A wire harness stripping device

A wire harness stripping and stripping technology, which is applied to electromechanical devices, cable installation devices, cable installations, etc., can solve the problems of quality problems and hidden dangers, low work efficiency and high rejection rate, and achieves convenient operation and simple structure. , the effect of less damage to the wiring harness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

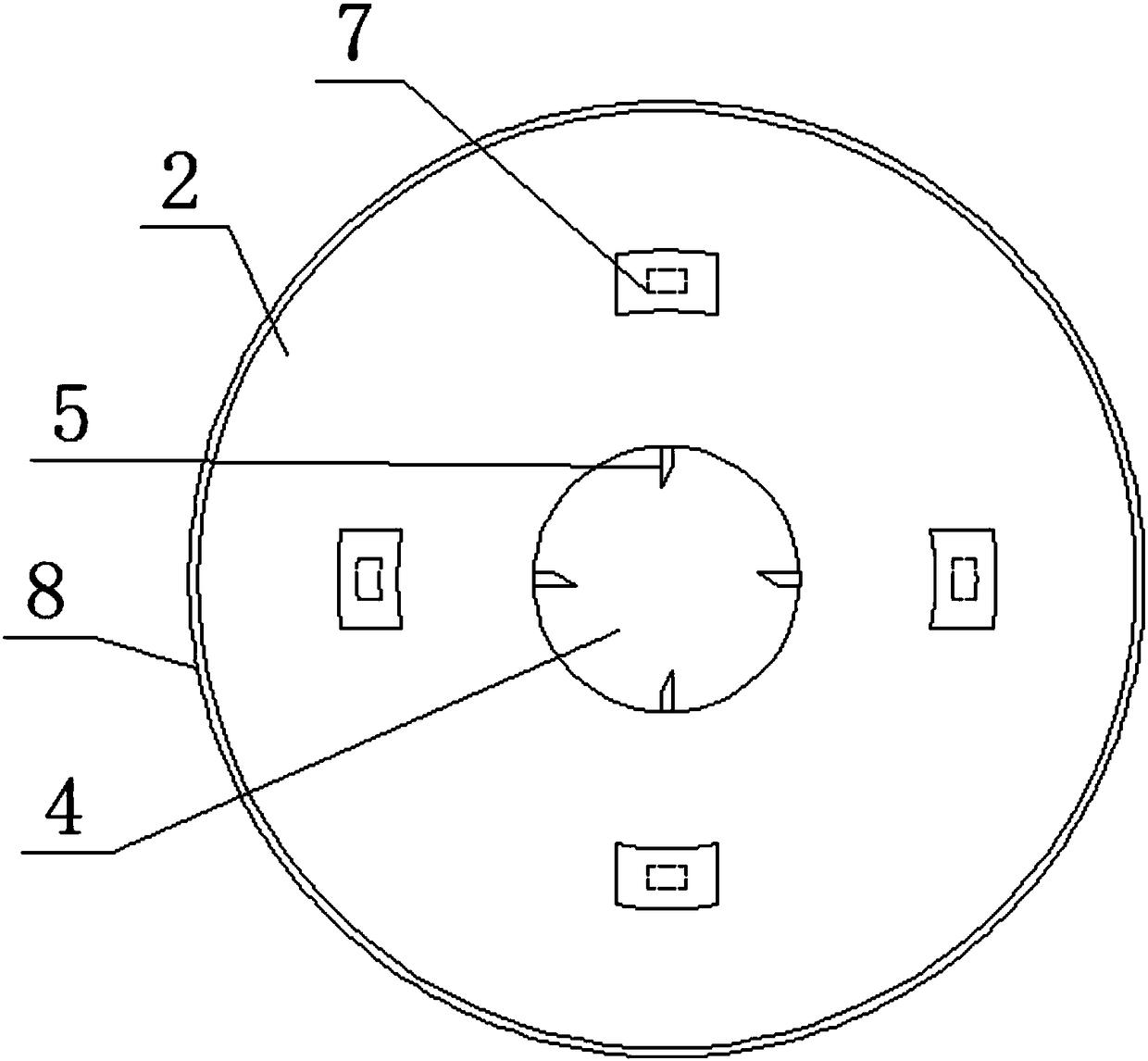

