Patents

Literature

32results about How to "Soft operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

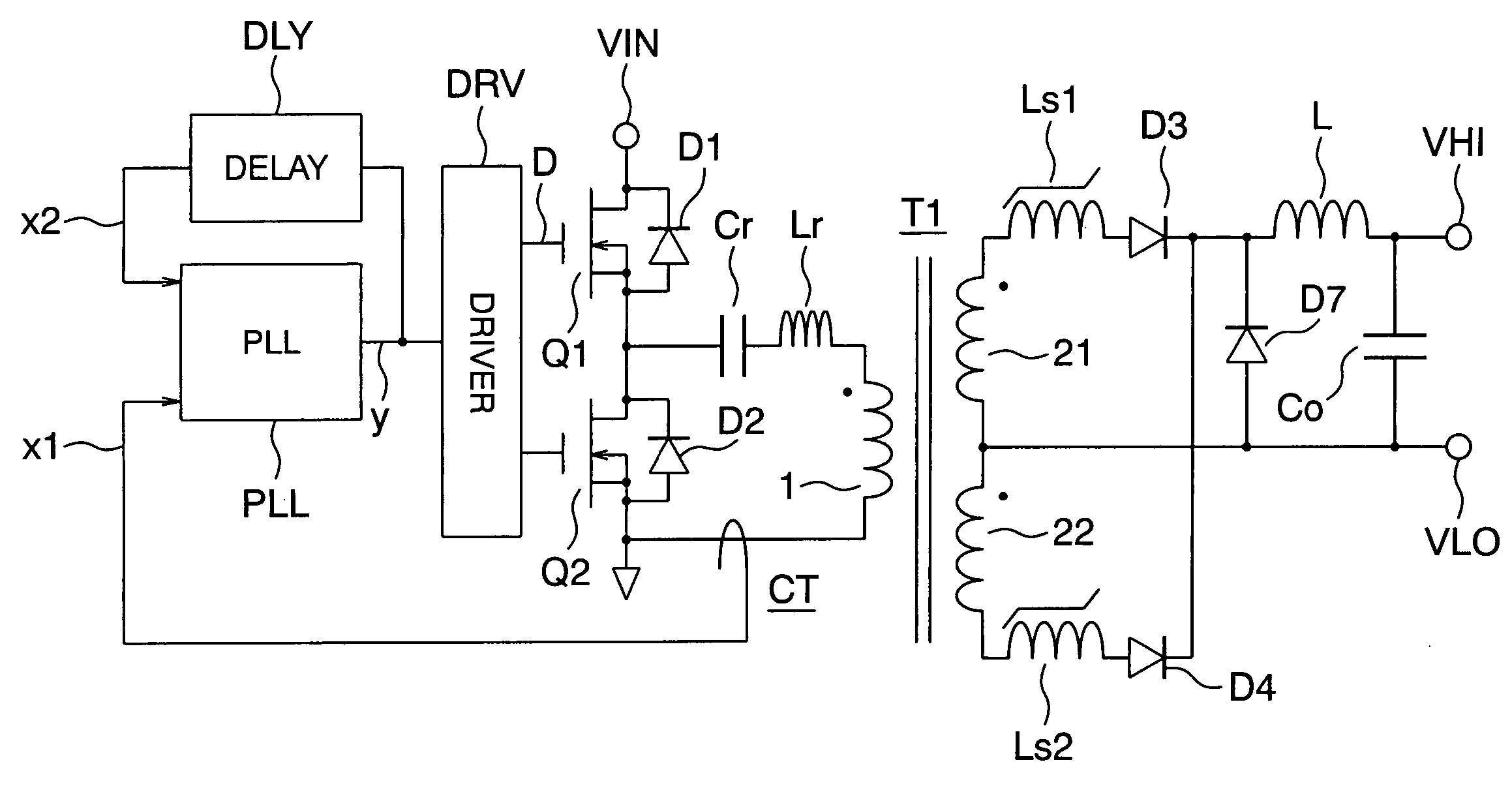

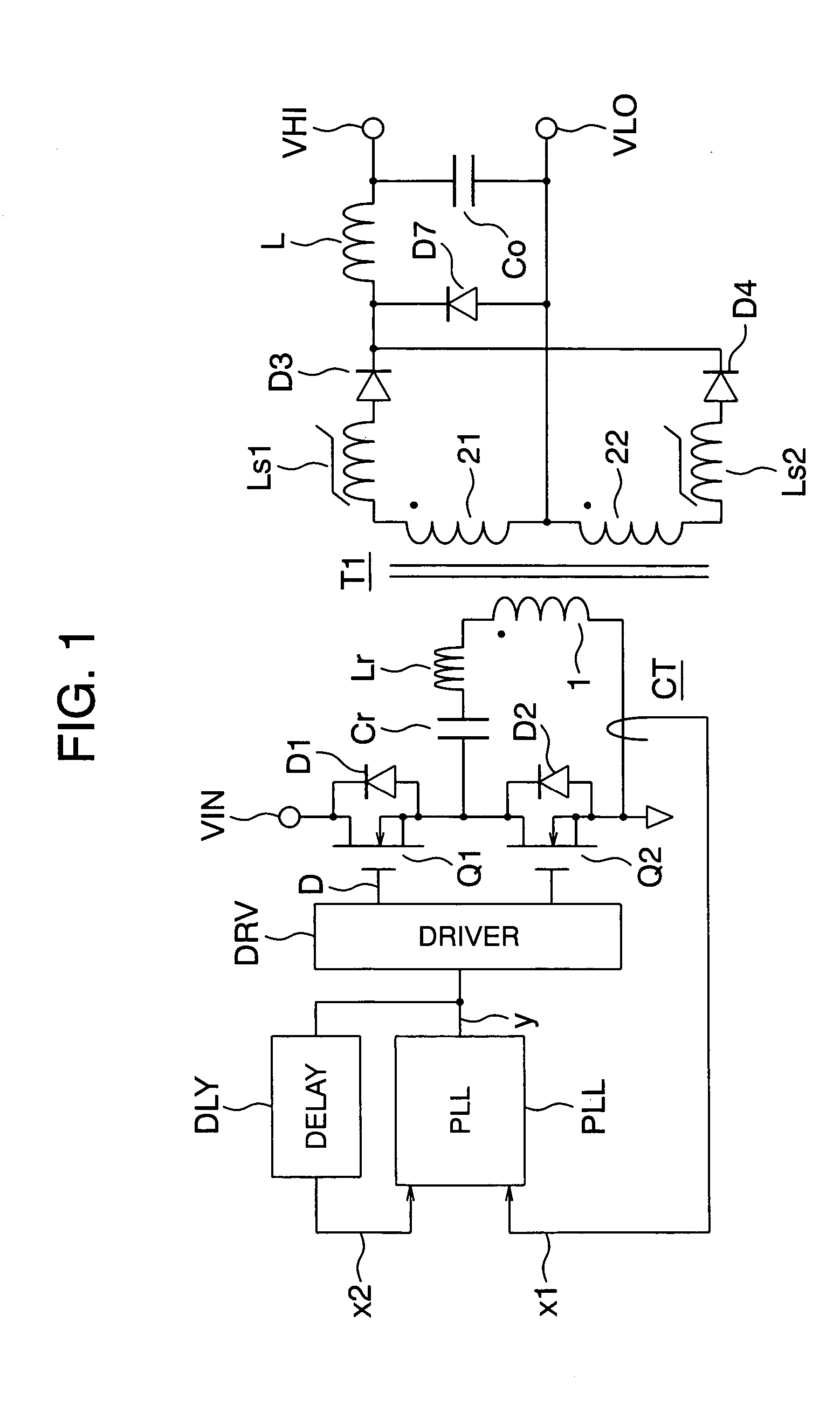

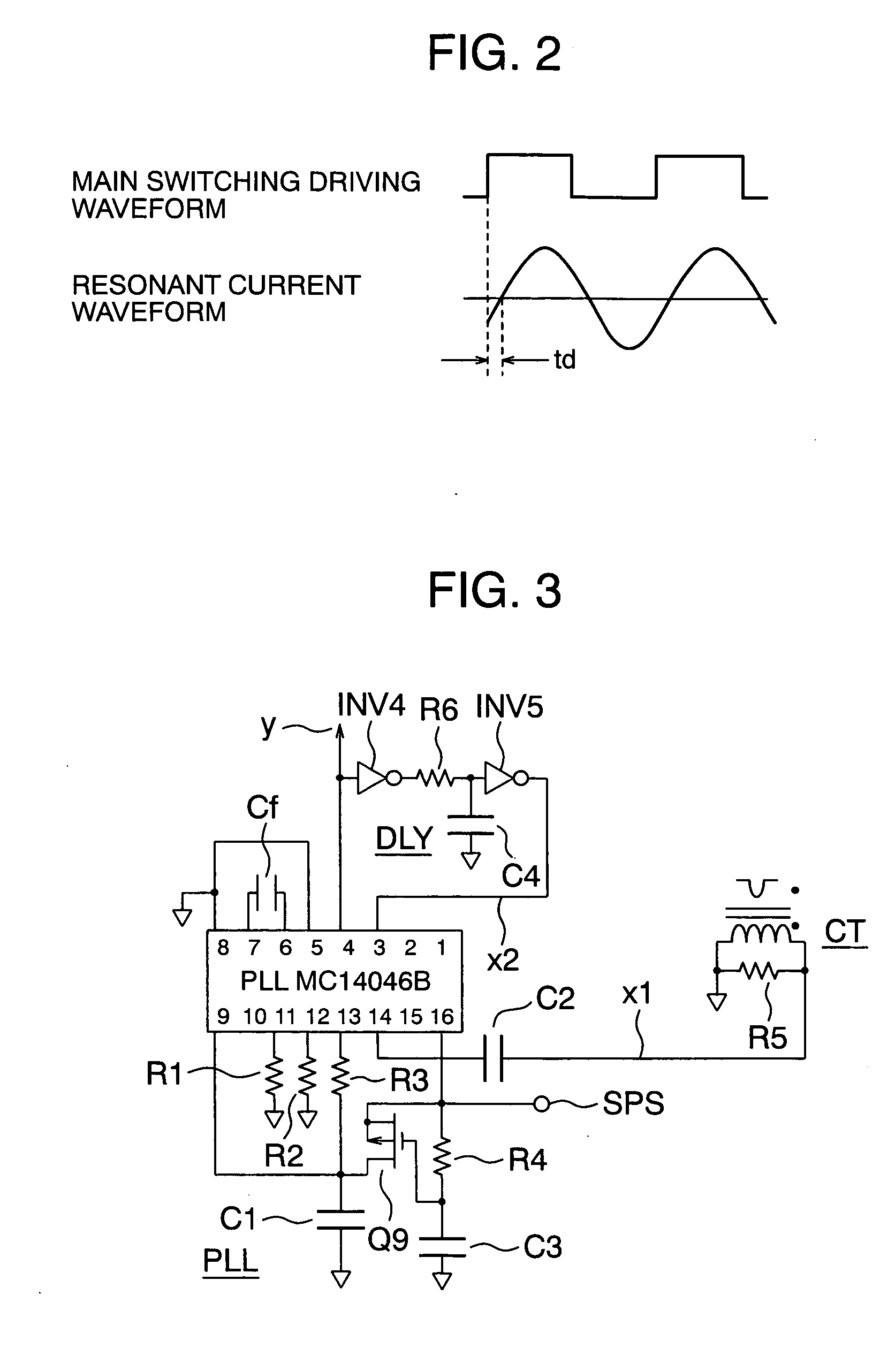

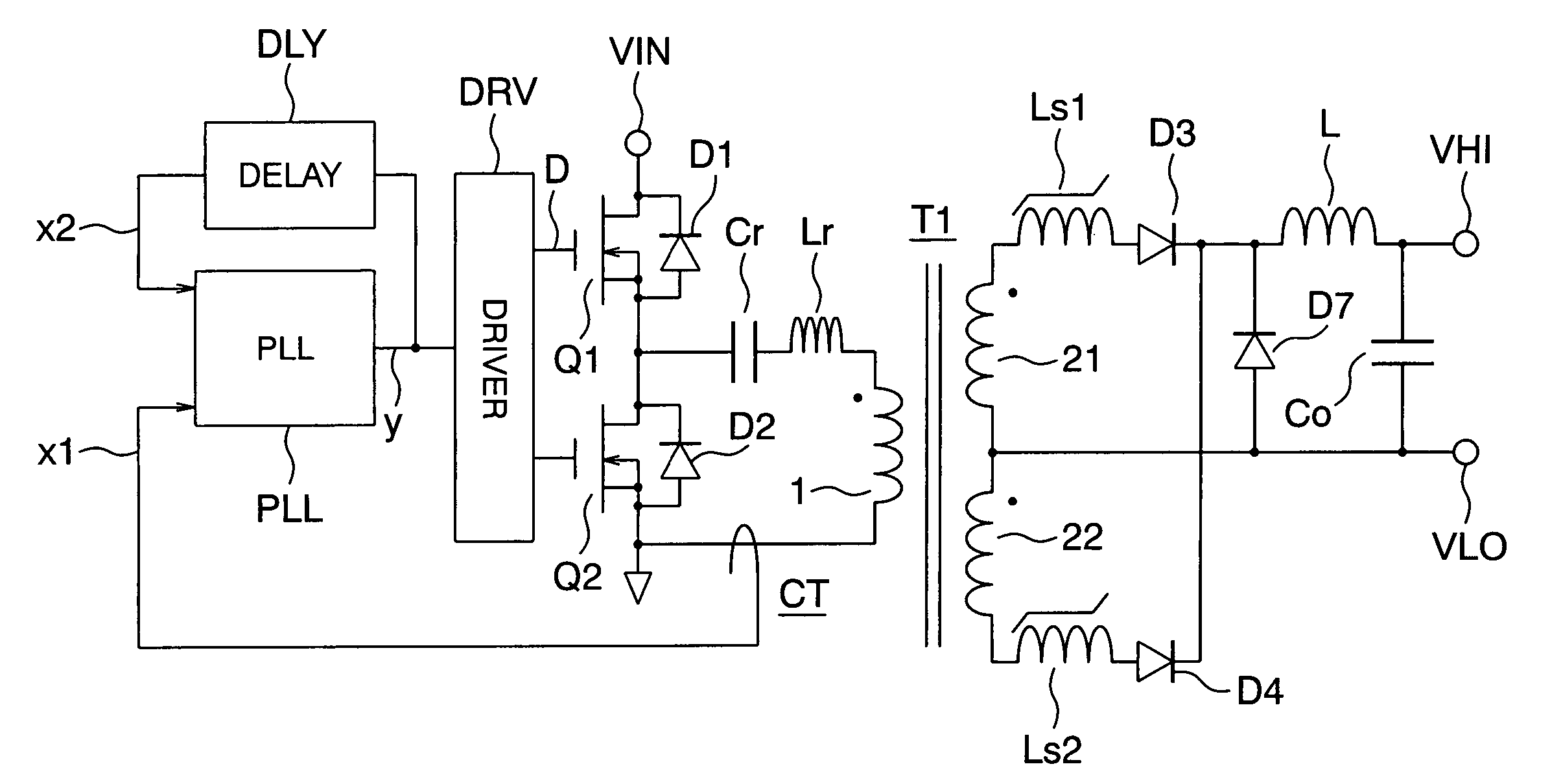

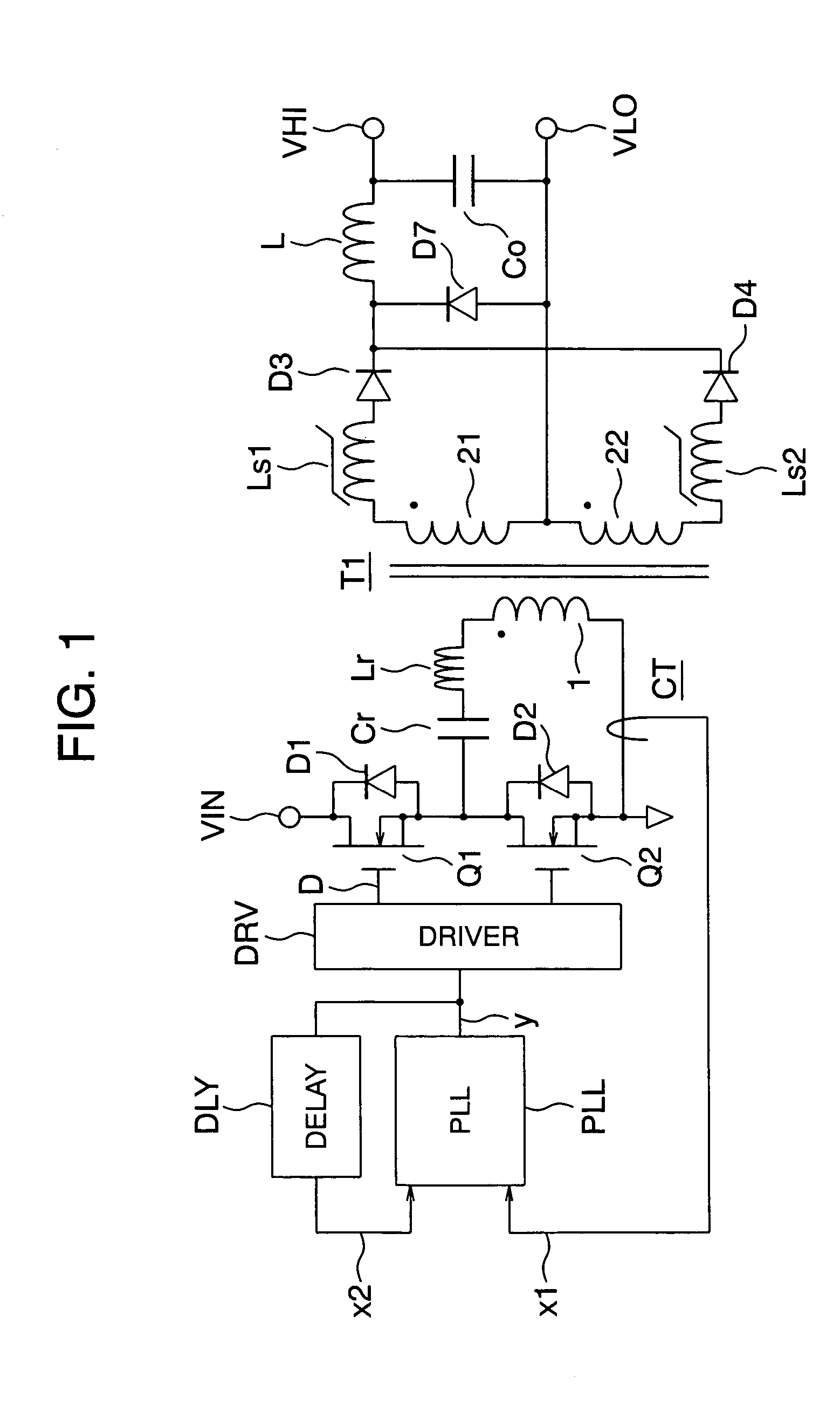

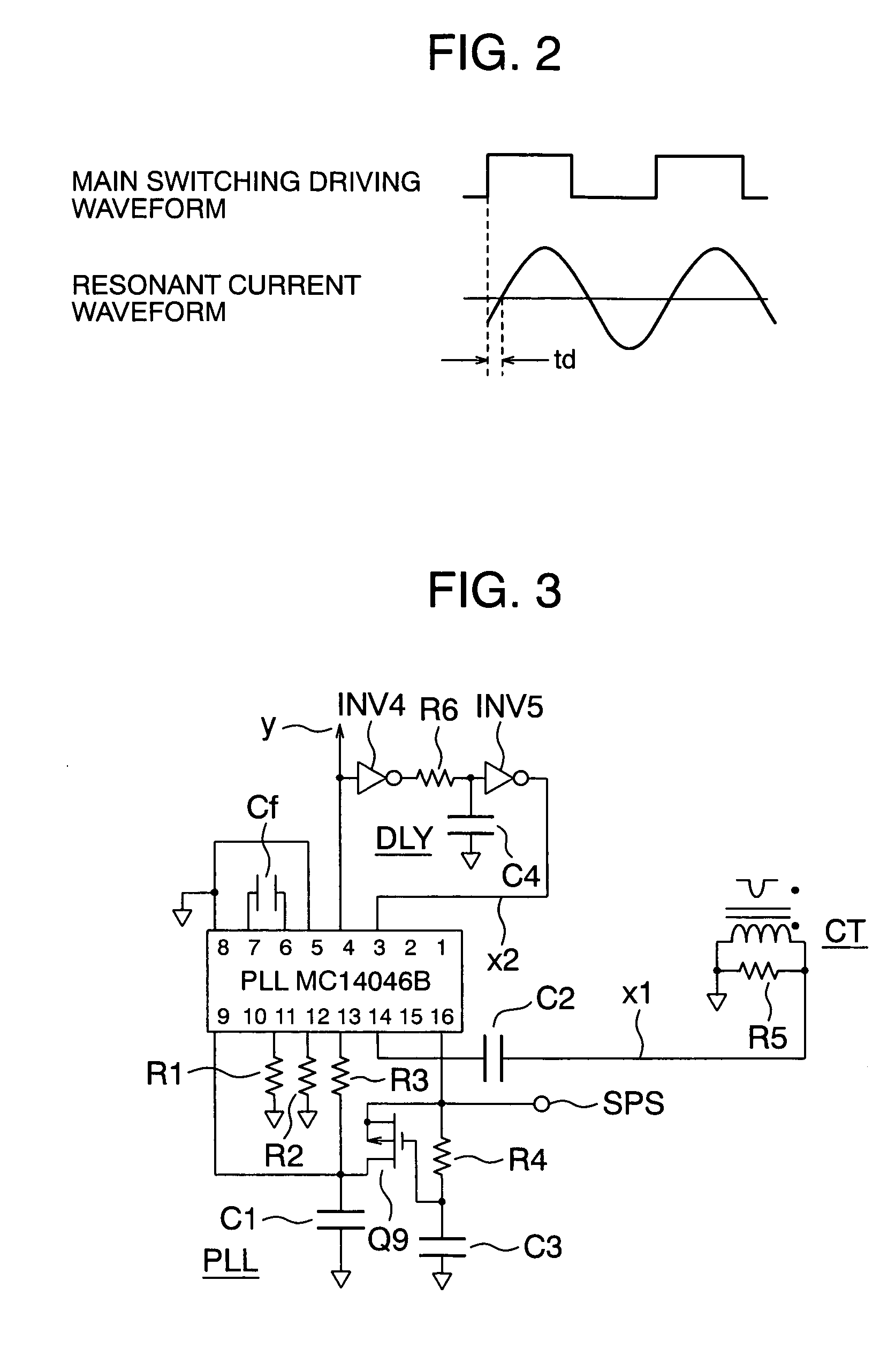

Resonant converter and control method thereof

InactiveUS20050099827A1Simple designReliable soft switching operationAc-dc conversion without reversalEfficient power electronics conversionSoft switchingZero phase

A resonant converter which can realize its easy design, eliminate the need for its adjustment, realize reliable soft switching operation, and increase an efficiency. A driver DRV of a main switching device uses a PLL circuit PLL to apply frequency tracking control in such a manner that a driving frequency fsw is made to track a resonant frequency fr (or 1 / N thereof, N being an odd number) and that the phase of the driving frequency fsw leads the current zero phase of the resonant frequency fr always by a desired time. As a result, such an optimum condition can be kept that the main switching device is triggered immediately before the zero-cross point of a resonant current. Thus the resonant converter which can always satisfy the optimum operational conditions, realize soft switching operation, and increase an efficiency can be realized with an easy design and a manufacturing adjustment-free arrangement.

Owner:HITACHI LTD

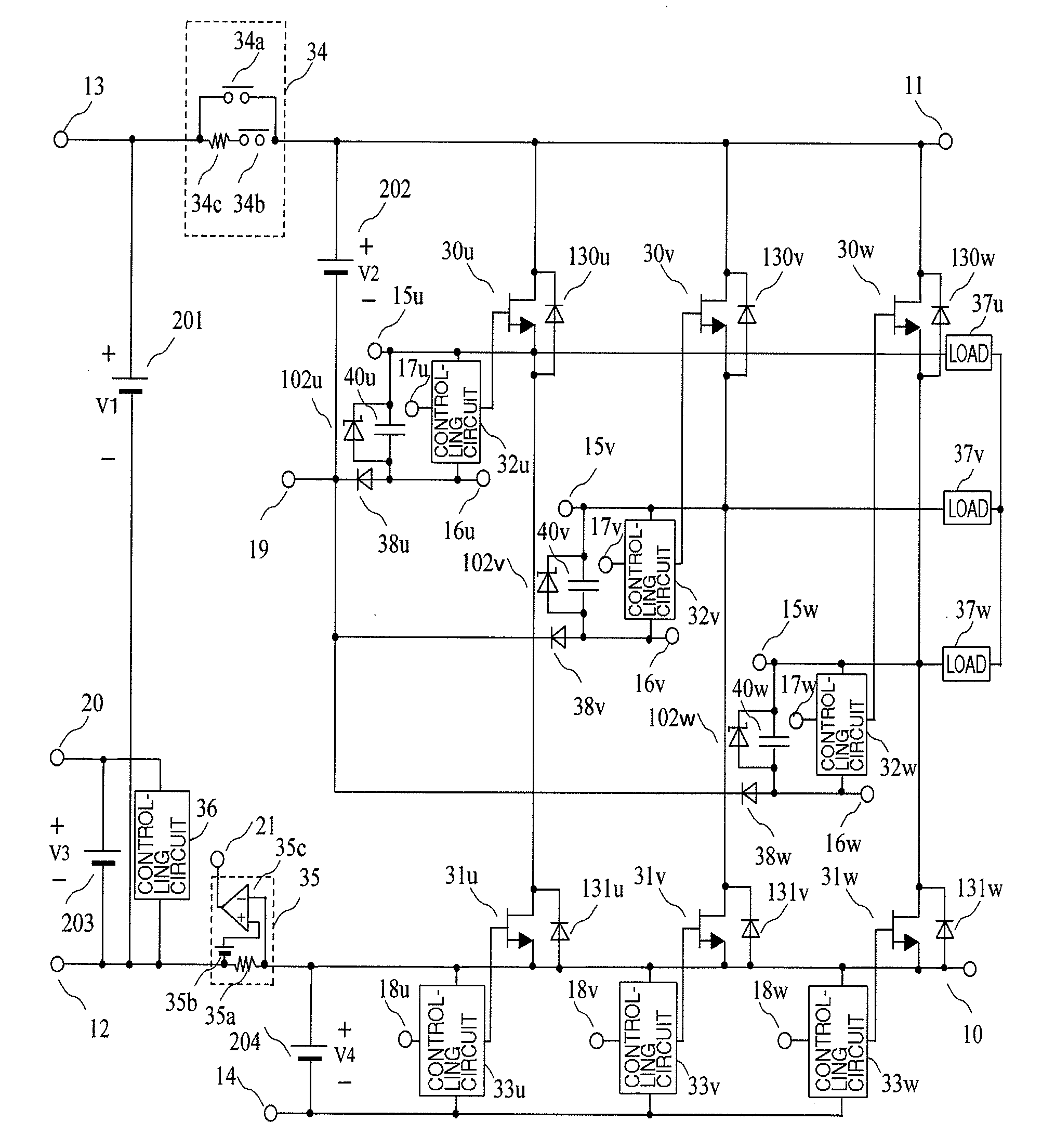

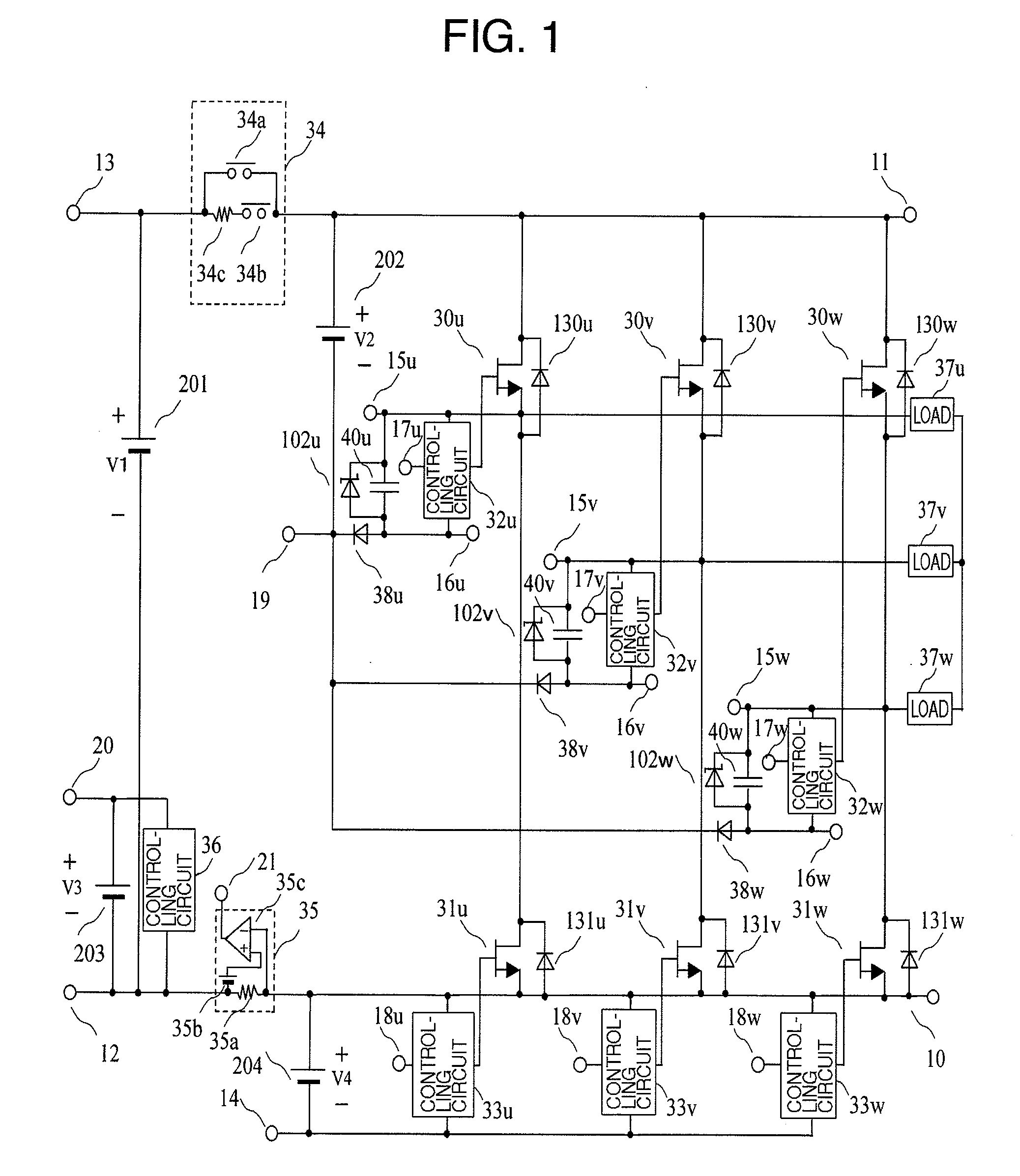

Semiconductor circuit

InactiveUS20070216469A1Small sizeImprove reliabilityTransistorElectronic switchingPower switchingNegative power

A semiconductor circuit suitable for normally-on switching elements or switching elements low in threshold voltage. A negative power supply is charged by a high-voltage power supply. A high-voltage switch controls the advisability of applying a voltage to a high-voltage terminal. With deducing the power supply to power switching elements, the high-voltage switch is turned off, and even in the case where the voltage of the controlling circuits of the power switching elements is reduced, the power supply capacitors for the controlling circuits are charged by the high-voltage terminal thereby to operate the controlling circuits. Further, a negative power source voltage generating circuit utilizes the energy charged to the capacitors from output terminals. A voltage terminal is inserted between the high-voltage terminal and a reference voltage terminal. The negative power source voltage generating circuit is interposed between the voltage terminal and a plurality of the output terminals.

