Clutch-separating cable

A technology of clutches and pulleys, applied in clutches, mechanically driven clutches, control devices, etc., can solve the problems of stiff operation of the clutch mechanism, laborious clutch operation, and large bearing force of the clutch pedal, so as to achieve small loss of mechanical efficiency, easy operation, and improved The effect of force transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

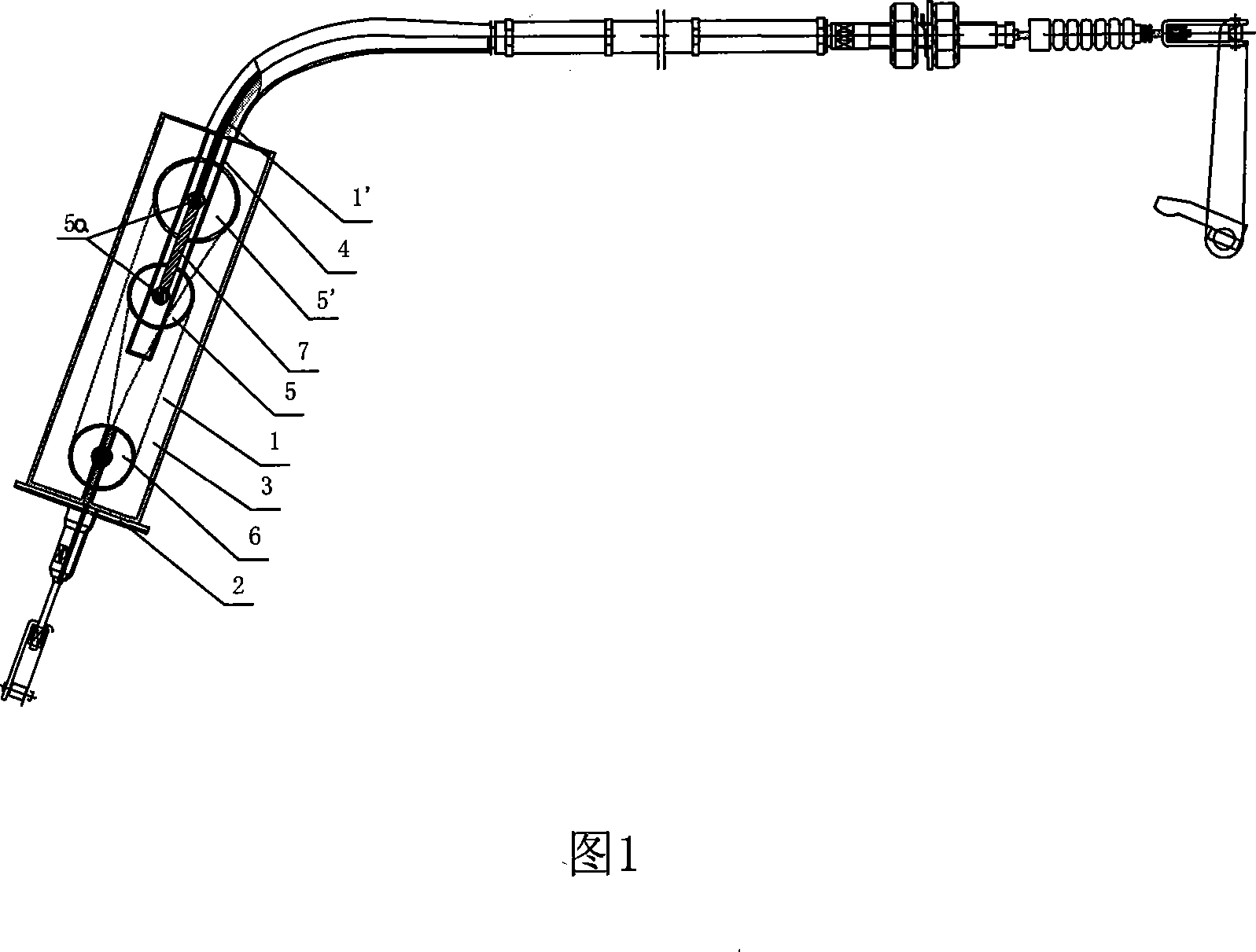

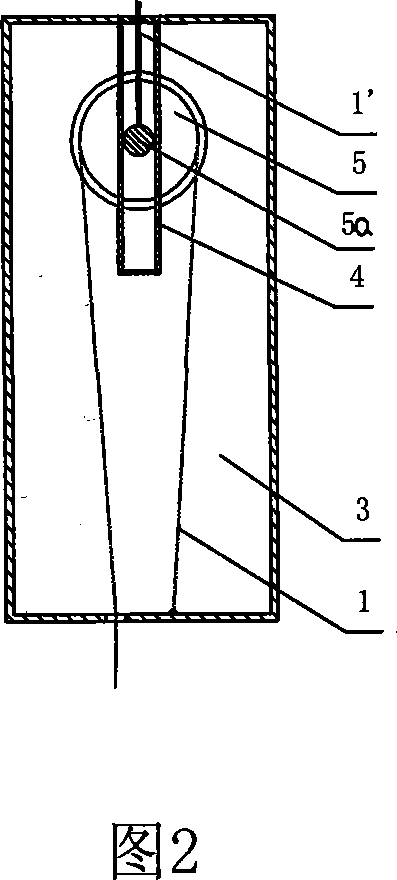

[0020] As shown in Figures 1 and 2: a clutch release cable device is composed of a pedal cable 1, a support 2, a pulley positioning box 3, a pulley mechanism, a pedal cable 1 and a release cable 1', the support 2 is fixed with a pulley positioning box 3, the pulley positioning box 3 is provided with a pulley mechanism, the pedal cable 1 passes through the support 2, stretches into the pulley positioning box 3 from one end of the pulley positioning box 3, and After bypassing the pulley mechanism, it is fixed on the pulley positioning box 3; a separation cable 1' is fixedly connected to the center of the pulley mechanism, and the separation cable 1' is connected from the other end of the pulley positioning box 3 Stretch out this pulley positioning box 3 outside.

[0021] Described pedal stay cable 1 and separation stay cable 1 ' are steel wire ropes.

[0022] The device is simple in structure, compact, small in size and cheap in price. It uses the traditional mechanical clutch ...

Embodiment 2

[0025] Embodiment 2, the structure principle of this embodiment 2 is consistent with that of embodiment 1, the difference is that

