High-end gift box liquor packaging equipment

A technology for packaging equipment and gift boxes, applied in the field of high-end gift box liquor packaging equipment, can solve problems such as affecting assembly efficiency, limiting production capacity, and low degree of automation, saving process waiting time, soft boxing operation, and improving positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

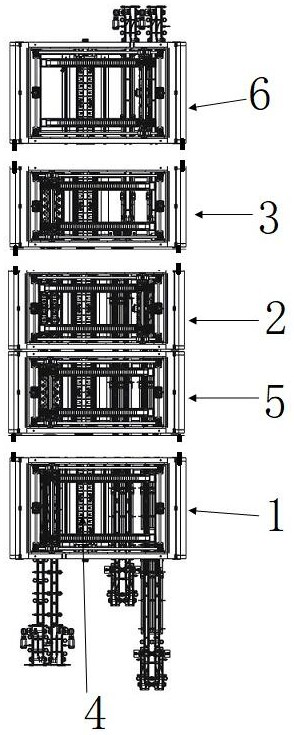

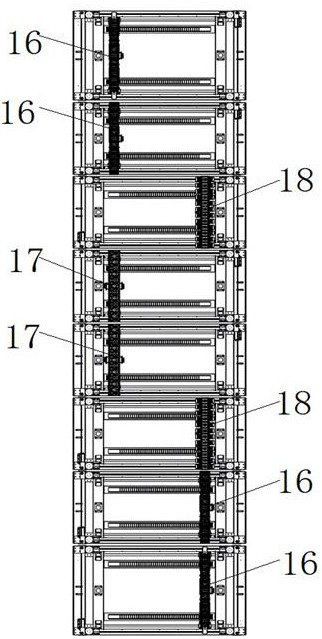

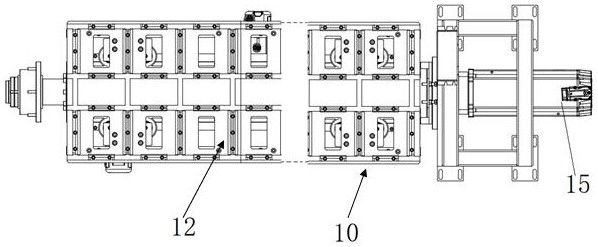

[0042] Such as figure 1 , figure 2 Shown is a high-end gift box liquor packaging equipment provided by the present invention, including a wine box feeding device 1 for wine box conveying and loading, a wine bottle feeding device 2 for wine bottle conveying and cartoning, for Lid feeding device 3 for lid conveying and feeding buckle lid, and circulation conveying device 4 for circular packaging conveyance; the wine box feeding device 1 and wine bottle feeding device 2 are arranged between the wine box feeding device 2 for separating wine boxes The separating device 5 of the box body and the lid, the lid feeding device 3 is next to the wine bottle feeding device 2, and the rear is provided with a wine box shipping device 6 for the packed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com