Owner:HITACHI LTD

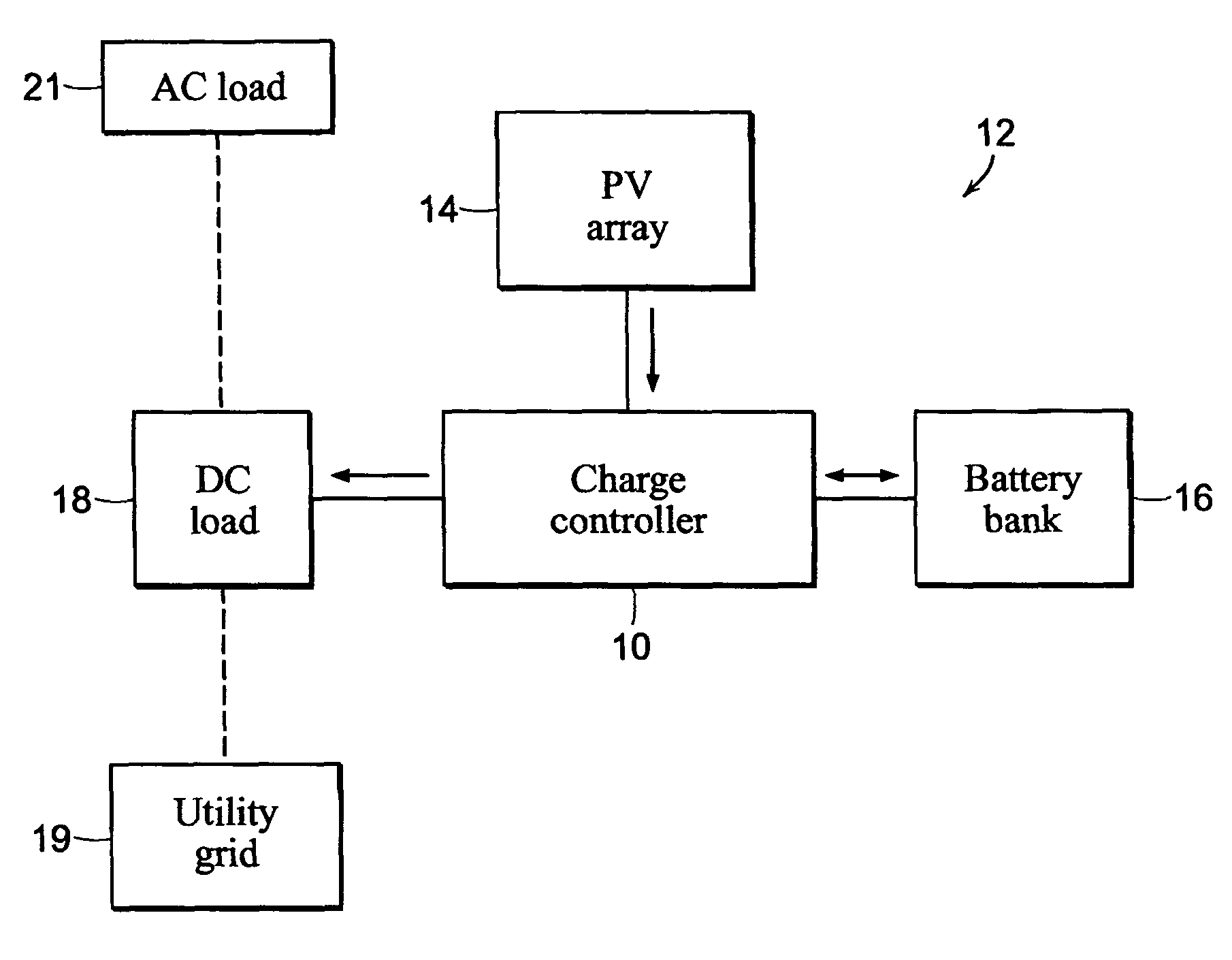

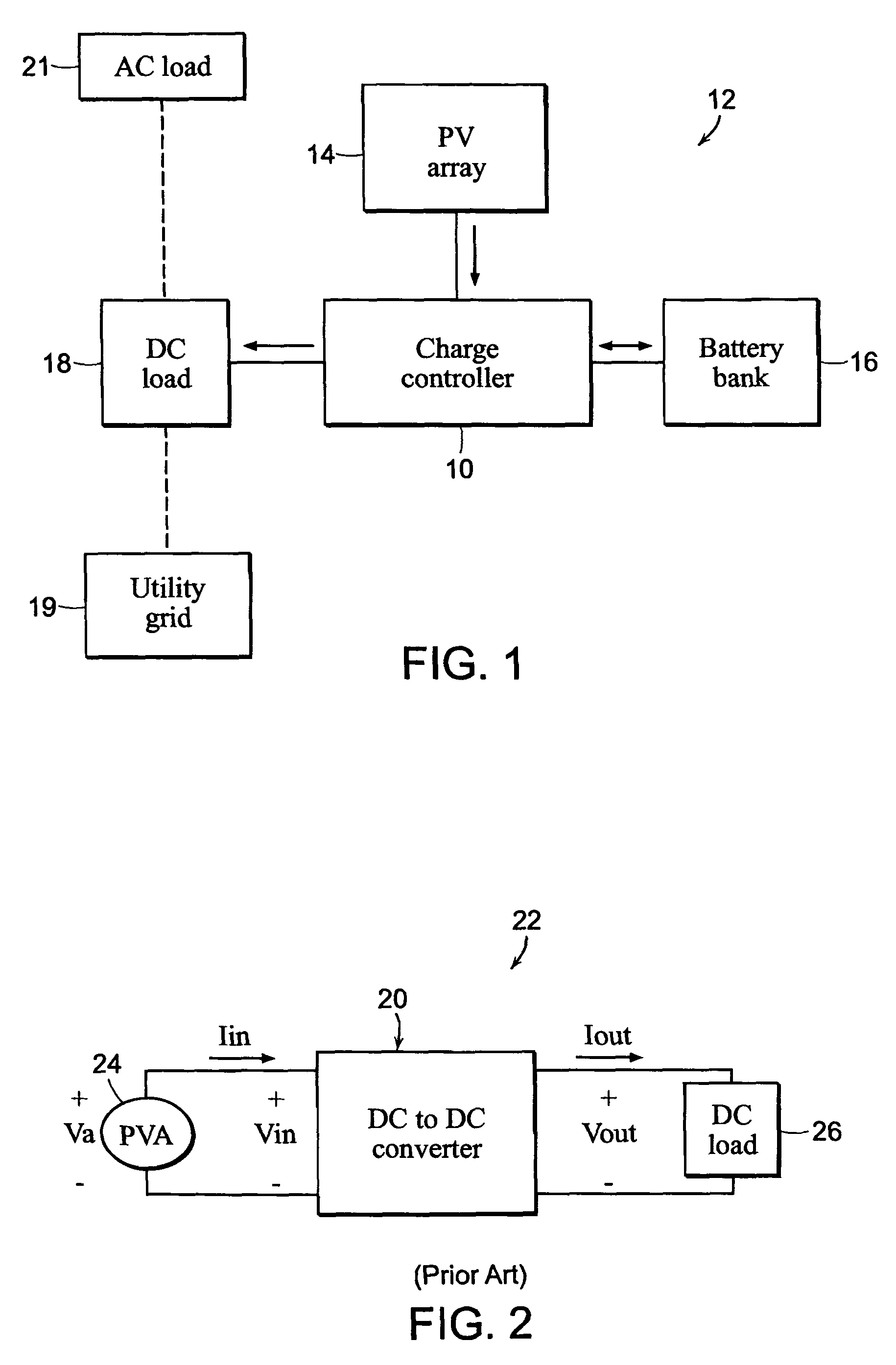

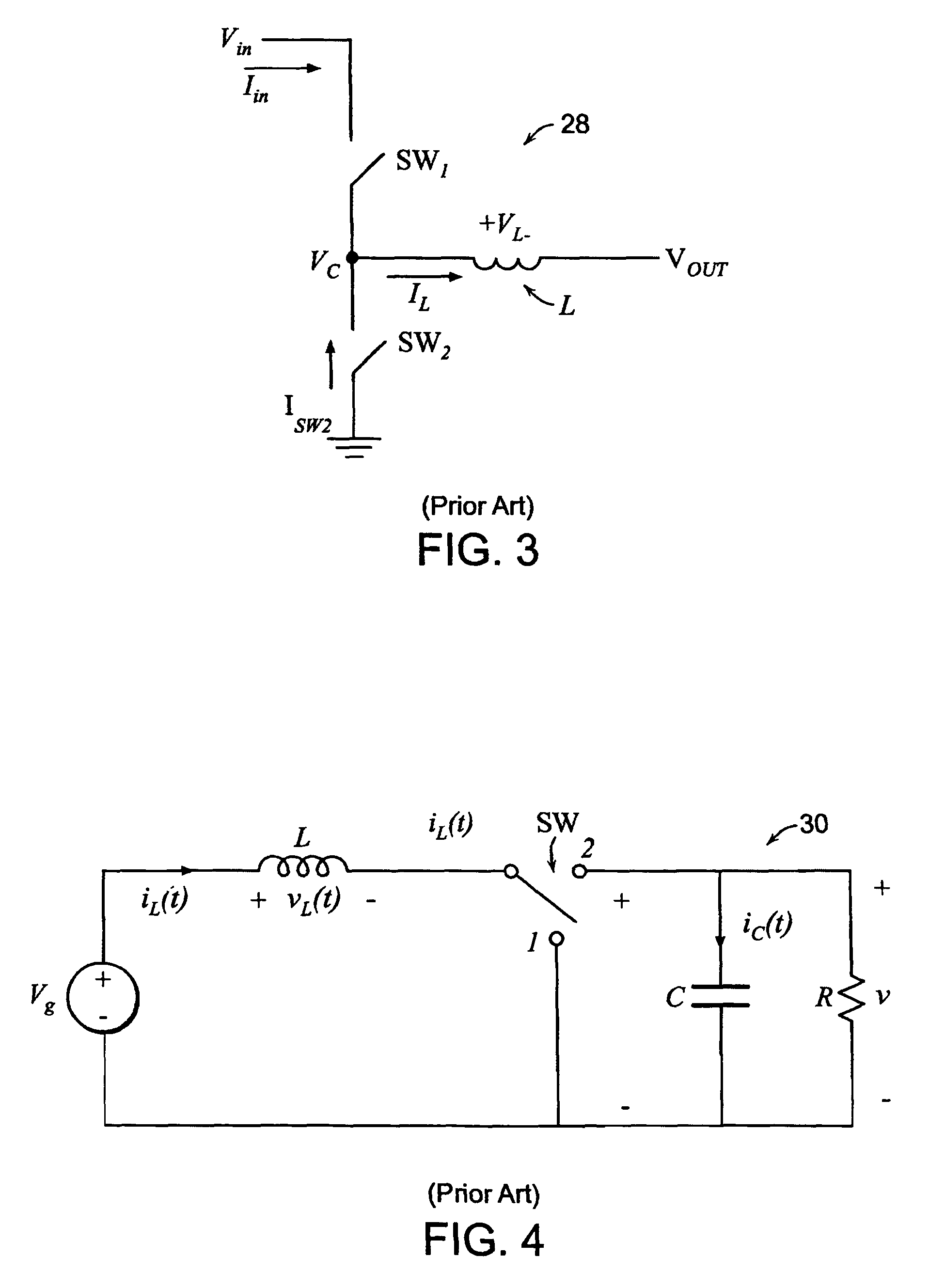

Modulation control scheme for power converters in photovoltaic system charge controllers

ActiveUS8970161B1Maximize efficiencyConduction loss can be minimizedEfficient power electronics conversionDc-dc conversionEngineeringMaximum power point tracking

A modulation control scheme for a series-connected dual active bridge (DAB) DC to DC converter in a maximum power point tracking charge controller used in a photovoltaic system controls operation of the converter in a forward direction power flow mode to control charging of a battery bank with electricity produced by the photovoltaic array. The modulation control scheme is also capable of operating the converter in a reverse direction power flow mode to control the flow of electricity from the battery bank to a DC load. The modulation control scheme divides the converter's operating range in each mode into five main cases of minimum root mean square (M-RMS) operating regions and seven main cases of full zero-voltage switching (F-ZVS) operating regions, as well as transition operating regions between adjacent main cases, based on applicable power level and value of voltage differential.

