend into is arranged in the mop rod, and a pull rod handle mechanism capable of driving the movable rod, the fixed rod and the mop head to synchronously move in the axial direction and used for achieving the folding water squeezing function is arranged in the handrail handle. The telescopic folding wringing collodion mop has the advantagesof being convenient to wring, good in wringing effect, wide in application range, capable of being used in multiple scenes, convenient to use and high in practicability.

Owner:蔡恩康

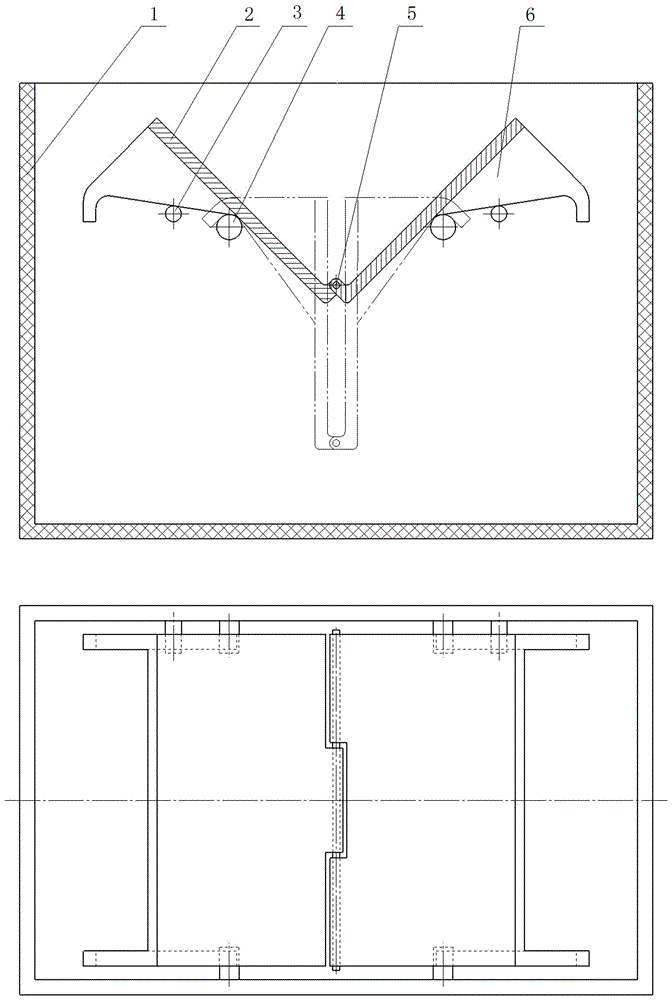

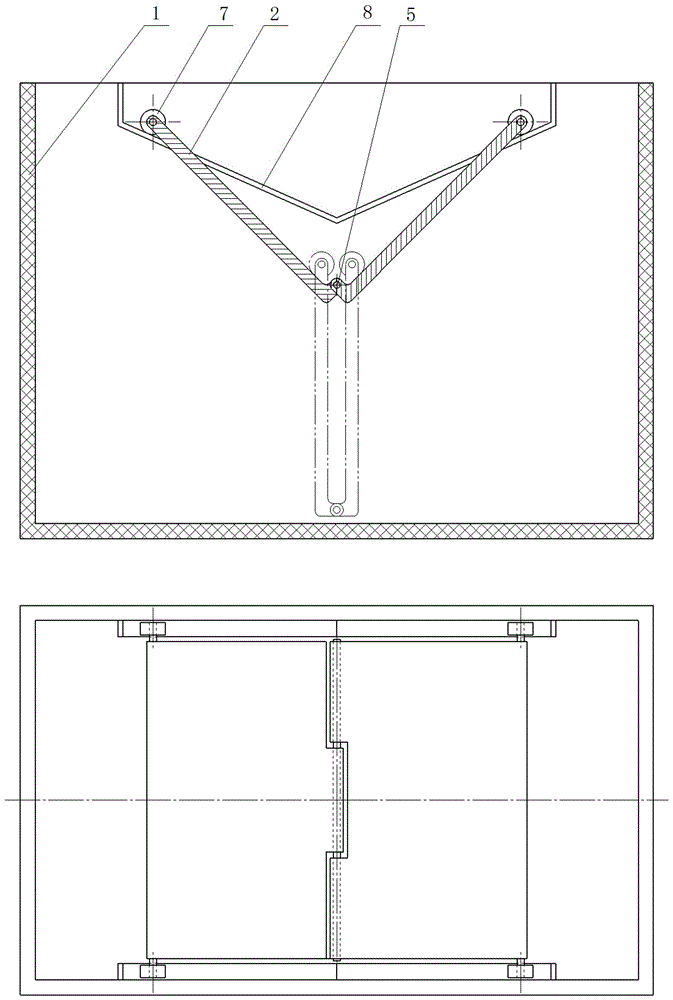

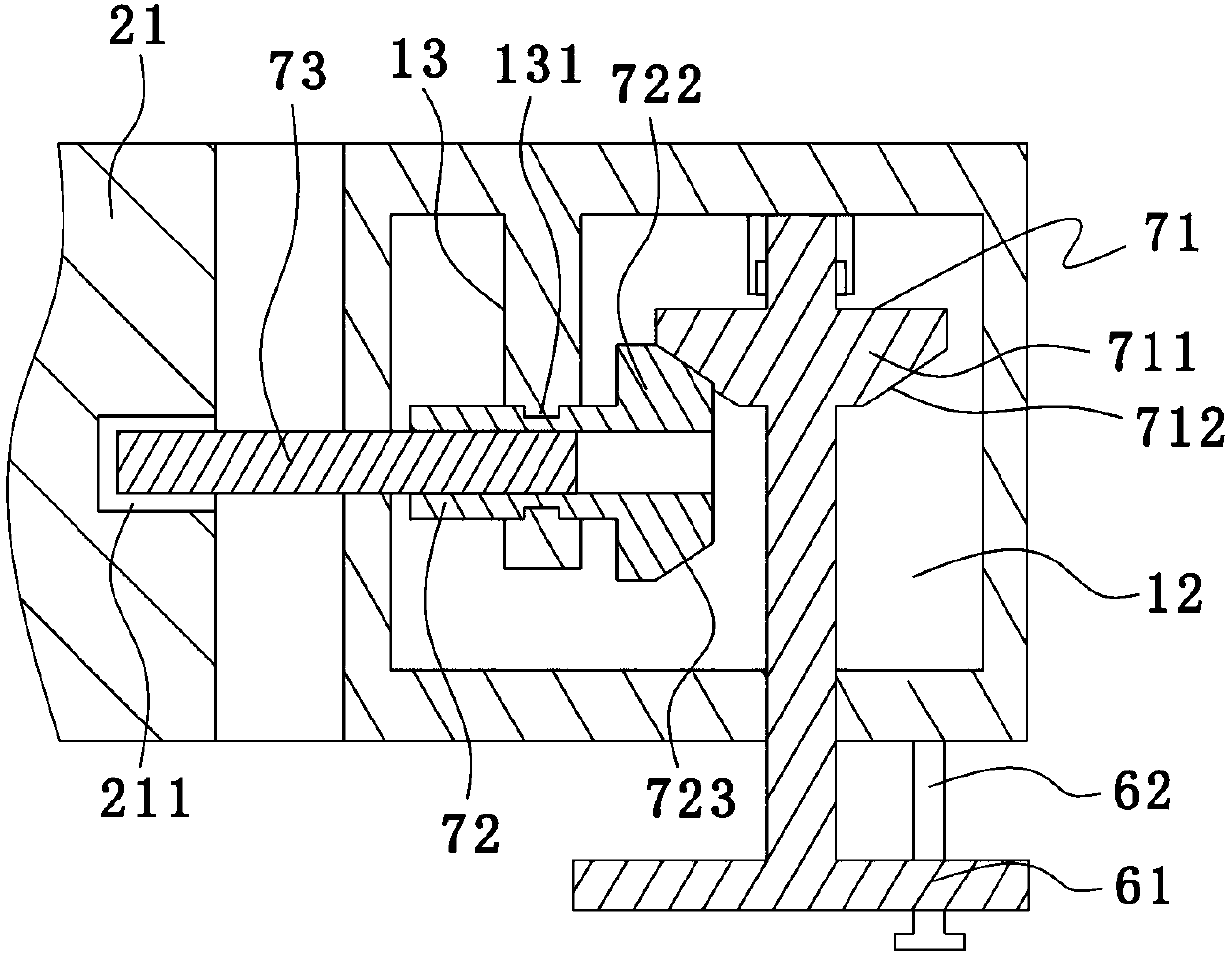

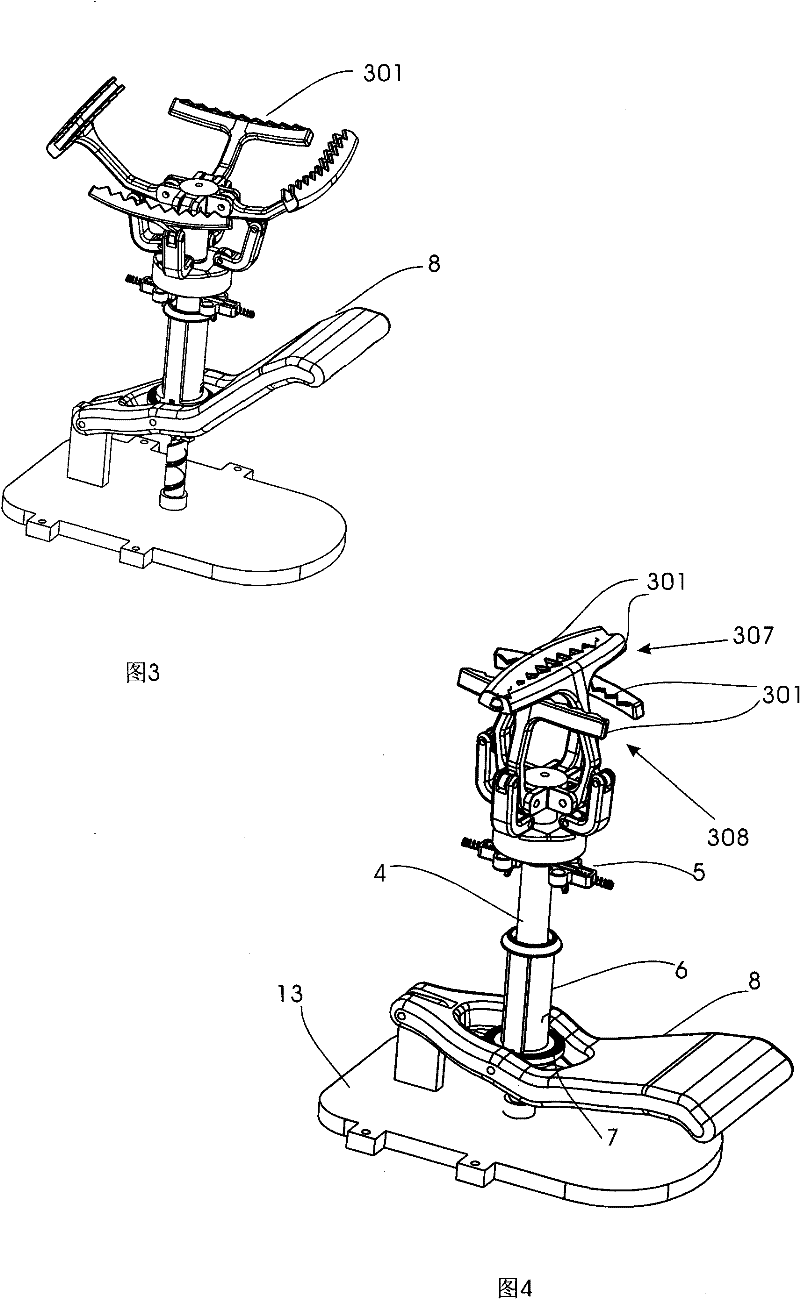

Collodion mop of cleaning tool

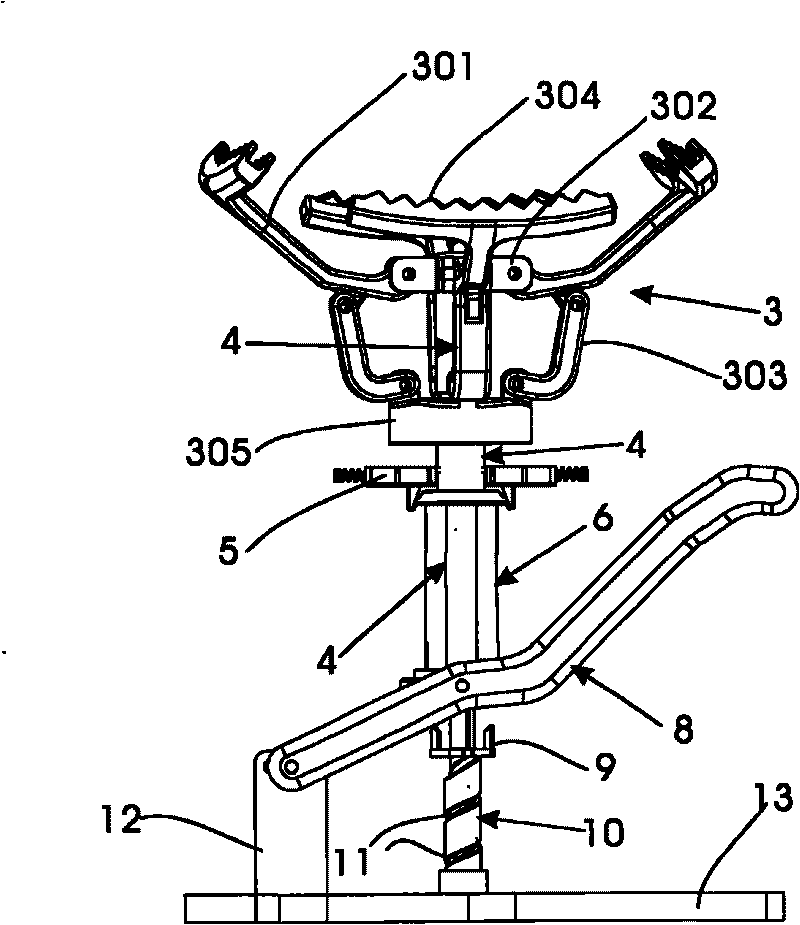

PendingCN110025270ASqueeze labor-savingSqueeze water wellCarpet cleanersFloor cleanersEngineeringHinge point

Disclosed is a collodion mop of a cleaning tool. The collodion mop comprises a mop rod, a squeezing device and a collodion head component, wherein the collodion head component comprises a squeezing plate and a collodion head arranged below the squeezing plate, the squeezing plate comprises a middle plate and side plates hinged to two sides of the middle plate respectively, and the squeezing devicecan squeeze the collodion head component which can move relatively to the squeezing device to be folded. The collodion mop is characterized in that each side plate is connected to one corresponding side of a squeezing frame through a force arm, and one end of each force arm is hinged to the squeezing frame while the other end thereof is hinged to or is rotatably or movably connected to each sideplate. From an unfolded state to a folded and squeezed state of the collodion head component, the force arms rotate around the hinge points of the force arms and the side plates to increase internal included angles formed by rotation of the force arms and the side plates and synchronize rotation of the force arms around the hinge points of the force arms and the squeezing frame, and the rotation angle can be larger than 150 degrees. With the extended force arms, the squeezing frame can be made small, and accordingly the manufacturing cost can be reduced; the collodion mop is more labor savingin squeezing and better in water squeezing effect.

