Vortex compressor with rotating loss reducing device

A scroll compressor and compression mechanism technology, applied in rotary piston machinery, rotary piston pumps, components of pumping devices for elastic fluids, etc., can solve problems such as oil bubbles, power loss, increased resistance, etc. , to achieve the effect of reducing rotation loss, improving efficiency and reducing mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

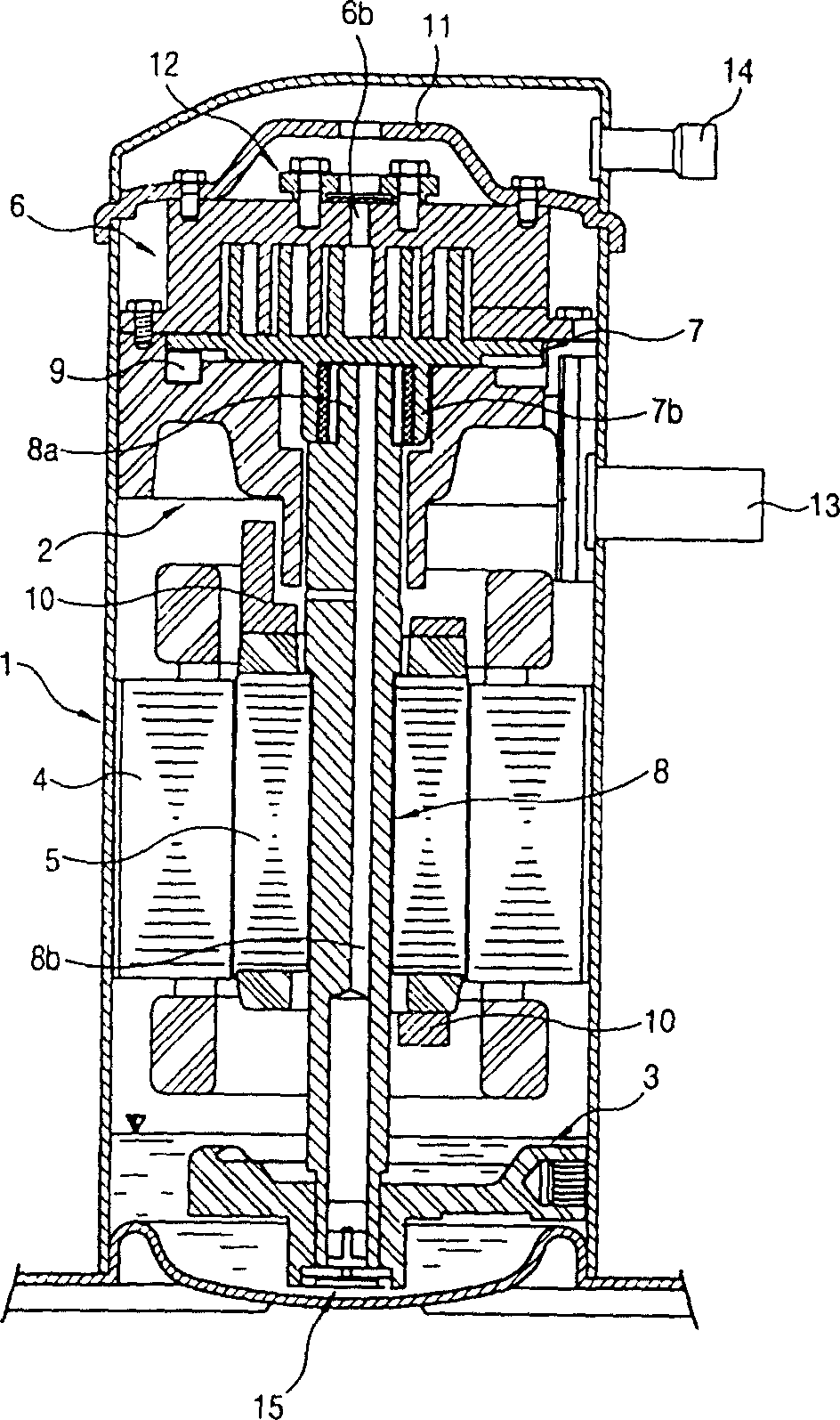

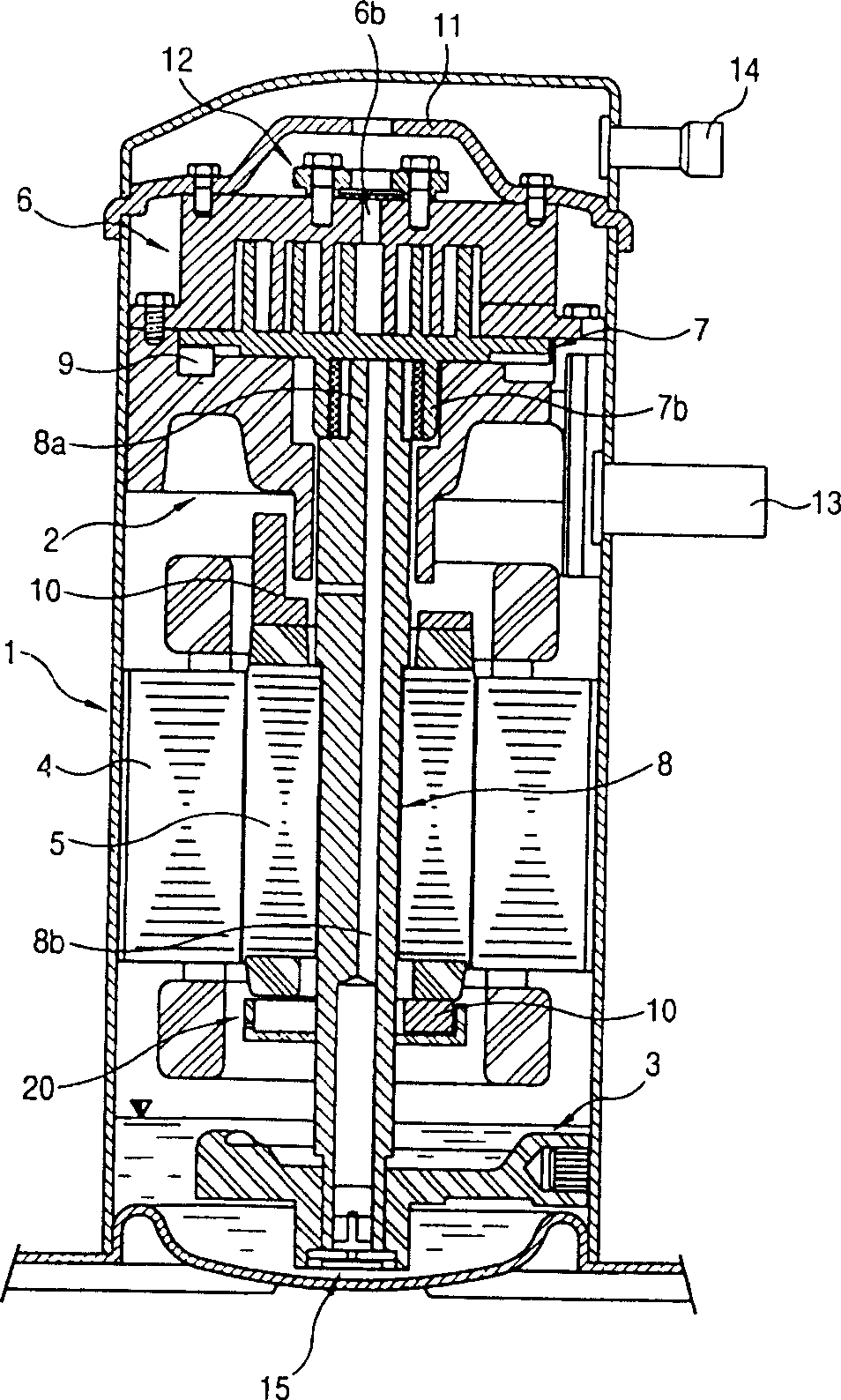

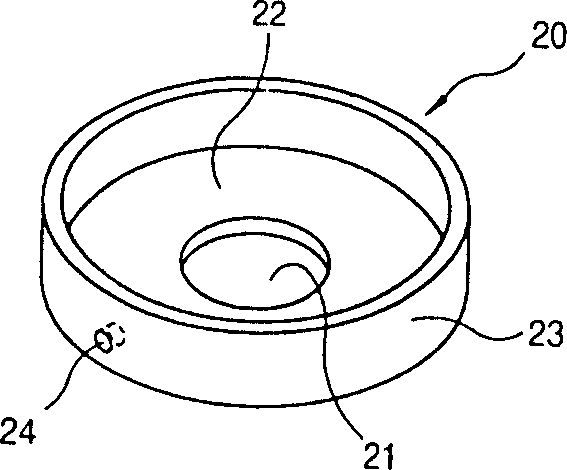

[0028] Referring to the example shown in the accompanying drawings, the embodiment of the scroll compressor with the rotation loss reducing device of the present invention will be described in detail as follows.

[0029] refer to figure 2 As shown, at first, the compression mechanism of the above-mentioned scroll compressor is inside the sealed container 1, respectively connecting the upper frame 2 and the lower frame 3, between the upper frame 2 and the lower frame 3, the stator 4 and rotor 5.

[0030] The upper end of the above-mentioned upper frame 2 maintains a predetermined interval and is fixedly connected with a fixed scroll 6, and between the above-mentioned upper frame 2 and the fixed scroll 6, a movable scroll 7 capable of rotating together with the fixed scroll 6 is inserted. And, it has a certain length, and an eccentric part 8a and a rotating shaft 8 are provided on one side thereof, which are pressed into the above-mentioned rotor 5 and inserted on the upper fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com