Owner:CUADROS CARLOS

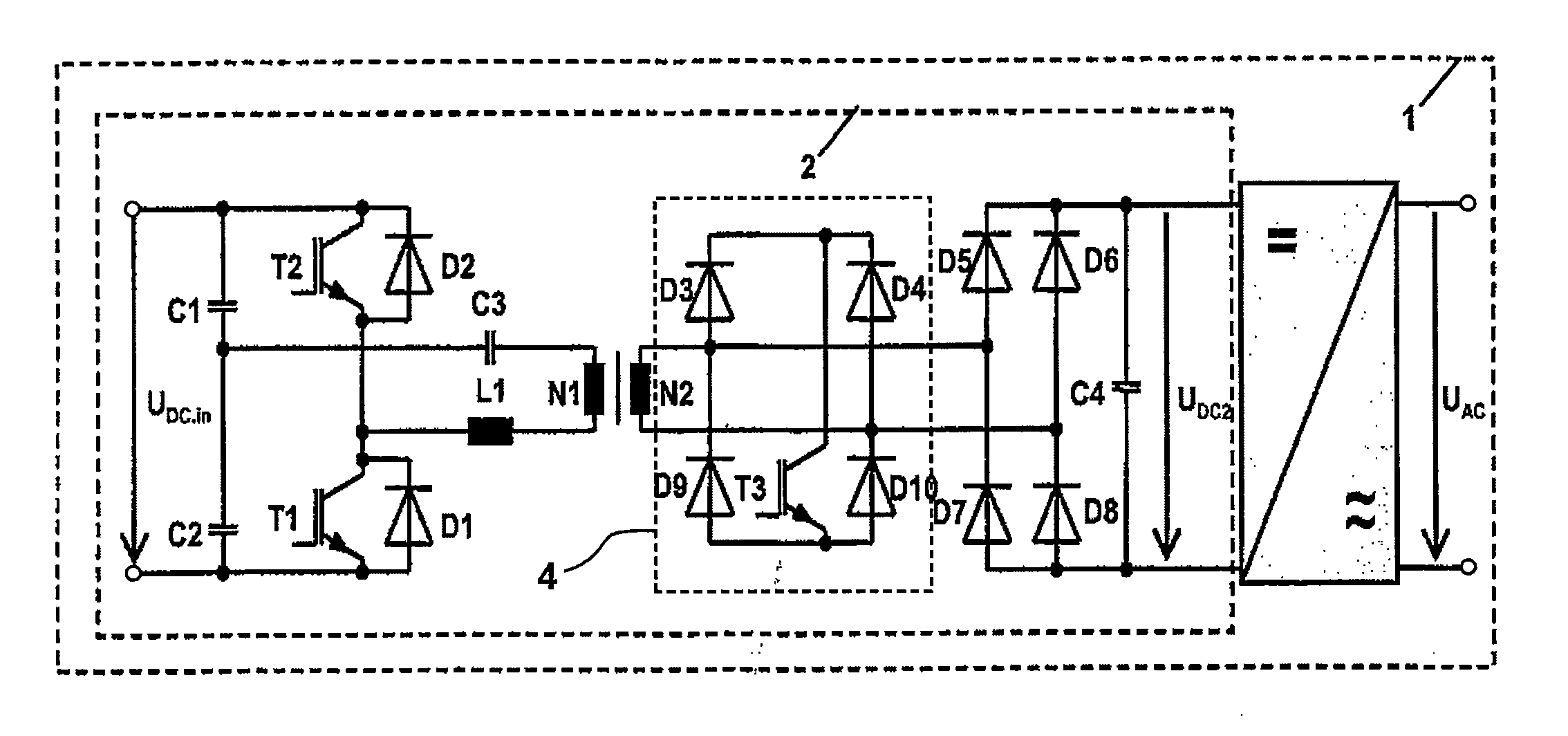

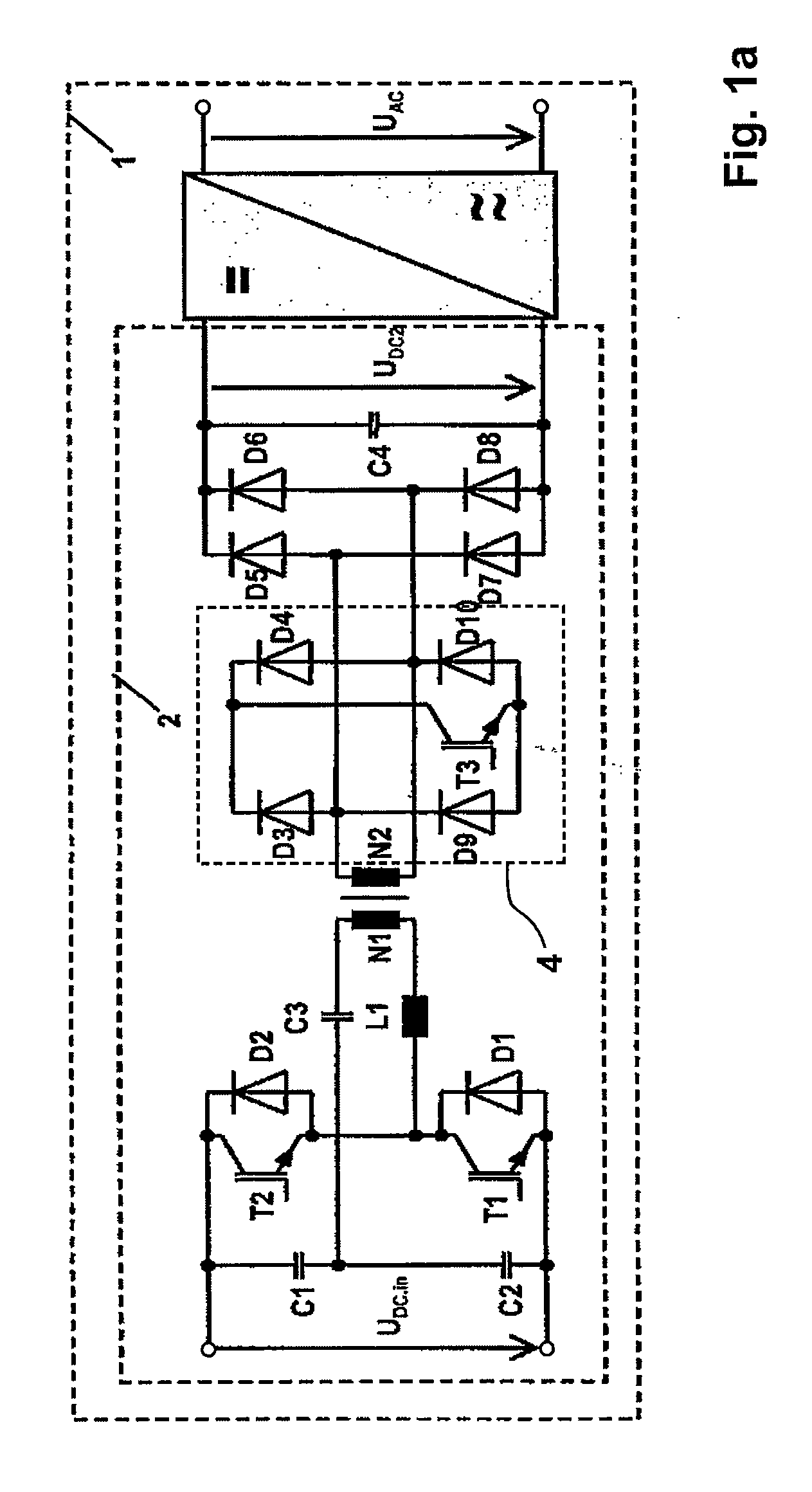

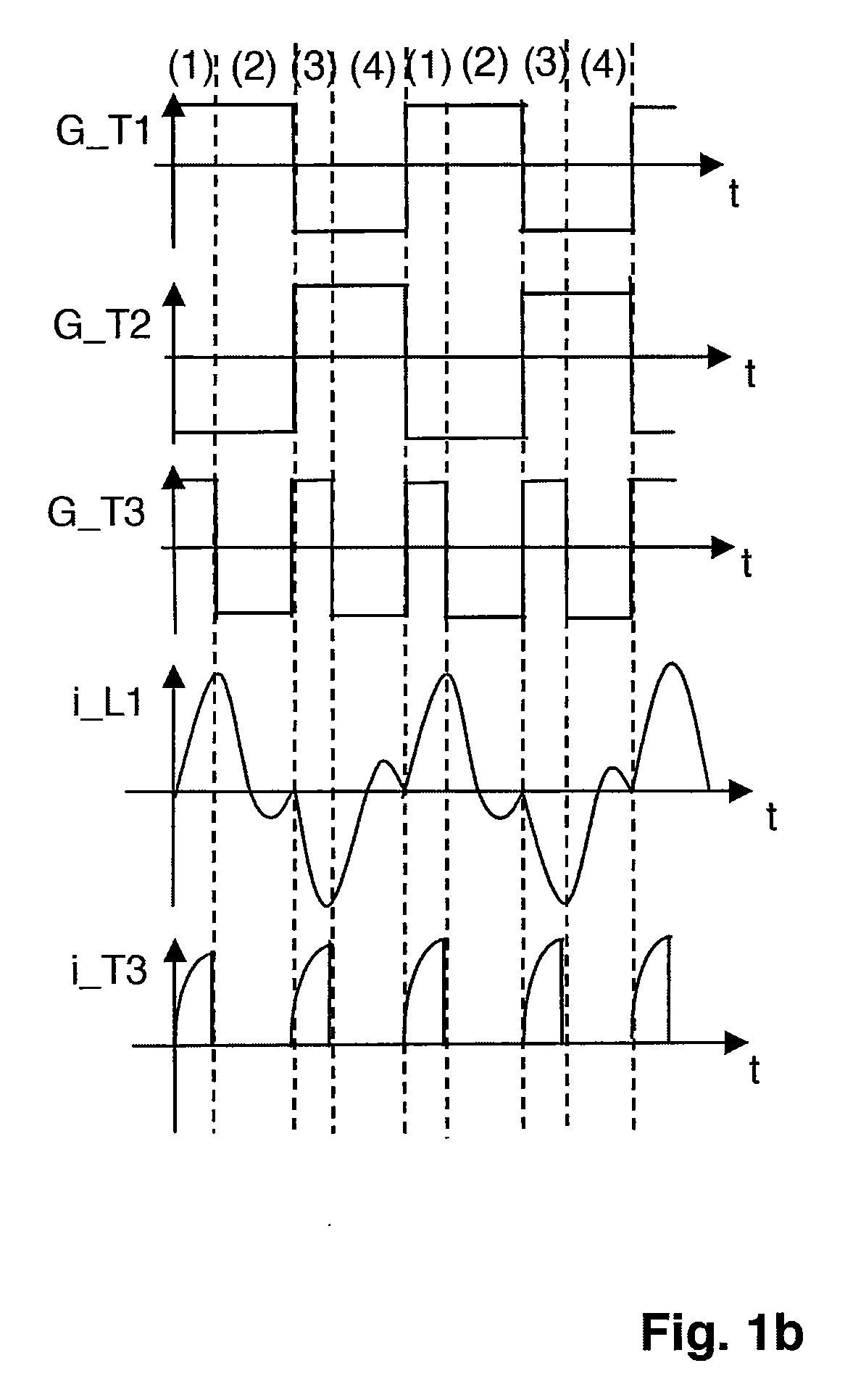

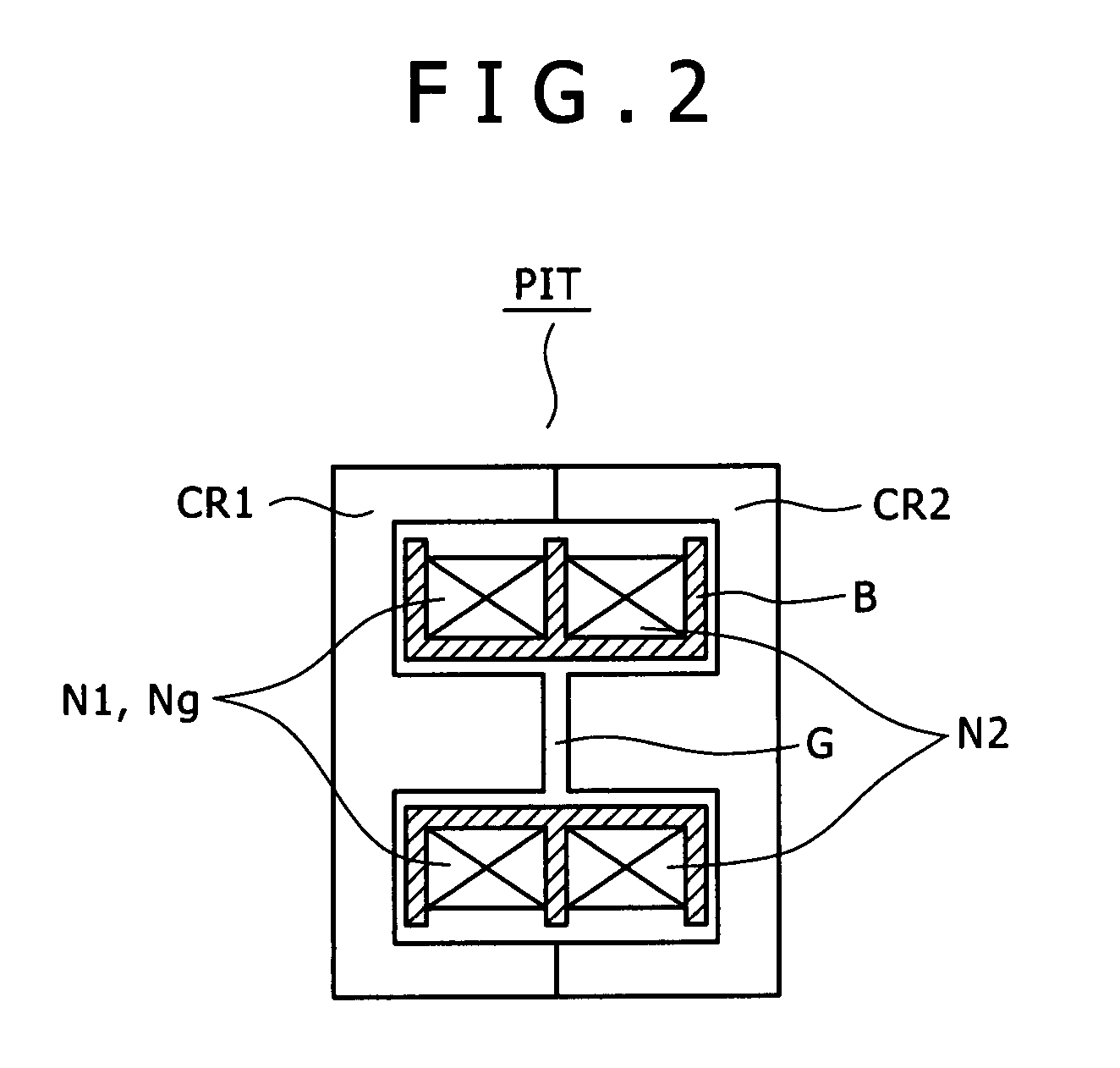

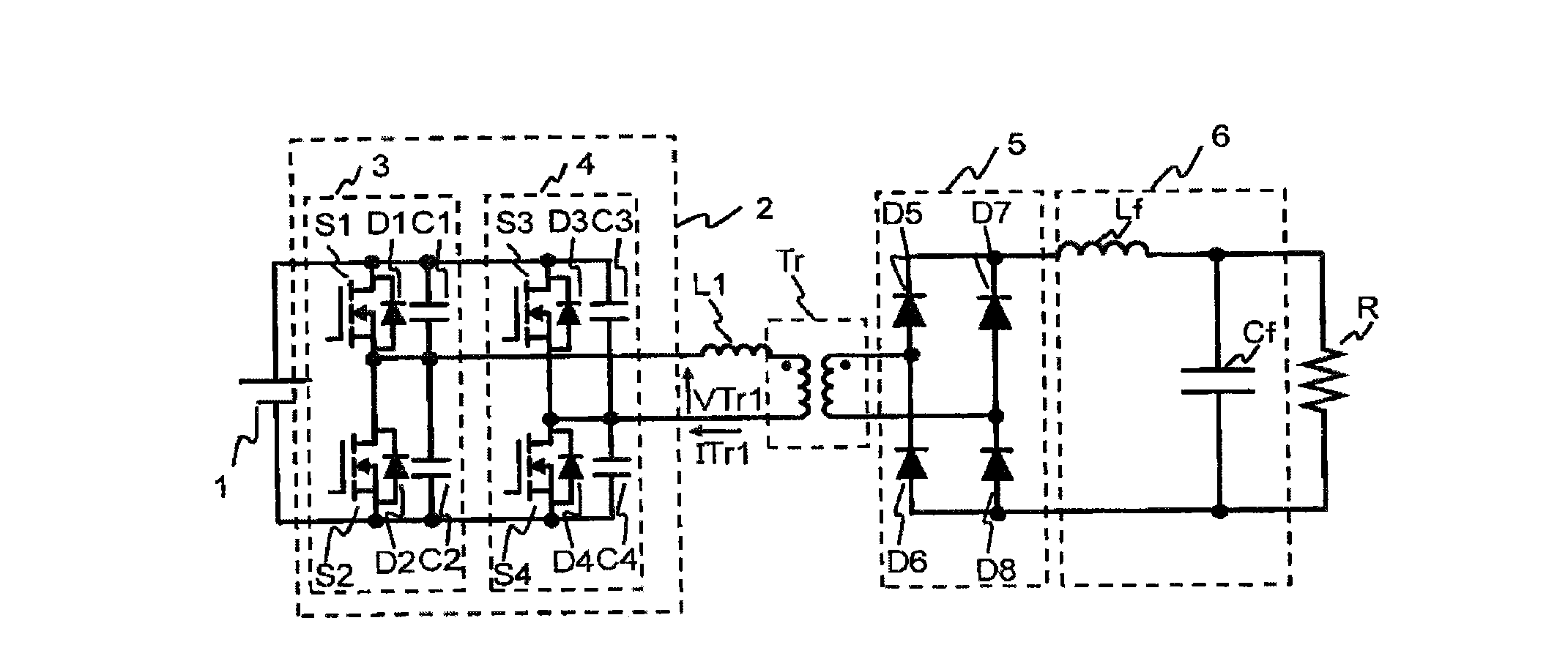

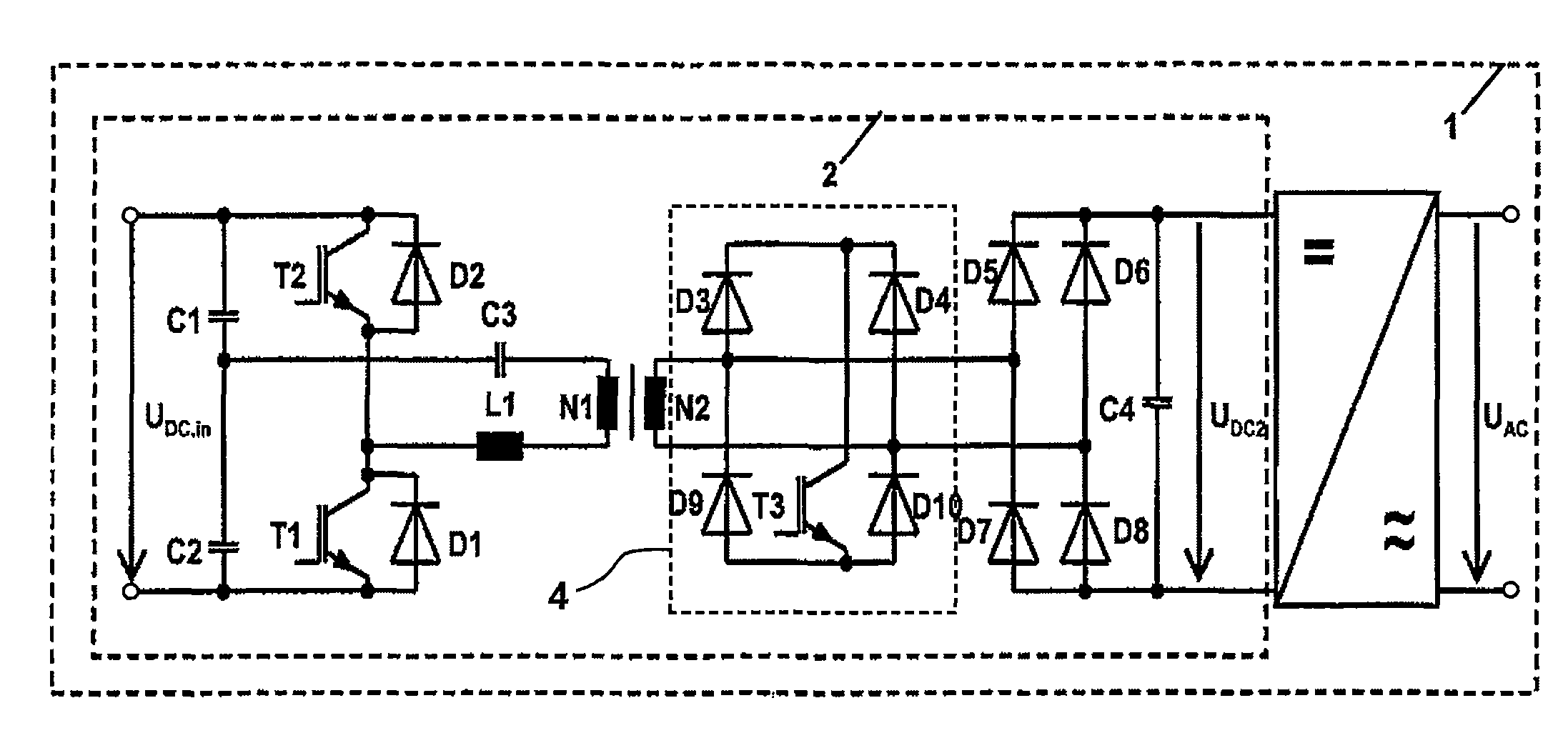

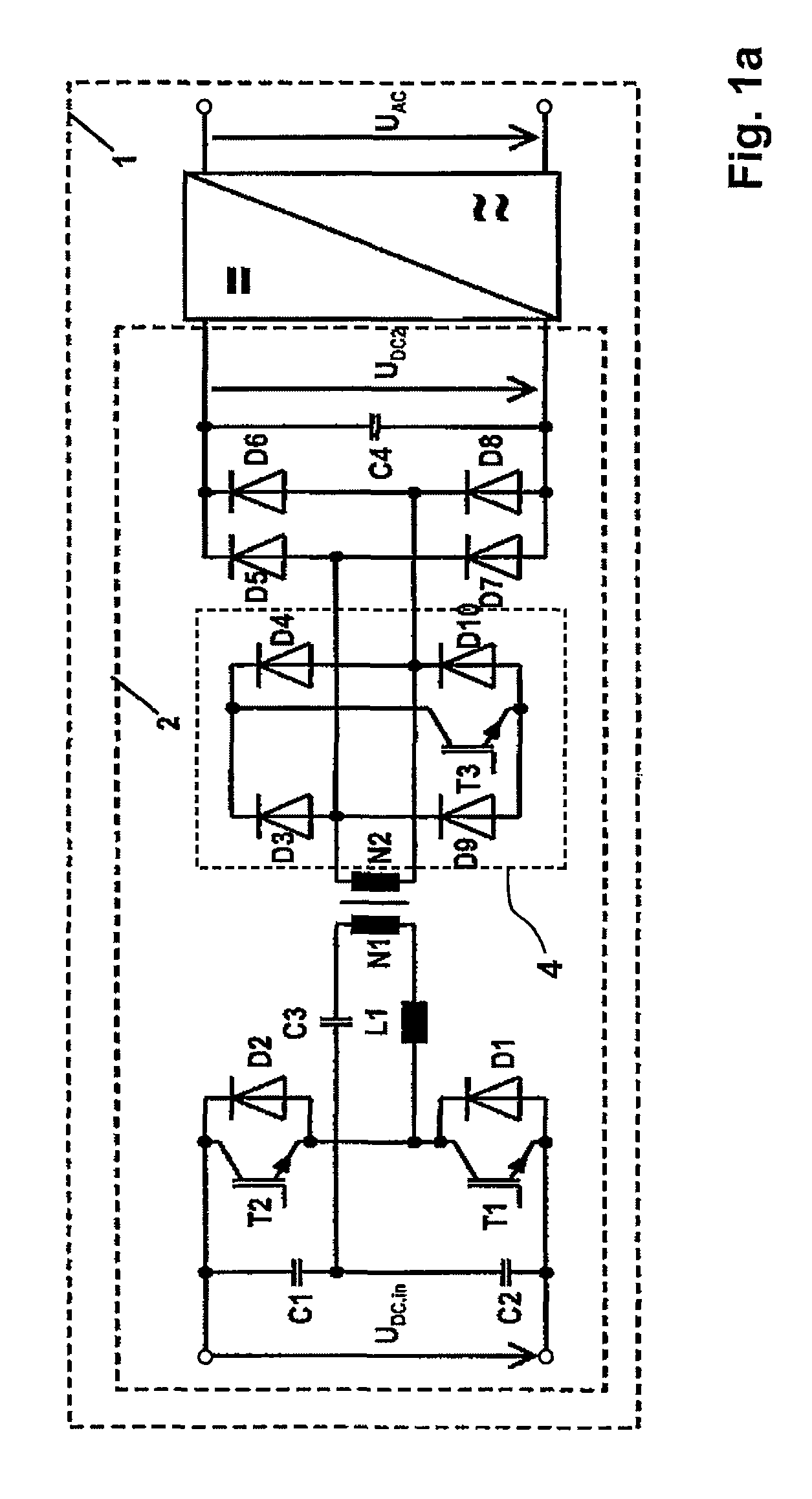

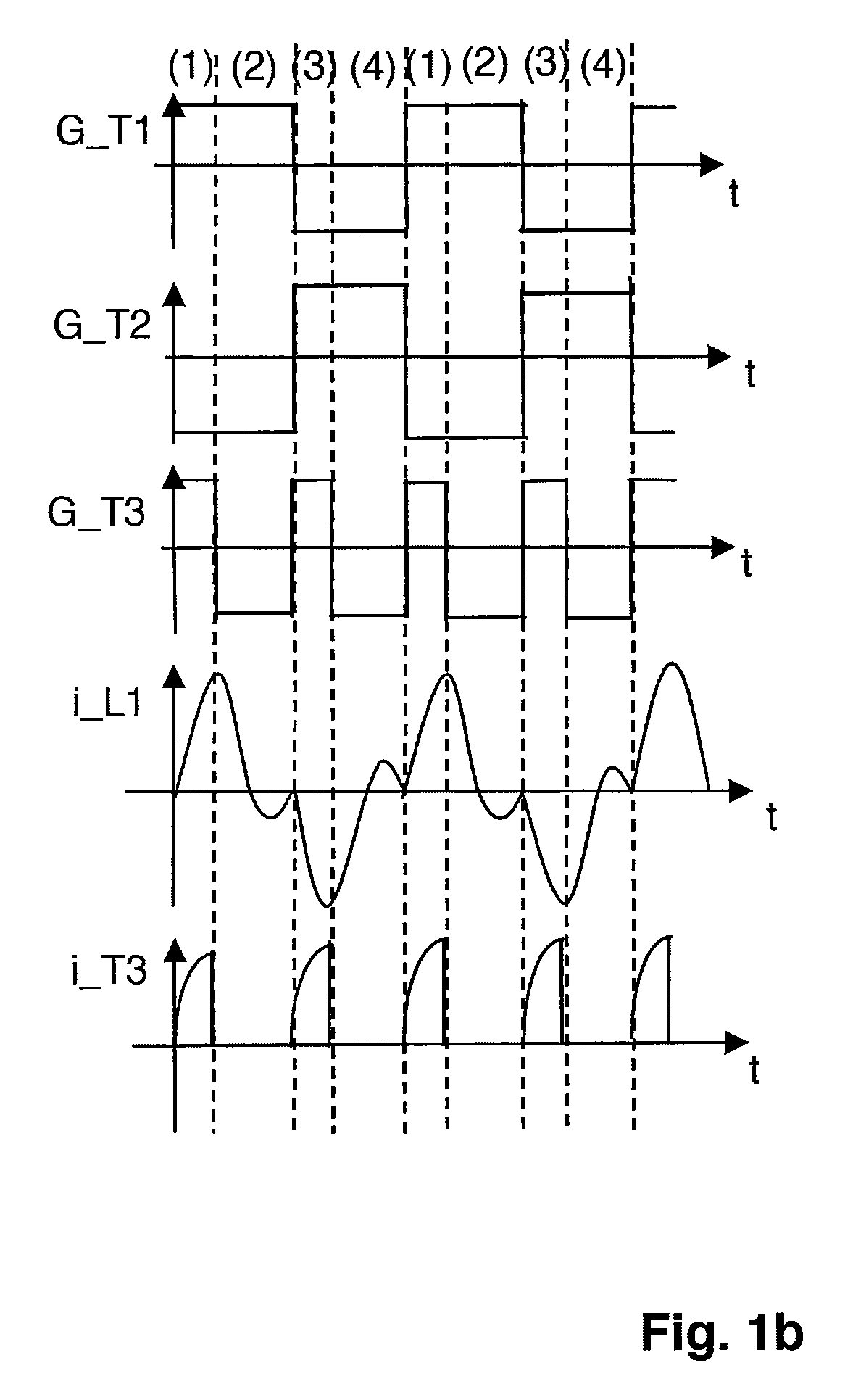

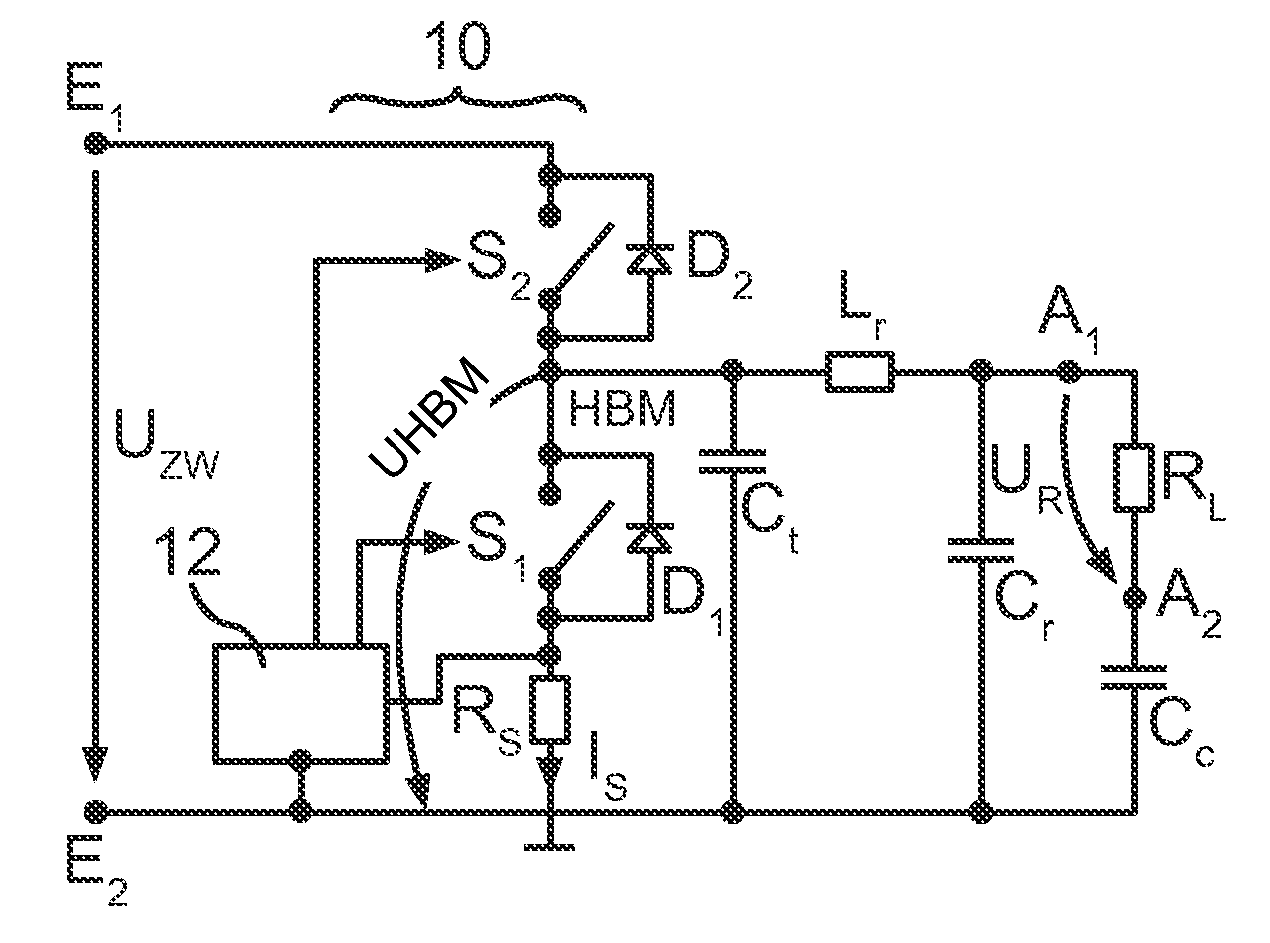

Dc/dc converter

ActiveUS20100008107A1Superior in pointSolve leakage currentAc-dc conversion without reversalEfficient power electronics conversionCapacitanceEngineering

A direct current-direct current (DC / DC) converter operated in the resonant mode of operation for converting a direct input voltage into a direct output voltage with a bridge circuit located on the input side and incorporating switching elements, with a resonance circuit incorporating a resonance inductance and a resonance capacitance as well as with a high-frequency transformer for galvanic separation is disclosed, the transformer incorporates at least one primary winding and at least one secondary winding with at least two winding terminals each. The alternating current (AC) output of the bridge circuit is connected to the primary winding and a rectifier bridge with diodes to the secondary winding. A voltage boosting circuit array is connected downstream of the resonant circuit in such a manner that at least one additionally controllable switching element is contained, which is connected in parallel or in series to at least one additional diode or to at least one diode of the rectifier bridge on the secondary side, this array being connected in parallel to the high-frequency transformer so that the additional switching element short-circuits the resonance circuit in a triggered condition so that energy is stored in the resonance inductance and is delivered in the non-triggered condition.

Owner:SMA SOLAR TECH AG

Resonant converter and control method thereof

InactiveUS7088594B2Simple designReliable soft switching operationAc-dc conversion without reversalEfficient power electronics conversionSoft switchingZero phase

A resonant converter which can realize its easy design, eliminate the need for its adjustment, realize reliable soft switching operation, and increase an efficiency. A driver DRV of a main switching device uses a PLL circuit PLL to apply frequency tracking control in such a manner that a driving frequency fsw is made to track a resonant frequency fr (or 1 / N thereof, N being an odd number) and that the phase of the driving frequency fsw leads the current zero phase of the resonant frequency fr always by a desired time. As a result, such an optimum condition can be kept that the main switching device is triggered immediately before the zero-cross point of a resonant current. Thus the resonant converter which can always satisfy the optimum operational conditions, realize soft switching operation, and increase an efficiency can be realized with an easy design and a manufacturing adjustment-free arrangement.

Owner:HITACHI LTD

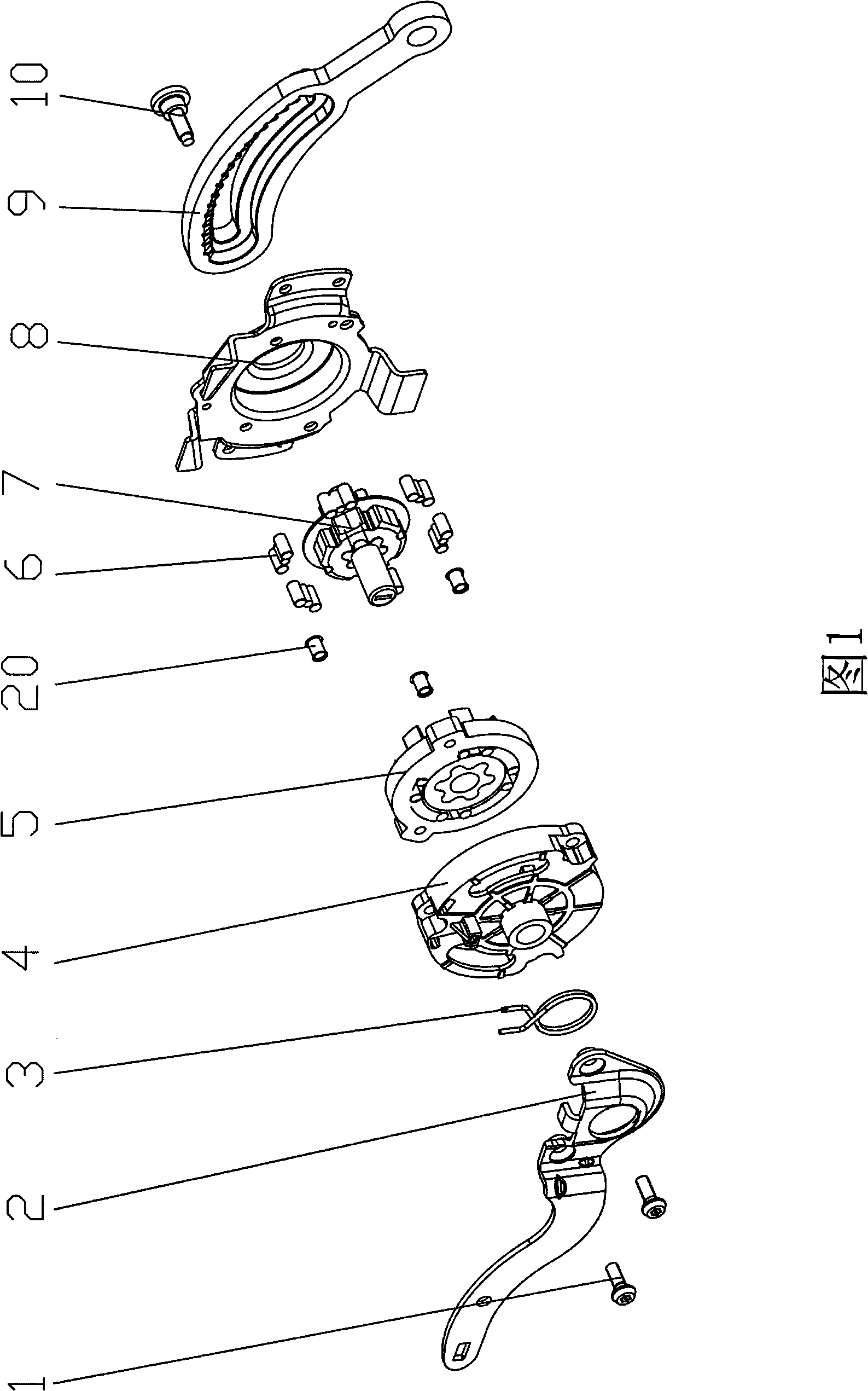

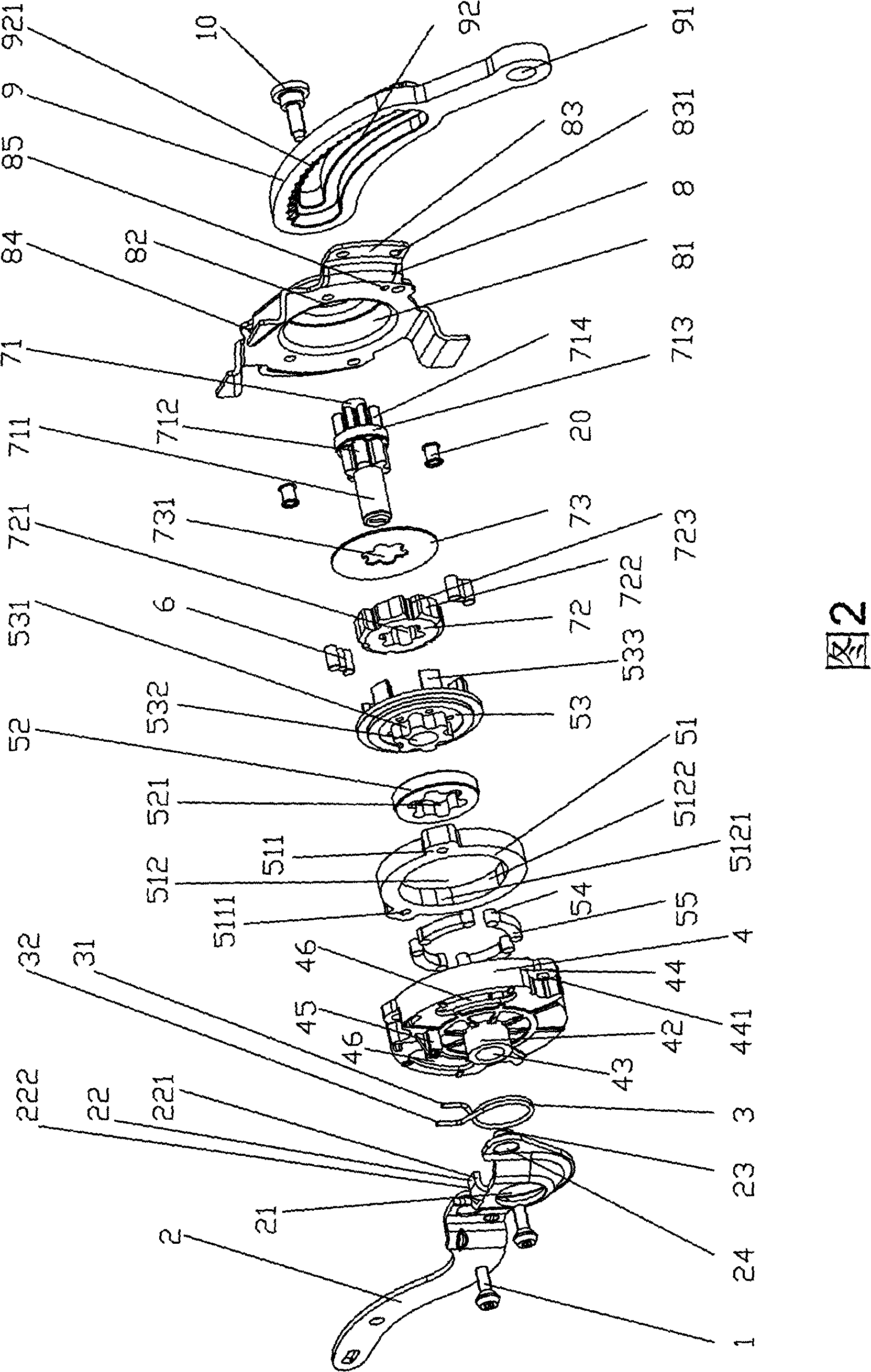

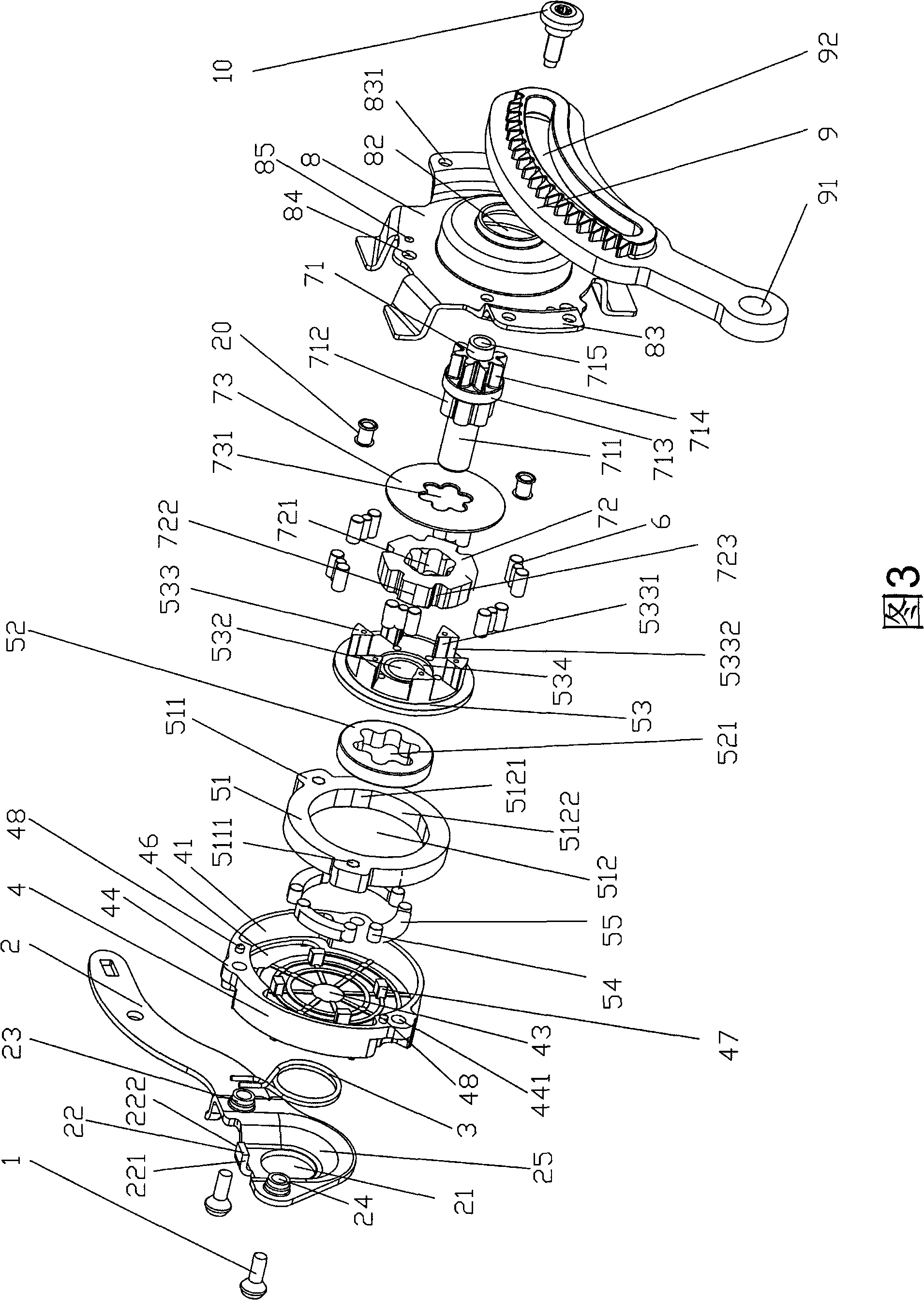

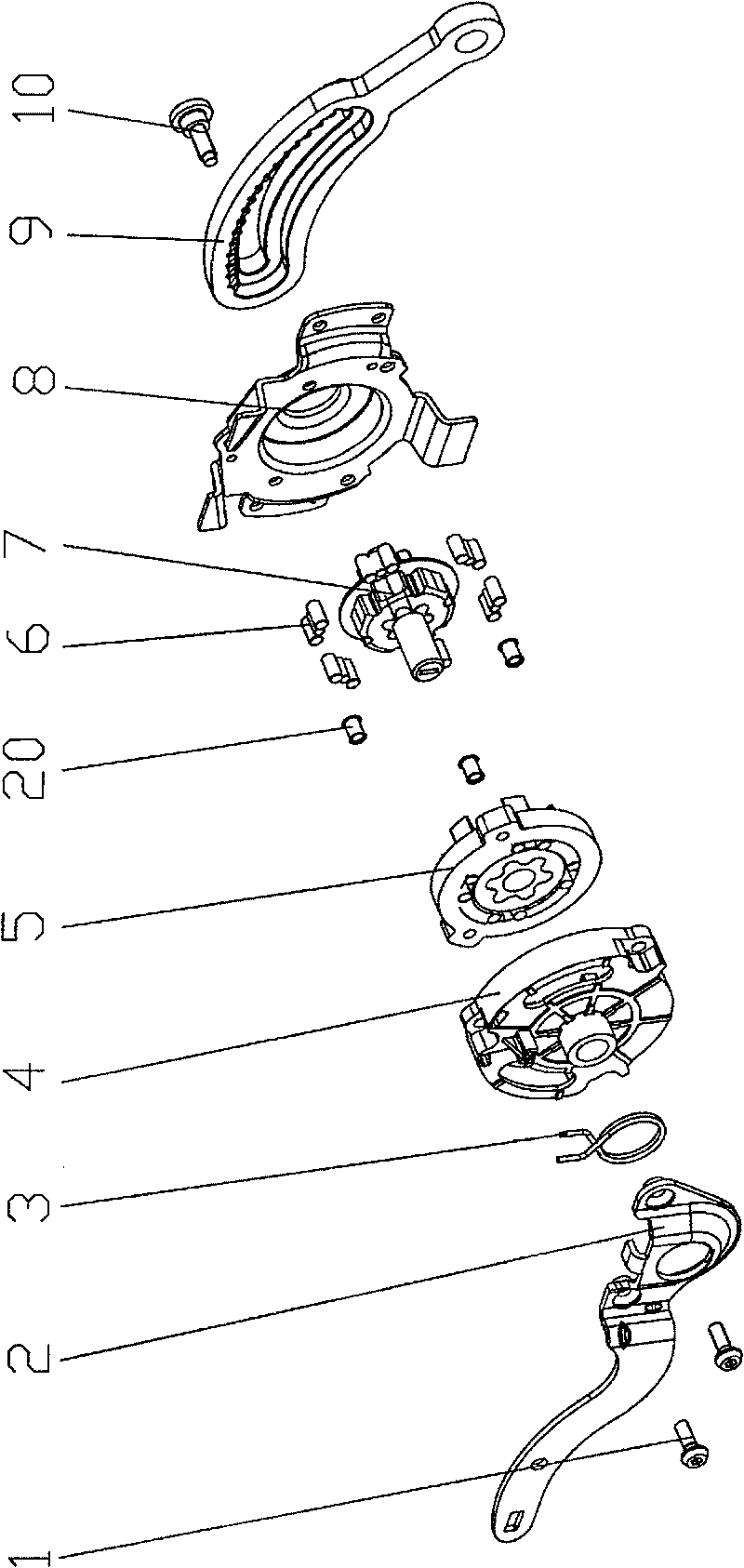

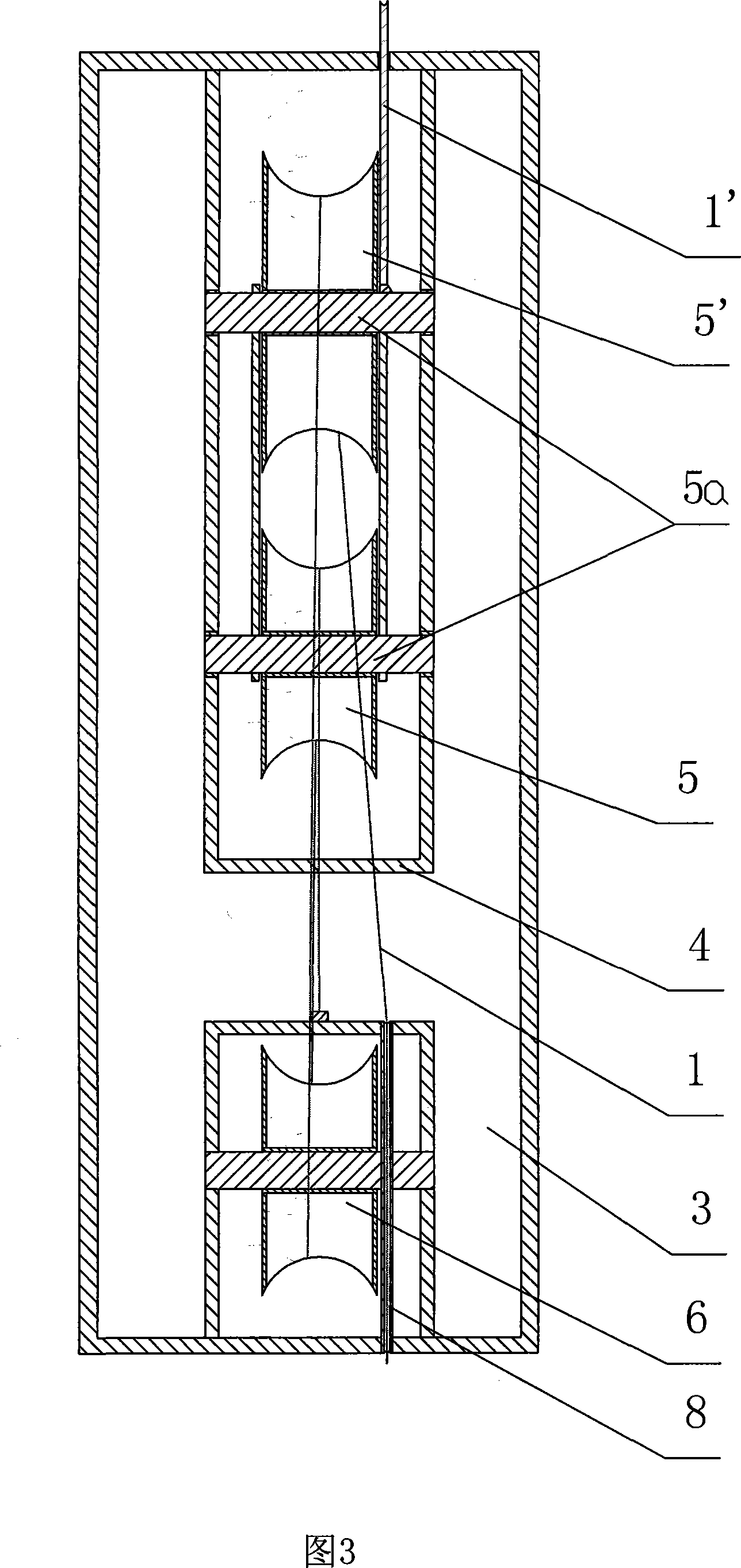

Seat height adjuster

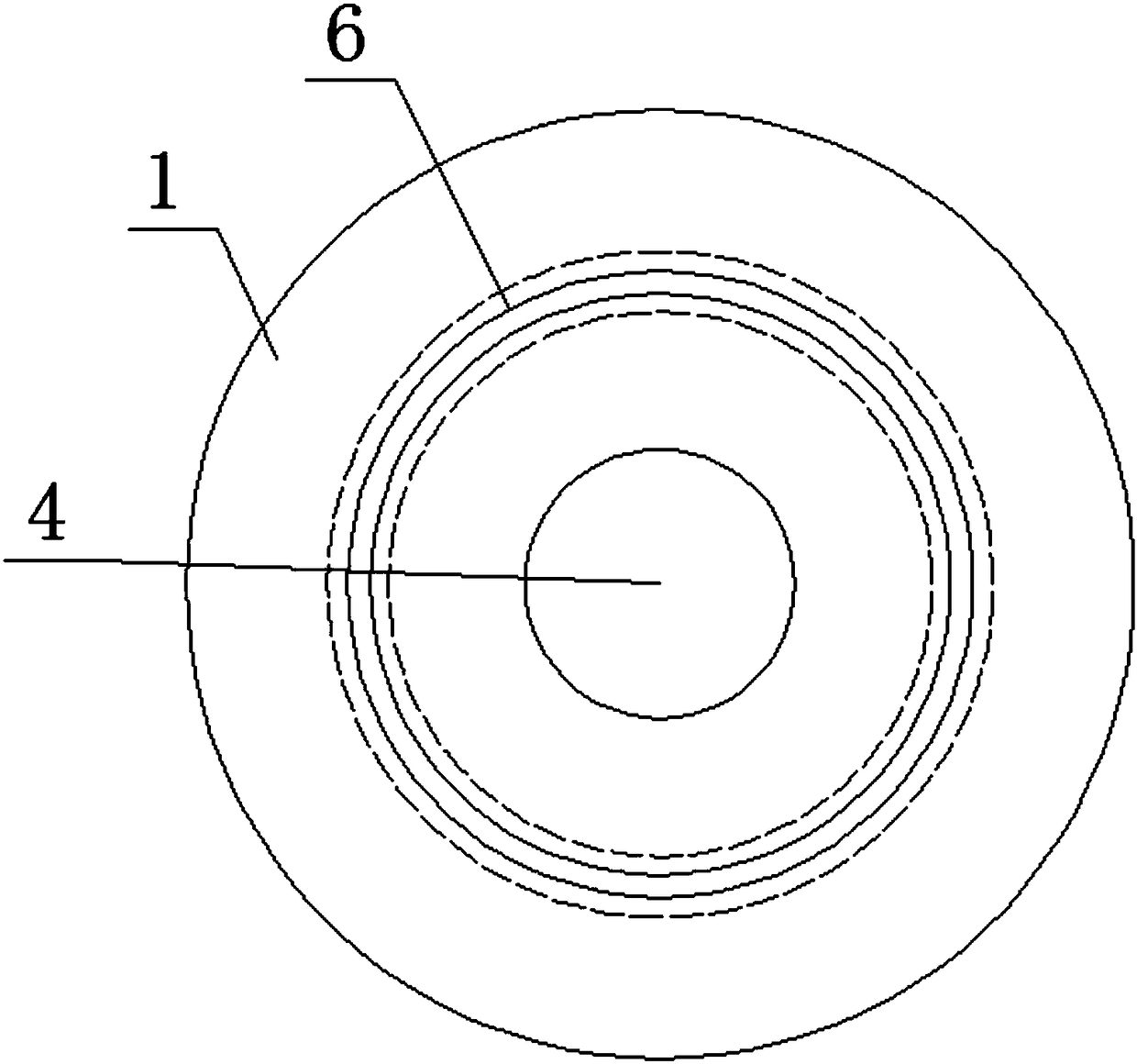

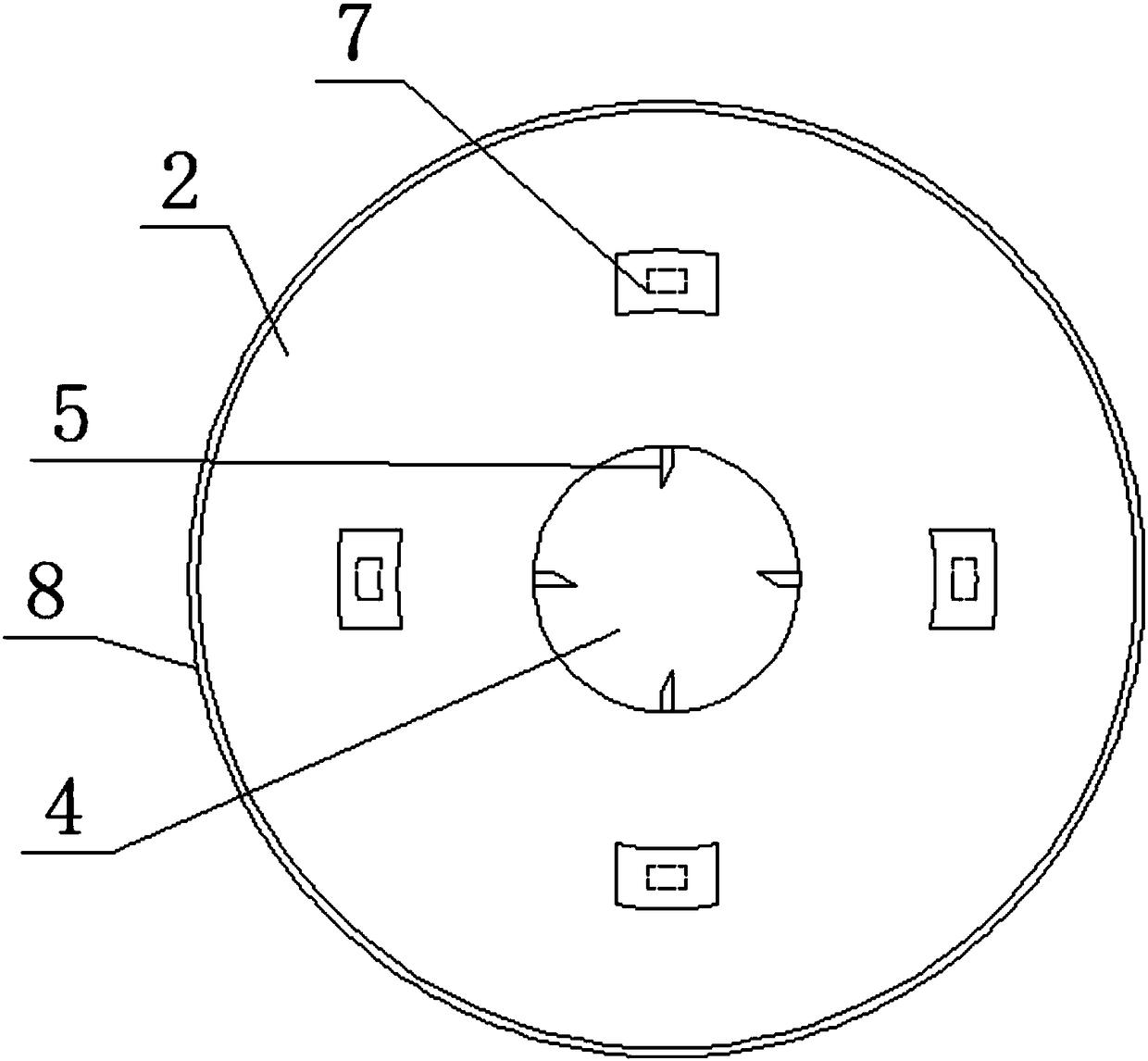

ActiveCN101323264ASmall range of reciprocating motionIncrease the use of spaceMovable seatsRange of motionReciprocating motion

A height regulator for a seat belongs to an automobile seat component, which comprises a first case which is provided with a first cavity, a second case which is connected with a side plate of the seat basin and is provided with a second cavity and a third axle hole, a first axle core a second axle core and a big roller which are arranged between the first cavity and the second cavity, a fan-shaped gear block which is connected with a seat cushion of the seat as well as a return spring and a wrench which are separately arranged at the outer side of the cover of the first case. The regulator has the advantages of small volume, simple structure and convenient installation; only one height regulator is needed on each seat, which can save usage cost; the movement has the good flexibility and the firm locking; as friction is used for driving and no space and gears exist between components, the operation is soft, flexible and energy-saving and the regulatory accuracy can be ensured; as the scope of the reciprocating motions of a wrench is small, the use space of the seat can be effectively increased; the free connection with any seat can be realized and the connection is simple; the height regulator for the seat of the invention has the wide application scope.