Owner:陈世广

Equipment for squeezing water in mop and mop thereof

InactiveCN1259020CIncrease material densityMaterial density is high or largeCarpet cleanersFloor cleanersEngineeringMechanical engineering

A mop squeezing device has a container made of flexible water-permeable sheet material or small mesh mesh material or low mesh area percentage mesh material, the opening of the container is connected with the non-circular container fixing port on the container fixing frame Connection, the rod penetrates the bottom of the container, the container holder and the rod are respectively connected with the two ends of the double motion mechanism, the double motion mechanism can make the relative rotation and displacement between the container holder and the rod at the same time, non-circular container An introduction opening and a mop fixing frame positioning surface are arranged above the fixing opening, and a clamping mechanism is arranged on the introduction opening. The invention satisfactorily solves the problems that the water squeezing effect of the mop squeezing device is poor and the container containing the mop is easily damaged.

Owner:陈光中

Continuous type leather squeezing device

The invention discloses a continuous type leather squeezing device which comprises a bottom plate, a squeezing platform and a cover plate. The squeezing platform is fixedly supported above the bottom plate through uprights, a support plate is arranged in the squeezing platform, a support is fixedly supported on one side of the squeezing platform through a shelf bracket, two electric elevators are respectively mounted at two ends of the bottom of the support through bolts, output ends of the electric elevators are fixedly connected with the cover plate, a slide bar is mounted at the top of the cover plate, a motion block is slidably mounted on the slide bar, one side of the motion block is fixedly connected with the support, a mounting frame is fixedly connected to one end of the support, and a squeezing roller is mounted on the inner side of the mounting frame through a rotating shaft. The motion block mounted on the slide bar at the top of the cover plate is driven to move through a drive motor, the drive motor drives the squeezing roller to squeeze leather repeatedly and continuously, squeezing effect is good, the surface of the squeezed leather is flat without folds, and accuracy in measurement is improved.

Owner:TAIZHOU LAI & KE INTELLIGENT TECH CO LTD

Water squeezing and stretching machine in improved structure

ActiveCN104278110AGood vertical stretchUniform thicknessLeather manufacturingSkins/hides/leather/fur manufacturing apparatusEngineeringConveyor belt

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Environment pollution reduction based on printing and dyeing system

InactiveCN111188147AAvoid drippingAchieve connectionMeasurement devicesLiquid/gas/vapor removal by squeezing rollersEnvironmental engineeringMechanical engineering

The invention discloses an environment pollution reduction based on printing and dyeing system. The system comprises a dyeing unit, a water squeezing unit and a scutching unit; the water squeezing unit comprises a frame body, a water squeezing device arranged on the frame body, a cloth tensioning device and a water receiving device matched with the water squeezing device; the water squeezing device comprises an active part, a water squeezing part and a driving part used for driving the active part to rotate; the water squeezing part comprises an upper water squeezing roller and a lower water squeezing roller; a water squeezing gap is formed between the upper and the lower water squeezing rollers; the frame body is provided with a cloth knotting detection device; and the cloth knotting detection device can control the driving part to stop working when conveyed cloth is knotted or wound. Printed and dyed cloth is subjected to water squeezing through the water squeezing device, so that the situation that water drops drip everywhere in a scutching process is avoided.

