Yarn pressing device of flat knitting machine

A crimping device and flat knitting technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of reducing production efficiency, knitting needles not hooking yarn, affecting fabric quality, etc., to improve stability, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

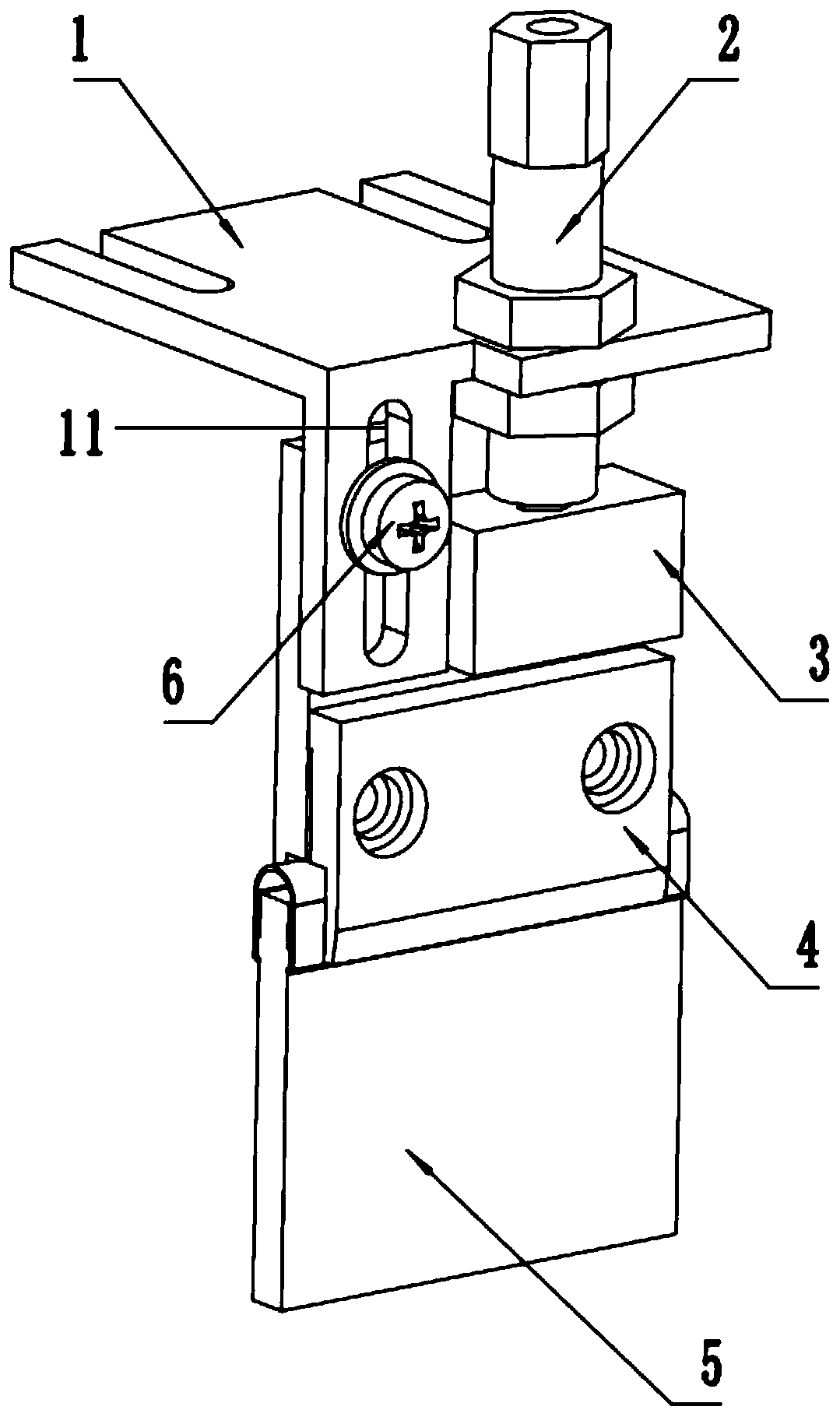

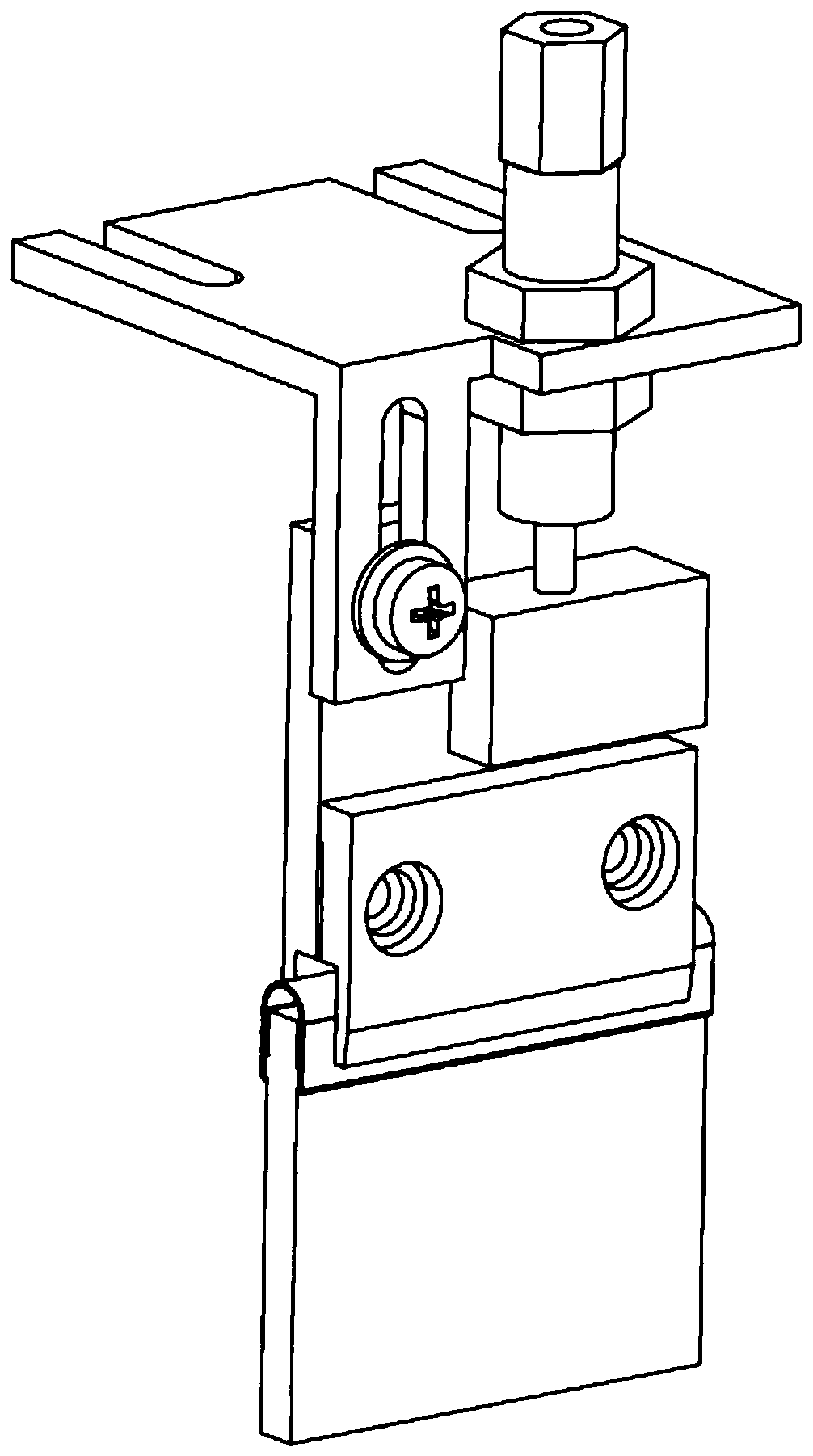

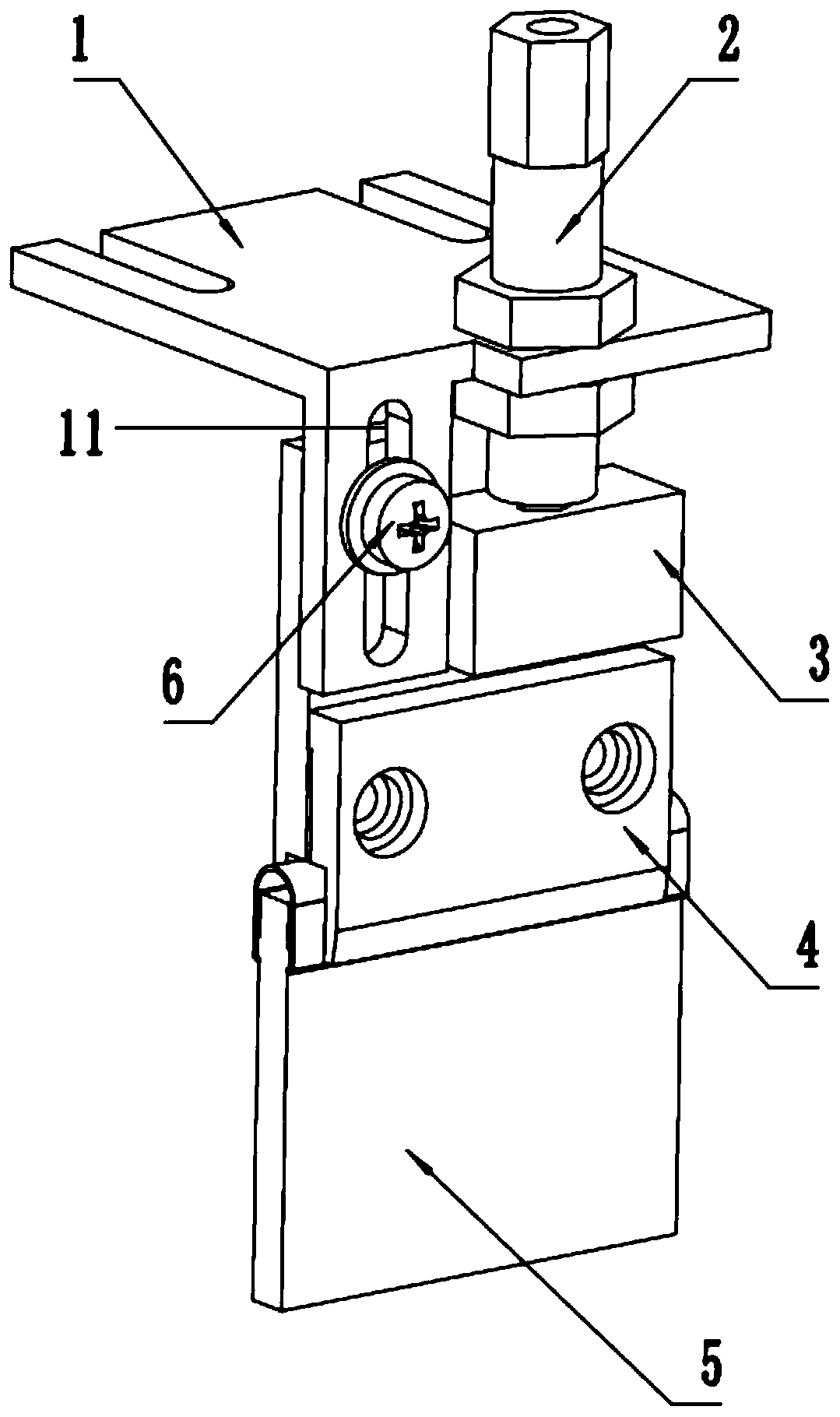

[0024] see figure 1 , figure 2 , the present embodiment provides a crimping device for a flat knitting machine, which is installed on the triangular carriage of the flat knitting machine, including a bracket 1, a brush seat 4 and a brush 5, and the bracket 1 is fixed on the triangular carriage ; The brush 5 is fixed on the brush seat 4 by a brush clip, and the brush 5 is a