Owner:JIANGSU ZHONGMING XIANGHE SEIKO

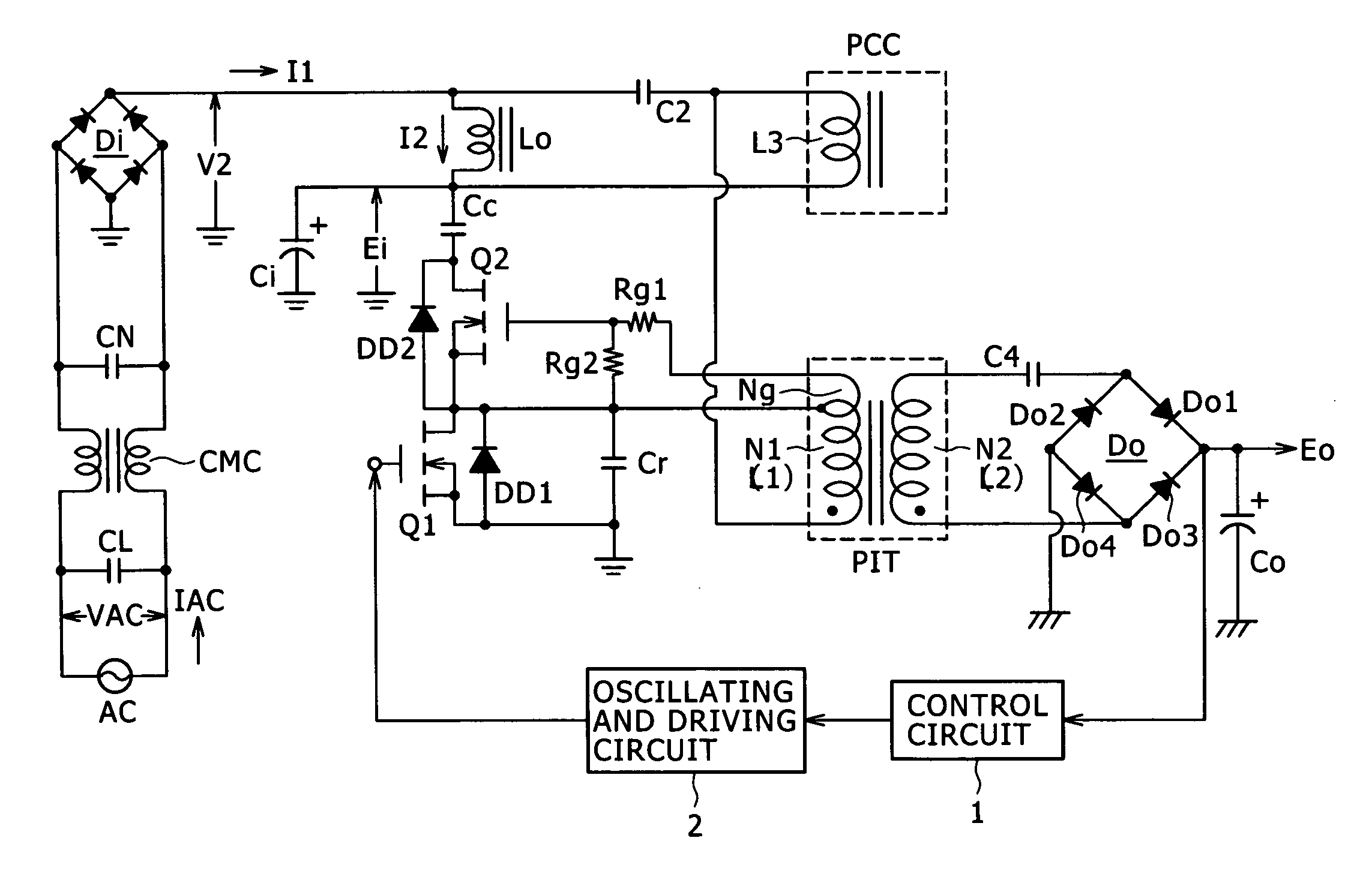

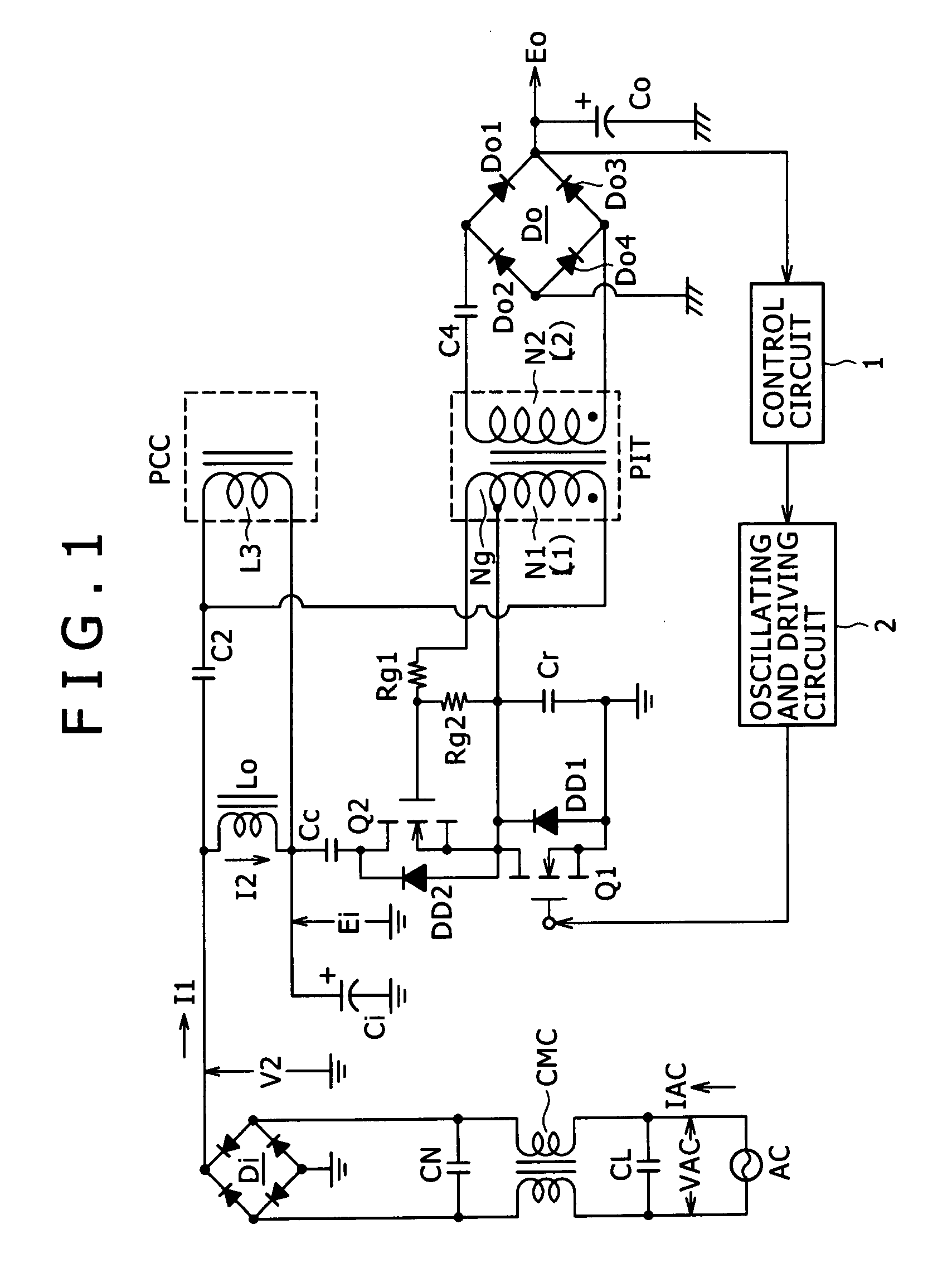

Switching power supply circuit

InactiveUS20080025052A1Improve power factorReduce switching noiseEfficient power electronics conversionAc-dc conversionPower factorEngineering

The present invention provides a switching power supply circuit which may include a rectifying and smoothing section, a converter section, and a power factor improving section. The rectifying and smoothing section may include a primary side rectifying element and a smoothing capacitor. The converter section may include a choke coil, a converter transformer, a main switching element, an oscillating and driving circuit, a primary side series resonant capacitor, a primary side parallel resonant capacitor, and an active clamping circuit. The power factor improving section may add and pass a current corresponding to a voltage generated in the primary side series resonant capacitor to the smoothing capacitor via the primary side rectifying element.

Owner:SONY CORP

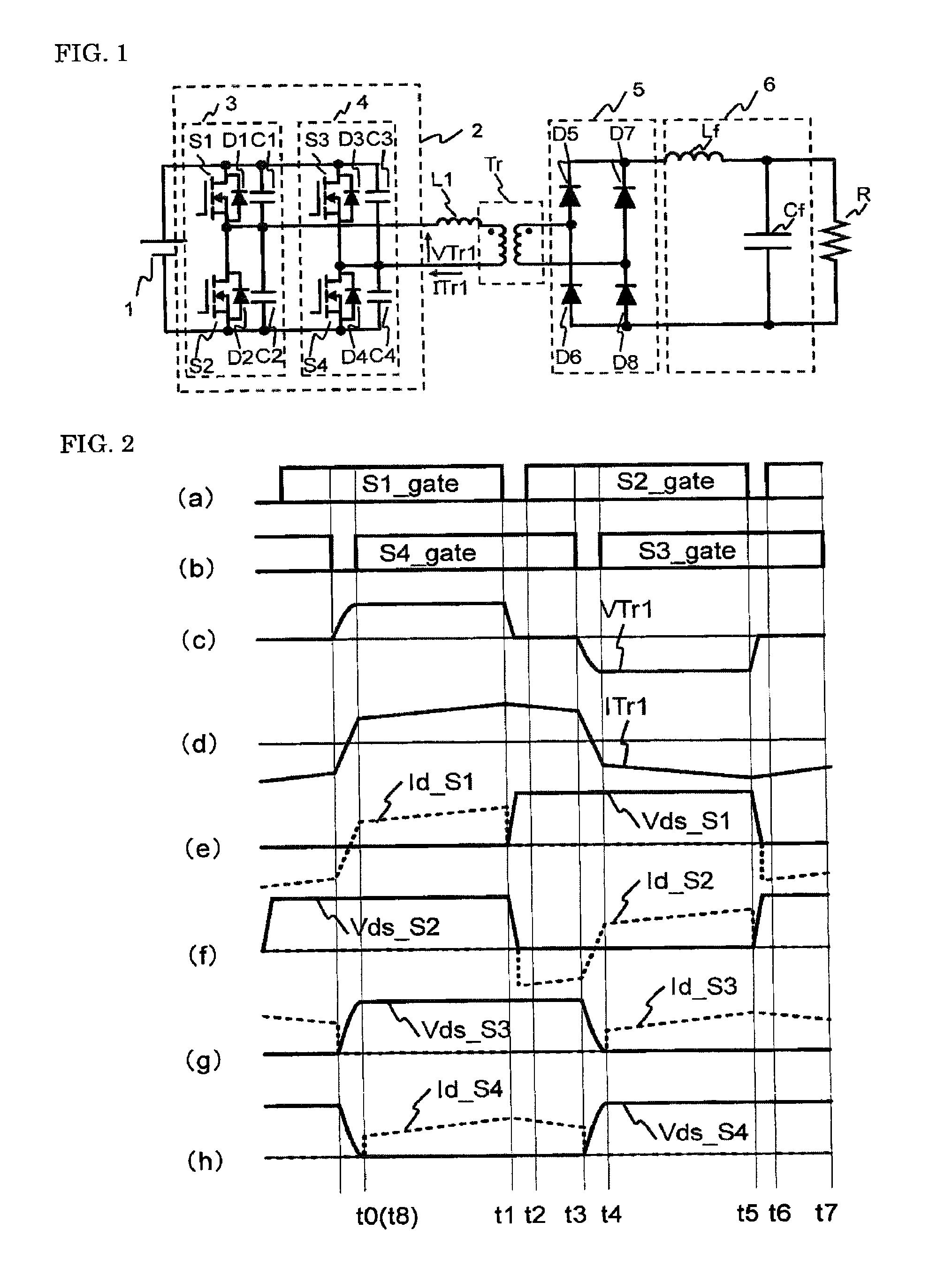

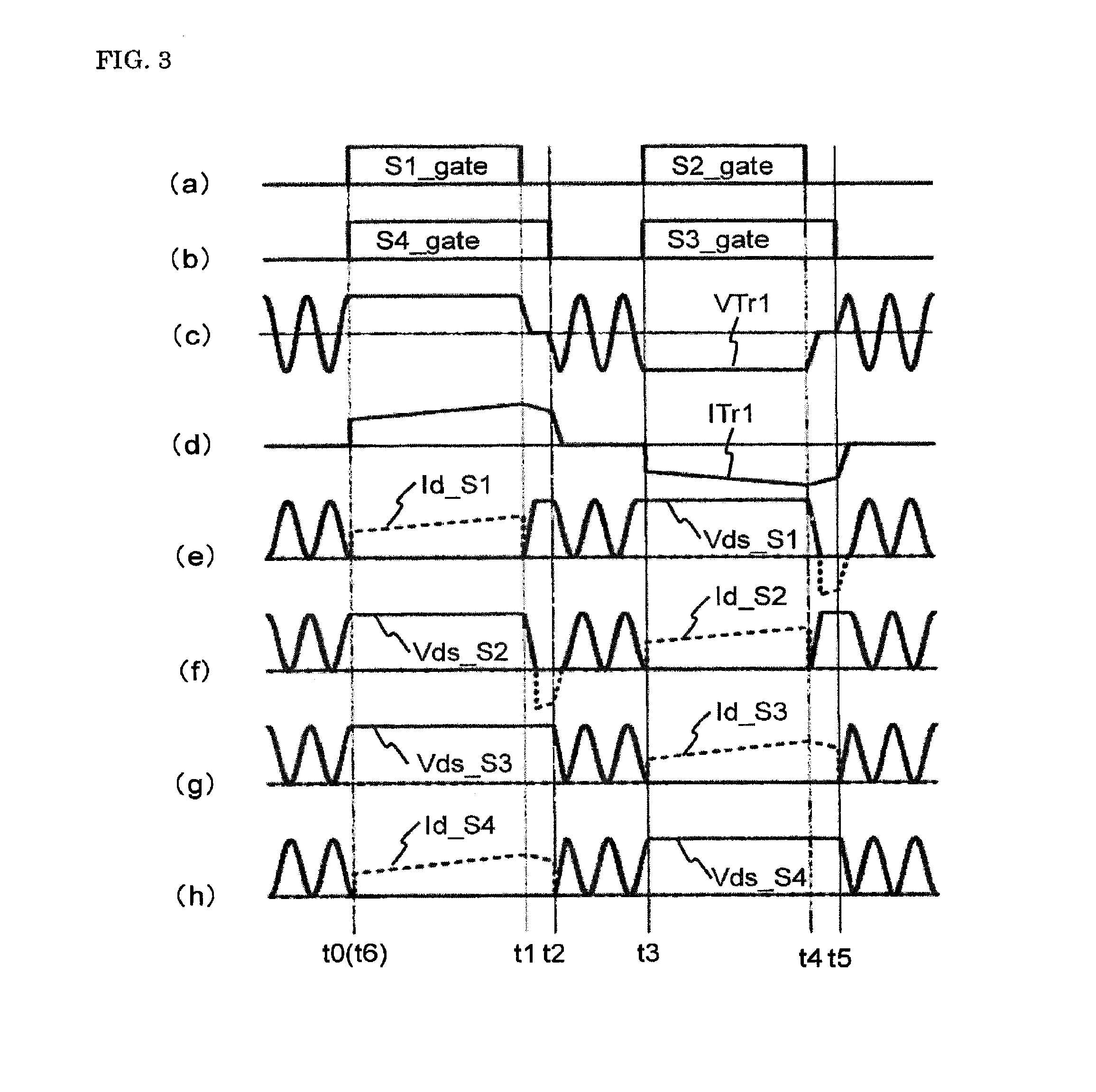

Dc-dc converter

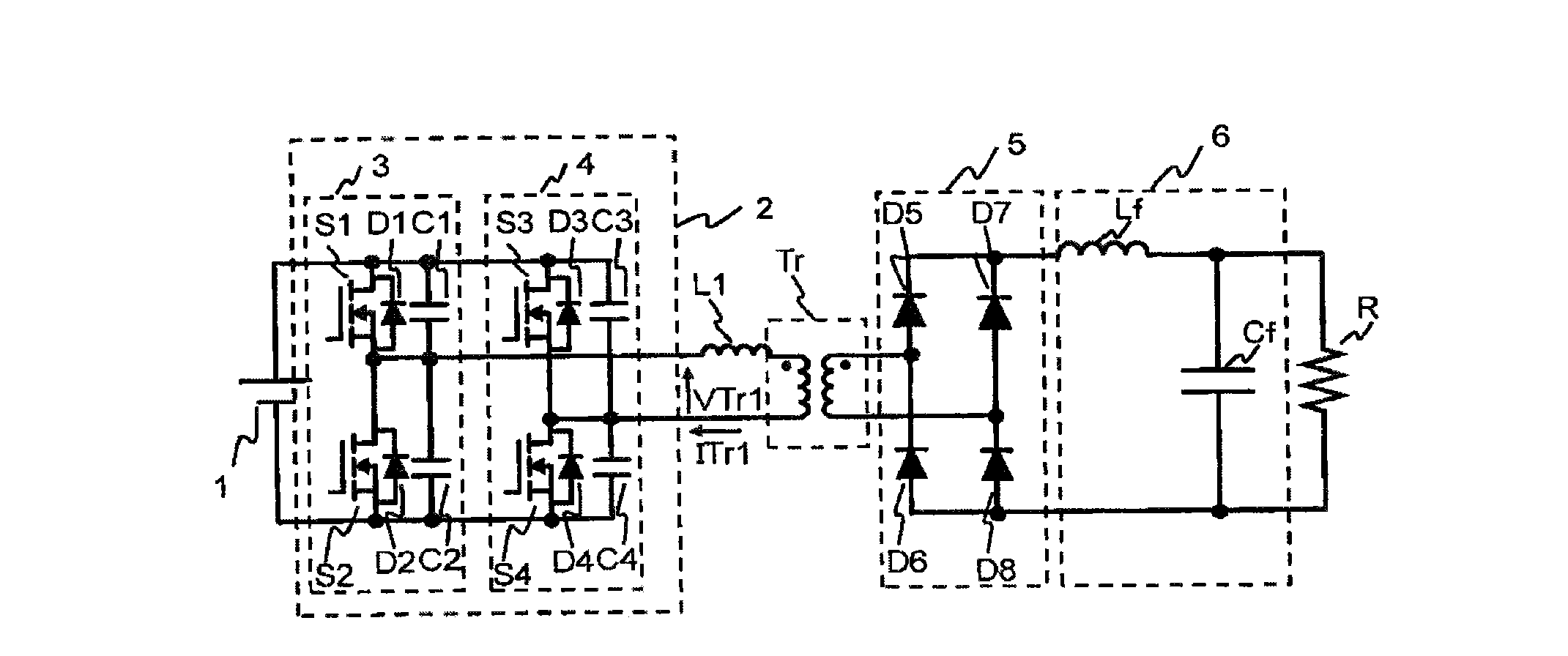

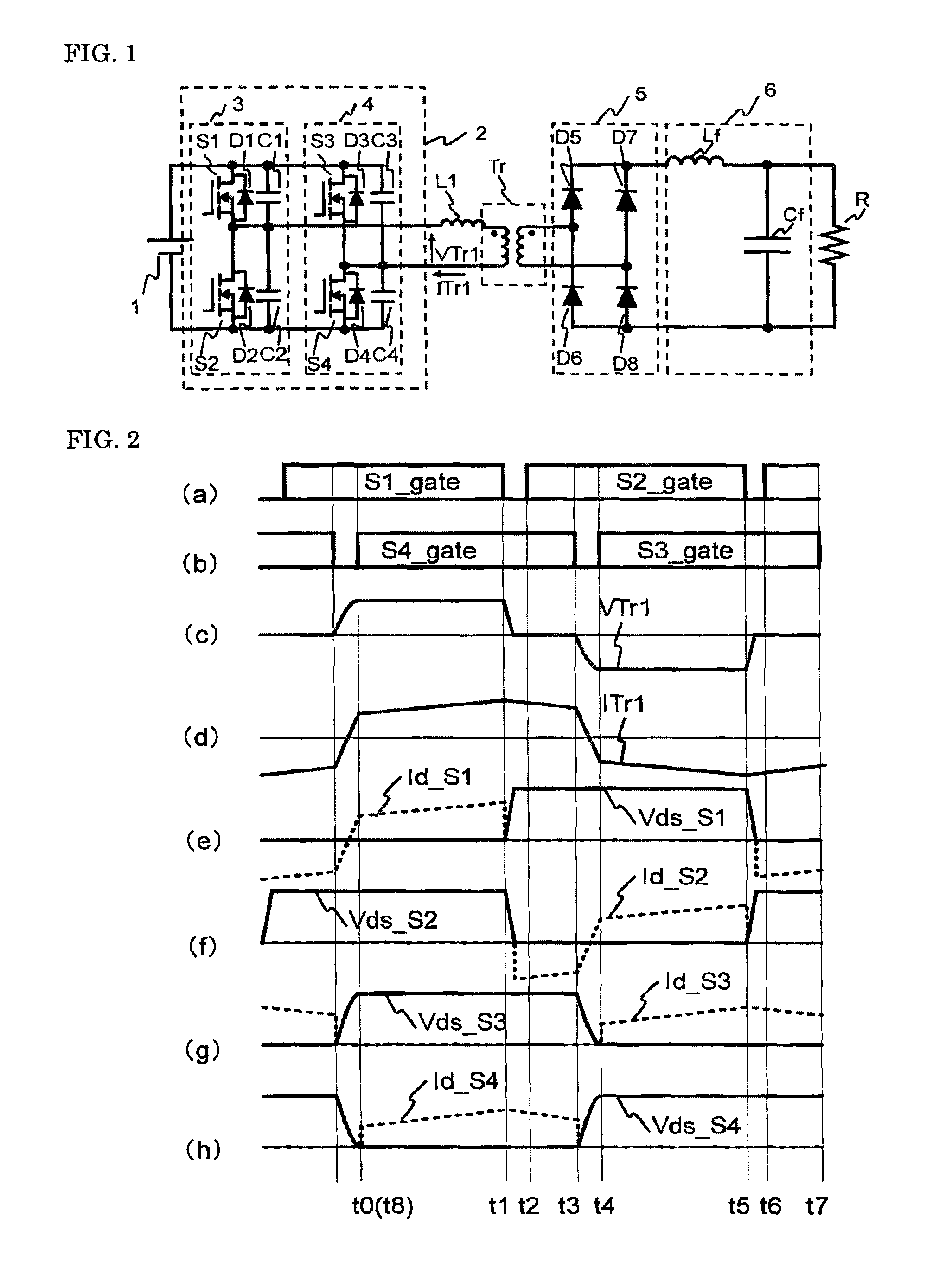

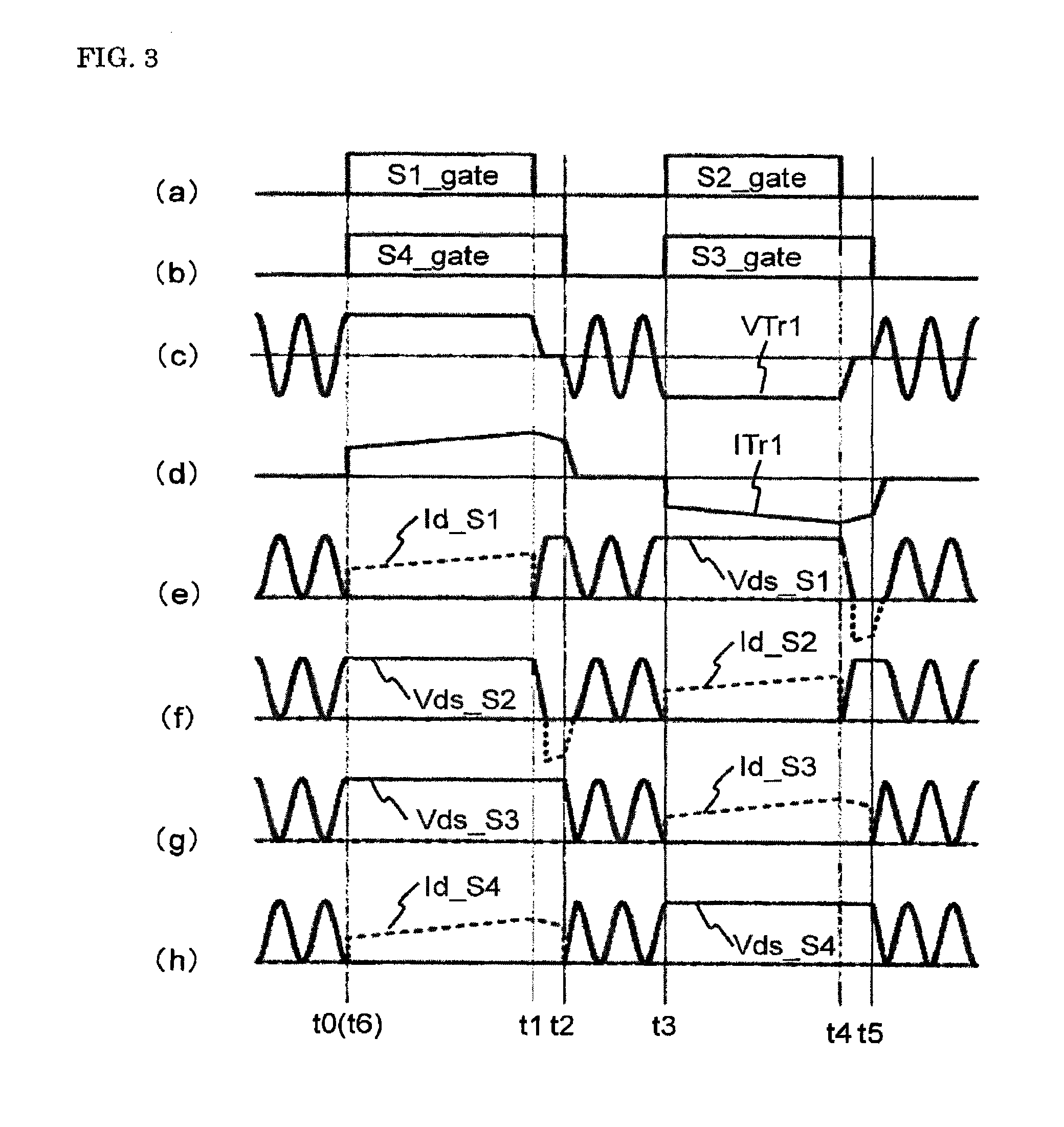

ActiveUS20150381063A1Reduced in size and weight and costReduce switchingEfficient power electronics conversionDc-dc conversionFreewheelFull bridge

A DC-DC converter wherein a series reactor and primary-side terminals of a transformer are connected between output terminals of a full-bridge inverter in which each of an upper arm and a lower arm includes a switching element and a freewheel diode, and a rectifier circuit and a filter circuit are connected to secondary-side terminals of the transformer. The DC-DC converter includes a circulation current generation mode in which a circulation current flowing between the transformer and the switching element is generated in a power non-transmission period, and a circulation current interruption mode in which the circulation current is interrupted.

