Vertical pressure mop squeezing water cleaning device

A technology of vertical pressure and cleaning device, applied in the direction of carpet cleaning, floor cleaning, cleaning equipment, etc., can solve the problems of increased procurement cost, limited extrusion effect, complex mop structure, etc., so as to reduce the labor intensity of the family and improve the comfort of life. , good effect of squeezing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

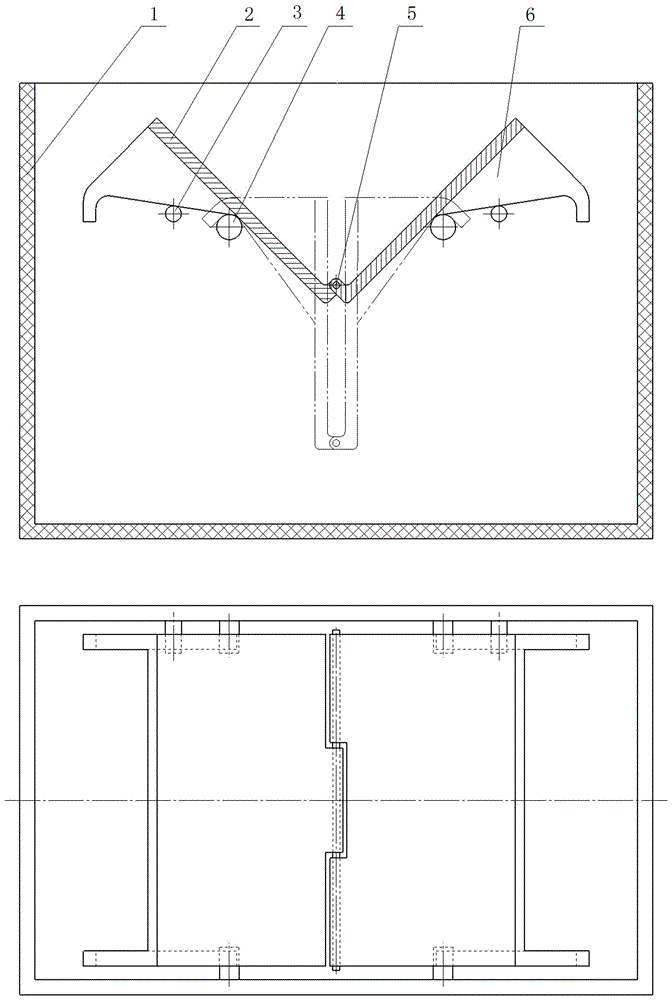

[0014] Embodiment 1 uses a water tank with supporting piles as a supporting device to support the structure of the slope-shaped protrusion on the back of the extruded plate, as shown in the attached drawing of the description figure 1 , (1) 4 (4) support piles are processed in symmetrical positions on the opposite sides of the water tank; two (2) extruded plates have (6) slope-like protrusions on the back, and (2) the lower end of the extruded plate passes through the (5) rotating shaft It is connected to form a hinge-like relative swing mechanism, which is supported on (4) support piles; (3) clamping piles are located on the upper side of (4) support piles, and (4) support piles work together to make (2) extrude plates More stable placement on support devices. A compression spring (omitted in the drawings) is installed between the connection between the lower ends of the two (2) extrusion plates and the bottom of the (1) water tank; on the extrusion surface of (2) the extrus...

