Device for wringing papermaking waste residues

A technology for papermaking waste residue and water, applied in the direction of manufacturing tools, presses, etc., can solve the problems of strong dependence on the operating status of the heating device, poor night production effect, limited drying capacity, etc., to achieve continuity and stability of protection, Good water squeezing effect and enhanced water squeezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing of description:

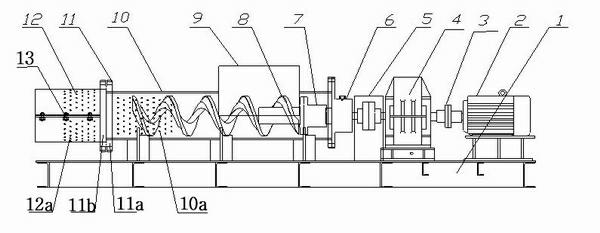

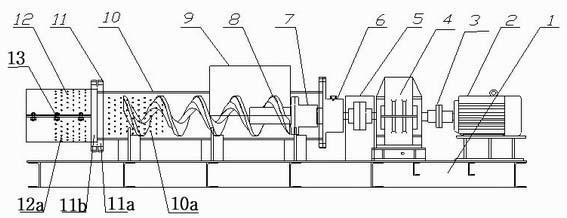

[0019] Such as figure 1 Shown, a device for squeezing water from papermaking waste slag, including a base 1, on which a motor 2, a gearbox 4 connected to the motor 2 through a first coupling 3, and a gearbox 4 are sequentially arranged on the base 1 through a bracket. The bearing base 6 connected by the second shaft coupling 5, the other end of the bearing base 6 is matched with the shaftless spiral body 8 through the third coupling 7, and the shaftless spiral body 8 is close to the bearing base 6. A feeding bin 9 is arranged above one end, and a shaftless spiral shell 10 is arranged outside the shaftless spiral body 8. The shaftless spiral shell 10 and the material seal shell 12 are connected by a flange 11. The shaftless spiral shell 10 and the Drainage holes are arranged on the material sealing shell 12 .

[0020] Such as figure 1 As shown, the shaftless h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com