Owner:MITSUBISHI ELECTRIC CORP

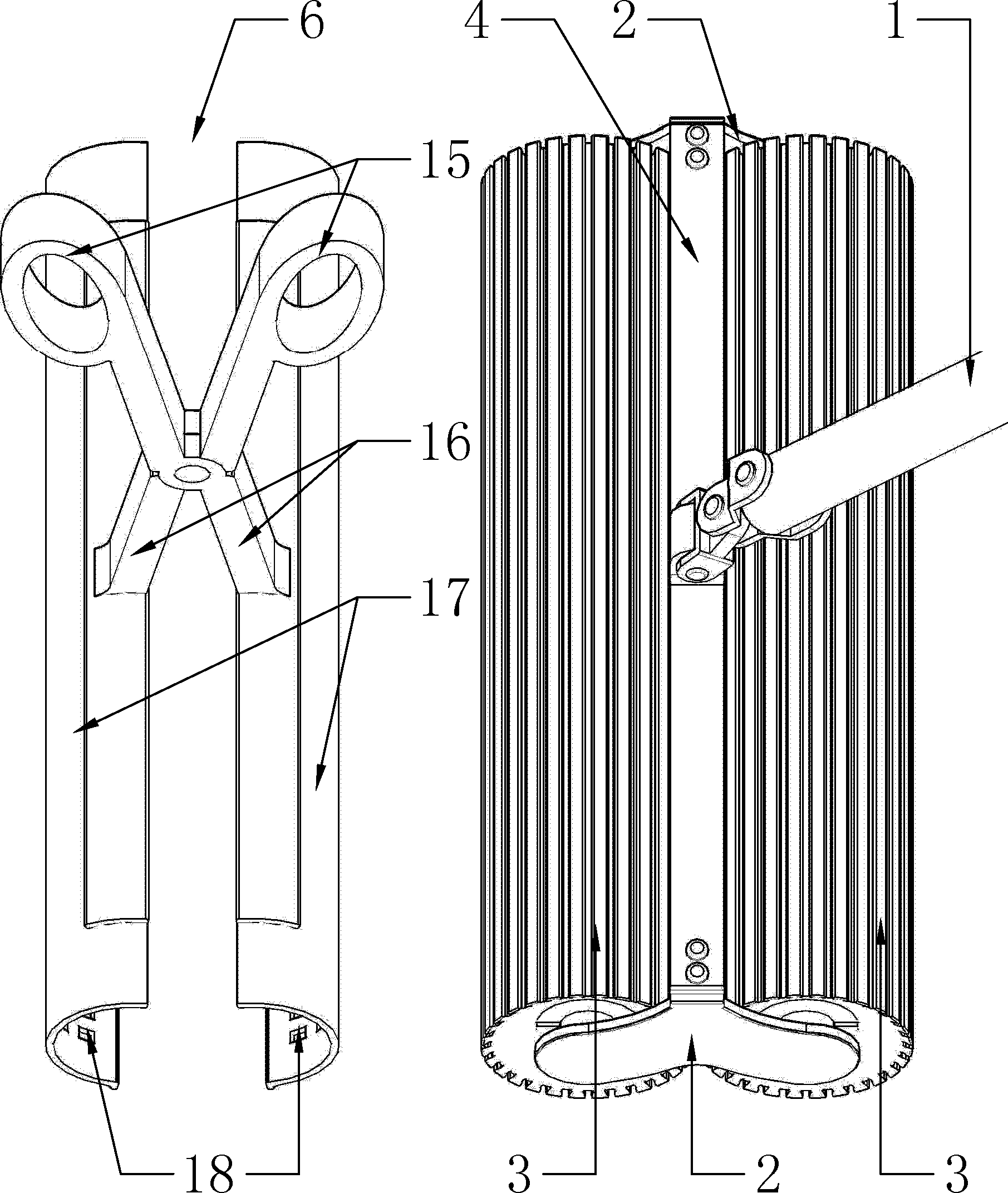

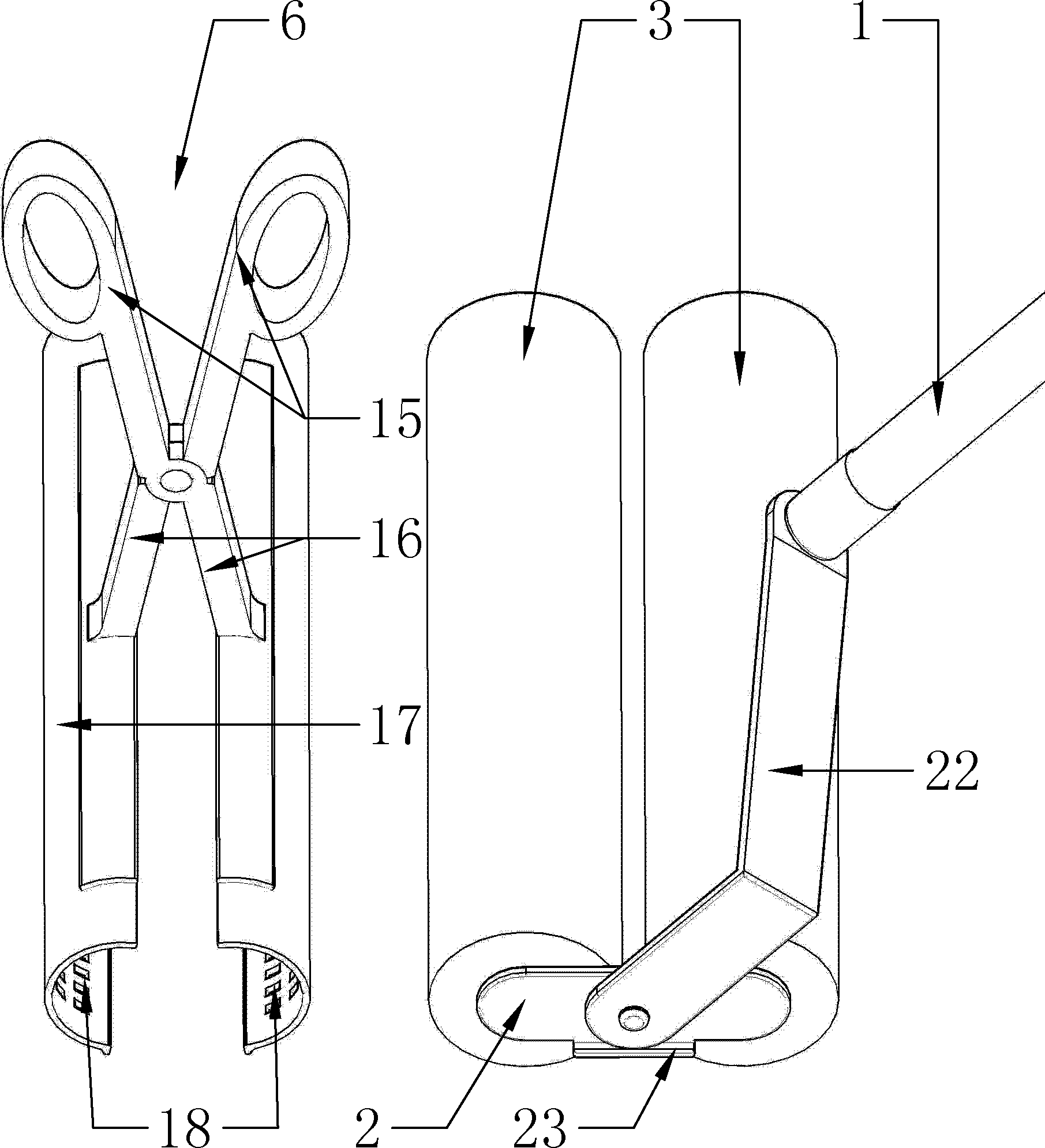

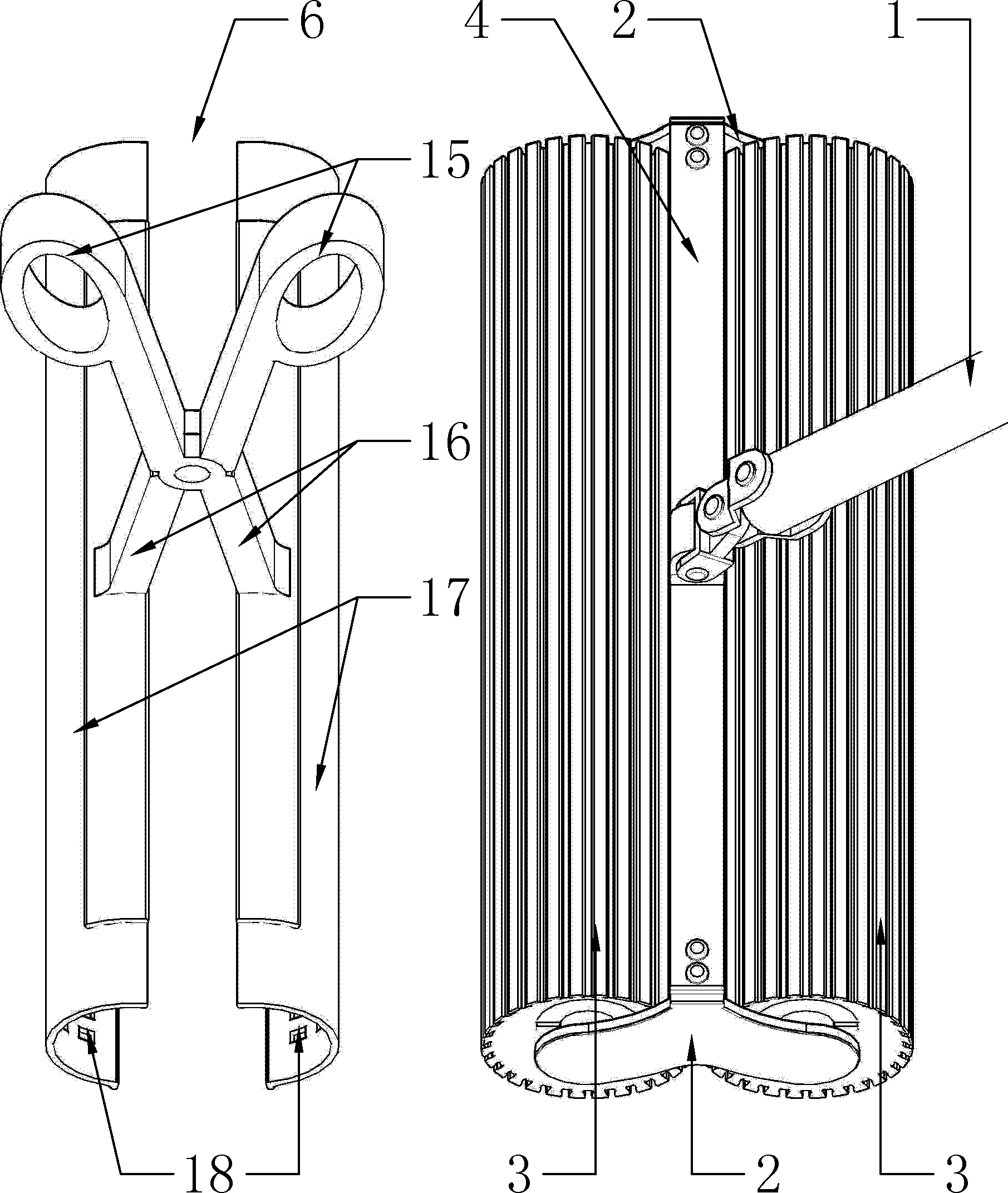

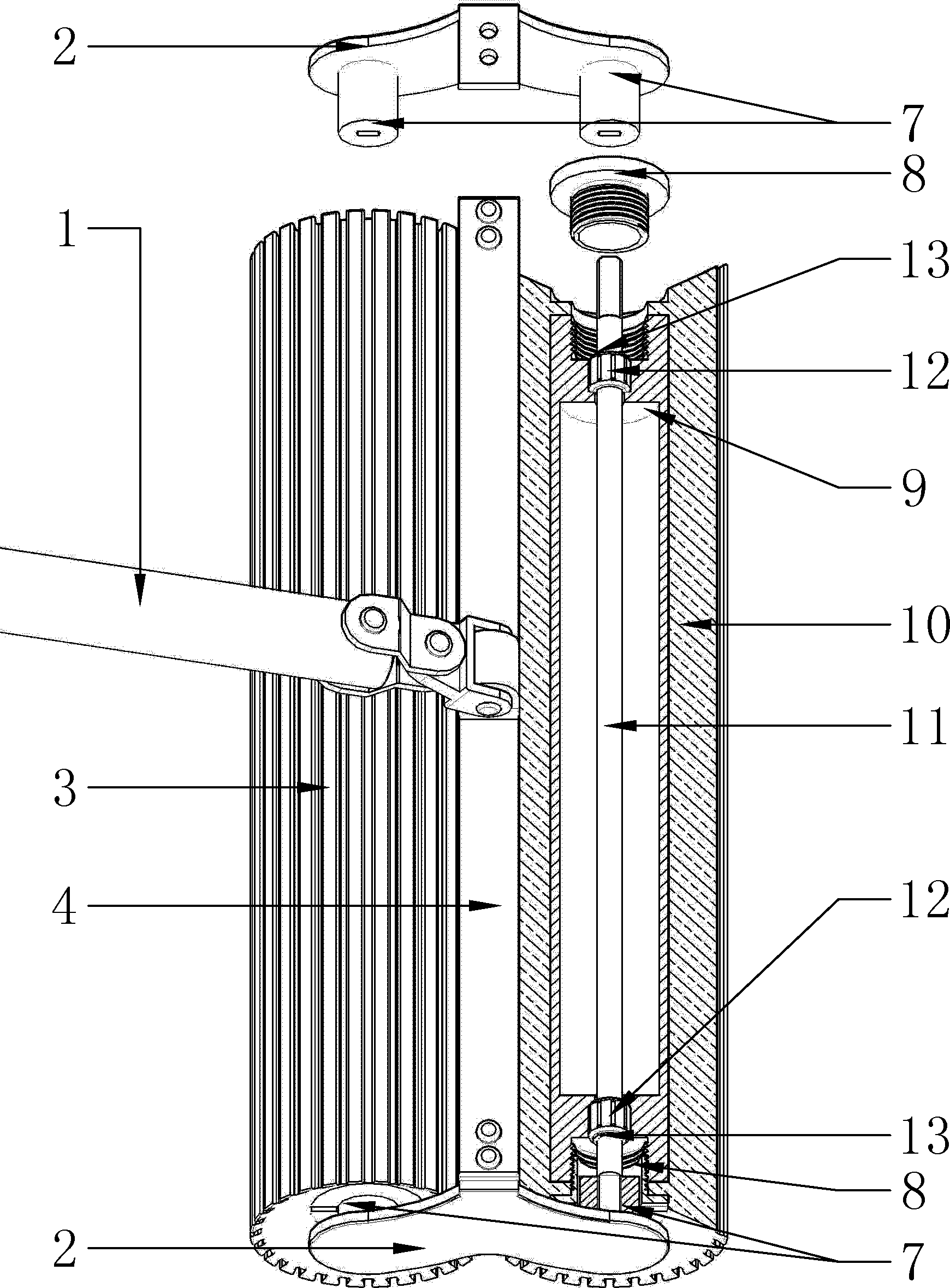

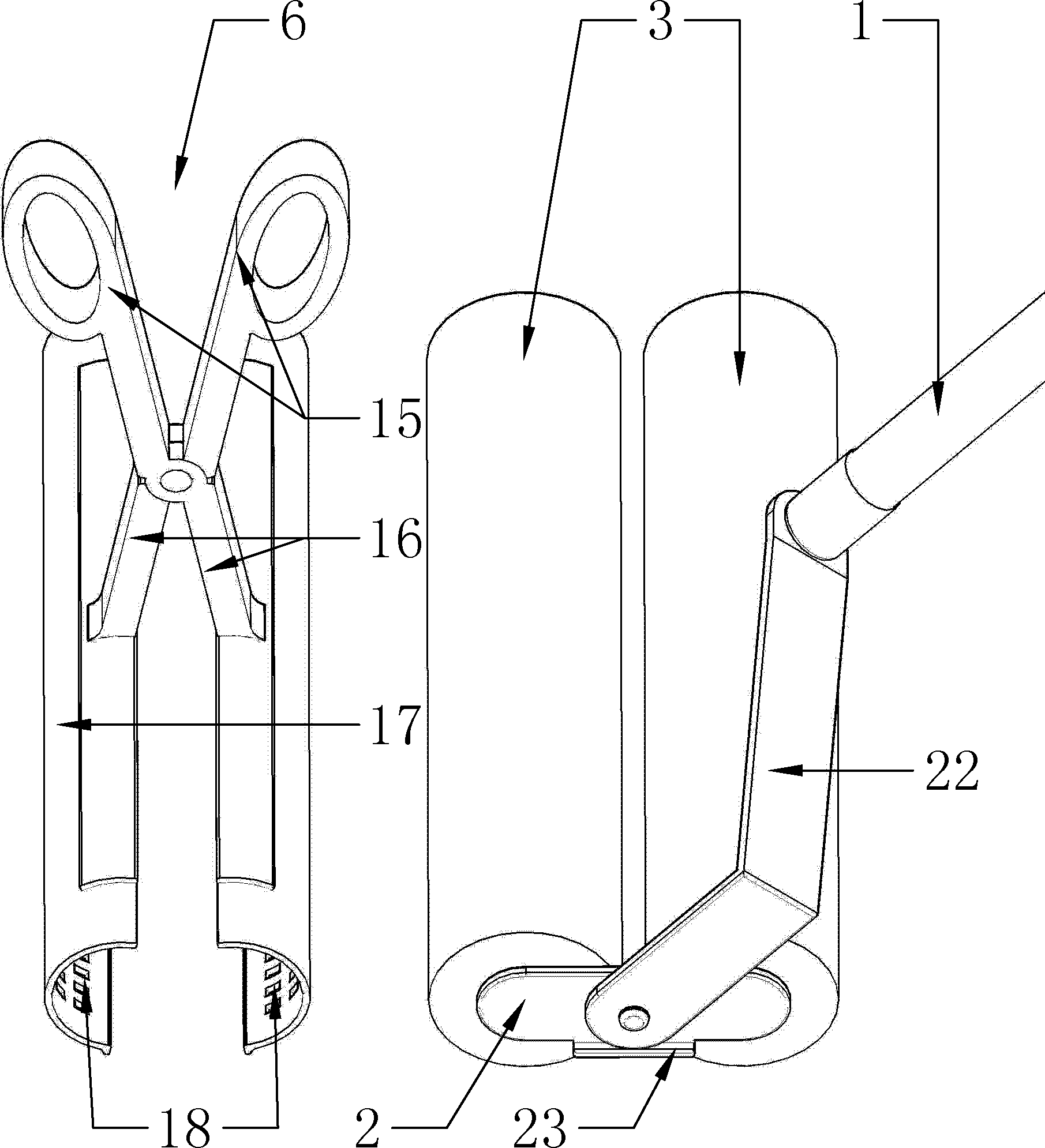

Mop

ActiveCN103070651ASimple structureAvoid damageCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a mop which comprises a holding rod, a bracket connected to the lower end of the holding rod, and two rows of wiping rollers, wherein the two rows of wiping rollers are arranged on the bracket in parallel back and forth and can unidirectionally rotate; non-return directions of the wiping rollers in front and back rows are opposite; when the mop pushes forwards, the roller in the front row rolls forwards to wet the ground, and the roller in the back row stops for wiping the ground; and when the mop is pulled backwards, the roller in the back row backwards rolls to wet the ground, and the roller in the front row stops to wipe the ground. In the mopping process, the surfaces of the wiping rollers can be fully utilized; even if the rollers are dirt, falling dirt in the rolling process can be collected by the roller in a stopping state and is limited between two rows of rollers, so that the phenomena that the dirt and stain are distributed along the movement of the mop can be reduced or avoided, and the times of cleaning the mop in the mopping process can be reduced. The mop further comprises a wringer arranged in a separating manner. The wringer is of a tong-shaped structure with a simple structure; when the wringer is operated, the damage of the wringer to the rollers is little; when the wringer is damaged or lost, the wringer is only needed to be independently replaced; and the wringer can be also used for clamping solid waste on the ground.

Owner:阳珉

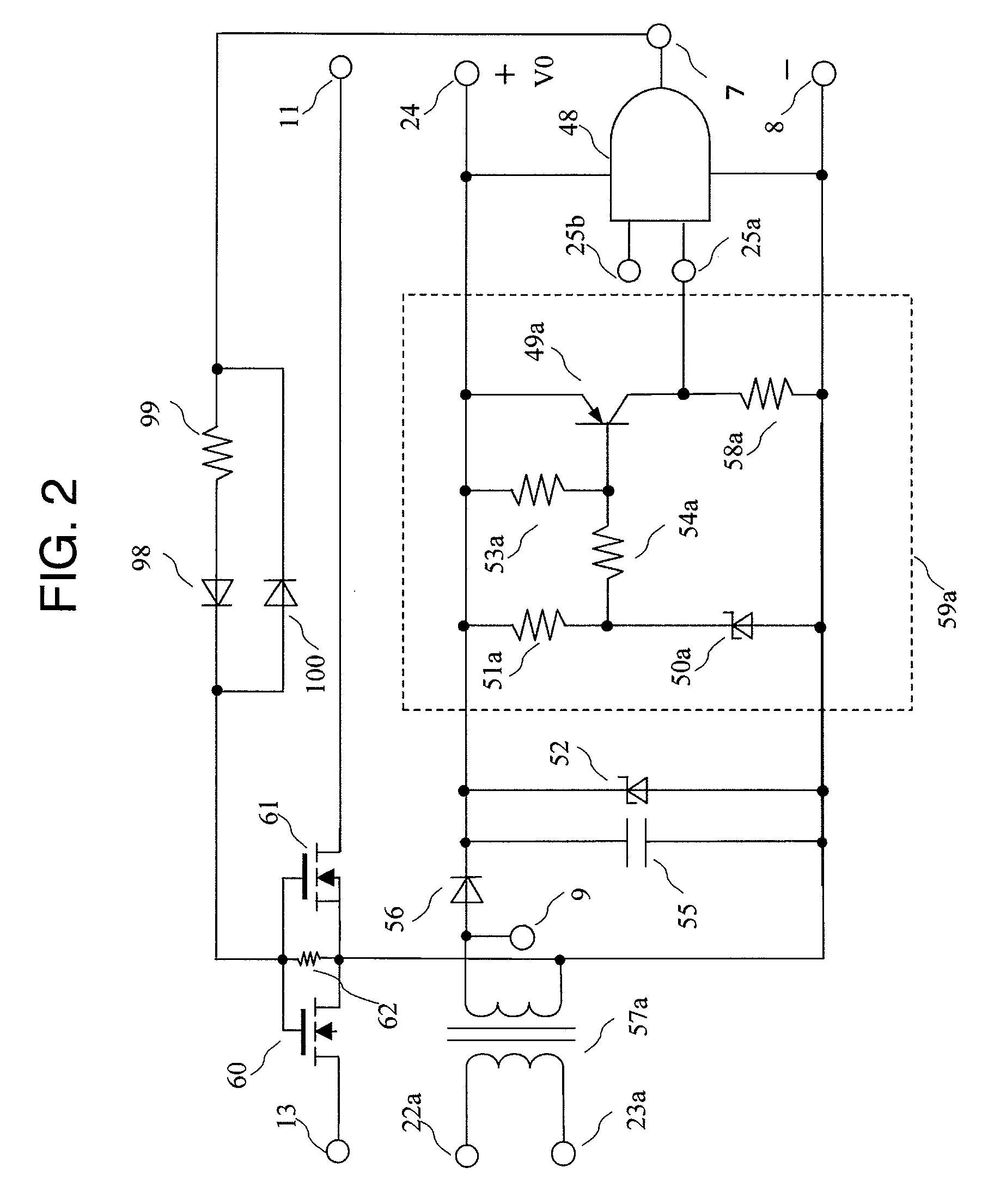

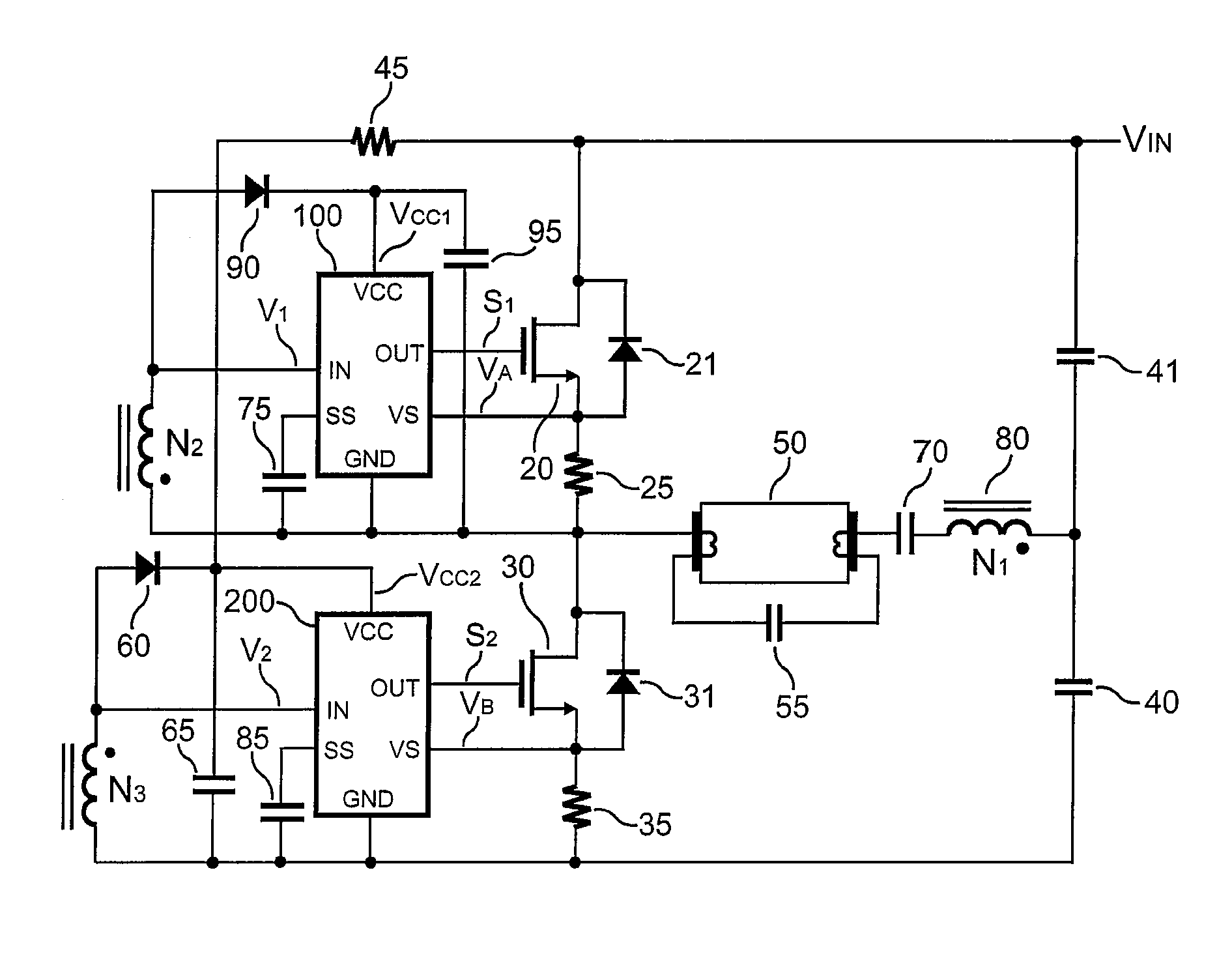

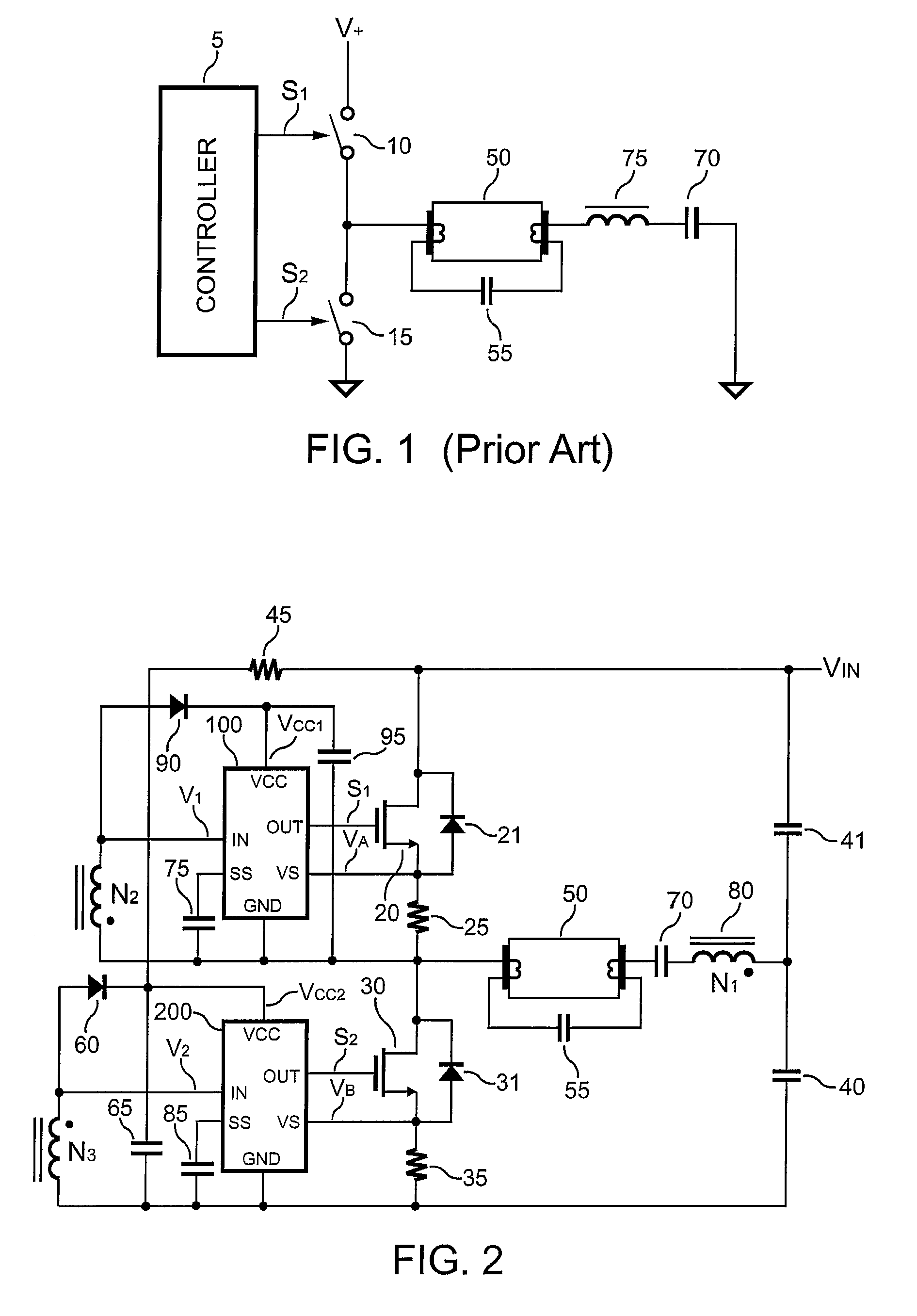

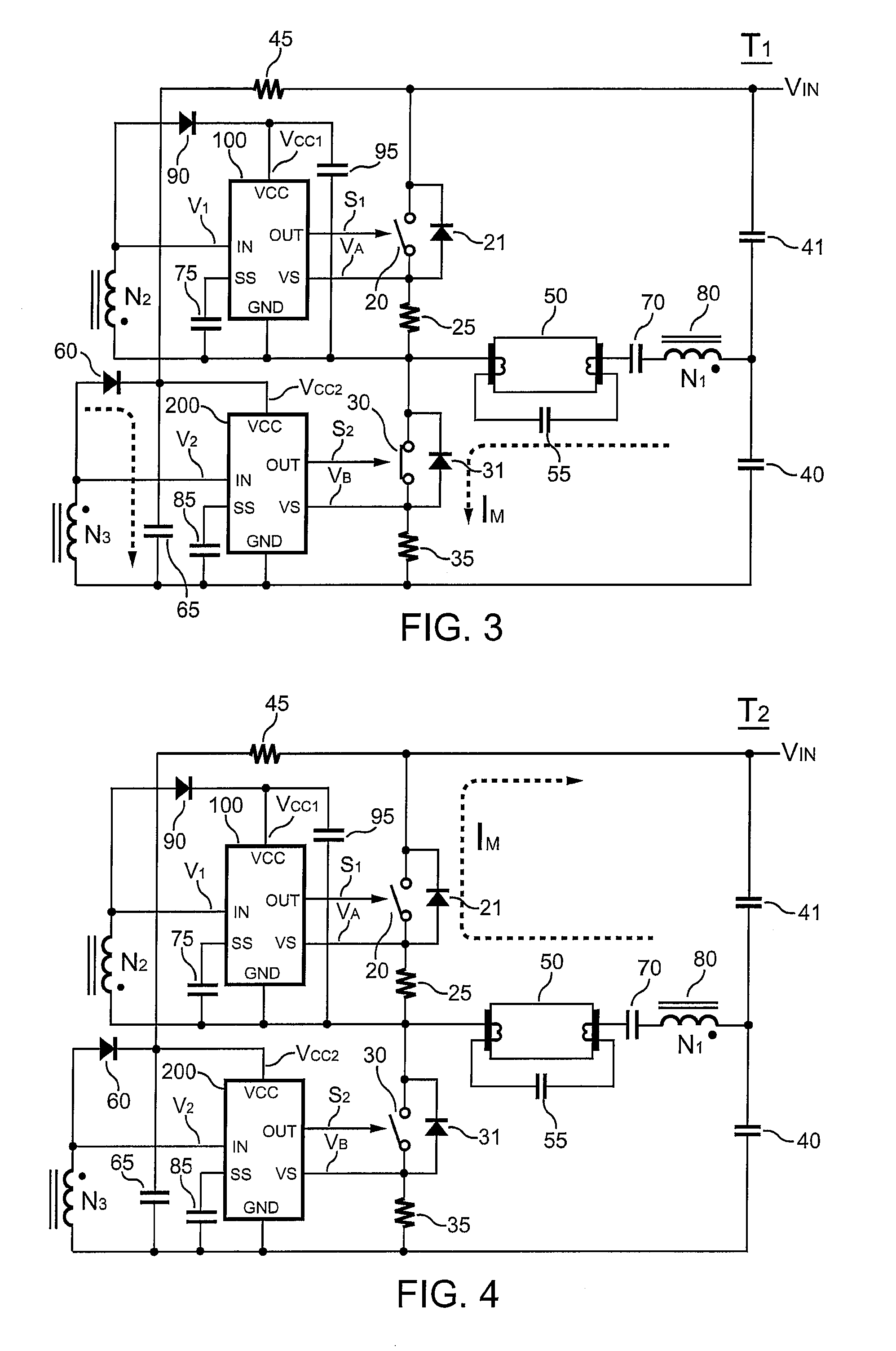

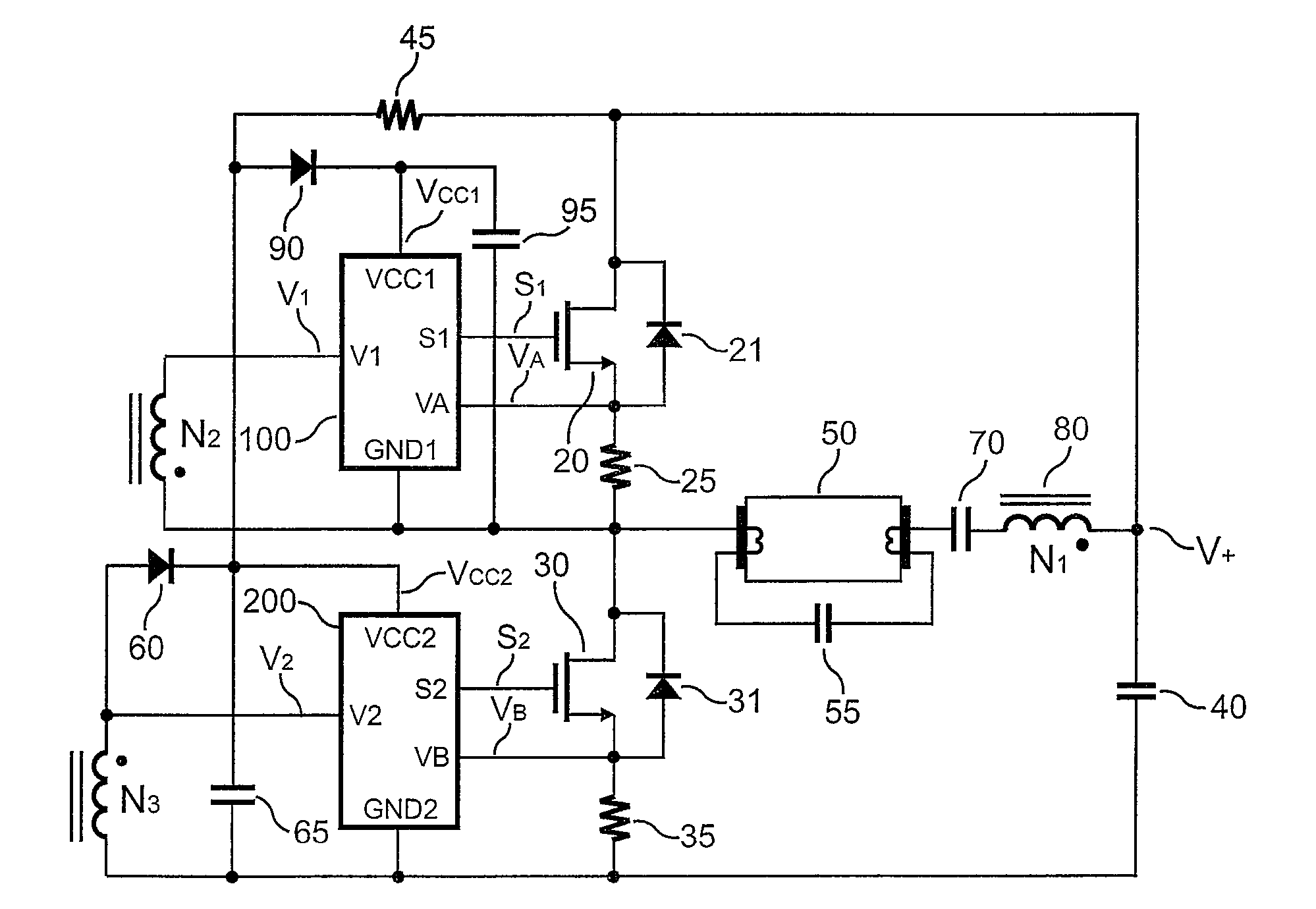

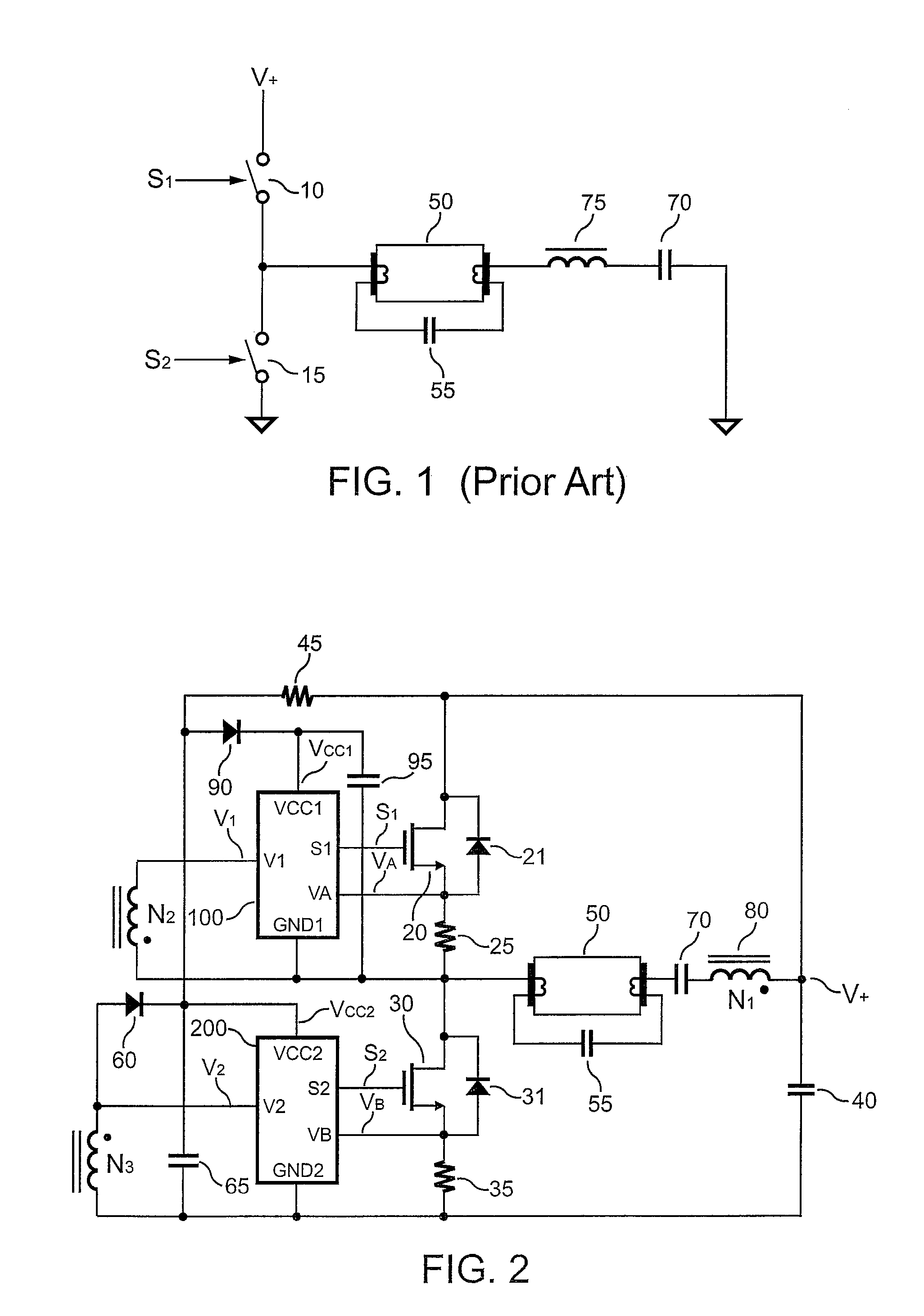

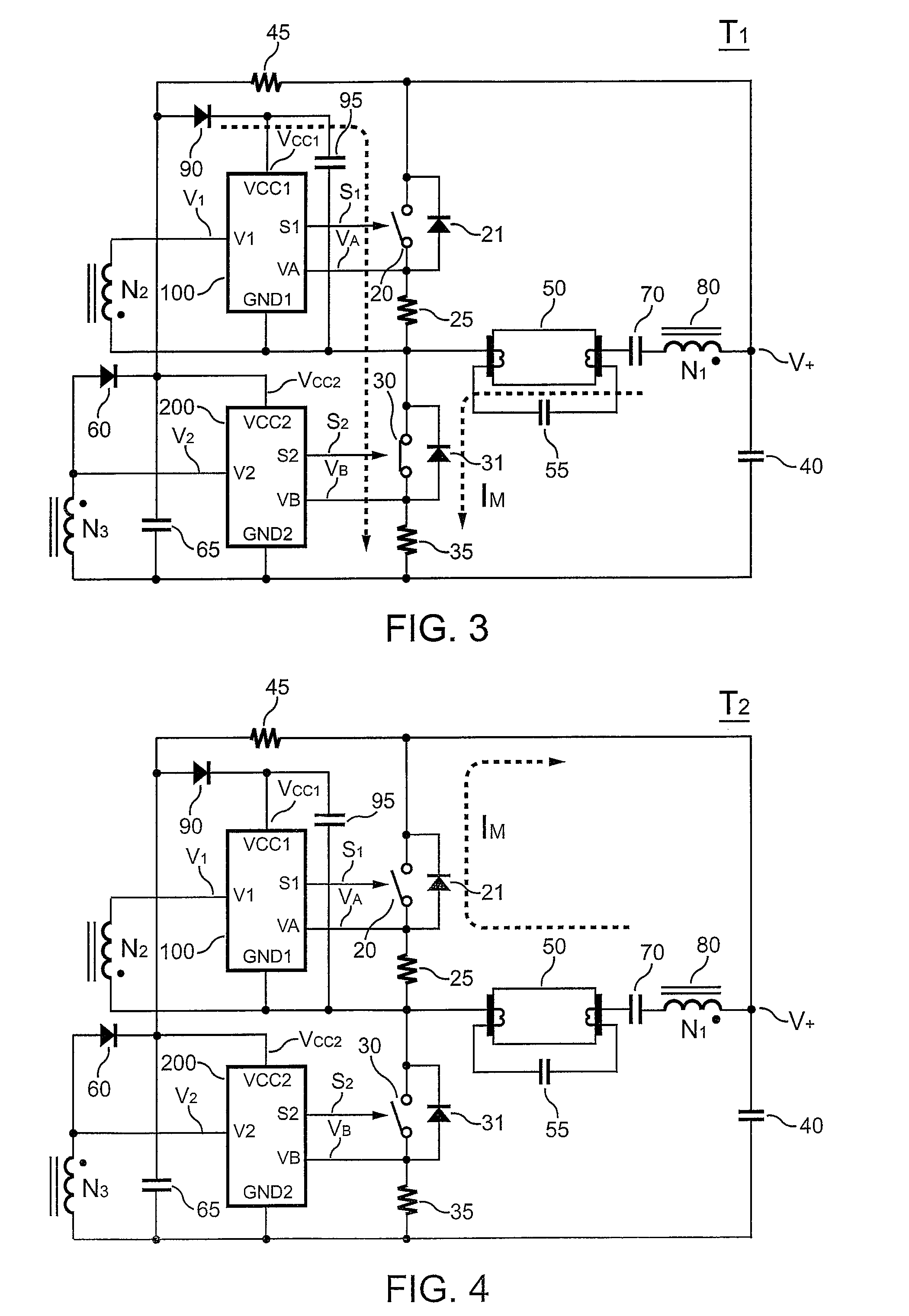

System and method for a power converter having a resonant circuit

ActiveUS8264857B2Improve efficiencySoft operationAc-dc conversion without reversalEfficient power electronics conversionCapacitanceConductor Coil

A direct current-direct current (DC / DC) converter operated in the resonant mode of operation for converting a direct input voltage into a direct output voltage with a bridge circuit located on the input side and incorporating switching elements, with a resonance circuit incorporating a resonance inductance and a resonance capacitance as well as with a high-frequency transformer for galvanic separation is disclosed, the transformer incorporates at least one primary winding and at least one secondary winding with at least two winding terminals each. The alternating current (AC) output of the bridge circuit is connected to the primary winding and a rectifier bridge with diodes to the secondary winding. A voltage boosting circuit array is connected downstream of the resonant circuit in such a manner that at least one additionally controllable switching element is contained, which is connected in parallel or in series to at least one additional diode or to at least one diode of the rectifier bridge on the secondary side, this array being connected in parallel to the high-frequency transformer so that the additional switching element short-circuits the resonance circuit in a triggered condition so that energy is stored in the resonance inductance and is delivered in the non-triggered condition.