Owner:李昊

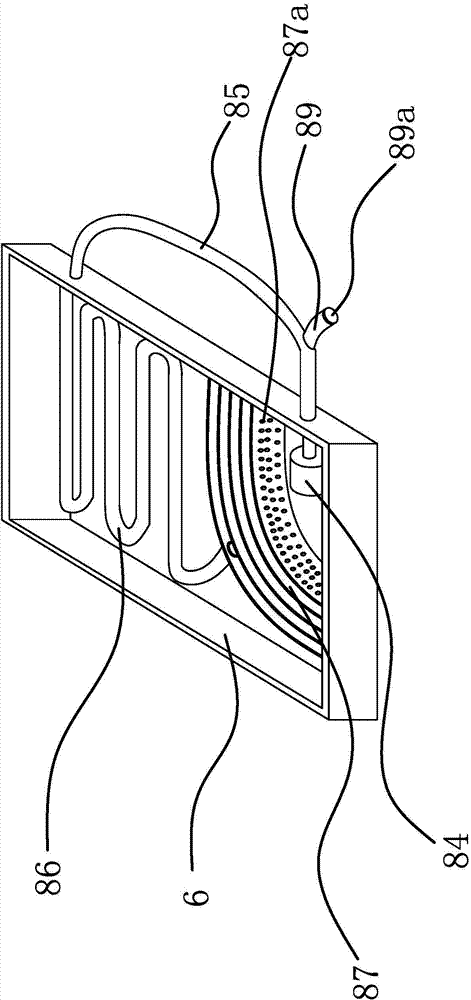

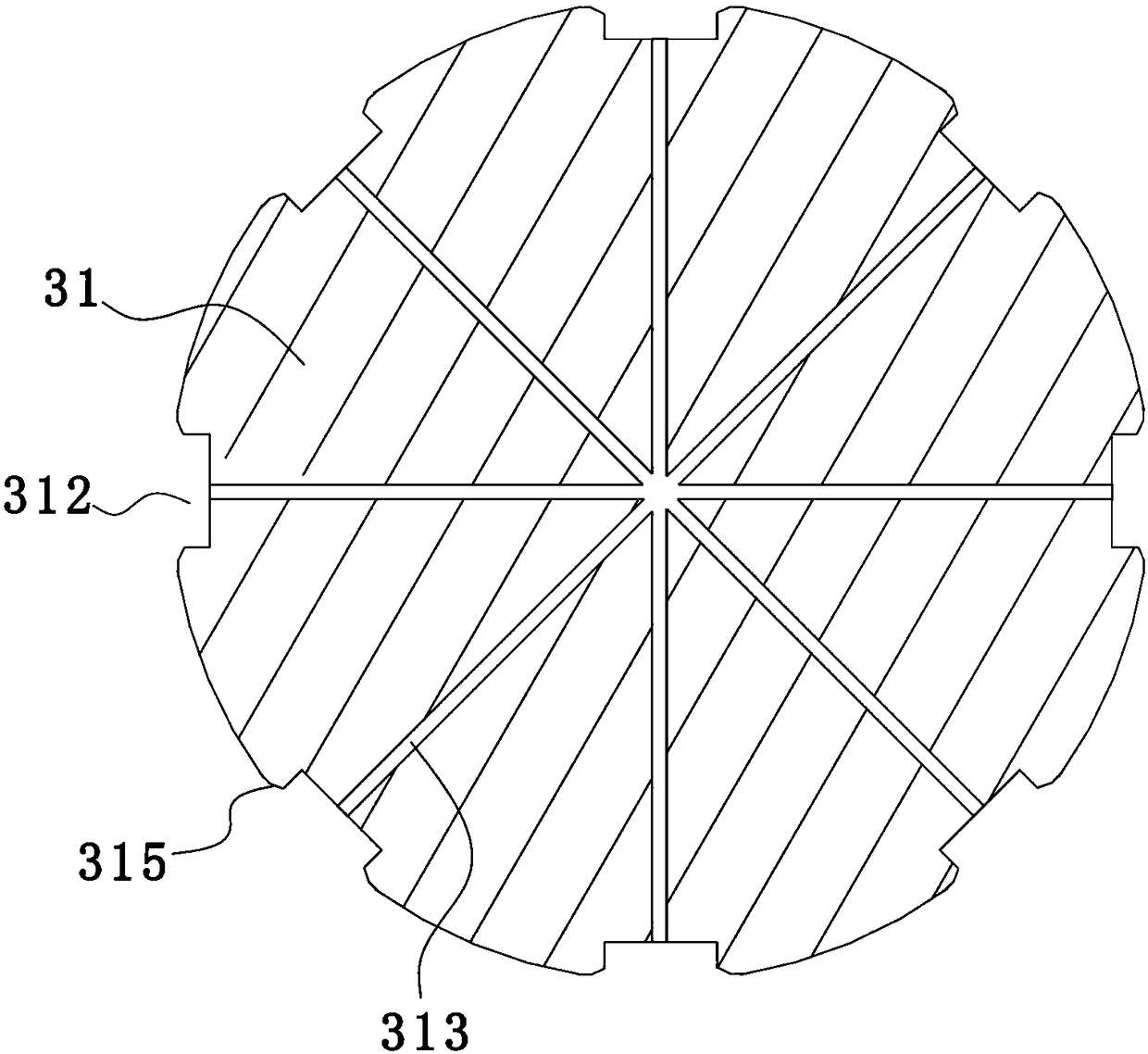

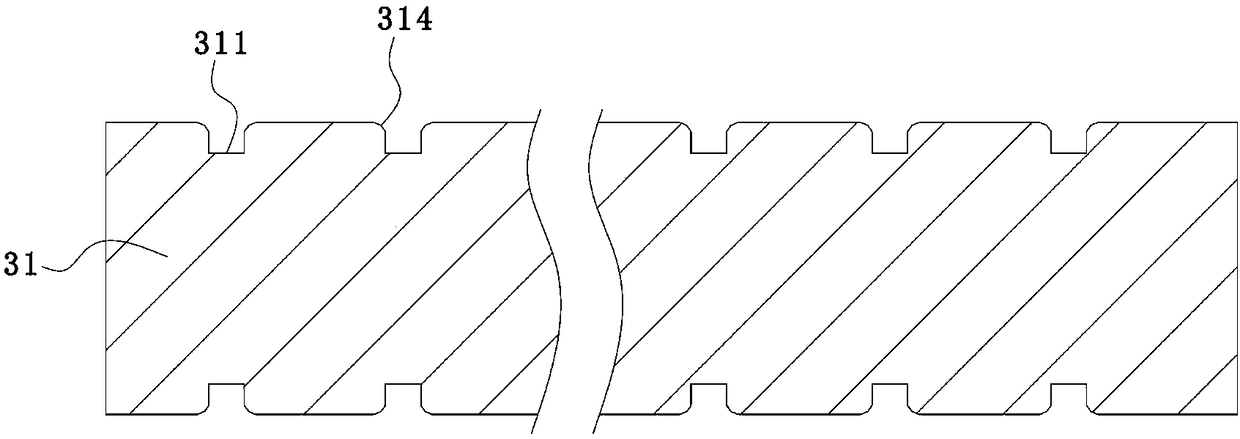

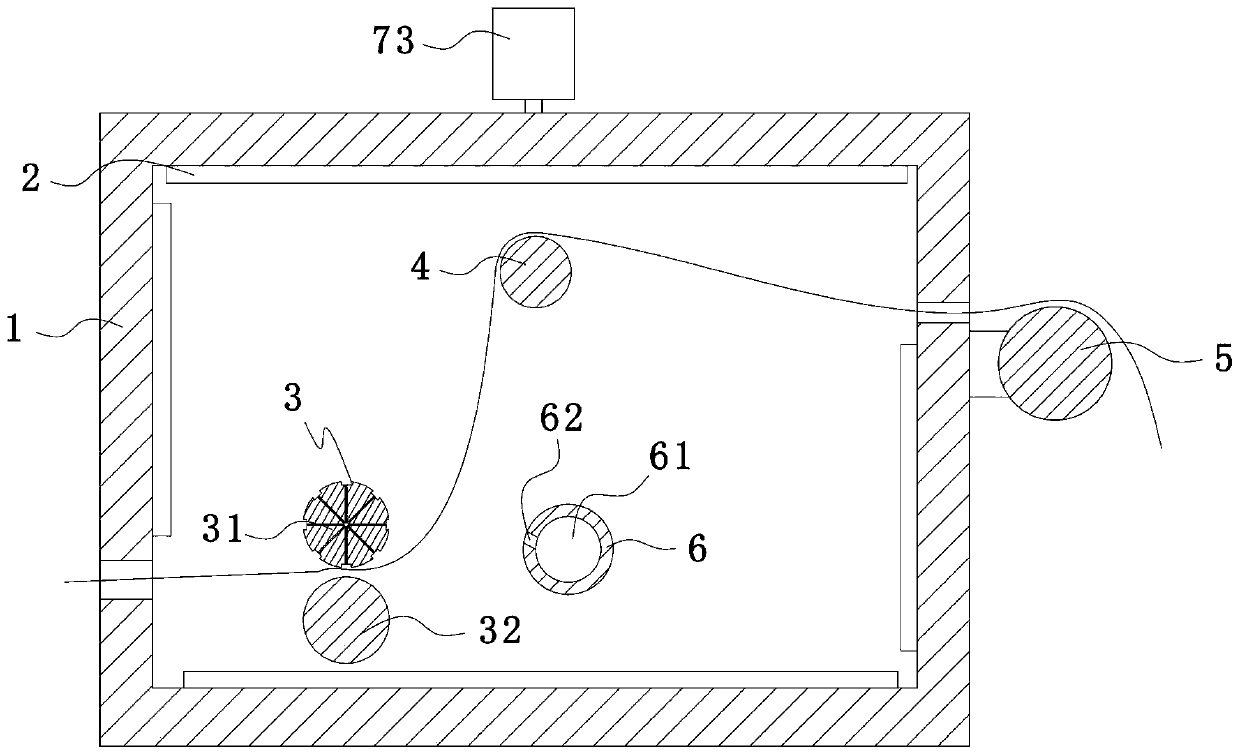

Squeezing-drying equipment for textile fabric processing

InactiveCN108507325AReduce frictional resistanceFast transferDrying solid materials without heatDrying gas arrangementsHeating elementTextile

The invention discloses squeezing-drying equipment for textile fabric processing. The squeezing-drying equipment for textile fabric processing comprises an oven, a heating element arranged on the inner wall of the oven, a squeezing device arranged in the oven, a drying device, a first cloth guide roll and a second cloth guide roll arranged outside the oven, wherein the squeezing device comprises afirst squeezing roll and a second squeezing roll which are arranged in the form of up-down symmetry, and a gap allowing fabric to penetrate through is formed between the first squeezing roll and thesecond squeezing roll; and a plurality of squeezing ring grooves are distributed in the first squeezing roll at a uniform interval in the length direction. According to the squeezing-drying equipmentfor textile fabric processing, through formation for the squeezing ring grooves in the length direction of the first squeezing roll, the high friction resistance of the fabric during squeezing is effectively reduced, then rapid conveying for the fabric is ensured, and high processing efficiency is achieved; and secondly, water squeezed from the fabric in the squeezing process can be rapidly drained outwards through the squeezing ring grooves, so that good squeezing effect, high processing efficiency and good drying effect are achieved.