Embodiment 2

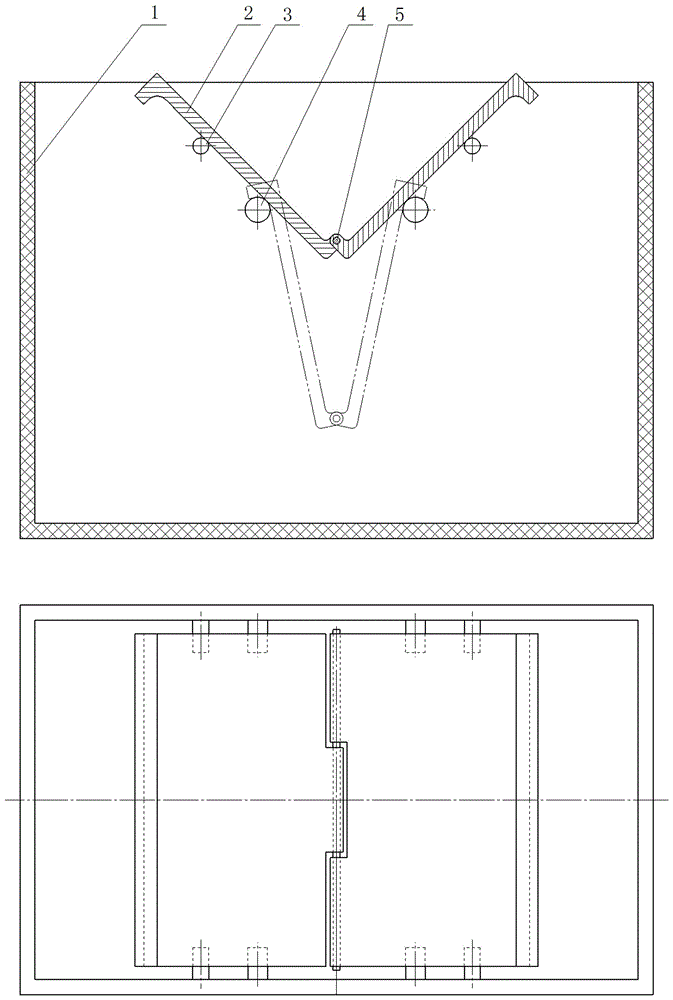

[0015] Embodiment 2 uses a water tank with support piles as a supporting device to directly support the structure on the back of the extruded plate, as shown in the accompanying drawings figure 2 , (1) Four (4) support piles are processed at symmetrical positions on the opposite sides of the water tank; the lower ends of the two (2) extruded plates are connected by (5) rotating shafts to form a hinge-like relative swing mechanism, which is supported on (4) On the pile; there is a (3) stuck pile at the upper side of the (4) support pile, which works together with the (4) support pile to make (2) the extruded plate be placed on the support device more stably. A torsion spring (omitted in the drawings) is installed on the (5) rotating shaft at the joint of the lower ends of the two (2) extrusion plates; A semicircle groove with a diameter slightly larger than the diameter of the conventional mop rod is processed in the direction of the midpoint; the diameter at the lower end of ...

Embodiment 3

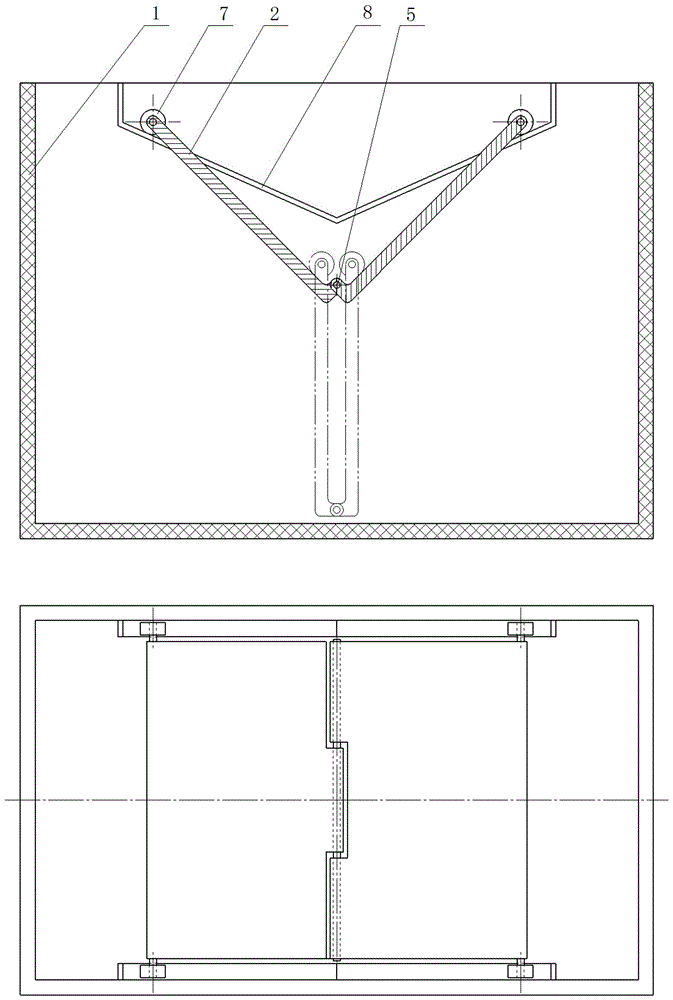

[0016] Embodiment 3 is a structure in which a water tank with guide rails is used as a support device to support an extruded plate with support piles, as shown in the accompanying drawings of the description image 3 , (1) The (8) guide rails are processed at symmetrical positions on the opposite sides of the water tank; the lower ends of the two (2) extrusion plates are connected by (5) rotating shafts to form a hinge-like relative swing mechanism; the top of the (2) extrusion plate has (7) Support piles with rollers; (7) Place the support piles with rollers on (8) guide rails; connect and stretch at the midpoint of the upper end of the back of the two (2) extruded plates and (1) water tank respectively Spring (omitted in the drawings); (2) The extrusion surface of the extrusion plate is processed with a semicircular groove with a diameter slightly larger than the diameter of a conventional mop rod along the direction from the upper midpoint of the extrusion plate to the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com