Water squeezing stretching machine

A transmission mechanism and roller technology, which is applied in small raw hide/big raw hide/leather/fur mechanical treatment, raw hide/leather/fur manufacturing equipment, small raw hide/big raw hide/leather/fur treatment, etc., which can solve the problem of leather stretching and flattening, difficult to guarantee leather quality, uneven leather thickness, etc., to achieve the effect of improved production efficiency, good water squeezing effect, and uniform leather thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

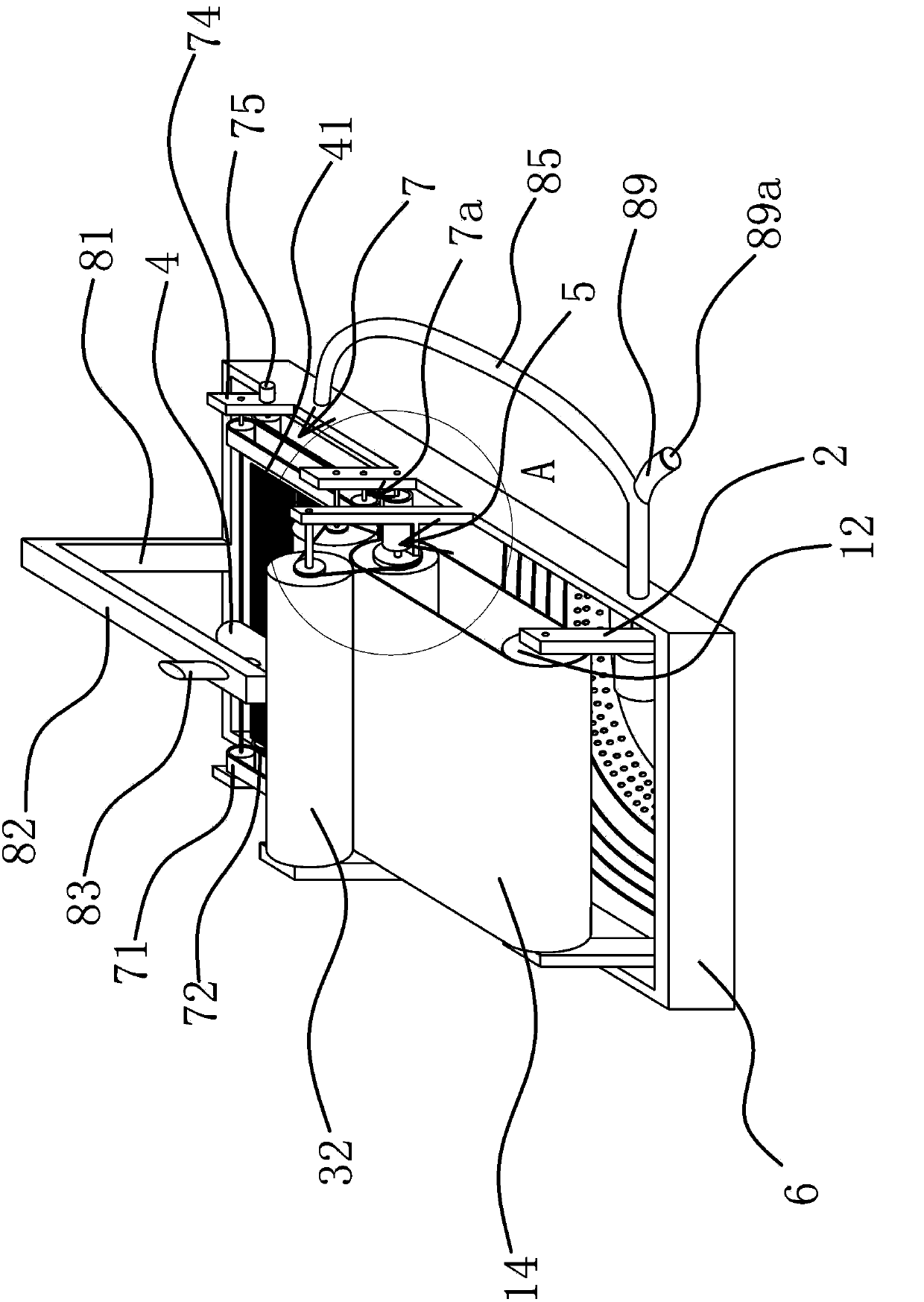

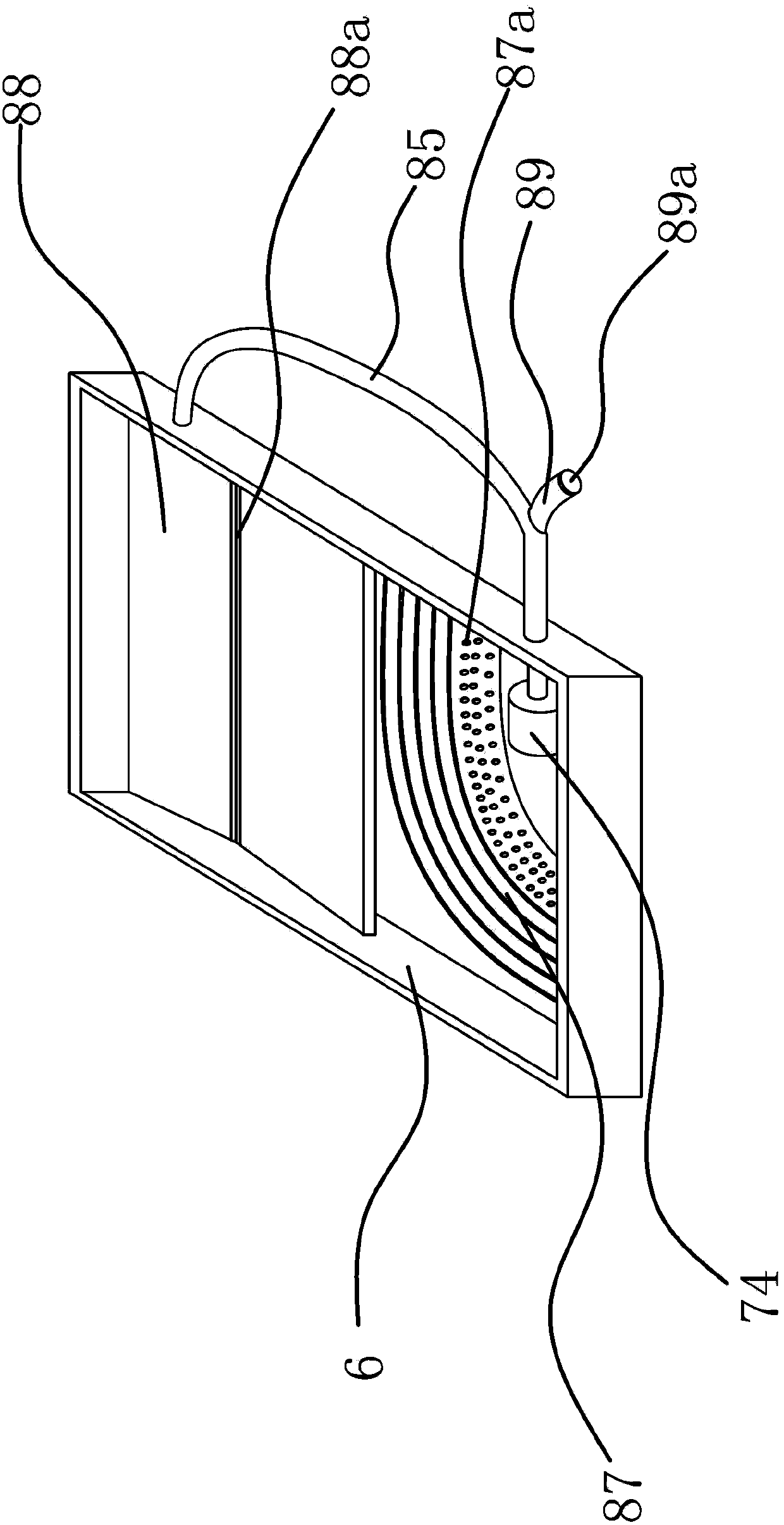

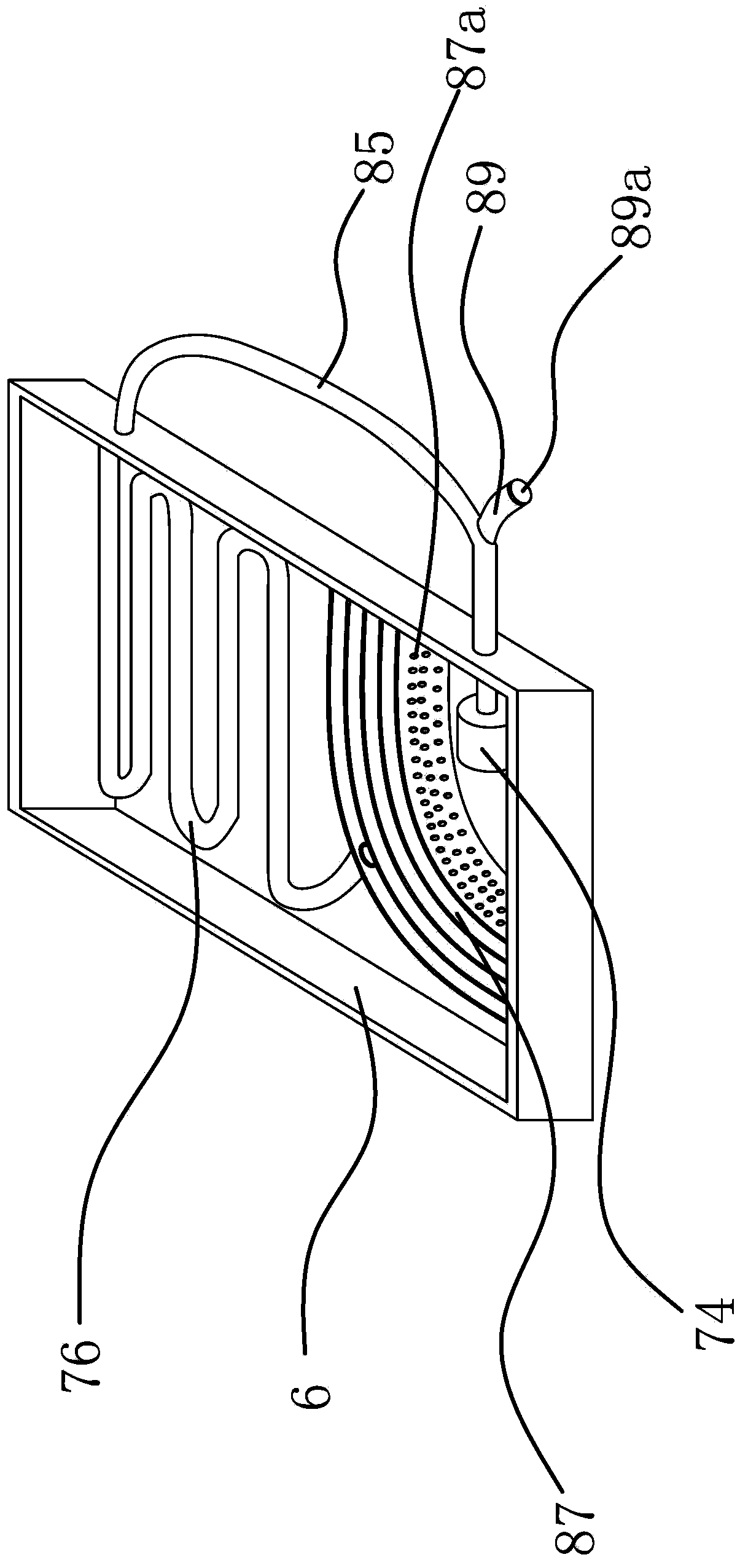

[0027] like figure 1 and Image 6 As shown, the water squeezing and stretching machine includes a driving roller 11 and a passive roller 12 that can rotate freely. The driving roller 11 is driven by a servo motor 13. A conveyor belt 14 is connected between the driving roller 11 and the passive roller 12. Relying on a longitudinal stretching roller 31 and a water squeezing roller 32, there is a device between the driving roller 11, the longitudinal stretching roller 31 and the squeezing roller 32, which transmits the power of the driving roller 11 to the longitudinal stretching roller 31 and the squeezing roller 32. The transmission mechanism 5, and the transmission mechanism 5 can increase the rotation speed of the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com