Owner:SMA SOLAR TECH AG

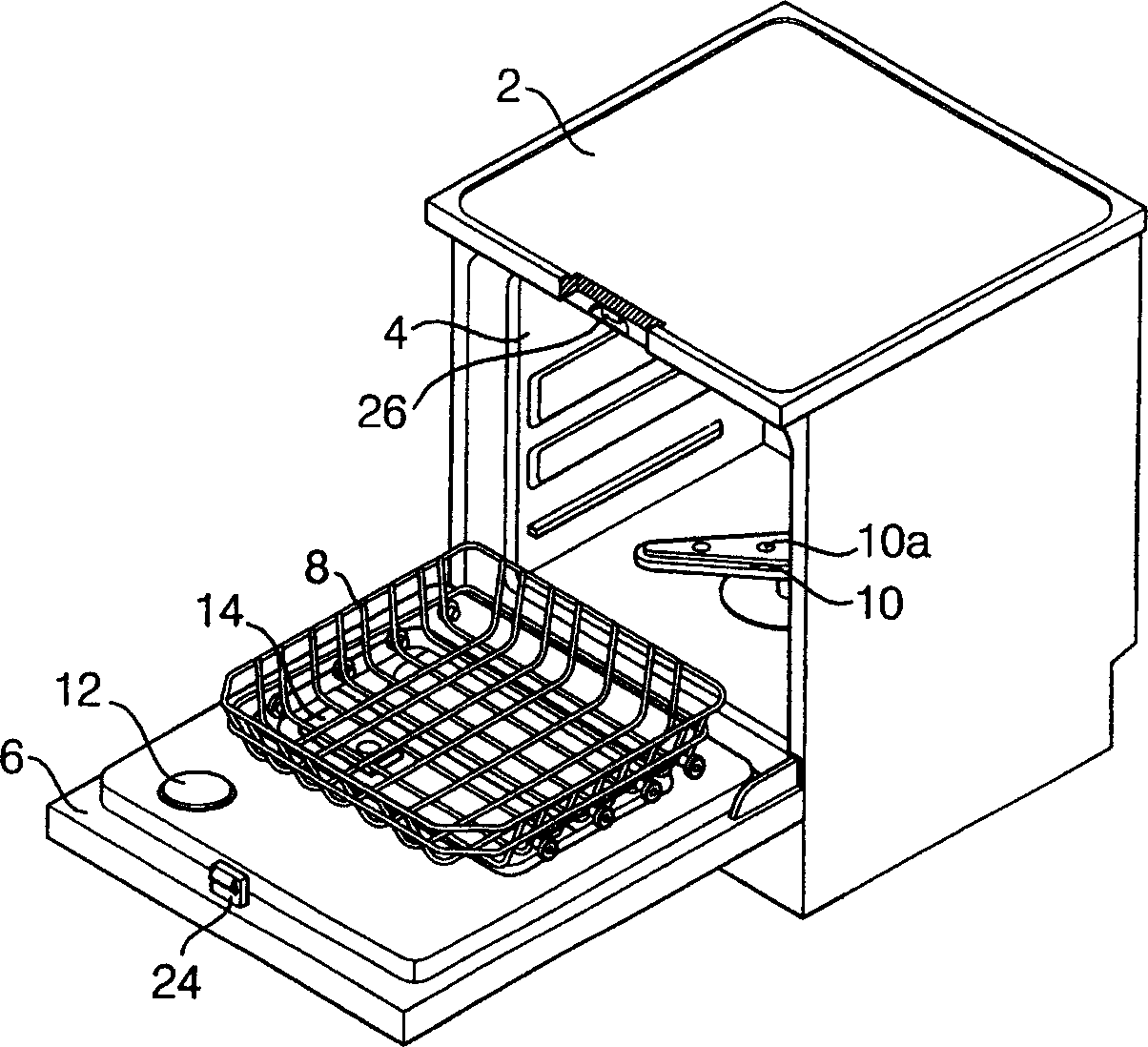

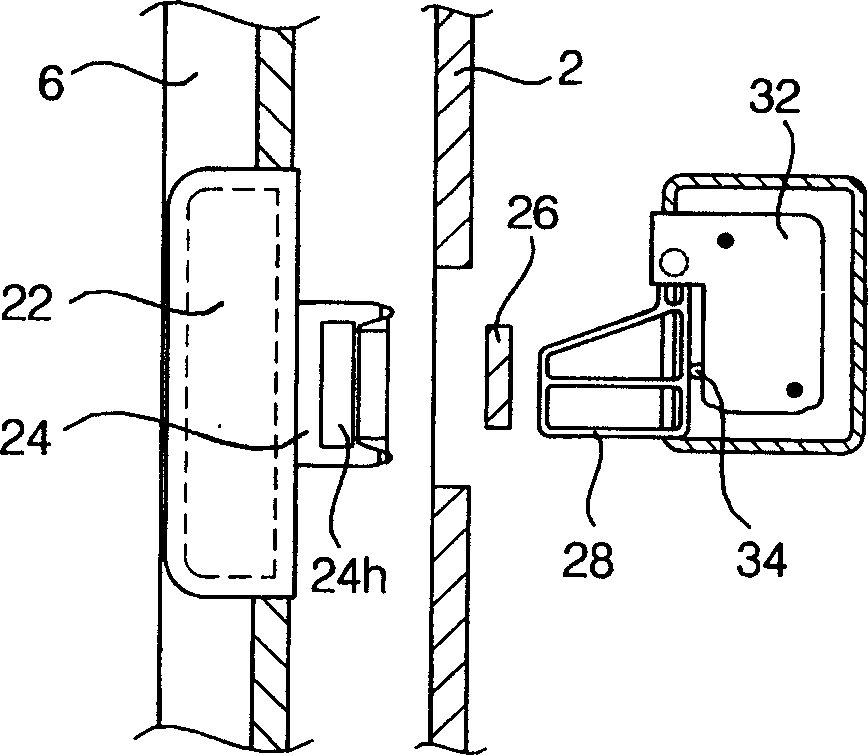

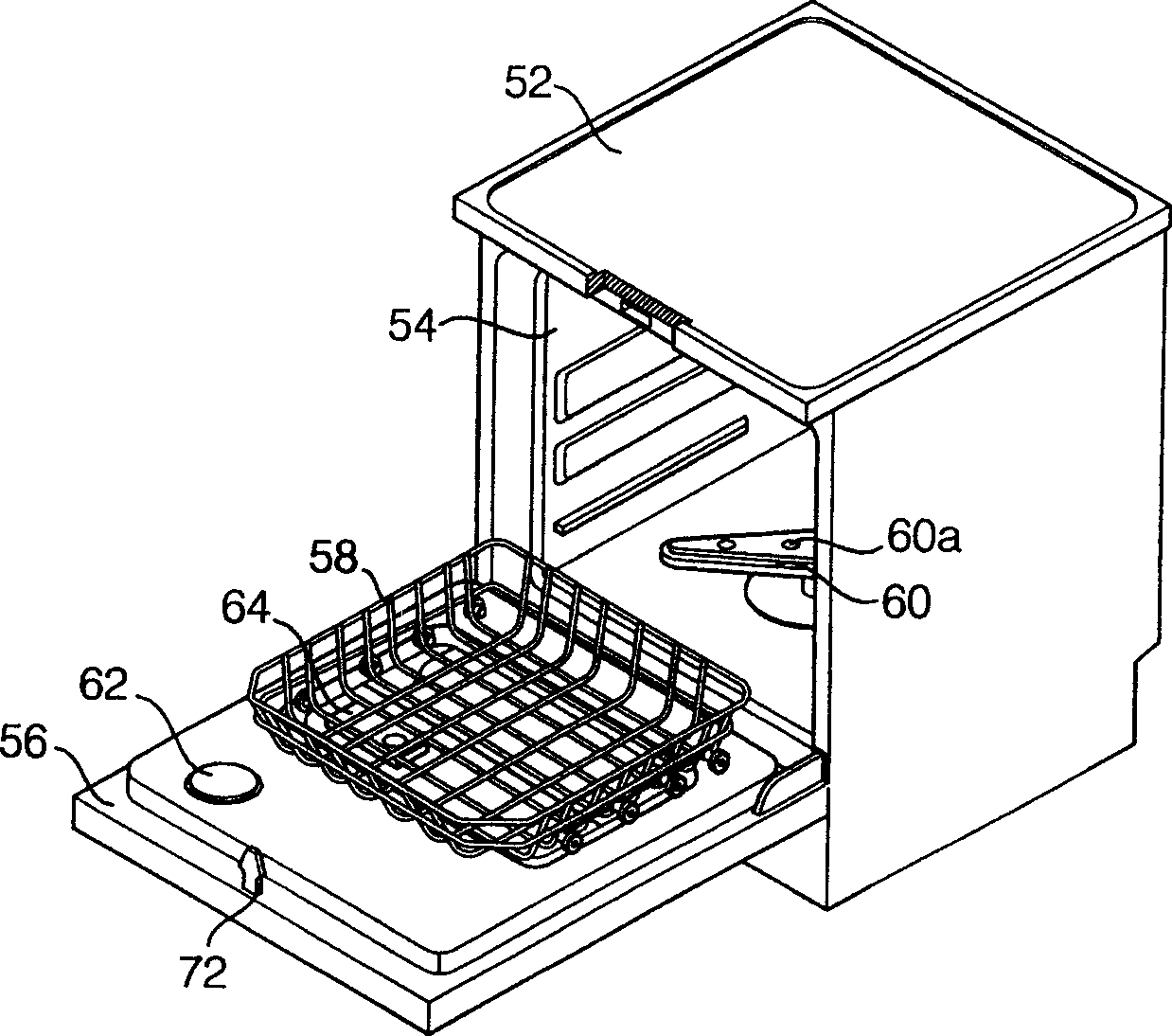

Mechanism for opening and closing door of dishwasher

A mechanism for opening or closing the door of dish washer is composed of a door able to be opened or closed, a latch hook on said door, a leaf spring matched with said latch hook to hold the door in close state, and a safety device for stopping the washing when the door is opened.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