Owner:绍兴市柯桥区炬旺纺织品有限公司

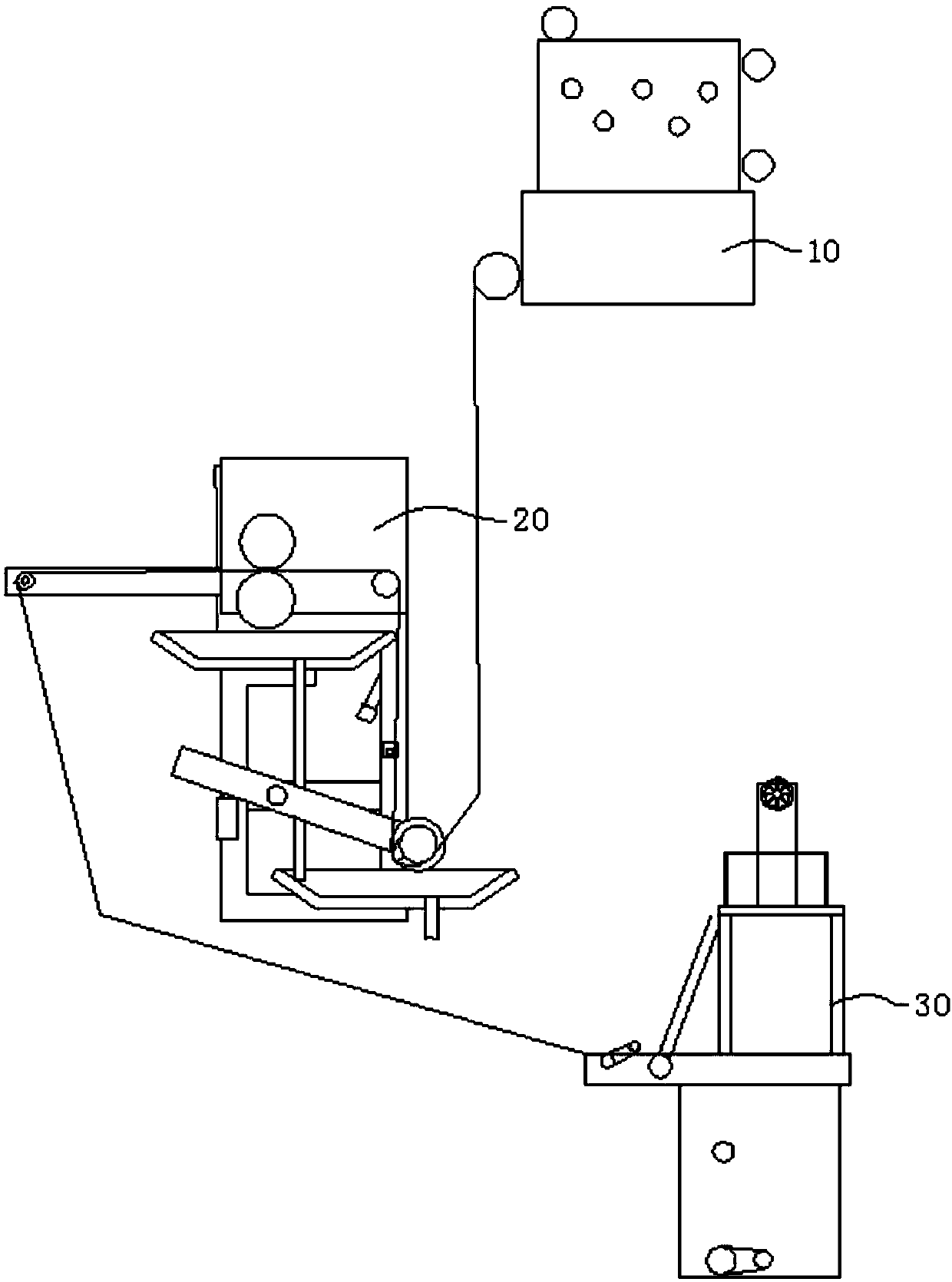

System for fabric printing and dyeing

ActiveCN107747177AAvoid unexpandableAvoid drippingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsStopped workEngineering

The invention discloses a system for fabric printing and dyeing. The system comprises a dyeing unit, a water extruding unit and a scotching unit which are arranged in sequence. The water extruding unit comprises a frame body, a water extruding device, a fabric tensioning device and a water receiving device matched with the water extruding device, wherein the water extruding device and the fabric tensioning device are arranged on the frame body. The water extruding device comprises an active part, a water extruding part and a driving part for driving the active part to rotate. The water extruding part comprises an upper water extruding roller and a lower water extruding roller, wherein a water extruding gap is formed between the upper water extruding roller and the lower water extruding roller. A fabric knotting detection device is arranged on the frame body and can control the driving part to stop working when a conveyed fabric is knotted or wound. The system avoids the situation thatwater drops drop all round in the scotching process by using the water extruding device to extrude water contained in printed and dyed fabrics.

Owner:SHAOXING JINMU PRINTING & DYEING

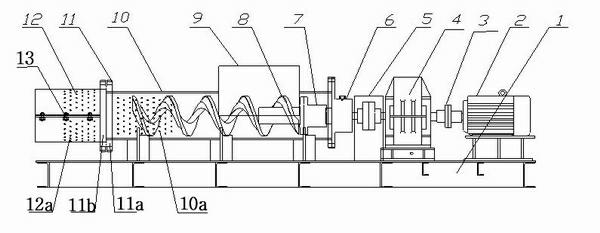

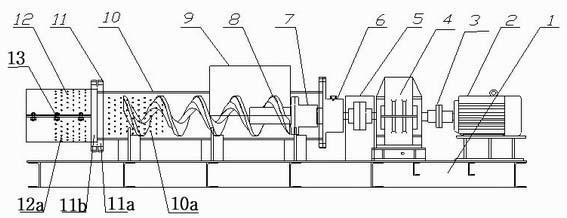

Device for wringing papermaking waste residues

A device for wringing papermaking waste residues belongs to the technical field of devices for wringing the papermaking waste residues, and comprises a base, wherein an electric motor, a transmission gear which is connected with the electric motor through a first coupling and a bearing base which is connected with the transmission gear through a second coupling are sequentially arranged on the base through a support, the other end of the bearing base is provided and connected with a shaftless spiral body in a matching way through a third coupling, a feed bin is arranged above one end of the shaftless spiral body in a matching way, which is close to the bearing base, a shaftless spiral body shell is arranged outside the shaftless spiral body, and is connected with a material seal shell through a flange, and drain holes are respectively arranged on the shaftless spiral body shell and the material seal shell in a matching way. The device adopts the technology, has a simple structure, thematerial extruding strength is increased, and the wringing effect is improved; and one end of the shaftless spiral body shell is connected with the material seal shell, the material traveling distance and the material forward resistance are increased, the extruding force on the material is improved, the wringing effect is enhanced, and the continuity and stability of the wringing process are protected.

