Equipment cooling device

A technology for equipment heat dissipation and equipment, which is applied in the direction of electrical equipment structural parts, cooling/ventilation/heating transformation, electrical components, etc., can solve problems such as increasing equipment burden, and achieve the effect of reducing design burden, avoiding dust, and effectively dissipating heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

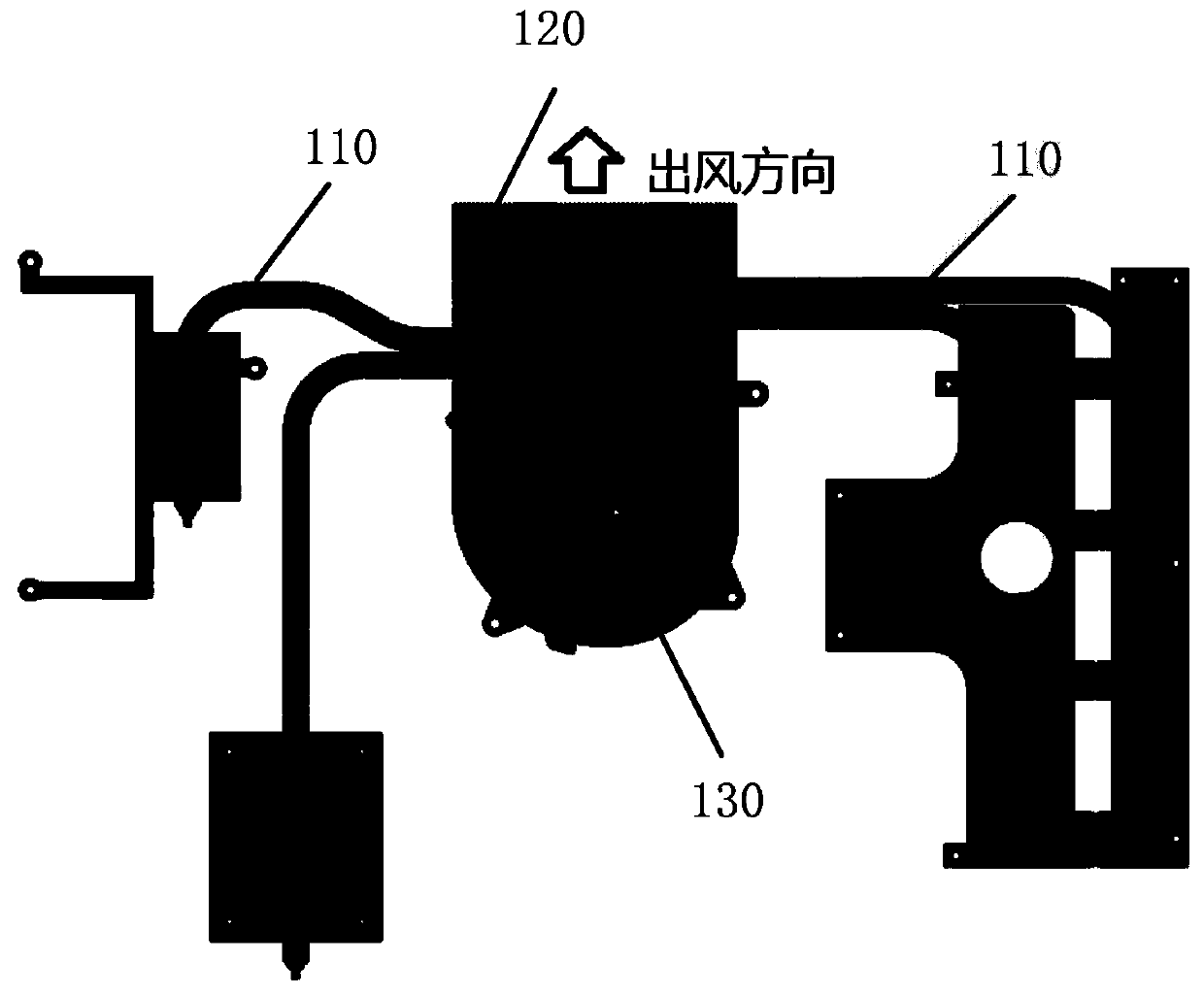

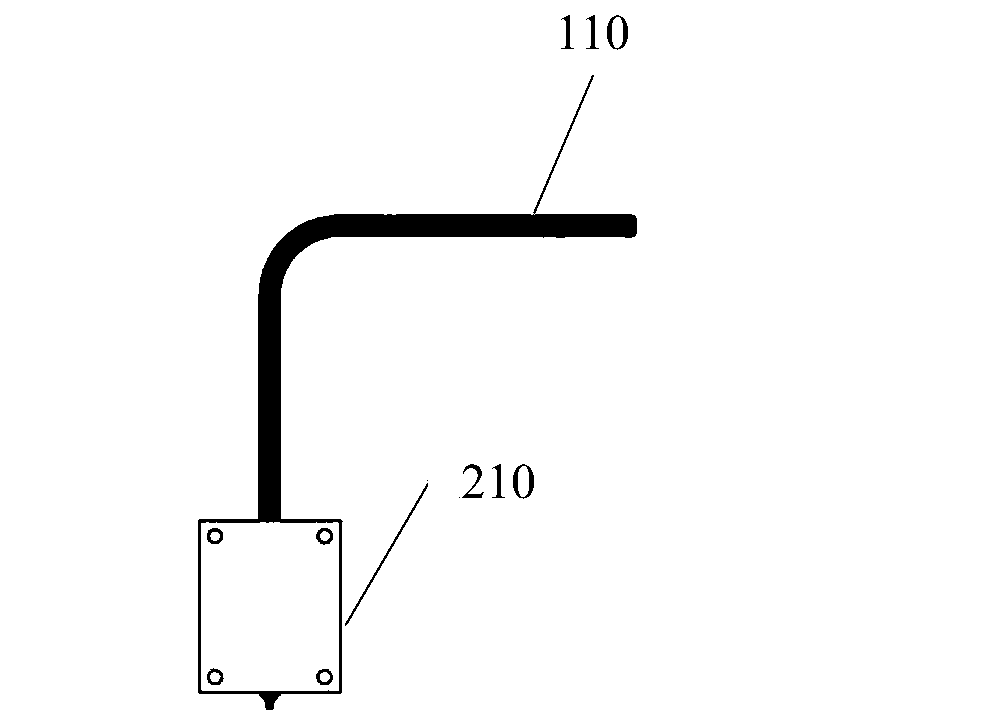

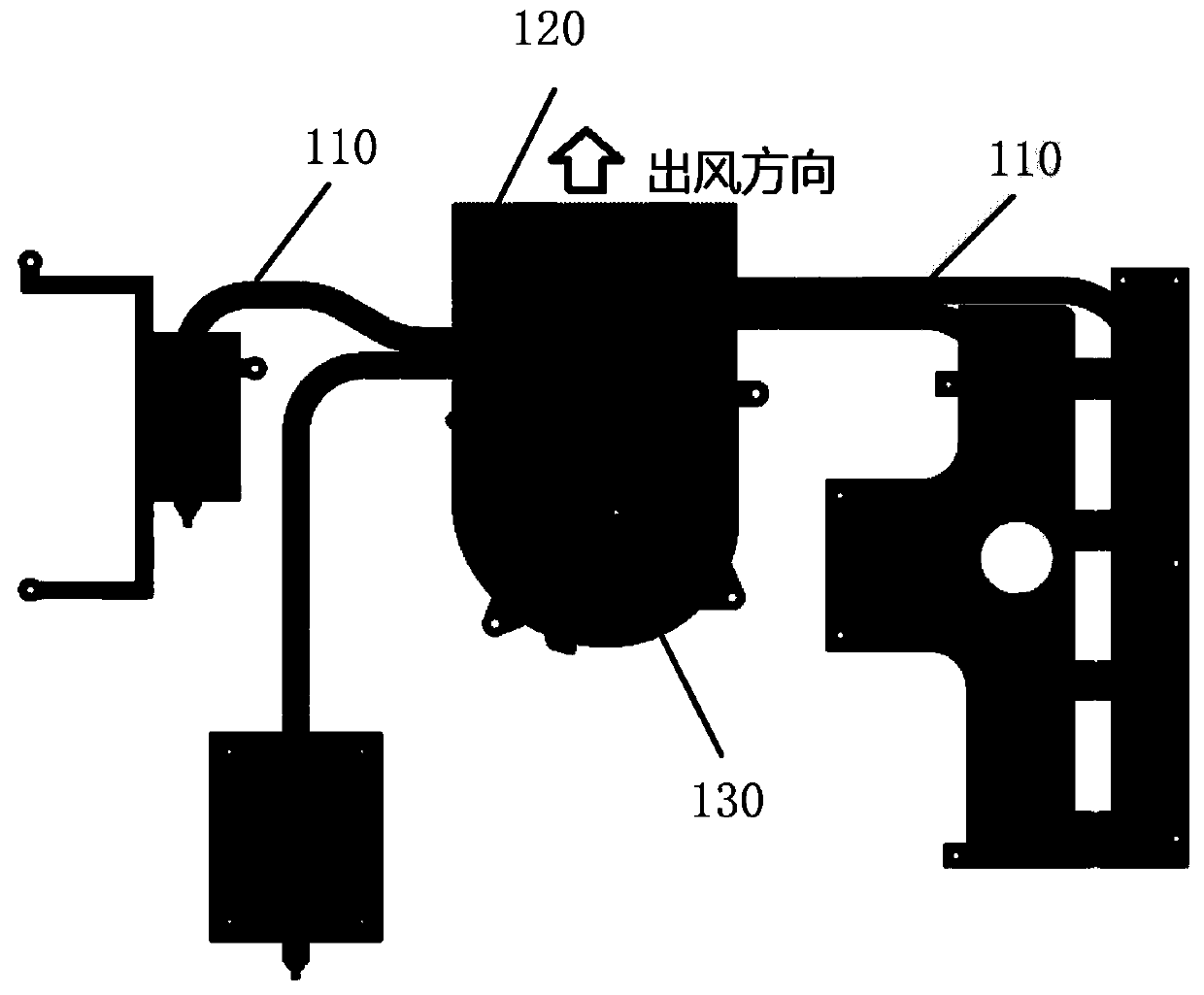

[0024] see figure 1 , which is a schematic structural diagram of a device cooling device provided in an embodiment of the present application, the device cooling device includes a heat pipe 110, a cooling fin 120 and a fan 130;