replaceable part to reduce costs; the brush seat 4 is connected to the support 1 movable relative to the support 1 , the bracket 1 is equipped with an actuator that can drive the brush seat to move up and down. When the needle hook of the flat knitting machine needs to hook the thread, the actuator drives the brush seat 4 to move down. At this time, the brush 5 presses down the yarn. When the needle hook of the flat knitting machine does not need to hook the thread, the actuator drives the brush seat 4 to move upwards, and the brush 5 resets now. In the present invention, by installing a pressing device o...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that the actuator described in this embodiment is an electromagnet, the electromagnet is fixed on the bracket 1, and the electromagnet is connected to the brush holder 4 by adsorption. When the power is turned on, the brush holder 4 moves up and resets under the action of the electromagnet, and when the electromagnet is powered off, the brush holder 4 moves down under its own weight or elastic structure. When the knitting needle enters the knitting area, according to the needs of knitting, the brush 5 is controlled to move up and down. When the needle hook needs to hook the thread, the electromagnet is powered off, and the brush seat 4 moves down to drive the brush 5 to move down to lower the yarn to ensure The knitting needle hooks the yarn smoothly; when the needle hook does not need to hook the thread, the electromagnet is powered on, the electromagnet picks up the brush holder 4, and resets to drive the brush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com