Owner:仁精科技(昆山)有限公司

Automatic printing and dyeing equipment for fabric processing

ActiveCN111197211AAvoid drippingAchieve connectionMeasurement devicesLiquid/gas/vapor removal by squeezing rollersStructural engineeringMechanical engineering

The invention discloses automatic printing and dyeing equipment for fabric processing. The equipment includes a dyeing unit, a water squeezing unit and a scutching unit which are arranged in sequence;the water squeezing unit includes a frame body, a water squeezing device disposed on the frame body, a fabric tensioning device, and a water receiving device matching the water squeezing device; thewater squeezing device includes an active part, a water squeezing part, and a driving part used for driving the active part to rotate, the water squeezing part includes an upper water squeezing rollerand a lower water squeezing roller, and a water squeezing gap is formed between the upper water squeezing roller and the lower water squeezing roller; and a fabric knot tying detection device is disposed on the frame body, and can control the driving part to stop working when conveyed fabric is knotted or twined. Squeezing and water squeezing are performed on fabric after printing and dyeing through the water squeezing device, so as to avoid a situation of water droplets dripping everywhere during a scutching process.

Owner:QUANZHOU TAIWANESE INVESTMENT ZONE SHENGTA NEW MATERIALS CO LTD

A printing and dyeing fabric squeezing device

ActiveCN108221233BGuaranteed normal rotationGuaranteed smoothLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsMechanical engineeringTextile

The invention discloses a printing and dyeing cloth water squeezing device. The device comprises a supporting frame, a first cloth pressing mechanism and a second cloth pressing mechanism; the first cloth pressing mechanism comprises a cloth feeding assembly for initially squeezing water from cloth and a cloth expanding assembly which cooperates with the cloth feeding assembly; the second cloth pressing mechanism includes a drive roller assembly, a driven roller assembly and a driving member for driving rotation of the drive roller assembly, and the drive roller assembly and the driven rollerassembly cooperate to each other for squeezing water from the cloth for the second time.

Owner:佛山市南海永其祥织染有限公司

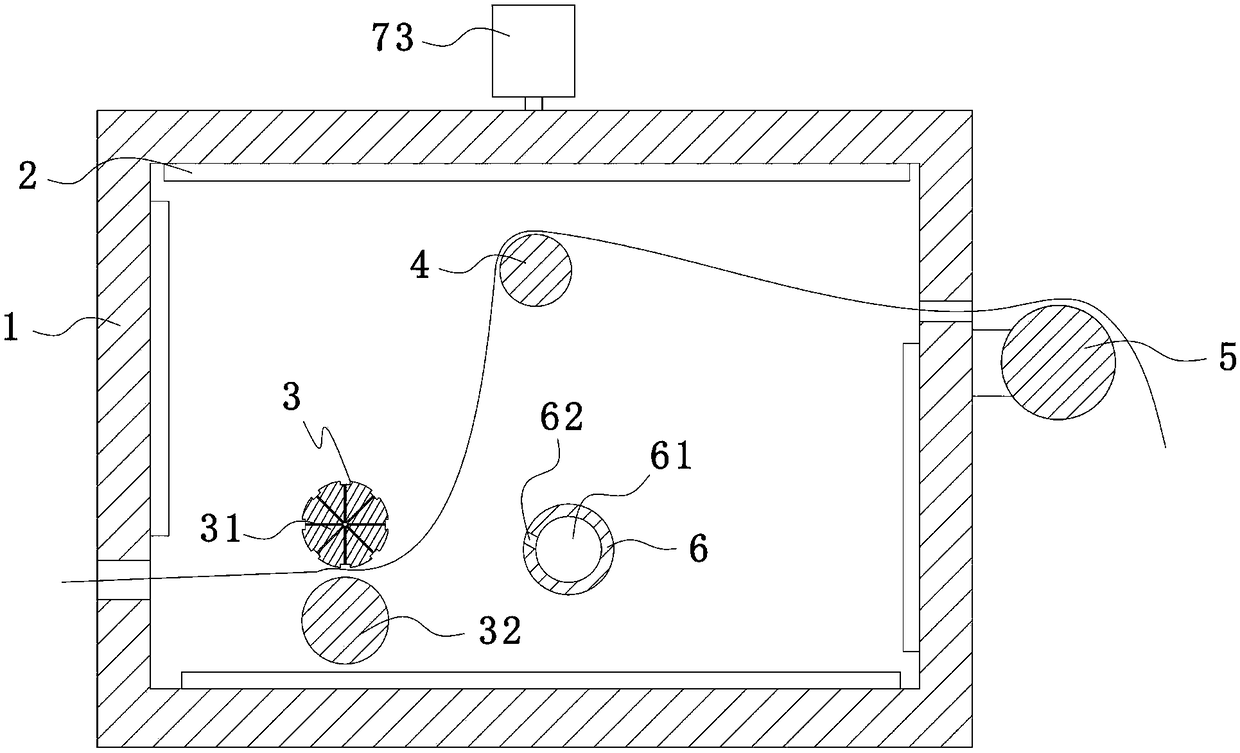

Water squeezing device of mop

InactiveCN102440743APrevent scatteredEasy to manufactureCarpet cleanersFloor cleanersEngineeringNet shape

The invention discloses a water squeezing device of a mop, and belongs to the field of daily necessities. The water squeezing device comprises a base, a water pressing plate and a soft-body net-shaped bag, wherein the soft-body net-shaped bag is arranged on the water pressing plate; the water pressing plate is arranged above the base and movably connected with the base through connecting holes and connecting rings on the base; openings are formed at the upper end and the lower end of the soft-body net-shaped bag; the upper surface of the base is a ladder-shaped arc surface; water leaking holes are formed on the upper surface of the base; triangular grooves are formed at the bottom of the water pressing plate; a circle of flange is manufactured on the periphery of the upper part of the water pressing plate; triangular projections are formed on the surface of the upper part of the water pressing plate; and the soft-body net-shaped bag is cylindrical and U-shaped or takes the shape of a half-side cylinder with openings on the lateral sides. The water squeezing device has the beneficial effects that a binding tape is arranged on the side edge of the opening at the lower end of the soft-body net-shaped bag, so that the mop is prevented from scattering; a treading type water squeezing manner is adopted, so the water squeezing device is easy, saves labor and achieves a good water squeezing effect; and the water squeezing device is simple to manufacture and requires a low production cost.

Owner:杨展

Vertical pressure mop squeezing water cleaning device

InactiveCN103156561BReduce labor intensityImprove living comfortCarpet cleanersFloor cleanersEngineeringExcess water

Owner:刘丰

A safe and environmentally friendly printing and dyeing system

InactiveCN107794667BUnable to expandAvoid drippingInspecting textilesLiquid/gas/vapor removal by squeezing rollersStopped workEngineering

The invention discloses a safe and environment-friendly printing and dyeing system which comprises a dyeing unit, a water extrusion unit and a scutching unit. The water extrusion unit comprises a frame body, a water extrusion device arranged on the frame body, a cloth tensioning device and a water receiving device matched with the water extrusion device. The water extrusion device comprises a driving piece, a water extrusion component and a driving piece for driving the driving piece to rotate, the water extrusion component comprises an upper water extrusion roller and a lower water extrusionroller, and a water extrusion gap is formed between the upper water extrusion roller and the lower water extrusion roller. A cloth knotting detection device is arranged on the frame body. The cloth knotting detection device can control the driving piece to stop working when a conveyed cloth is knotted or twisted. The dyed cloth is subjected to extrusion and water extrusion through the water extrusion device, and the phenomenon that water drips around in the scotching process is avoided.