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

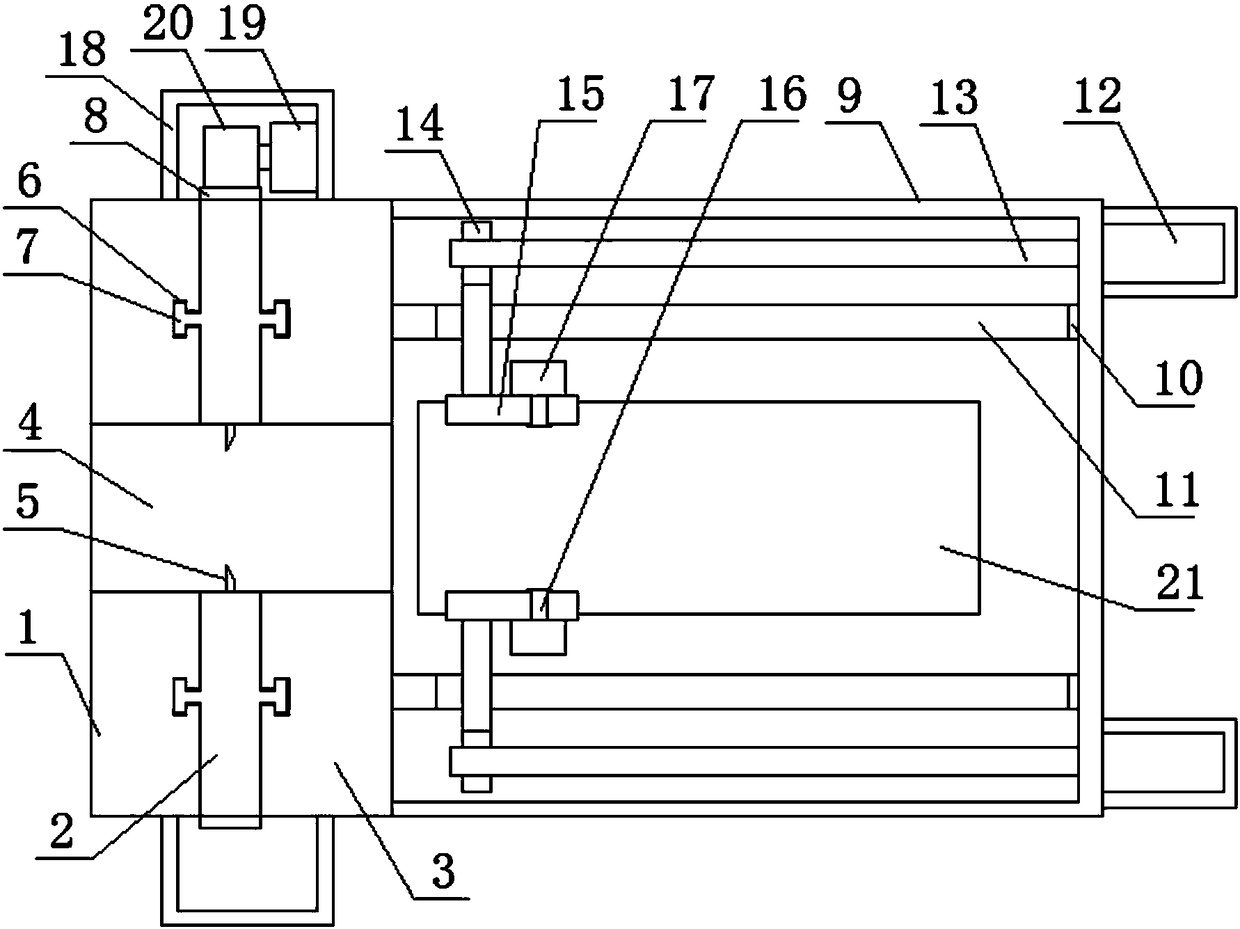

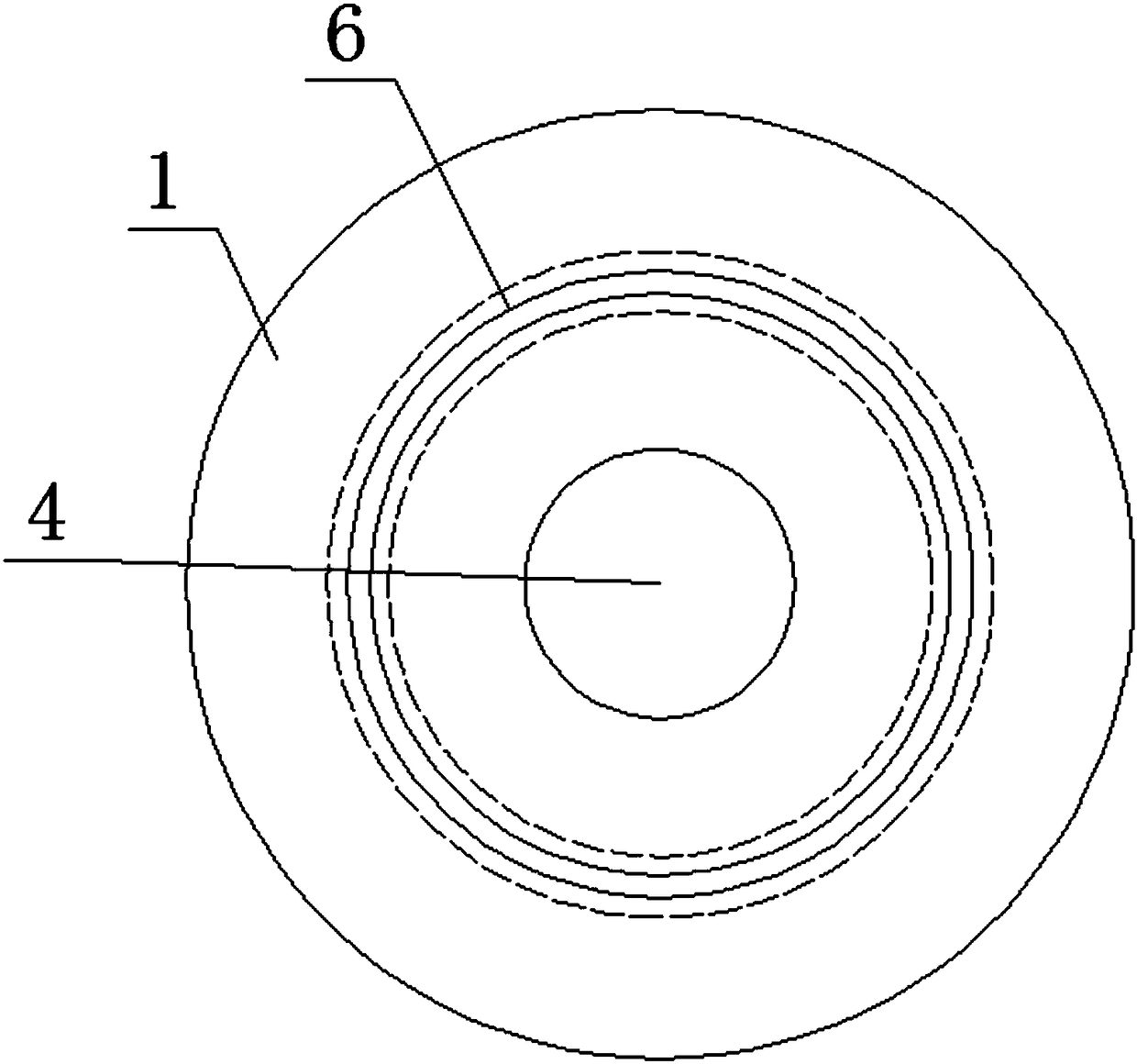

[0018] Figure 1-5 A specific embodiment of the present invention is shown: a wire harness stripping device, including a wire cutting device and a wire stripping device, and the wire cutting device includes a front assembly disc 1, a tangent sheath disc 2 and a rear assembly disc 3, the The axle centers of the front assembling disc 1, the tangent sheath disc 2 and the rear assembling disc 3 are all provided with a wire entry hole 4, and the inner peripheral surface of the tangent sheath disc 2 is provided with several blades 5, said The inner side walls of the front assembly disc 1 and the rear assembly disc 3 are provided with a convex ring groove 6, and the two side walls of the tangent leather disc 2 are evenly provided with four convex sliders 7. The circumferential surface of the tangent sheath disc 2 is provided with some tooth grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com