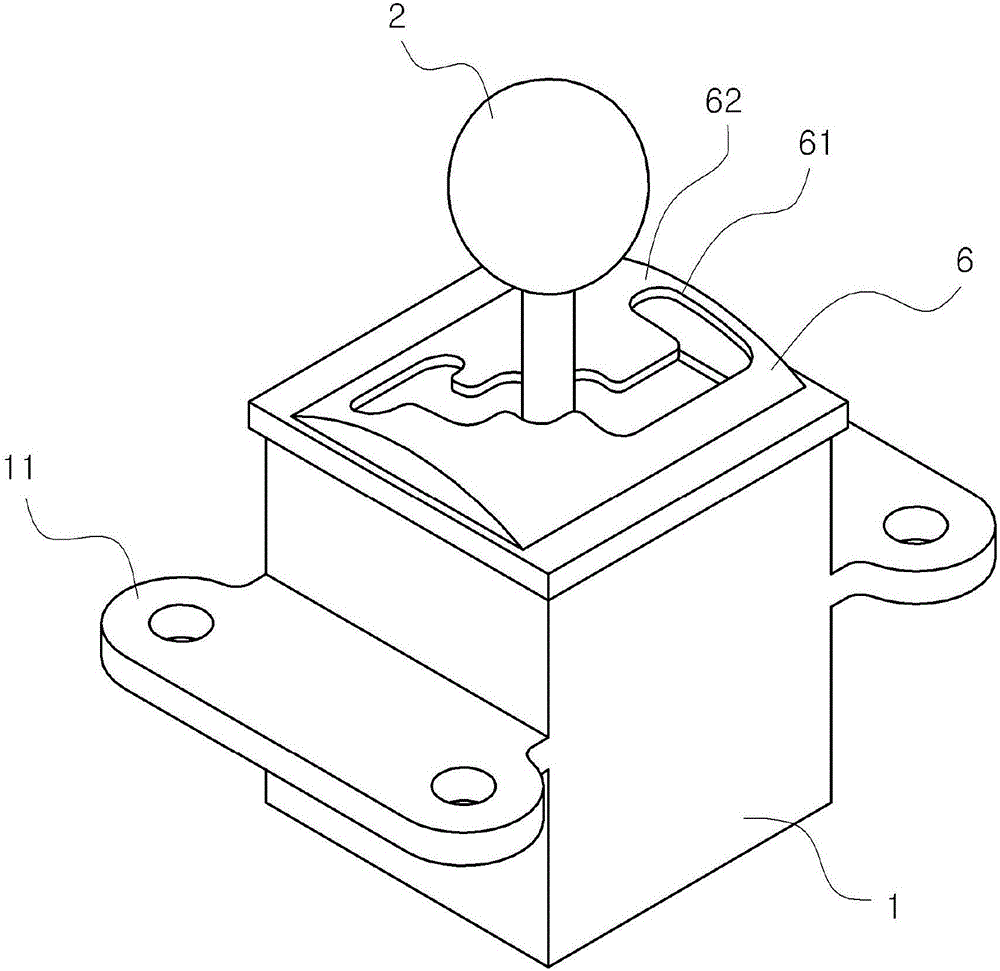

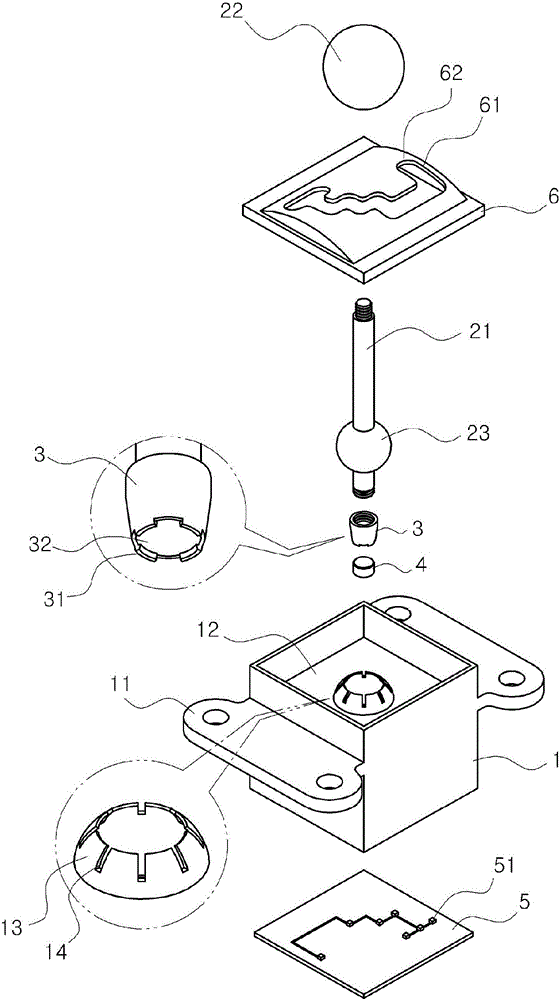

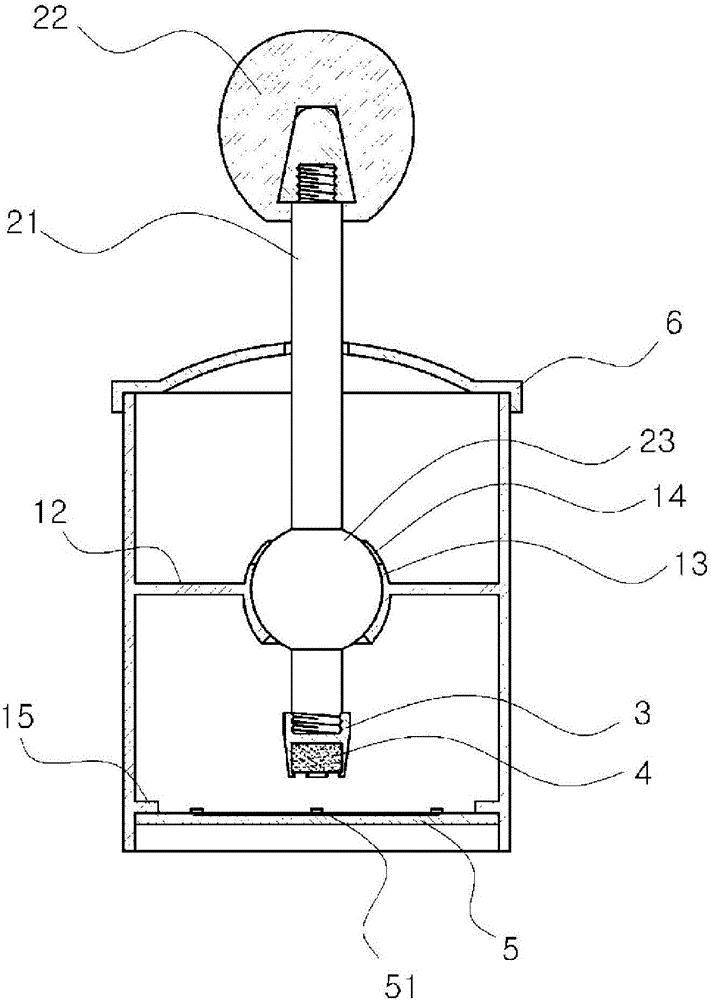

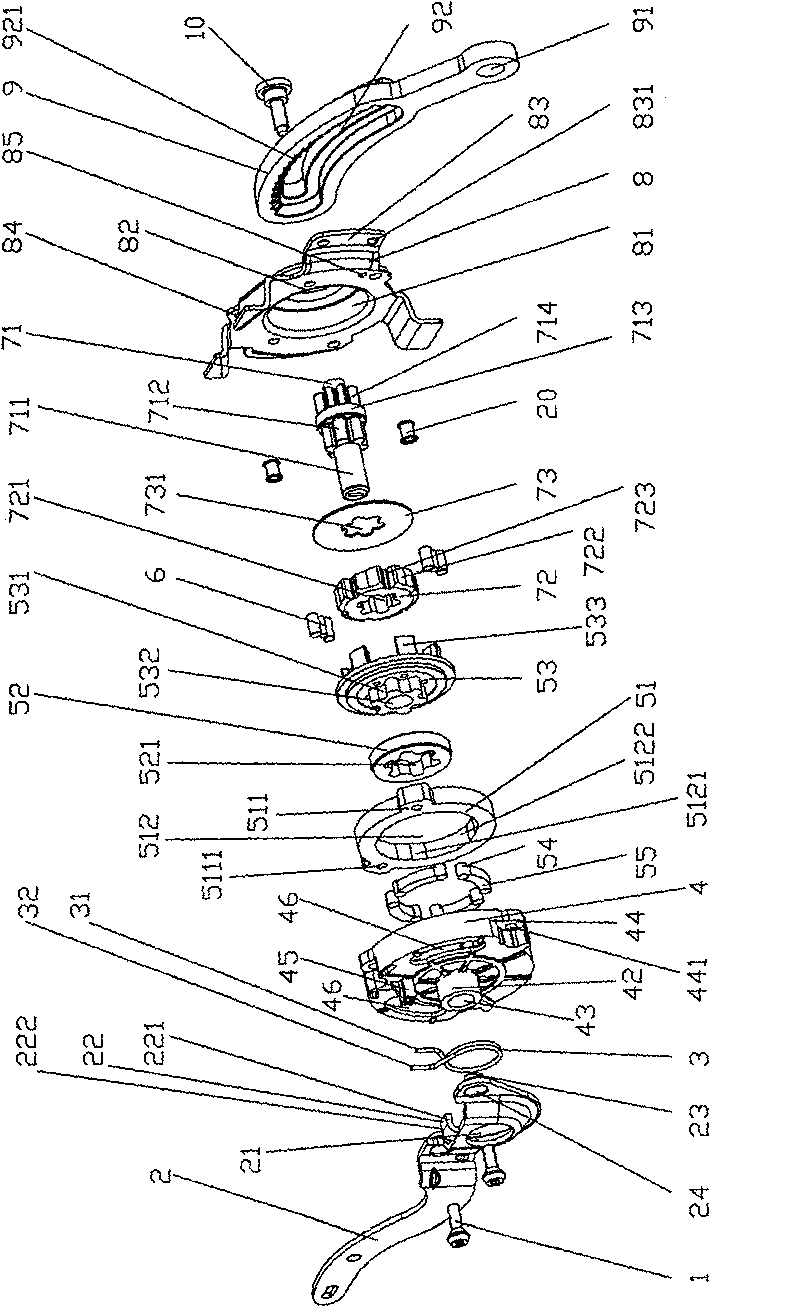

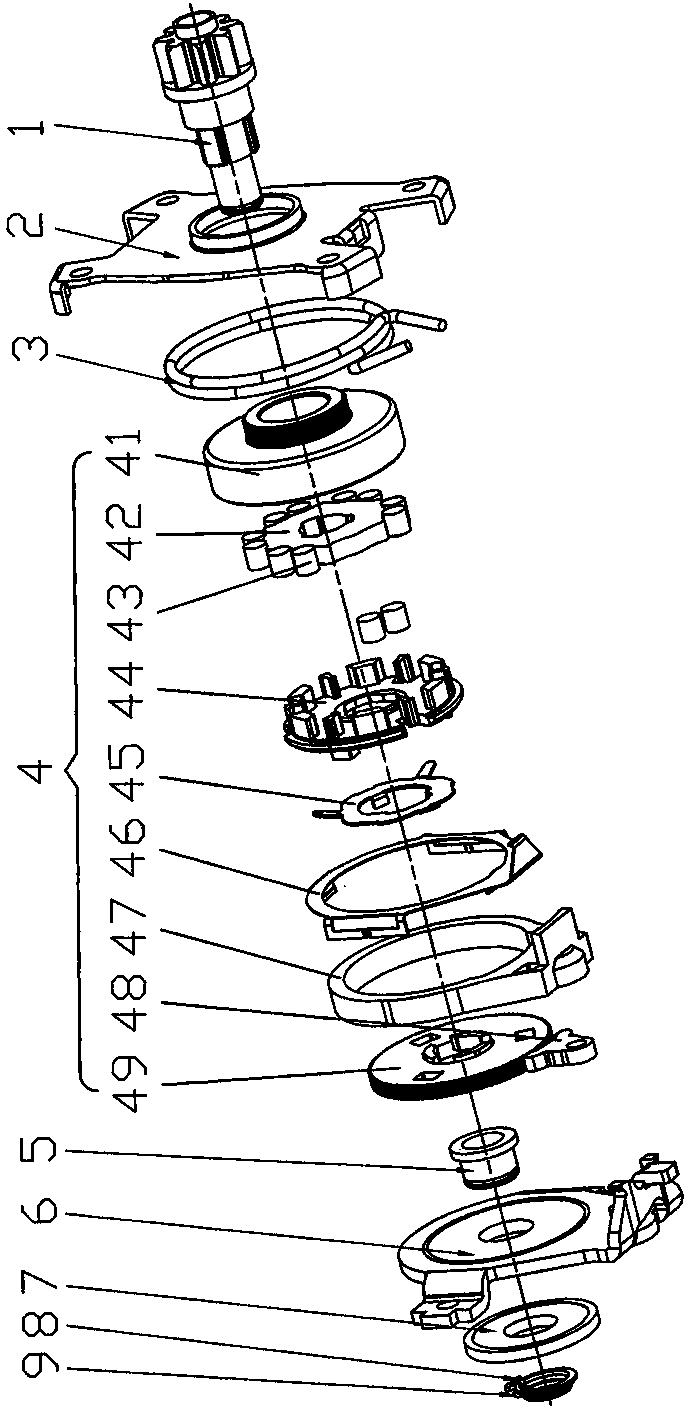

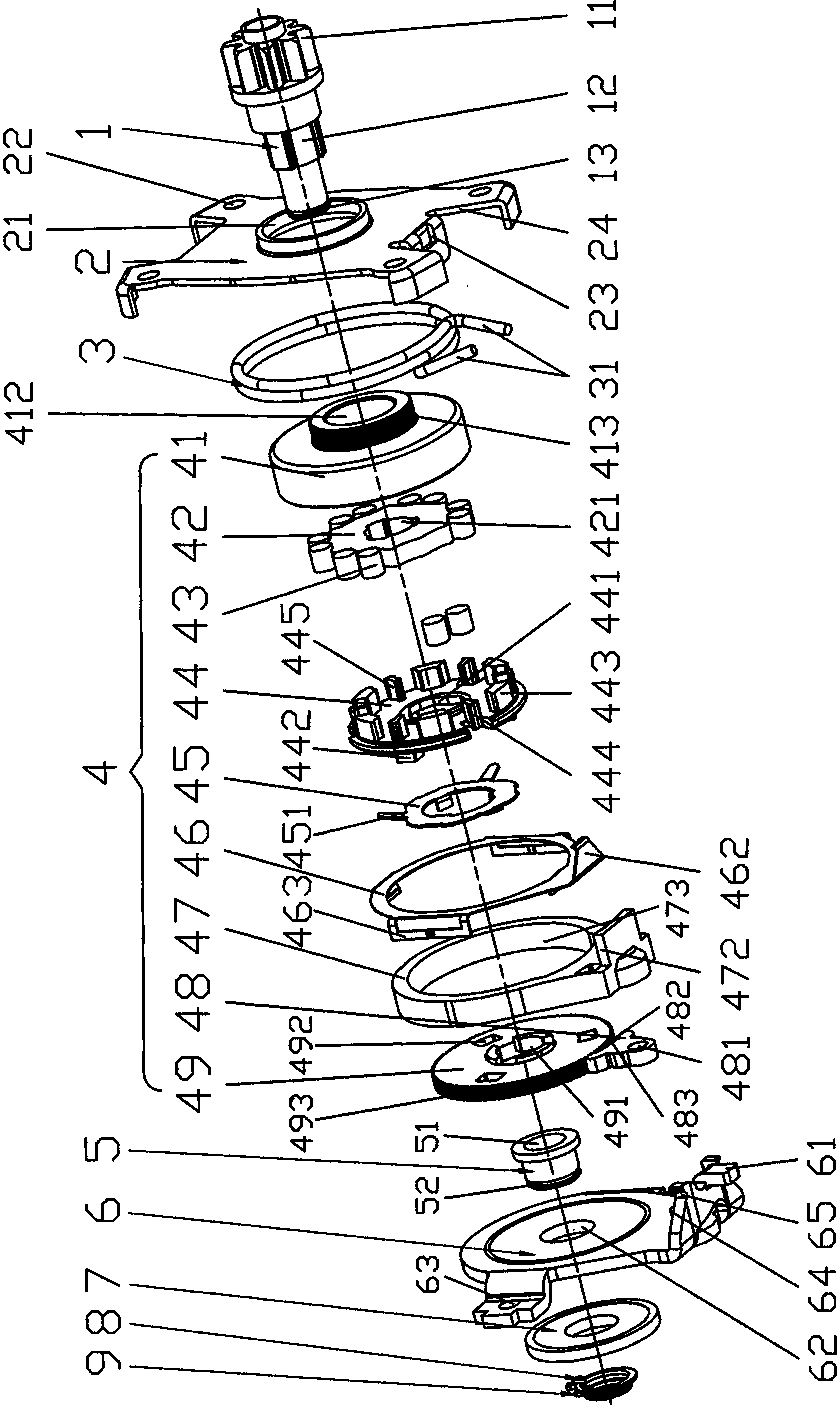

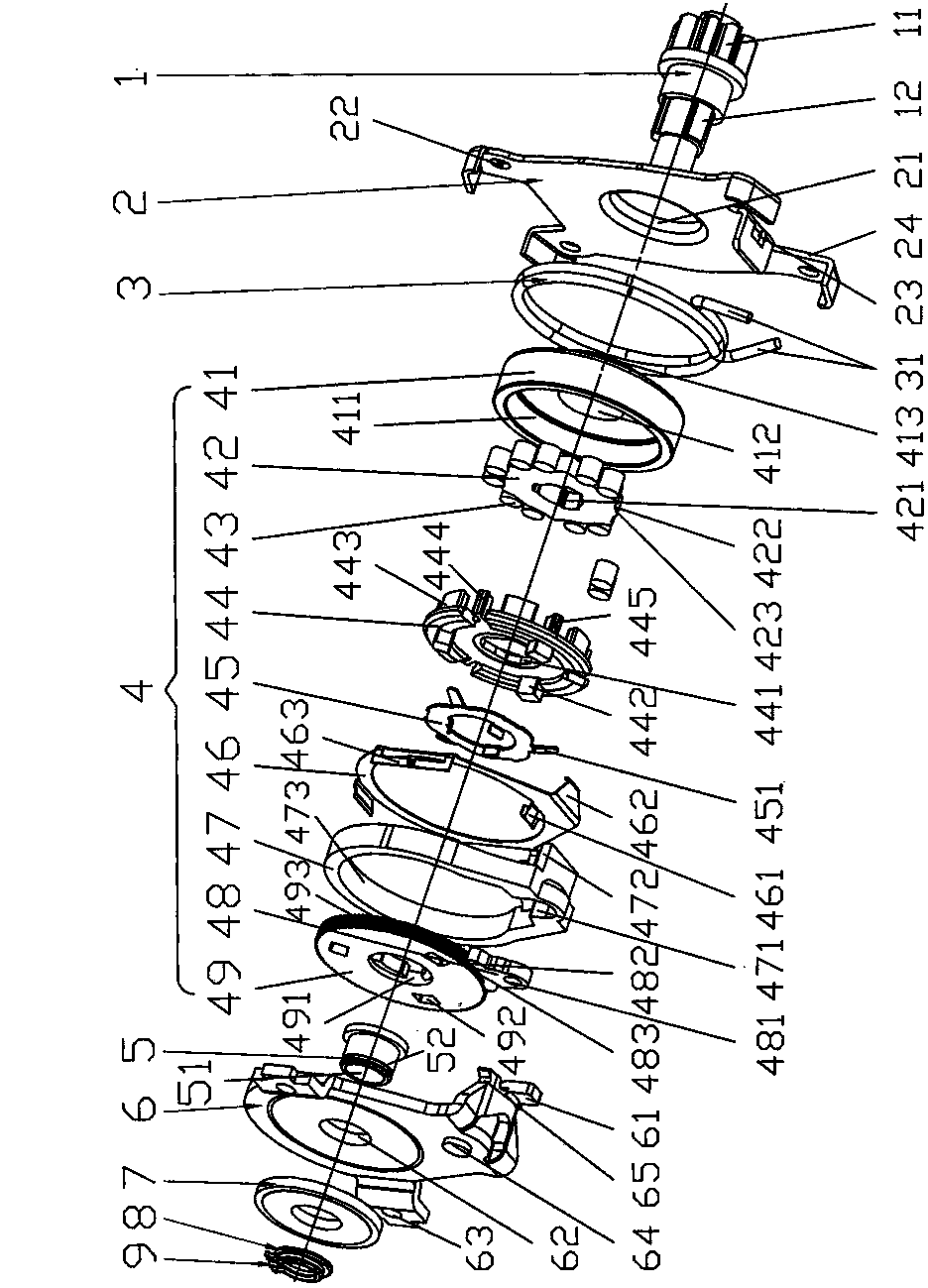

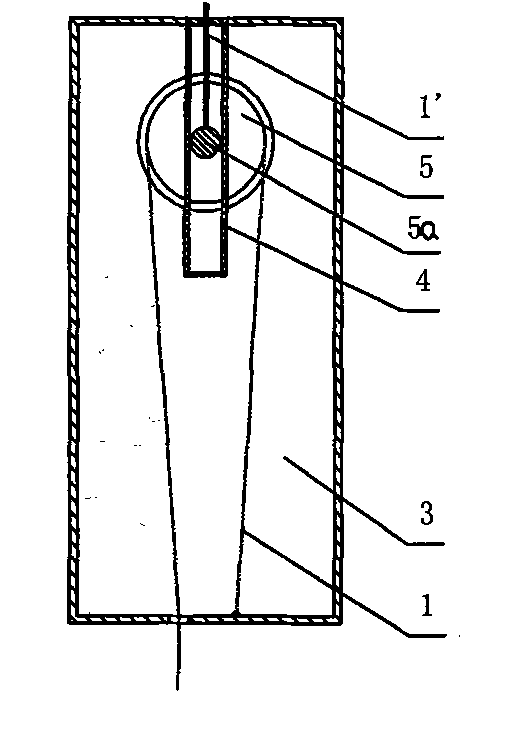

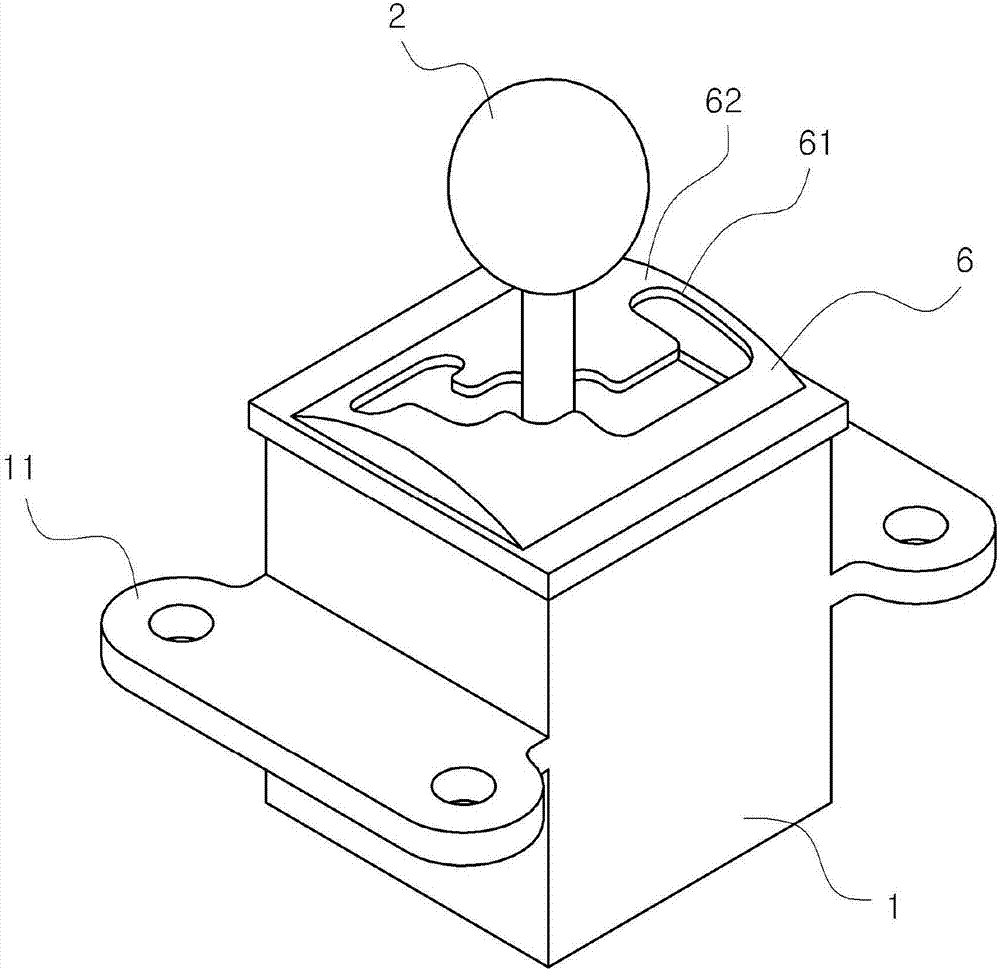

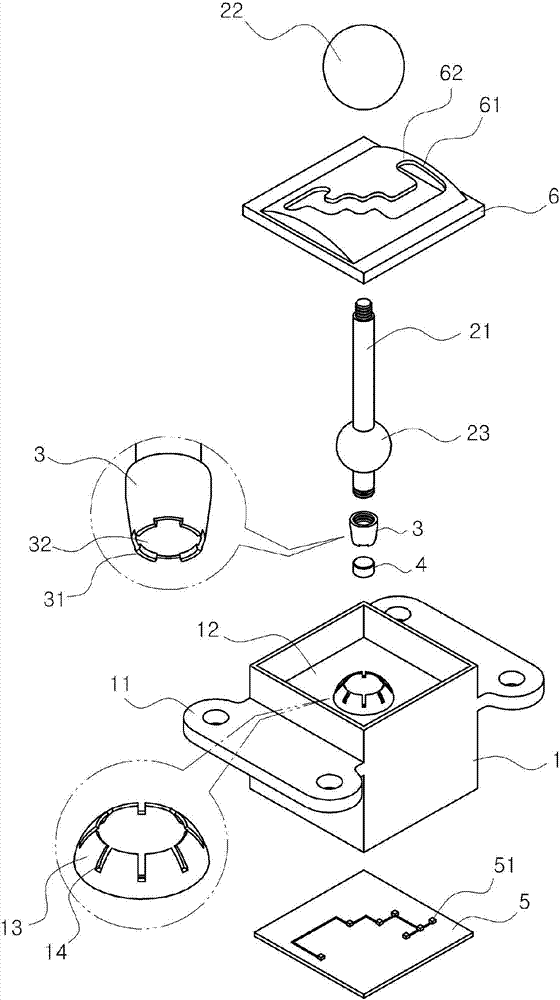

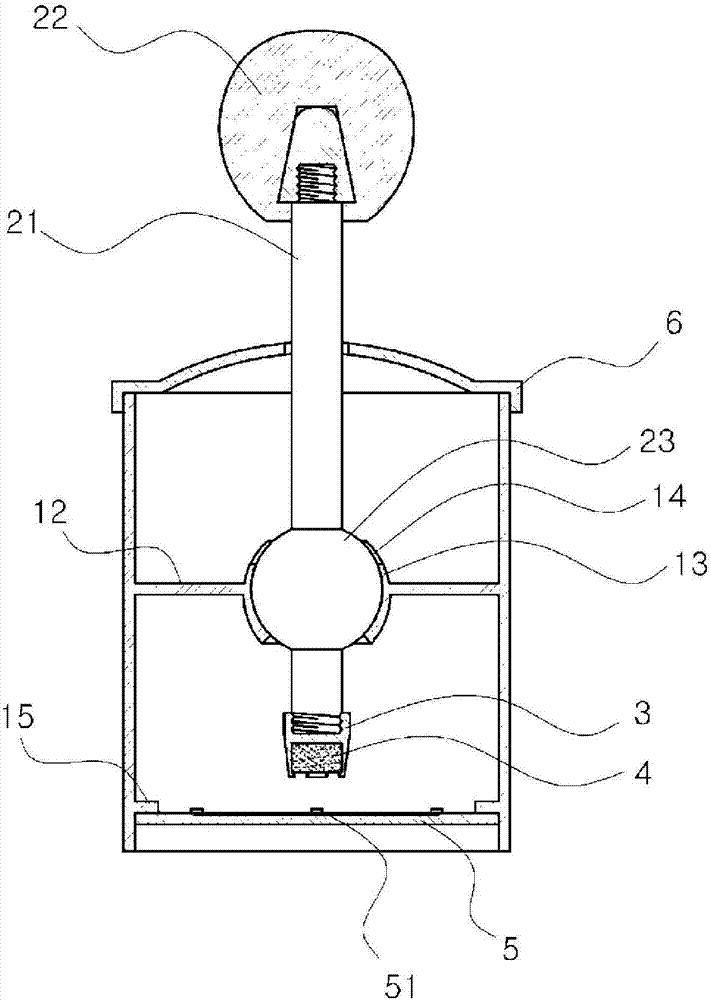

Electronic shift lever device

InactiveCN105682971AFreedom of movementSimple structureGearing controlControl devicesEngineeringMagnet

The present invention relates to an electronic shift lever device capable of controlling the transmission stage of a vehicle, using an electrical signal. Particularly, the purpose of the present invention is to provide an electronic shift lever device for simplifying a lever operation means and a sensing means, allowing the operation and the sensing to become smoother, and enabling dual use of AT and MT and compatibility of a main body according to the shape of a gate (61). The electronic shift lever device suggested in the present invention is characterized in that the lower part of a lever (2) is ball-combined to a main body (1); a magnet (4) is mounted on the lower end of the lever (2); a substrate (5) in which a hole sensor (51) is arranged on the lower part of the magnet (4) is horizontally mounted; and a gate cover (6) and the substrate (5) are combined so as to be replaced from the main body (1) by opening the internal upper and lower ends of the main body (1).

Owner:SMC CORP

Dispersion method for surface non-covalent modification of nickel nanowire

InactiveCN105642903AGood dispersionUniform dispersionMaterial nanotechnologyTransportation and packagingElectricityNanowire

The invention provides a dispersion method for surface non-covalent modification of a nickel nanowire, and belongs to the field of dispersion of nickel nanowires. The dispersion method comprises the following steps: surface treatment solution of the nickel nanowire is prepared; the nickel nanowire is added in the surface treatment solution for constant-temperature stirring to remove an oxide layer; after the nickel nanowire is repeatedly washed to become neutral, water solution of the nickel nanowire is prepared; a proper amount of surfacant is added in the water solution of the nickel nanowire; and the constant-temperature stirring is performed. The dispersion method uses hexadecyl trimethyl ammonium bromide, belonging to cation surfacant, as a dispersing agent to be easily bonded with the nickel nanowire with negative electricity on the surface in the neutral water solution, so that the surface energy of the nickel nanowire is largely reduced, the nickel nanowire can be uniformly dispersed more stably, and the easy agglomerating or winding problem of the nickel nanowire in the water solution is solved; and the dispersion method is gentle, simple in operation, convenient, low in cost, excellent in effect and broad in application prospect.

Owner:HOHAI UNIV

DC-DC converter

ActiveUS9570993B2Reduced in size and weight and costReduce switchingEfficient power electronics conversionConversion with intermediate conversion to dcTransformerEngineering

A DC-DC converter wherein a series reactor and primary-side terminals of a transformer are connected between output terminals of a full-bridge inverter in which each of an upper arm and a lower arm includes a switching element and a freewheel diode, and a rectifier circuit and a filter circuit are connected to secondary-side terminals of the transformer. The DC-DC converter includes a circulation current generation mode in which a circulation current flowing between the transformer and the switching element is generated in a power non-transmission period, and a circulation current interruption mode in which the circulation current is interrupted.

Owner:MITSUBISHI ELECTRIC CORP

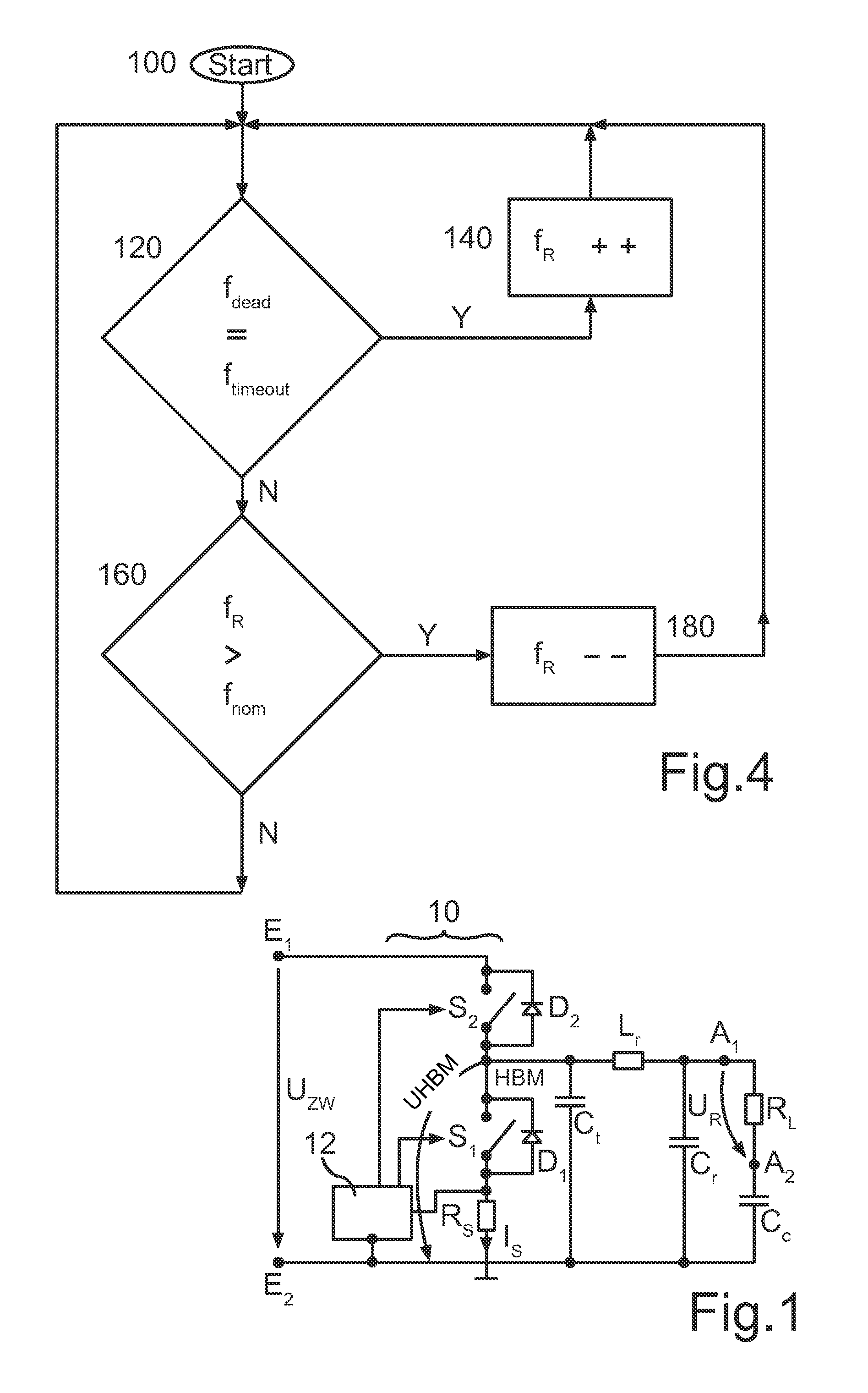

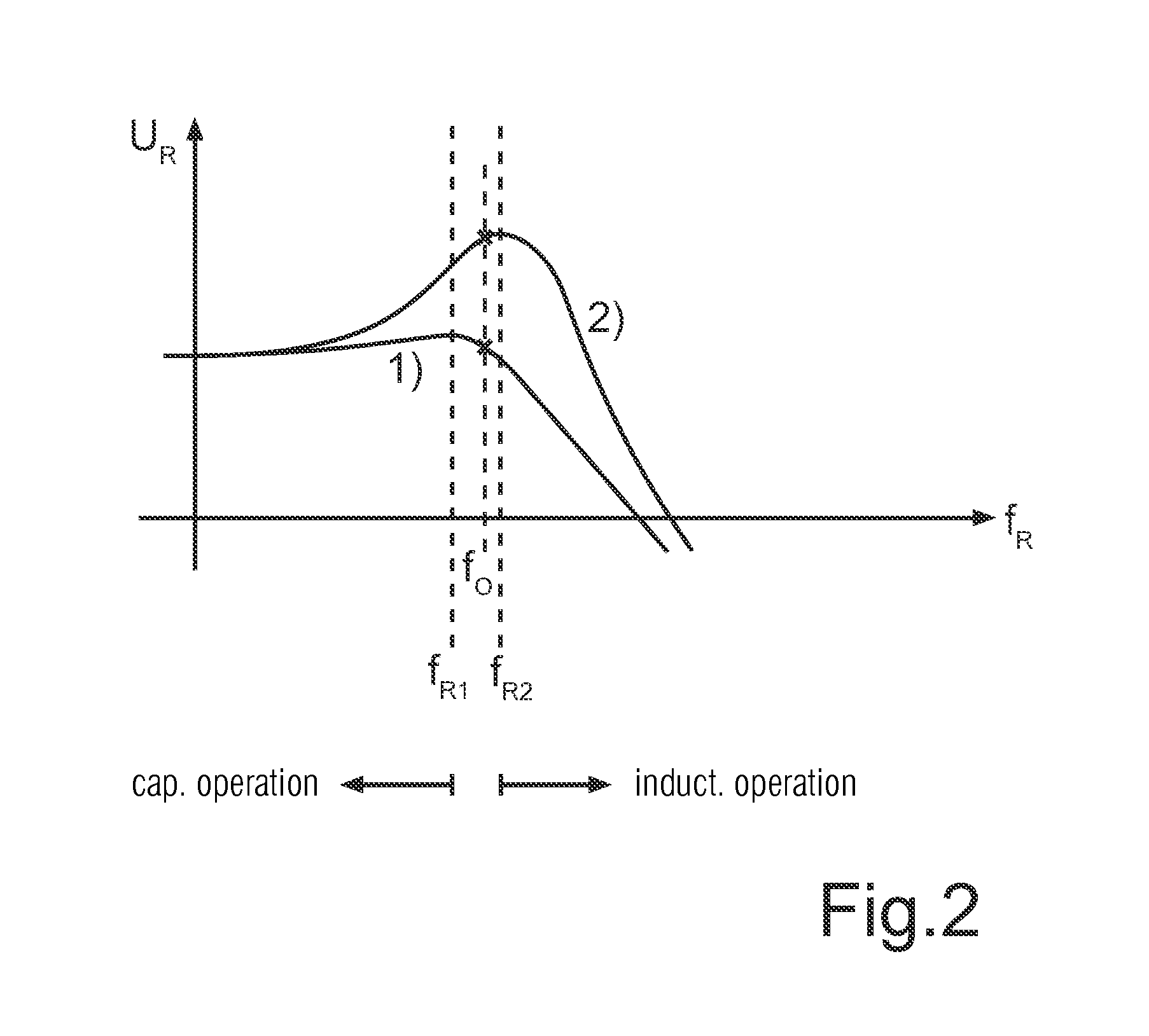

Electronic ballast and method for operating at least one discharge lamp

InactiveUS20120181945A1Minimal lossLarge amplitudeElectrical apparatusElectric light circuit arrangementGas-discharge lampCoupling

In various embodiments, ballast for a discharge lamp includes input and output connections; inverter with bridge circuit with electronic switches and control device for controlling electronic switches, wherein switches are connected in series between input connections, wherein one electronic switch is coupled to first input connection and second electronic switch to second input connection, wherein a bridge midpoint is between electronic switches; including a current measuring device for measuring second electronic switch current; lamp choke series-connected between bridge midpoint and first output connection; capacitor parallel-connected with one of electronic switches; and coupling capacitor; wherein control device is coupled to current measuring device and renders an electronic switch conducting, if negative threshold value is exceeded when electronic switch is rendered nonconducting; or if negative threshold value of current through electronic switch is not exceeded after another electronic switch is rendered nonconducting, wherein control device increases first frequency in second case.

Owner:OSRAM GMBH

Preparation method of natural antibacterial latex liner for underwear

The invention relates to the technical field of natural rubber materials, and concretely relates to a preparation method of a natural antibacterial latex liner for underwear. The preparation method comprises the following steps: mixing natural rubber with water, adding a supramolecular solvent to the mixed solution, removing proteins, and performing freeze drying to obtain a natural latex; dissolving chitosan in an acetic acid-water mixed solution, adding natural latex, nano-cellulose, an inorganic filler, glutaraldehyde and a silane modifier, carrying out a reaction, filtering the obtained solution, and performing freeze drying to obtain a natural latex master batch; and performing high-speed stirring and mixing on the natural latex master batch, a natural antibacterial agent, an oxidant,nano-silica and a punching agent, heating and melting the obtained mixture at 100-150 DEG C, injecting the melted mixture into a grinding tool, carrying out curing molding, keeping the temperature at60-75 DEG C for 2-4 h, and cooling, washing and drying the cured mixture to obtain the natural antibacterial latex liner for underwear. The method of the invention is simple to operate, and the prepared latex liner has the advantages of soft texture, excellent mechanical properties, good air permeability and good antibacterial and anti-oxidation properties.

Owner:唐卫兵

Resonant inverter

ActiveUS7755296B2Soft operationAc-dc conversionElectric light circuit arrangementResonant inverterSoft switching

Owner:SEMICON COMPONENTS IND LLC

Seat height adjuster

ActiveCN101323264BSmall range of reciprocating motionIncrease the use of spaceMovable seatsRange of motionReciprocating motion

A height regulator for a seat belongs to an automobile seat component, which comprises a first case which is provided with a first cavity, a second case which is connected with a side plate of the seat basin and is provided with a second cavity and a third axle hole, a first axle core a second axle core and a big roller which are arranged between the first cavity and the second cavity, a fan-shaped gear block which is connected with a seat cushion of the seat as well as a return spring and a wrench which are separately arranged at the outer side of the cover of the first case. The regulator has the advantages of small volume, simple structure and convenient installation; only one height regulator is needed on each seat, which can save usage cost; the movement has the good flexibility and the firm locking; as friction is used for driving and no space and gears exist between components, the operation is soft, flexible and energy-saving and the regulatory accuracy can be ensured; as the scope of the reciprocating motions of a wrench is small, the use space of the seat can be effectively increased; the free connection with any seat can be realized and the connection is simple; the height regulator for the seat of the invention has the wide application scope.

Owner:JIANGSU ZHONGMING XIANGHE SEIKO

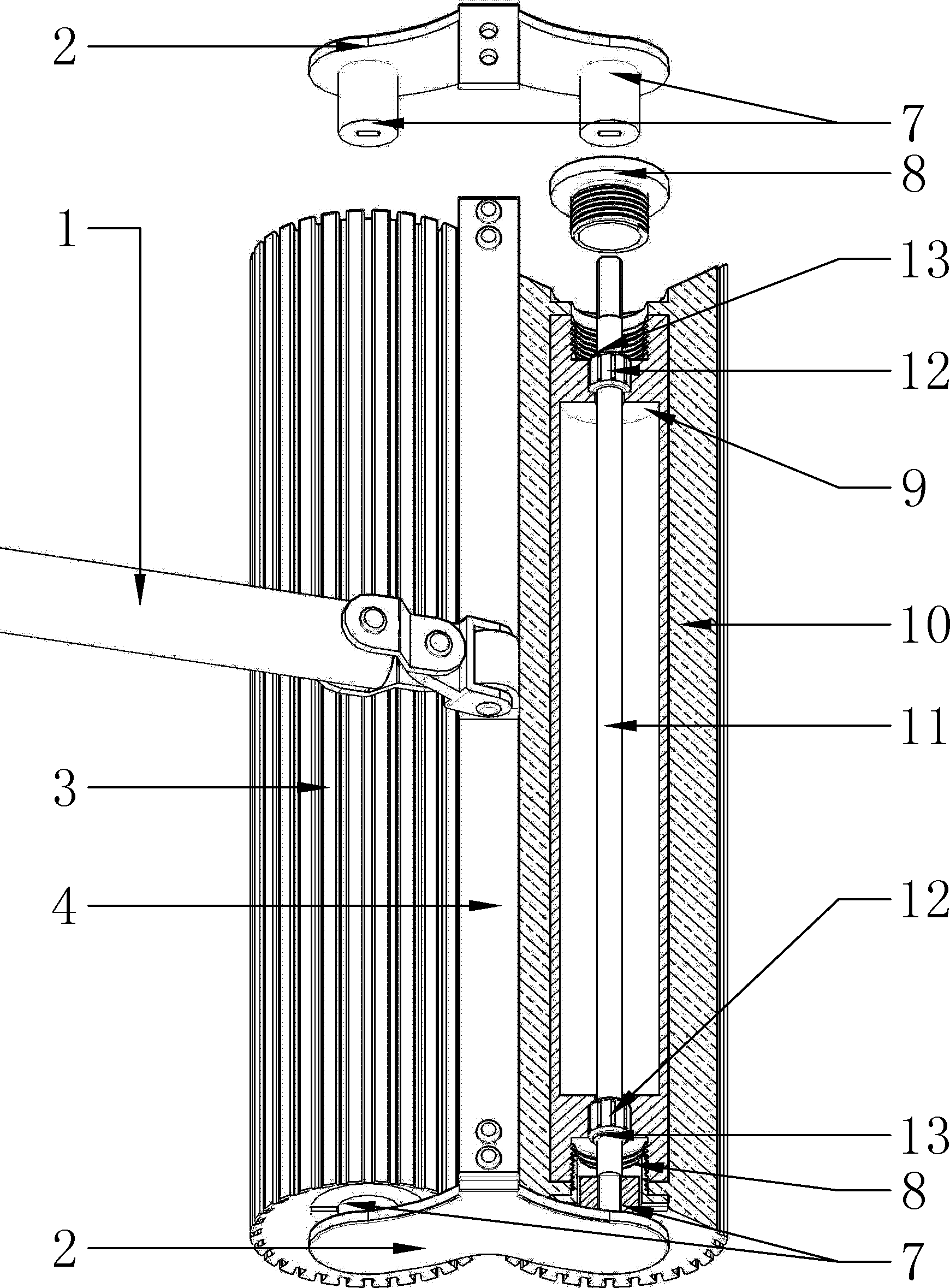

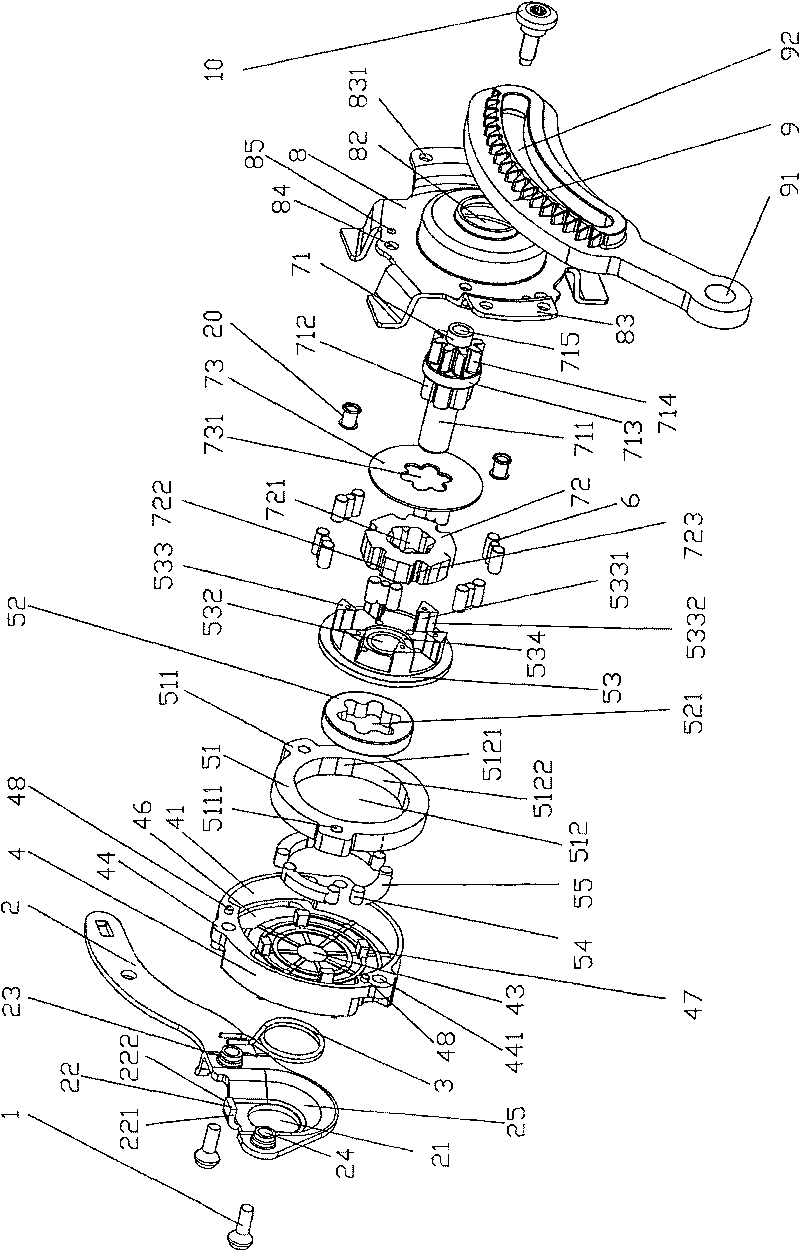

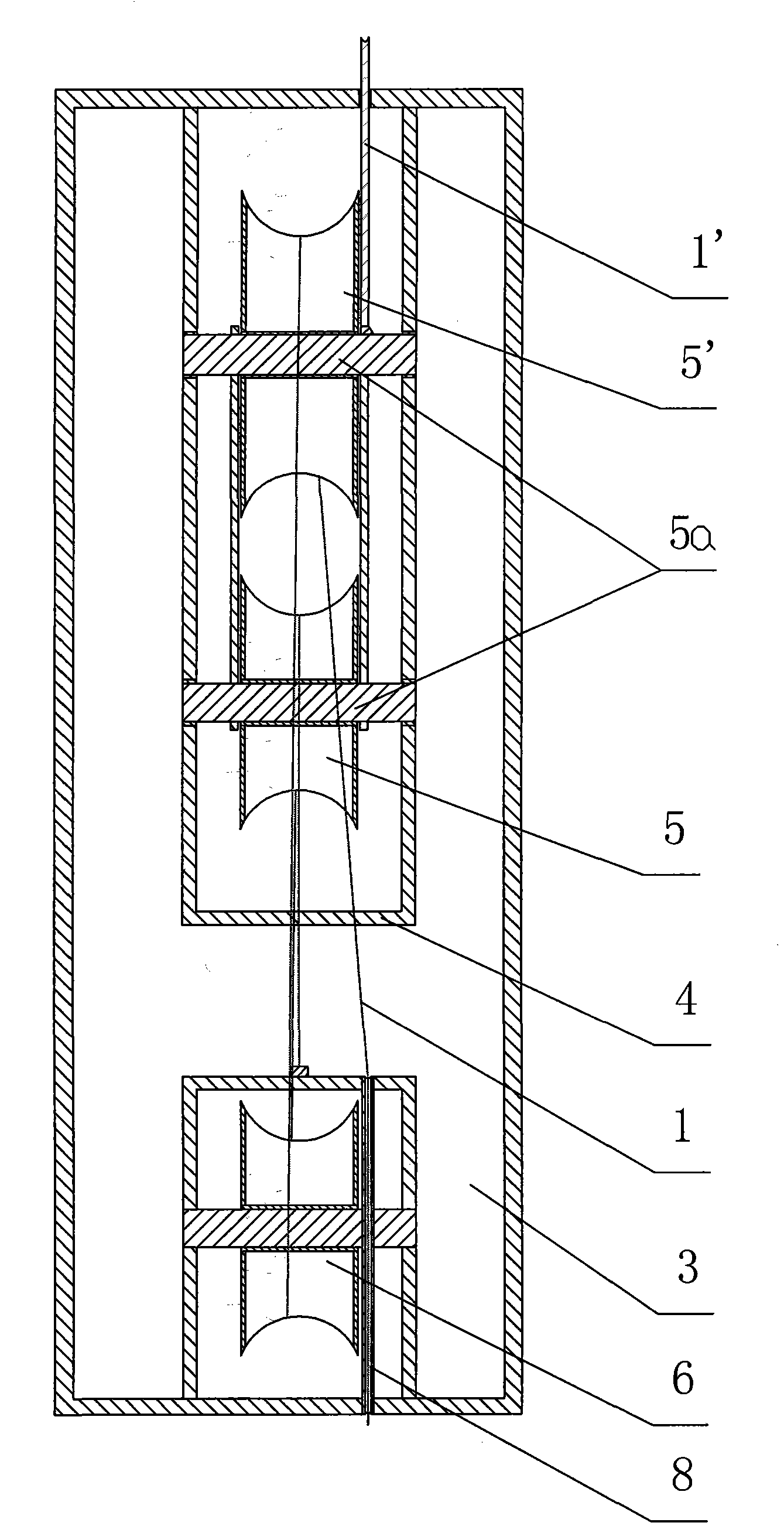

Height adjusting device for seat

ActiveCN102848937BSmall range of reciprocating motionIncrease the use of spaceMovable seatsRatchetReciprocating motion

A seat height adjustment device belongs to vehicle seat accessories. Including: the central shaft connected with the tooth plate on the seat and the entire height adjustment device, the connecting plate fixed with the side plate of the seat basin, the return spring, the transmission mechanism has a pair of interacting pawls and ratchet wheels, and the accommodating pawl The ratchet plate, the anti-backlash plate to eliminate the axial gap, the shift block for the transmission torque, the wheel housing for accommodating the transmission block and the roller, the shaft sleeve, the wrench cover connected with the wrench, the gasket and the circlip. Advantages: small size, simple structure, easy assembly, and only one height adjuster needs to be installed on each seat, which can save the cost of use; good movement flexibility and firm locking; friction transmission is used, and there is no gap between the parts Clearance, no gear position, soft, flexible and labor-saving operation, which can ensure the adjustment accuracy; no clearance in the axial direction; small reciprocating movement range of the wrench, which can effectively increase the use space of the seat; it can realize the connection with any seat, and Simple connection and wide application range.