Owner:佛山市南海润鸿浆染织造有限公司

Water squeezing device

PendingCN110638387ASimple structureSqueeze water wellCarpet cleanersFloor cleanersEnvironmental engineeringMechanical engineering

Owner:袁开靖

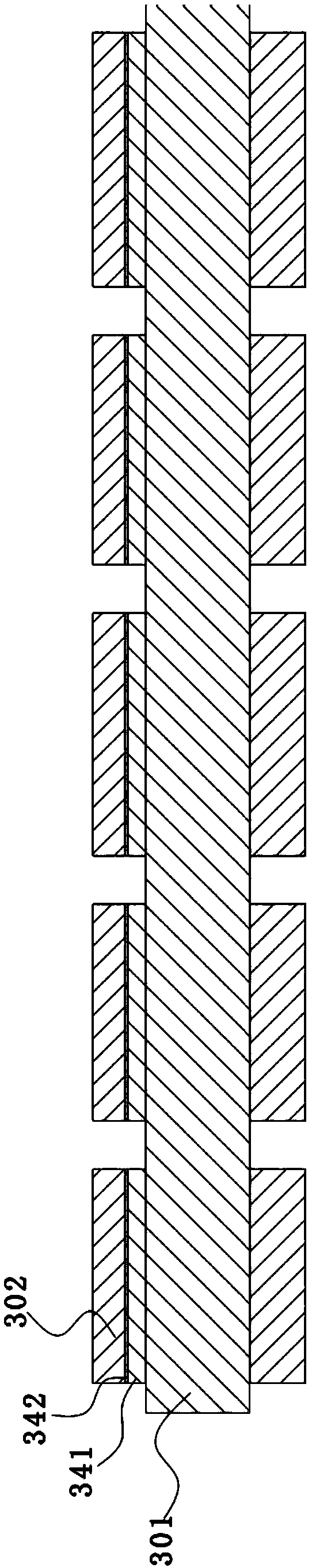

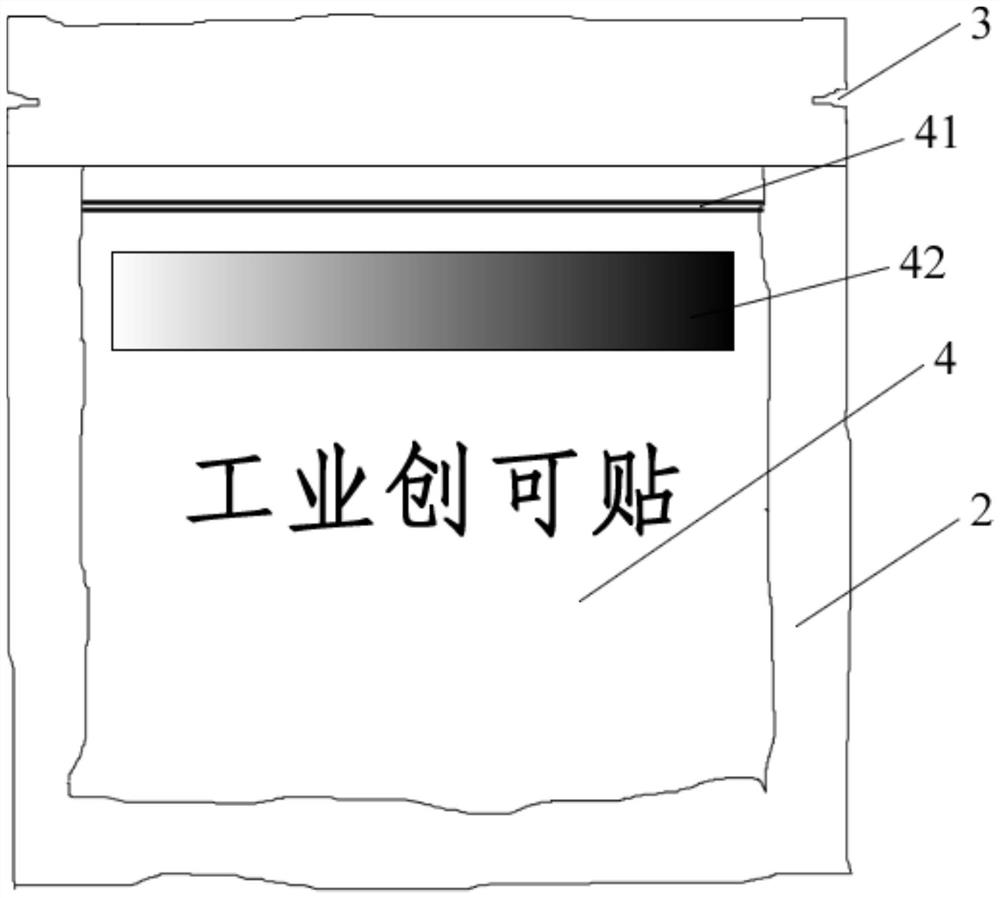

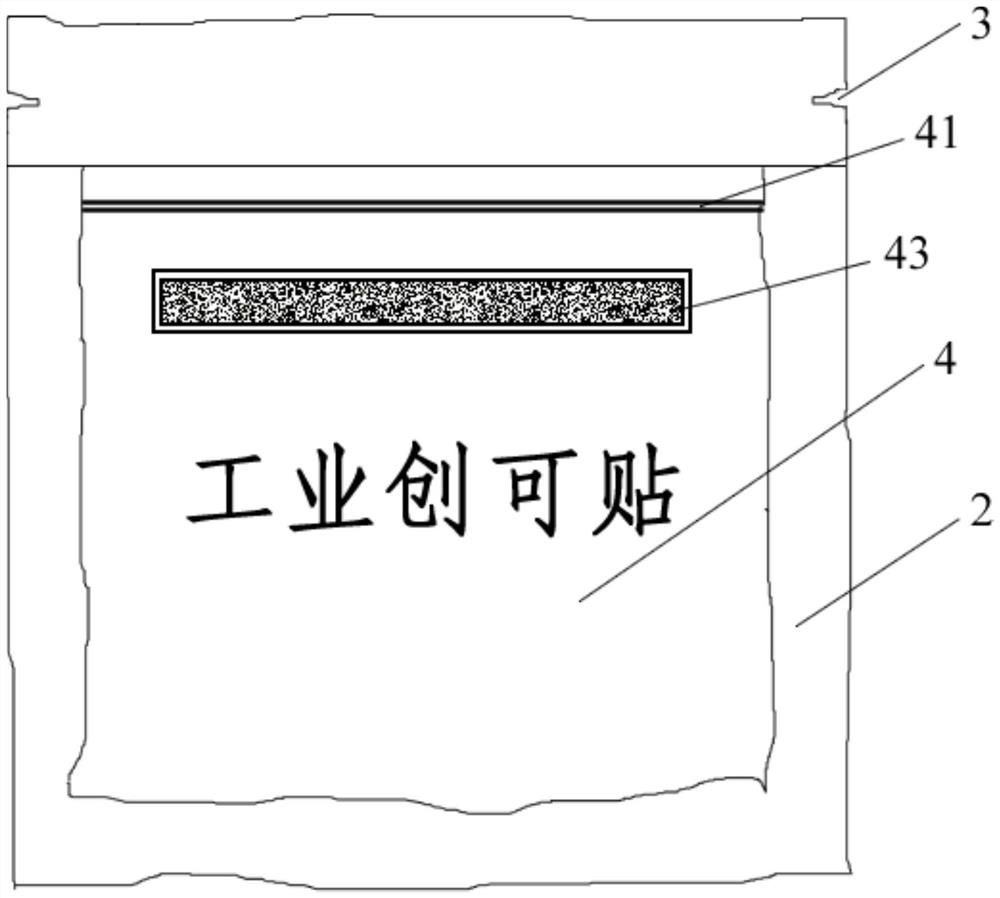

Laying method of industrial band-aid

ActiveCN114017578AEasy to implementTo achieve the repair effectPackage recyclingPipe elementsAdhesive beltLap joint