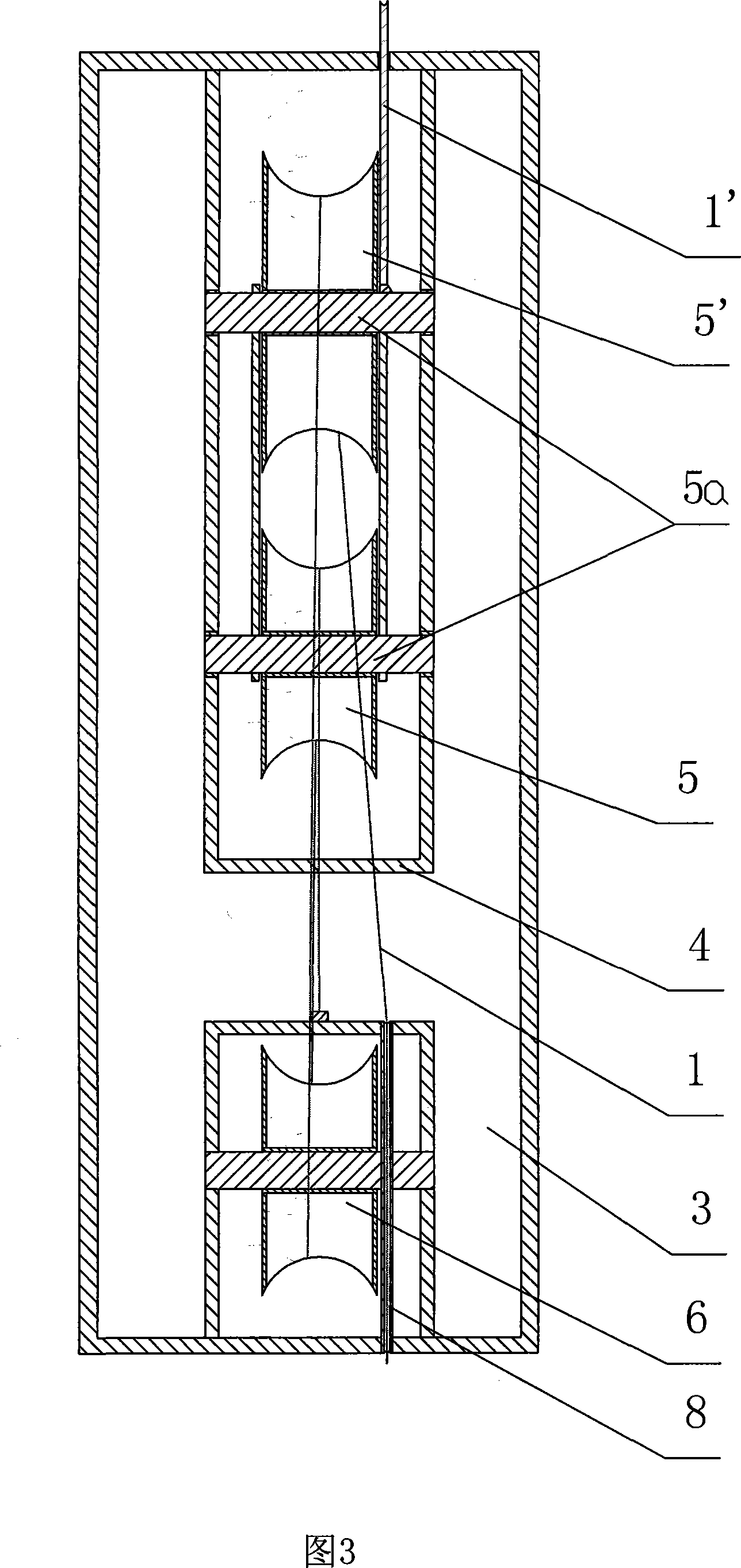

[0026] As shown in Fig. 1, 3: described pulley mechanism is made up of fixed pulley block, movable pulley groove 4, movable pulley block, wherein movable pulley groove 4 is fixed in the described pulley positioning box 3, and described movable pulley block is made up of at least two movable pulleys 5, The main shafts of the two movable pulleys 5 are vertically inserted into the movable pulley groove 4, and interlocking bars 7 are fixedly connected between the main shafts 5a of each movable pulley 5, and the separation cable 1' is fixed on the main shaft 5a; After cable 1 stretches into the pulley positioning box 3, it is fixed on the described pulley positioning box 3 after walking around the movable pulley block and the fixed pulley block.

[0027] The inner wall of the pulley positioning box 3 is provided with a wire-passing pipe 8 , and the ped...

Embodiment 3

[0029] Embodiment 3, the structure principle of this embodiment 3 is consistent with that of embodiment 2, the difference is that

[0030] As shown in Figure 4: the fixed pulley block is composed of the first fixed pulley 6 and the second fixed pulley 6', and is located at one end of the pulley positioning box 3, and the movable pulley block is composed of the first movable pulley 5, the second movable pulley 5 'and the third movable pulley 5", and is located at the other end of the pulley positioning box 3, after the pedal cable 1 extends from one end of the fixed pulley block into the pulley positioning box 3, it goes around the third movable pulley 5" in turn , the second fixed pulley 6 ', the second movable pulley 5', the first fixed pulley 6, and the first movable pulley 5 are then fixed on the pulley positioning box 3.

[0031] It works as follows: .

[0032] Fix the support 2 on the car body, install the pulley positioning box 3 on the support 2, design the pulley bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com