Owner:JIANGSU ZHONGMING XIANGHE SEIKO

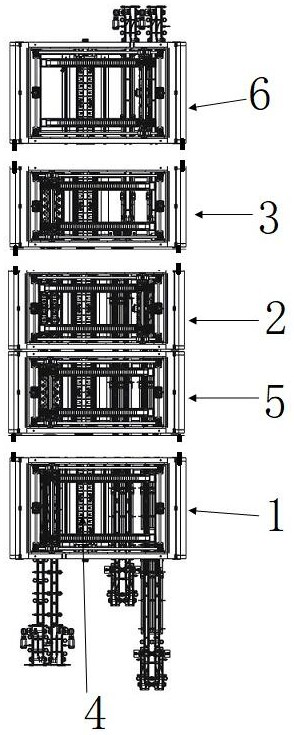

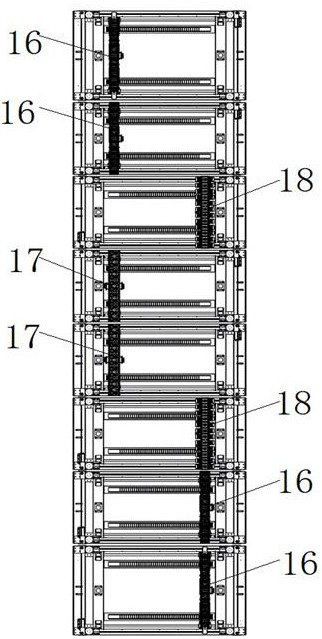

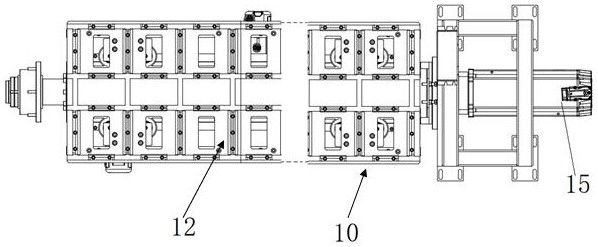

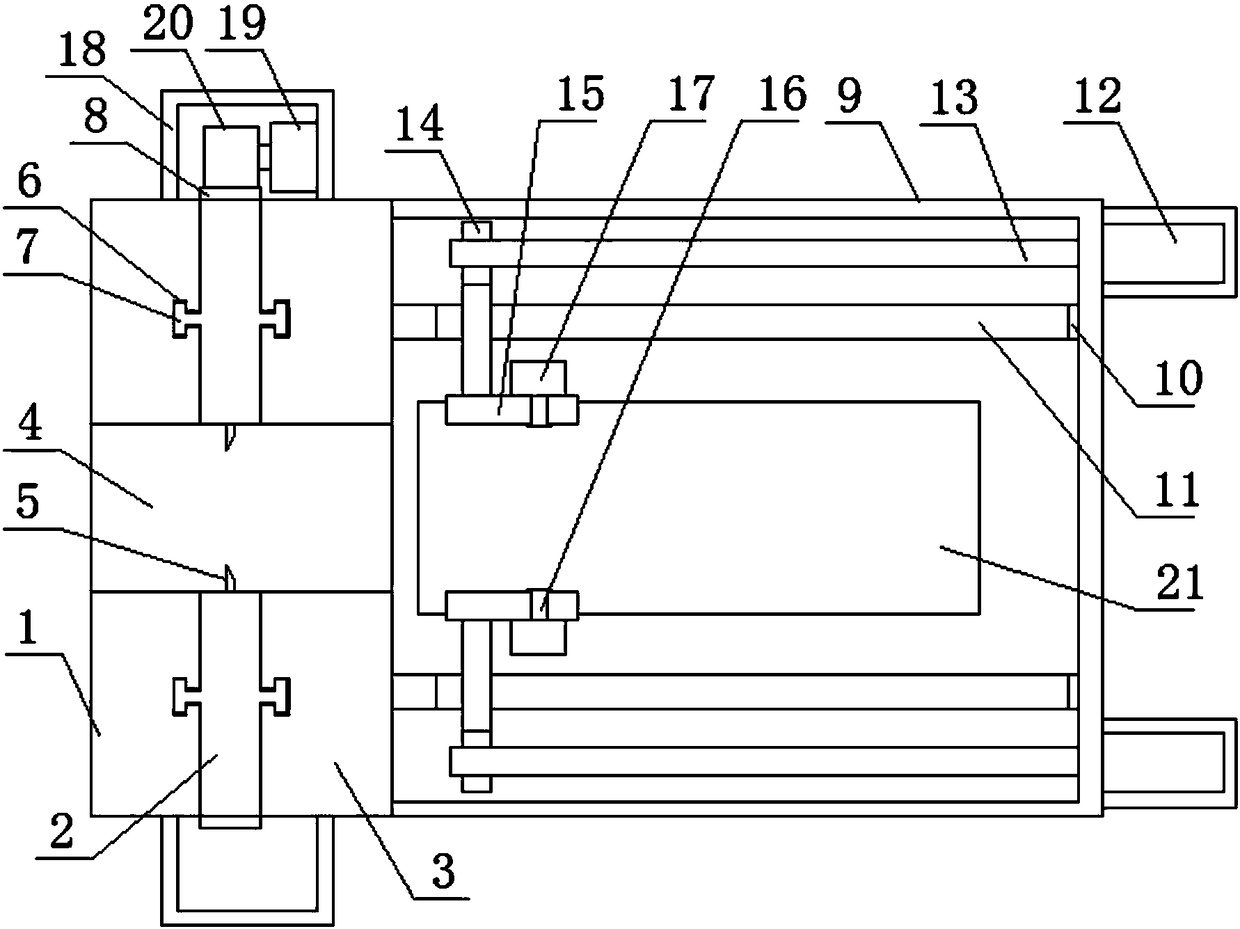

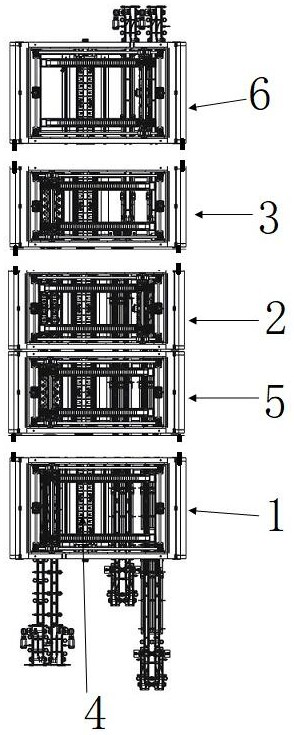

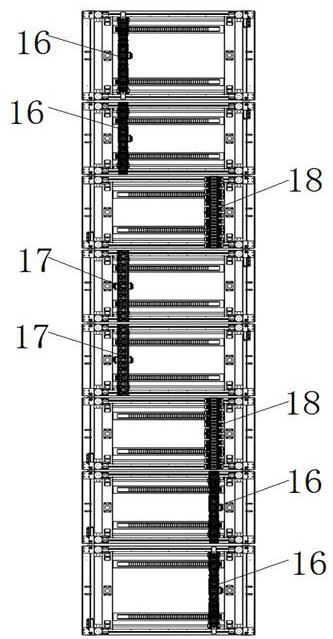

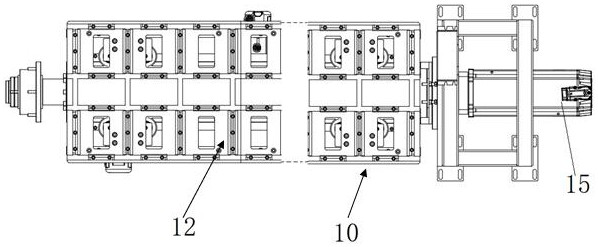

High-end gift box liquor packaging equipment

ActiveCN112158377AIncrease the number ofReduce process waiting timePackaging automatic controlPackaging bottlesProcess engineeringBottle

The invention discloses high-end gift box liquor packaging equipment, which belongs to the technical field of liquor packaging. The high-end gift box liquor packaging equipment comprises two liquor box feeding devices, two liquor bottle feeding devices, a box cover feeding device, a circulating conveying device, and a box body and box cover separating device for separating a liquor box, wherein the liquor bottle feeding devices and the liquor box feeding devices form a multi-feeding structure, each liquor box feeding device is provided with a liquor box conveying channel, and each liquor bottle feeding device is provided with at least two liquor bottle conveying channels; a multi-feeding structure and multi-conveying-channel mode is adopted, feeding is conducted in a crossed mode, it is guaranteed that the feeding process is not interrupted, and the feeding waiting time is shortened; due to an independently-arranged liquor bottle, liquor box and box cover arranging device, accurate positioning and accurate matching are guaranteed, the packaging process is smoother, and working hours are saved; and the overturning type circulating conveying device and a carrier trolley which is arranged on the circulating conveying device and driven by a gear and rack mechanism can meet the requirements for strength and stability of high-speed packaging, and the productivity is effectively improved.

Owner:南京华创机械设备有限公司

Mushroom mooncake and making method thereof

InactiveCN108703186AImprove the coagulation effectPromote recoveryPreservation by coatingBakery productsCooking & bakingTaurine

The invention discloses mushroom mooncake and a making method thereof. The mushroom mooncake is made with mushrooms, glutinous rice, salt, corn oil, maltol, lye, low-gluten flour, beaten egg, maltodextrin, dietary fiber powder, citric acid, and chitosan. The dietary fiber powder is made by enzymatically hydrolyzing soybean residue via a composite enzyme containing hypericin and taurine; syrup is made by boiling; skin is made; stuffing is made; shaping is performed after filling with the stuffing; baking is carried out before cooling and packaging to obtain the mushroom mooncake. The mushroom mooncake is a novel mooncake type having novel flavor, rich dietary fiber, low sugar and fat, and thin skin and bright stuffing, is oily and sweet, and has the advantages of high safety, good palatability, rich sensory experience, naturalness, zero additives, and greenness and health; the making method is simple to perform and has high production efficiency and good processing convenience, is environmentally friendly since waste is turned into wealth, allows industrial production to be easily implemented, can provide improved economic benefit for enterprises and good social benefit.

Owner:兰溪市捷喜食品加工技术有限公司

Mop

ActiveCN103070651BSimple structureAvoid damageCarpet cleanersFloor cleanersMechanical engineeringEngineering

The invention discloses a mop which comprises a holding rod, a bracket connected to the lower end of the holding rod, and two rows of wiping rollers, wherein the two rows of wiping rollers are arranged on the bracket in parallel back and forth and can unidirectionally rotate; non-return directions of the wiping rollers in front and back rows are opposite; when the mop pushes forwards, the roller in the front row rolls forwards to wet the ground, and the roller in the back row stops for wiping the ground; and when the mop is pulled backwards, the roller in the back row backwards rolls to wet the ground, and the roller in the front row stops to wipe the ground. In the mopping process, the surfaces of the wiping rollers can be fully utilized; even if the rollers are dirt, falling dirt in the rolling process can be collected by the roller in a stopping state and is limited between two rows of rollers, so that the phenomena that the dirt and stain are distributed along the movement of the mop can be reduced or avoided, and the times of cleaning the mop in the mopping process can be reduced. The mop further comprises a wringer arranged in a separating manner. The wringer is of a tong-shaped structure with a simple structure; when the wringer is operated, the damage of the wringer to the rollers is little; when the wringer is damaged or lost, the wringer is only needed to be independently replaced; and the wringer can be also used for clamping solid waste on the ground.

Owner:阳珉

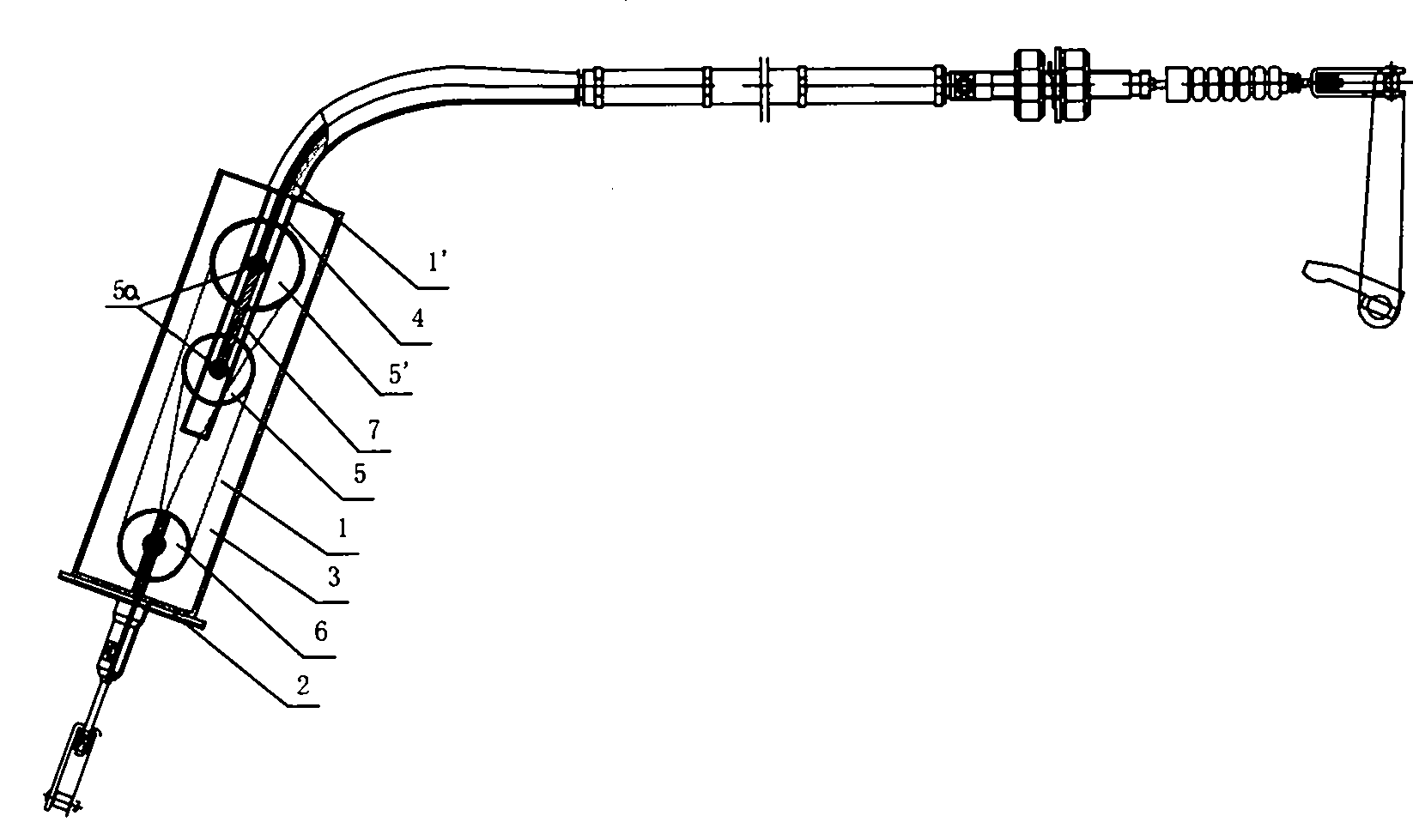

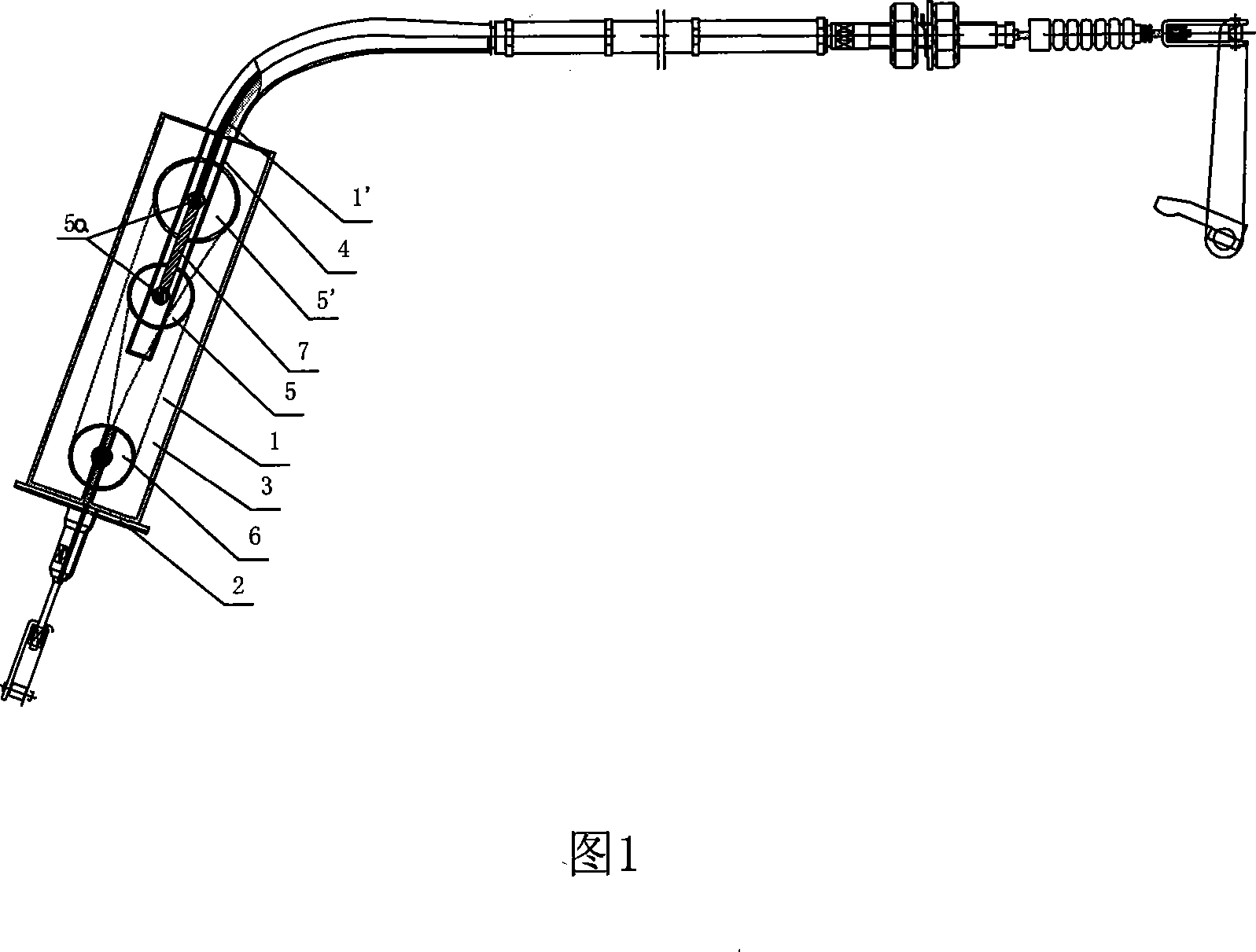

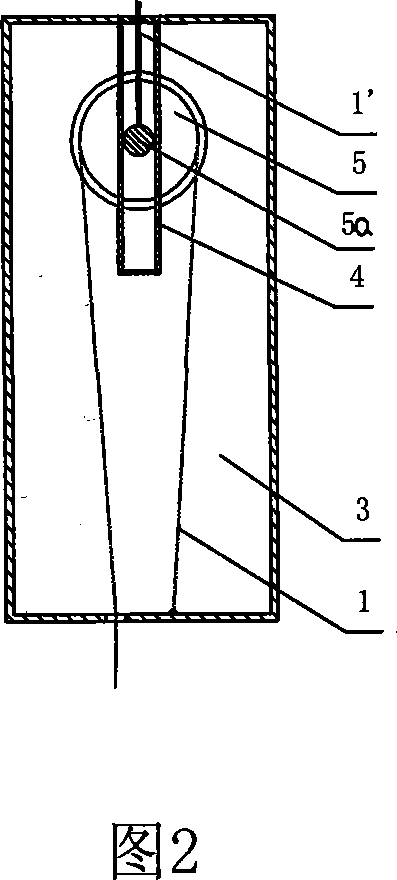

Clutch-separating cable

InactiveCN101074705BHigh force transmission efficiencySimple structureMechanical actuated clutchesControl devicesDriver/operatorEngineering

Owner:力帆科技(集团)股份有限公司

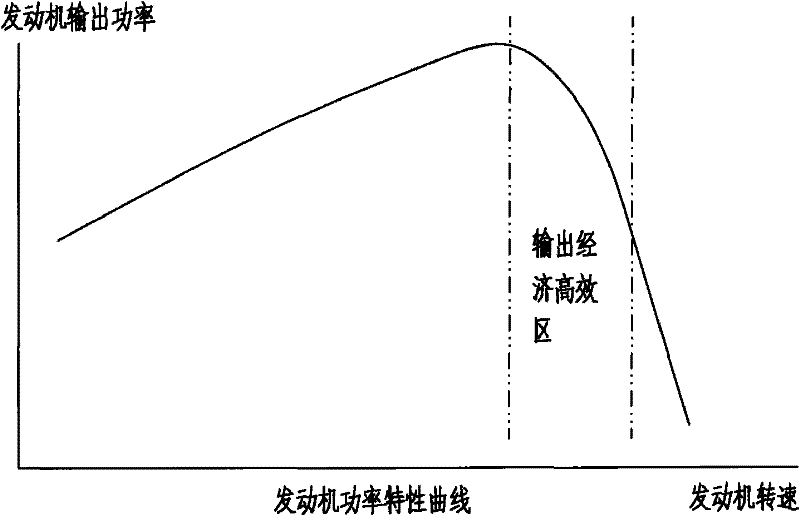

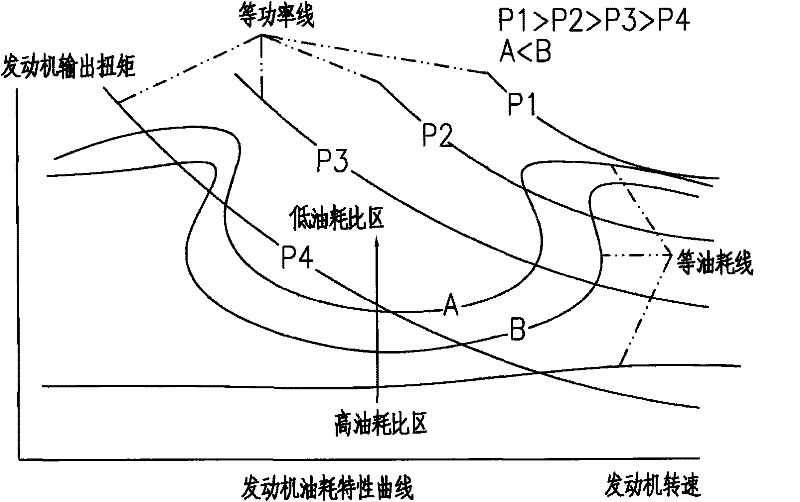

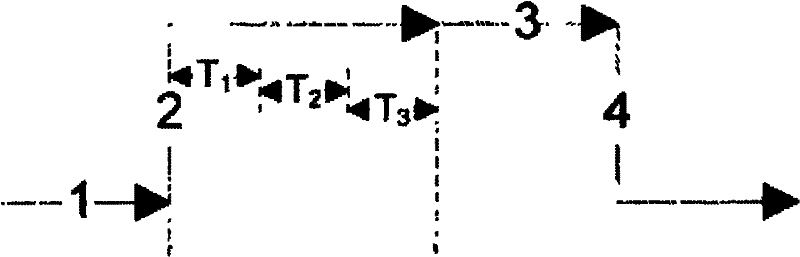

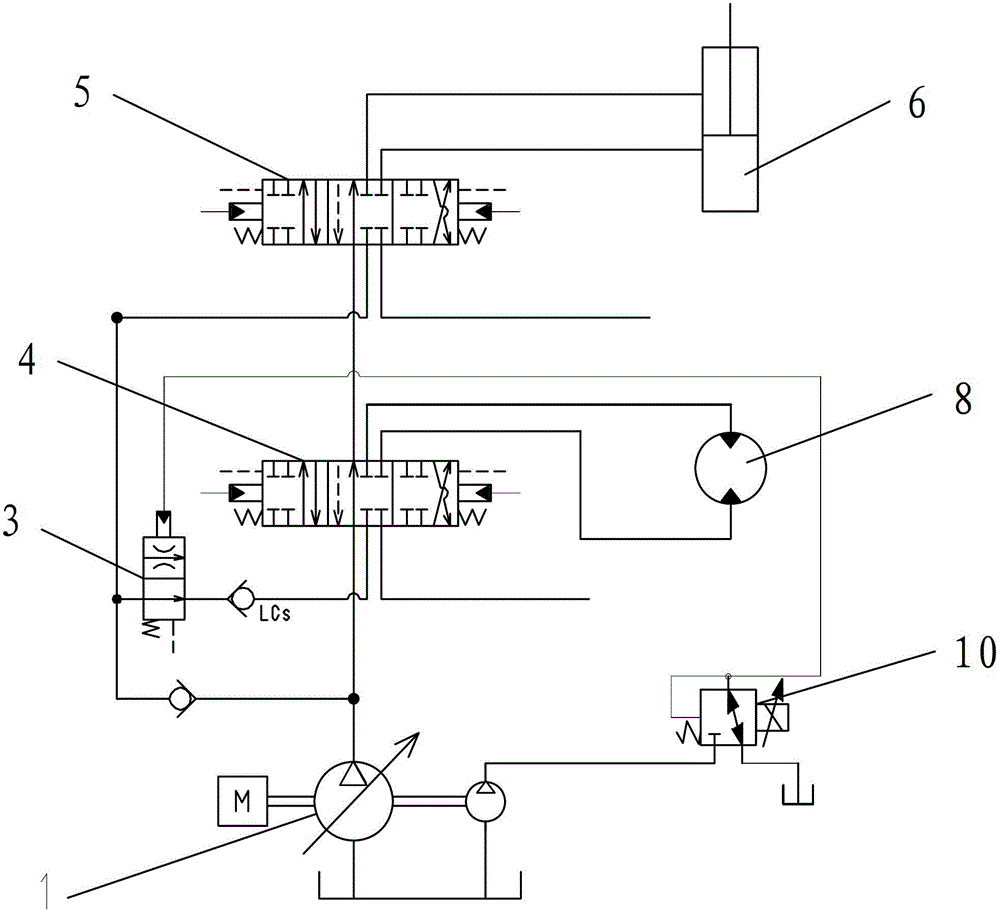

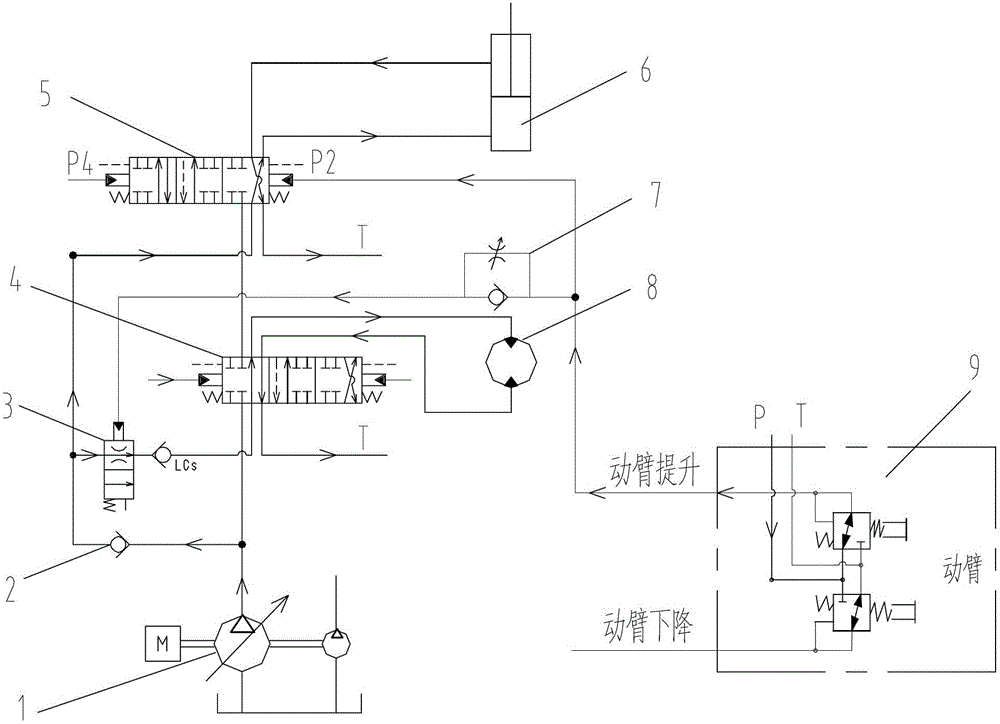

Power matching method of hydraulic excavator

InactiveCN101761105BStable speedAction speed is stableSoil-shifting machines/dredgersPower flowHydraulic pump

The invention relates to a power matching method of a hydraulic excavator, which comprises the following steps: setting a plurality of rotating speeds and outputting different powers according to the known rotating speed of an engine-power characteristic data so as to meet the requirement of different work conditions; the power matching method is characterized in that when the hydraulic excavatorworks, the method causes that the power of a hydraulic pump and the output power of the engine are matched; when the external load is suddenly added in the working process of the hydraulic excavator,the electric current I of a proportional valve of the hydraulic pump are amplified step by step so that the delivery volume V of the hydraulic pump is amplified step by step and finally the output power of the hydraulic pump is steadily increased; and when the external load is suddenly added in the working process of the hydraulic excavator, the dynamic actual electric current is output by tracking the variation condition of the rotating speed of the engine and the detected real-time pump pressure. The power matching method has the advantages of meeting the operational requirement of the excavator by using the power of the engine, thus achieving the purpose of increasing the operational efficiency and reducing the oil consumption.

Owner:龙工(上海)机械制造有限公司 +2

A wire harness stripping device

ActiveCN107069587BAvoid damageSoft operationMechanical energy handlingApparatus for removing/armouring cablesHydraulic cylinderEngineering

The invention discloses a wire harness stripping device. A wire sheath cutting device comprises a front-mounted disc, a wire sheath cutting disc and a rear-mounted disc, wire inlet holes are formed in axle centers of the front-mounted disc, the wire sheath cutting disc and the rear-mounted disc, a plurality of blades are arranged on the inner circumferential surface of the wire sheath cutting disc, a tooth space is arranged on the outer circumferential surface of the wire sheath cutting disc, convex ring grooves are formed in the inner side walls of the front-mounted disc and the rear-mounted disc, and four convex sliding blocks are uniformly arranged on two side walls of the wire sheath cutting disc; a wire sheath stripping device comprises a hollow stripping mounting base, two vertical partition plates are arranged in the hollow stripping mounting base, rectangular sliding chutes are formed in the vertical partition plates, two hydraulic cylinders are arranged at the rear end of the hollow stripping mounting base, a mounting block is fixedly arranged at the front end of a telescopic rod, the mounting block penetrates through the rectangular sliding chutes, a wire suction plate is fixedly arranged at the front end of the mounting block, the wire suction plate is provided with a suction hole and a centrifugal fan, and the suction hole traverses the wire suction plate to be communicated with the centrifugal fan. The wire harness stripping device disclosed by the invention is simple in structure, ensures that wire sheaths are stripped through negative pressure suction, saves more time and labor, and can achieve automatic production.

Owner:WUHU QIAOYUN & YOUXING ELECTRICAL IND CO LTD

Clutch-separating cable

InactiveCN101074705AReduce mechanical efficiency lossHigh force transmission efficiencyMechanical actuated clutchesControl devicesDriver/operatorEngineering

The invention discloses a clutch cable separation devices, including cable and pedal bearings, and its characteristics are: a fixed period pulley bearings on the location box, the box set up a pulley positioning pulley, cable referred to pedal through the bearings, pulley position from the above box side to enter into position inside the pulley, and bypass the agencies mentioned in the pulley, the pulley fixed in the position described on the box in the center of bodies referred to the pulley fixed connection from Rafah Cable, the cable separation from the position described in the pulley box out the other end of the pulley location box. The present invention is the dominant effect: simple, compact, small size, cheap, easy to operate soft clutch, the driver brought to the driving comfort.

Owner:力帆科技(集团)股份有限公司

High efficiency resonant ballast

InactiveUS7615934B2Reduce switching lossesImprove efficiencyElectric light circuit arrangementElectric discharge lampsSwitched currentControl signal

The present invention provides a low-cost ballast circuit for fluorescent lamps. A resonant circuit has a transformer to operate the fluorescent lamp. The fluorescent lamp is connected in series with a first winding of the transformer. A first transistor and a second transistor are coupled to switch the resonant circuit. A second winding and a third winding of the transformer are used for generating control signals in response to a switching current of the resonant circuit. Furthermore, the present invention achieves soft operation for the first transistor and the second transistor.

Owner:FAIRCHILD TAIWAN

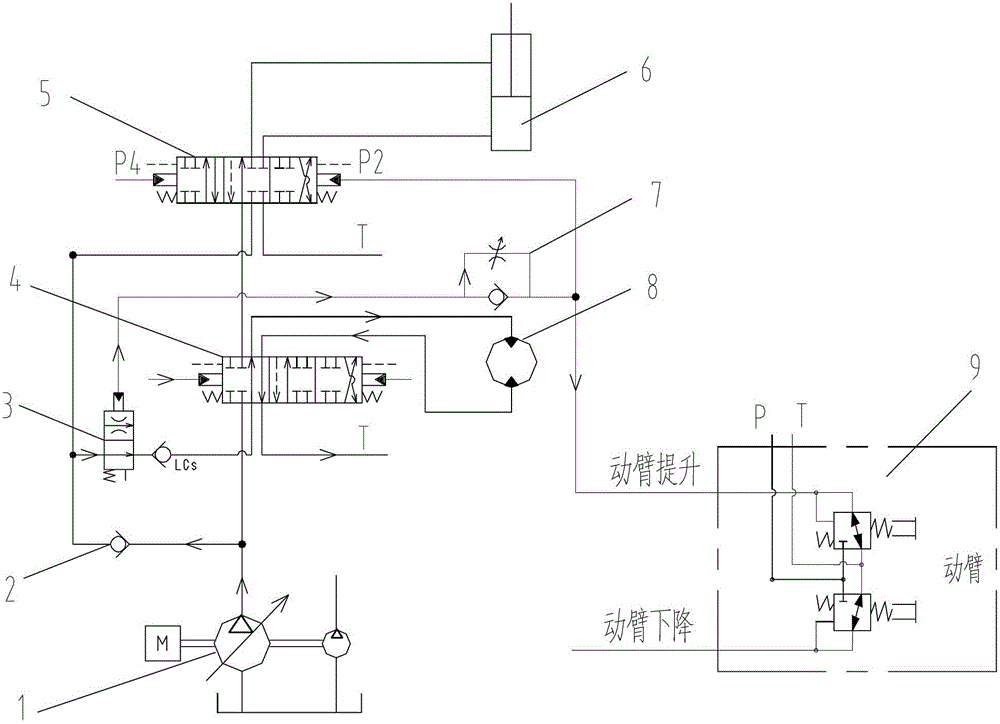

Excavator and priority control loop of excavator

The invention provides an excavator and a priority control loop of the excavator. The priority control loop of the excavator comprises a main pump, a swing arm lifting oil way and a swing action oil way, wherein the swing arm lifting oil way and the swing action oil way are connected in parallel. The swing arm lifting oil way comprises a swing arm reversing valve and a swing arm drive oil cylinder, wherein the swing arm reversing valve and the swing arm drive oil cylinder are connected with the main pump in series. The swing action oil way comprises a prior valve, a swing reversing valve and a swing motor, wherein the prior valve, the swing reversing valve and the swing motor are connected with the main pump in series. The swing action oil way further comprises a buffering valve and a manual pilot valve. A working oil port of the manual pilot valve is simultaneously communicated with an oil inlet of the buffering valve and a control end of the swing arm reversing valve. An oil outlet of the buffering valve is communicated with a control end of the prior valve. The prior valve is in a circulating state when the control end of the prior valve is under no pressure, and is in a throttling state when the control end of the prior valve is under pressure. Due to the facts that the manual pilot valve is used in the priority control loop of the excavator for outputting voltage so as to control the prior valve, and a proportional valve or a controller does not need to be added, cost is effectively reduced, stability is high, operation is gentle, and the problem of abrupt acceleration caused by an abrupt change of flow is solved.

Owner:SANY HEAVY MACHINERY

Electronic shift lever device

InactiveCN105682971BFreedom of movementSimple structureGearing controlControl devicesEngineeringElectric signal

The present invention relates to an electronic shift lever device capable of controlling the transmission stage of a vehicle, using an electrical signal. Particularly, the purpose of the present invention is to provide an electronic shift lever device for simplifying a lever operation means and a sensing means, allowing the operation and the sensing to become smoother, and enabling dual use of AT and MT and compatibility of a main body according to the shape of a gate (61). The electronic shift lever device suggested in the present invention is characterized in that the lower part of a lever (2) is ball-combined to a main body (1); a magnet (4) is mounted on the lower end of the lever (2); a substrate (5) in which a hole sensor (51) is arranged on the lower part of the magnet (4) is horizontally mounted; and a gate cover (6) and the substrate (5) are combined so as to be replaced from the main body (1) by opening the internal upper and lower ends of the main body (1).

Owner:SMC CORP

A high-end gift box liquor packaging equipment

ActiveCN112158377BIncrease the number ofReduce process waiting timePackaging automatic controlPackaging bottlesWine bottleProcess engineering

The invention discloses a high-end gift box liquor packaging equipment, which belongs to the technical field of liquor packaging and includes a wine box feeding device, a wine bottle feeding device, a box cover feeding device, a circulation conveying device, and a box body for separating wine boxes, The separation device for the box cover; among them, there are at least two wine bottle feeding devices and wine box feeding devices, forming a multi-feeding structure. Each wine box feeding device is equipped with a wine box conveying channel, and each wine bottle is equipped with The feeding device is equipped with at least two conveying channels for wine bottles; it adopts the method of multi-feeding structure and multiple conveying channels, and the feeding is carried out crosswise to ensure that the feeding process will not be interrupted and reduce the waiting time for feeding; independently set wine bottles, wine The material sorting device of the box and box cover ensures accurate positioning and accurate matching, making the packaging process smoother and saving man-hours; the flip-type circular conveying device and the carrier trolley driven by the gear and rack mechanism on the circular conveying device can meet high-speed packaging Requirements for strength and stability, effectively increasing production capacity.

Owner:南京华创机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com