Hydraulic jacking device for rotating mechanism

The technology of a jacking device and a rotating mechanism is applied in the direction of a lifting device, a lifting frame, mechanical equipment, etc., and can solve the problems that the thrust and rotation cannot be taken into account at the same time, the rotating mechanism does not have the dual functions of rotation and jacking, and the structure is complicated. Achieve the effect of solving the problem of balanced axial thrust, improving effective work efficiency, and solving complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

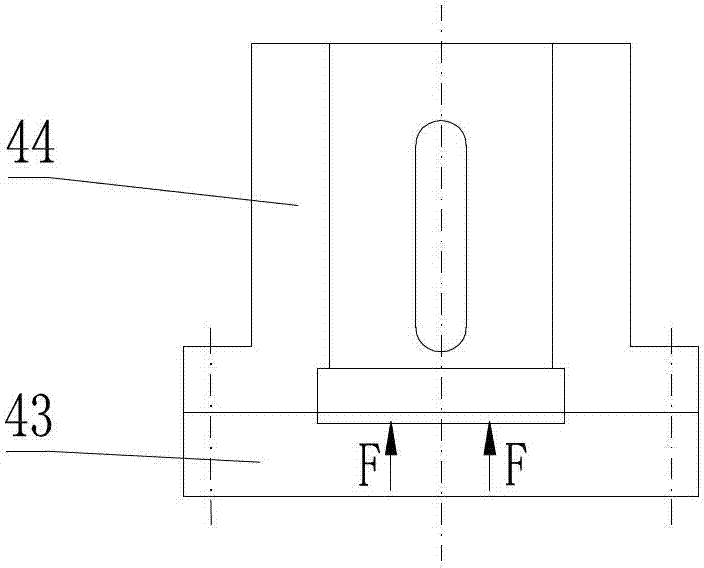

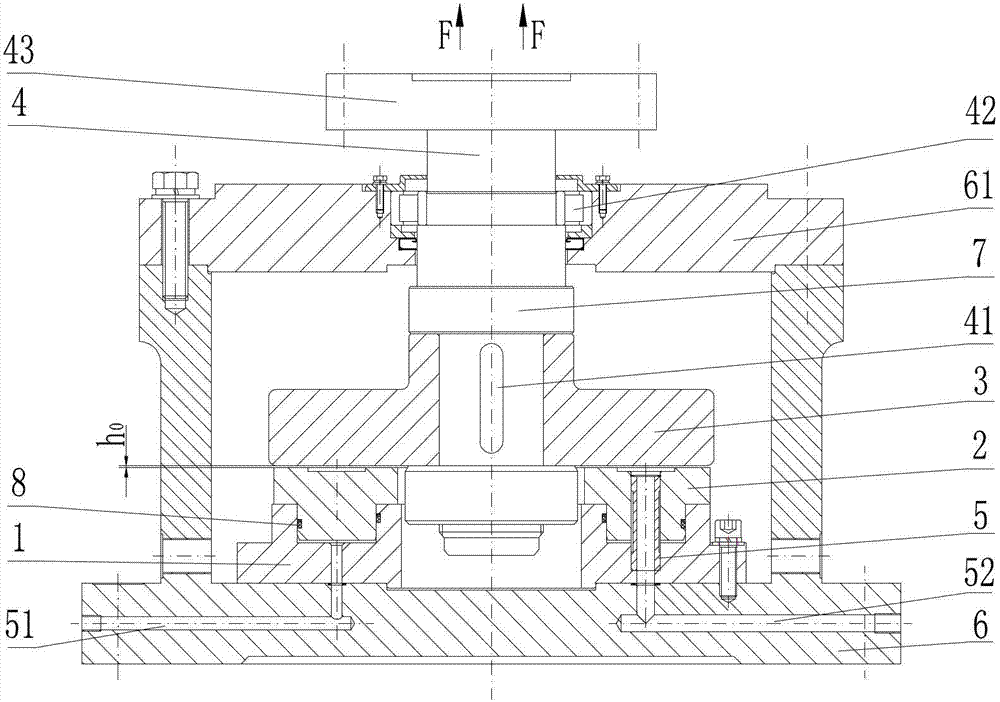

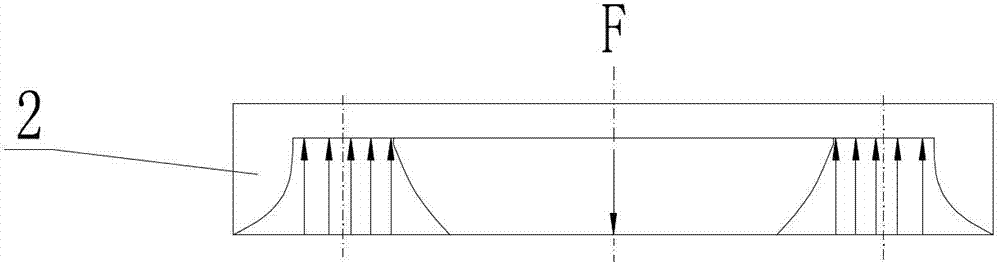

[0038]As shown in the drawings, a hydraulic jacking device for a rotating mechanism, the loading cylinder 1 is fixed on the box body 6, the follower cylinder 2 is arranged in the loading cylinder 1 and distributed radially along one side of the thrust plate 3, the box Oil passage A51 and oil passage B52 are provided on the body 6; in order to make the oil film on the surface of the thrust plate 3 uniform and have a relatively high pressure, so as to achieve the best rotation effect, at least three passages are arranged between the follower cylinder 2 and the loading cylinder 1. The oil pipe 5 and the oil pipe 5 are evenly arranged in the adjacent area between the follower cylinder 2 and the loading cylinder 1 in the radial direction; in order to realize the fast and efficient rotation function, one end of the oil pipe 5 is directly connected to the disk surface of the thrust disk 3, The other end is nested in the oil passage B52 of the loading cylinder 1; the oil passage A51 pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com