The invention provides a laying method of an industrial band-aid, which utilizes an industrial band-aid package and / or an element in the industrial band-aid package as a tool to perform adhesion of the industrial band-aid. The method comprises the following steps: performing basic treatment; applying a dressing for an industrial band-aid and performing polishing; calculating an inclination angle theta according to a width of an adhesive tape, a winding perimeter of a to-be-repaired object and an expected lap joint proportion; immersing the adhesive tape with water; placing the adhesive tape on a pressing piece of a water squeezing belt, enabling a pulling piece to bypass the adhesive tape and penetrate through a second through hole, and holding a connecting buckle by hand to pull a handle to squeeze out redundant water in the adhesive tape; putting the adhesive tape into an auxiliary bag body, and enabling an end of the adhesive tape to penetrate through an opening in the auxiliary bag body to be exposed; according to the inclination angle theta, determining an inclination angle of the adhesive tape relative to the to-be-repaired object by using an angle indication line on the adhesive tape; and monitoring whether a lap joint proportion of the adhesive tape meets the expectation or not by using a lap joint indication line. By adopting the laying method of an industrial band-aid provided by the invention, construction operation specifications can be conveniently executed, and the maintenance effect is good.

Owner:张一平

Mop

ActiveCN103070651BSimple structureAvoid damageCarpet cleanersFloor cleanersMechanical engineeringEngineering

The invention discloses a mop which comprises a holding rod, a bracket connected to the lower end of the holding rod, and two rows of wiping rollers, wherein the two rows of wiping rollers are arranged on the bracket in parallel back and forth and can unidirectionally rotate; non-return directions of the wiping rollers in front and back rows are opposite; when the mop pushes forwards, the roller in the front row rolls forwards to wet the ground, and the roller in the back row stops for wiping the ground; and when the mop is pulled backwards, the roller in the back row backwards rolls to wet the ground, and the roller in the front row stops to wipe the ground. In the mopping process, the surfaces of the wiping rollers can be fully utilized; even if the rollers are dirt, falling dirt in the rolling process can be collected by the roller in a stopping state and is limited between two rows of rollers, so that the phenomena that the dirt and stain are distributed along the movement of the mop can be reduced or avoided, and the times of cleaning the mop in the mopping process can be reduced. The mop further comprises a wringer arranged in a separating manner. The wringer is of a tong-shaped structure with a simple structure; when the wringer is operated, the damage of the wringer to the rollers is little; when the wringer is damaged or lost, the wringer is only needed to be independently replaced; and the wringer can be also used for clamping solid waste on the ground.

Owner:阳珉

A kind of cloth printing and dyeing processing equipment

ActiveCN108265442BReduce workloadHigh degree of automationTextile treatment machine partsLiquid/gas/vapor removal by squeezing rollersEngineeringMechanical engineering

The invention discloses a cloth printing and dyeing device comprising a support frame, a detecting mechanism and a cloth bucket mechanism; the device is characterized in that the detecting mechanism comprises a cloth feeding assembly for extruding cloth and a cloth support assembly installed on the support frame; the cloth support assembly is cooperated with the cloth feeding assembly. According to the invention, by means of the cloth feeding assembly, most printing and dyeing waste water in cloth can be removed; and cloth can also be spread out and the effective squeezing is achieved; cloth can be spread out by the cloth support assembly so as to be convenient for workers to directly observe the state of the cloth after primary treatment; the cloth can also be straightened by the cloth support assembly to avoid overlap of cloth.

Owner:张家港华福日新染业有限公司

A dehydration device for clothing fabrics

ActiveCN108385312BAdjustable widthSmall residual moistureLiquid/gas/vapor removal by squeezing rollersTextile treatment carriersPulp and paper industryDehydration

The invention discloses a dehydration device of garment fabric. The dehydration device of the garment fabric comprises a machine frame, a first water squeezing roller, a water squeezing roller, a cloth guide roller and a driving part, wherein the first water squeezing roller and the second water squeezing roller are arranged on the machine frame; the cloth guide roller is matched with the fabric;the driving part is used for driving the cloth guide roller to rotate to drive the fabric to move; a water squeezing gap for the fabric to pass through is formed between the first water squeezing roller and the second water squeezing roller; a rotating piece and a transmission part are arranged on the machine frame; the transmission part is matched with the first water squeezing roller; and when the rotating piece rotates, the first water squeezing roller can be driven by the transmission part to move, so that the width of the water squeezing gap is adjusted. The width of the water squeezing gap can be adjusted, so that a water squeezing device adapts to water squeezing and process of the fabric with different thickness, materials and water-absorbing conditions without controlling the width of the water squeezing gap, the phenomenon of damage to the fabric caused by excessive squeezing is avoided, the water squeezing effect is good, the drying speed at the later stage is high and the processing efficiency is effectively improved.

Owner:中亨(绍兴)科技有限责任公司

Mop water twisting barrel

The invention relates to a mop water twisting barrel, which comprises a barrel body. The invention is characterized in that a mop water twisting device is arranged in the barrel body, and the mop water twisting device comprises a rotating shaft, a guide tube and a threaded guide post, wherein the upper part of the rotating shaft is connected with a mop tight grasping assembly, the guide tube is connected with a pedaling element, the lower part of the rotating shaft is arranged in the guide tube in a penetrating way, and the threaded guide post, which drives the guide tube to rotate, is arranged at the lower part of the guide tube. The invention has the advantages of clean dewatering effect on mop cloth and convenient use.

Owner:HUIZHOU QIANGLI DAILY NECESSITIES

A squeeze drying equipment for textile fabric processing

InactiveCN108507325BReduce frictional resistanceFast transferDrying solid materials without heatDrying gas arrangementsEngineeringHeating element

The invention discloses squeezing-drying equipment for textile fabric processing. The squeezing-drying equipment for textile fabric processing comprises an oven, a heating element arranged on the inner wall of the oven, a squeezing device arranged in the oven, a drying device, a first cloth guide roll and a second cloth guide roll arranged outside the oven, wherein the squeezing device comprises afirst squeezing roll and a second squeezing roll which are arranged in the form of up-down symmetry, and a gap allowing fabric to penetrate through is formed between the first squeezing roll and thesecond squeezing roll; and a plurality of squeezing ring grooves are distributed in the first squeezing roll at a uniform interval in the length direction. According to the squeezing-drying equipmentfor textile fabric processing, through formation for the squeezing ring grooves in the length direction of the first squeezing roll, the high friction resistance of the fabric during squeezing is effectively reduced, then rapid conveying for the fabric is ensured, and high processing efficiency is achieved; and secondly, water squeezed from the fabric in the squeezing process can be rapidly drained outwards through the squeezing ring grooves, so that good squeezing effect, high processing efficiency and good drying effect are achieved.

Owner:绍兴市柯桥区炬旺纺织品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com