[0025] Wherein, the heat pipe 110 is installed on each heat dissipation element of the equipment, and is used for conducting the heat of each heat dissipation element to the heat dissipation fin 120;

[0026] The fan 130 is mounted on the heat sink 120 for dissipating heat from the heat sink 120 .

[0027] At present, the conduction efficiency of the heat pipe can reach more than 85%. The equipment cooling device provided by the embodiment of the present application can effectively conduct the heat of the heat source to the heat sink by using the heat pipe.

[0028] In order to achieve effective heat dissipation, at least one heat pipe is installed on each heat dissipation element of the device. If the heat pipe efficiency is insufficient, effective ...

Embodiment 2

[0035] Portable devices usually have limited internal space. If there are many heat points inside the portable device, it is obviously unfeasible to use the heat dissipation method of installing heat sinks at each heat point inside the device in the prior art. Taking portable ultrasonic equipment as an example, the current portable ultrasonic equipment on the market is to install heat sinks on each hot spot on the PCB board, and introduce air through the fan to cool each heat sink to ensure that each chip on the PCB board is in a suitable position. Reliable operation at high temperature.

[0036] In practical applications, due to the high frequency and high density of the electronic circuit in the analog signal part, the power consumption of portable ultrasound equipment is very large, and the cooling method of air duct is still widely used at present. In order to ensure the portability of the product, multiple small fans are required to be placed at the air inlet and outlet r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com