gear box clamp

A gear box and fixture technology, which is applied in the field of tooling and fixtures, can solve the problems of lack of alignment function, inconvenient use, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The clamp of the gear box that the present invention proposes is especially suitable for such as Figure 5 In the shown gearbox, the side wall of the gearbox is symmetrically arranged with three supporting columns along the center, so that each supporting column is facing the hollow groove between the other two supporting columns.

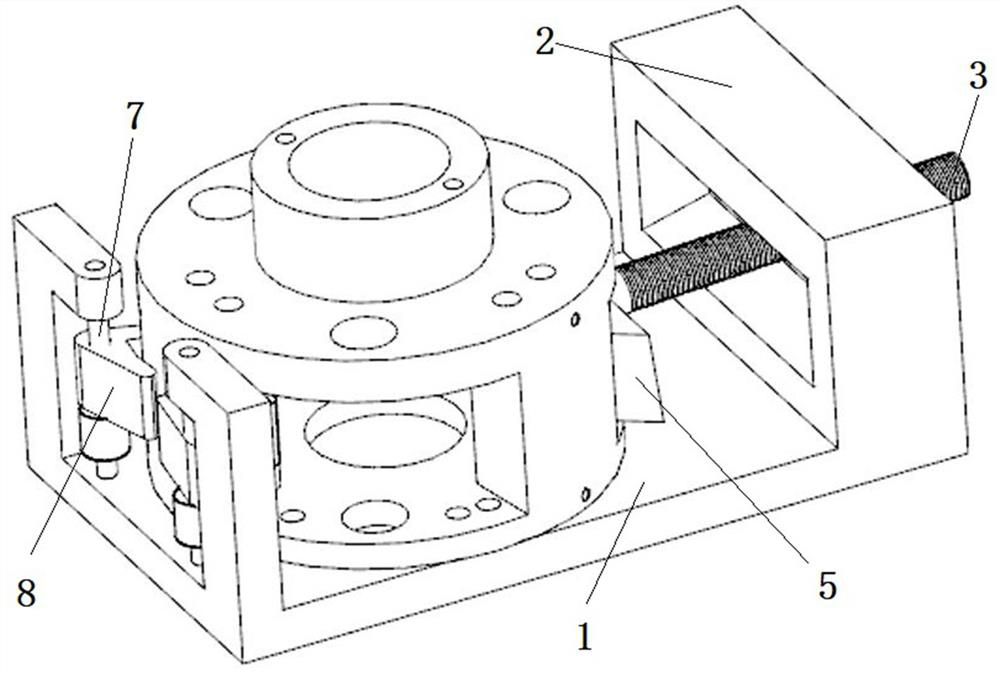

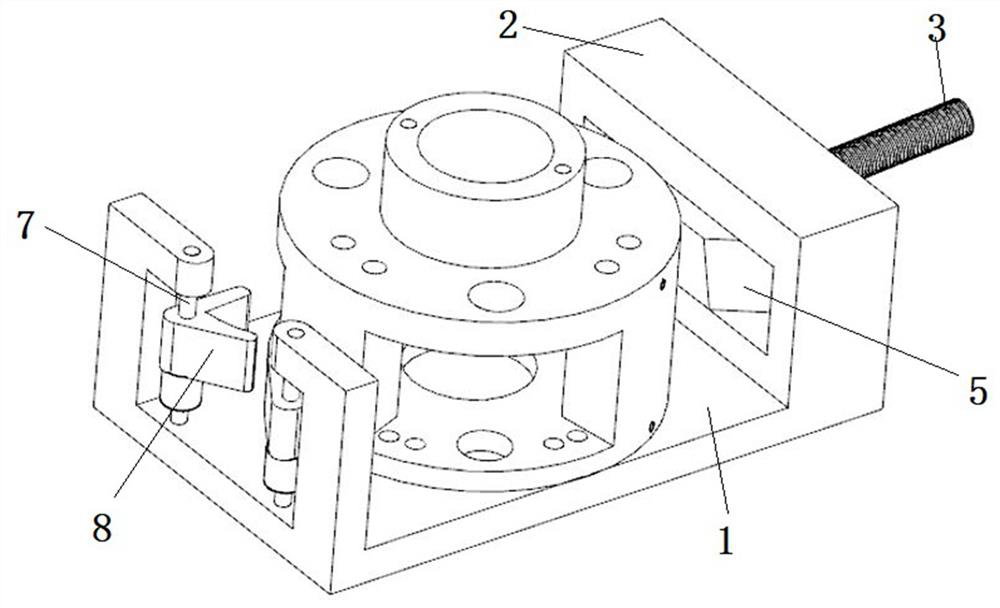

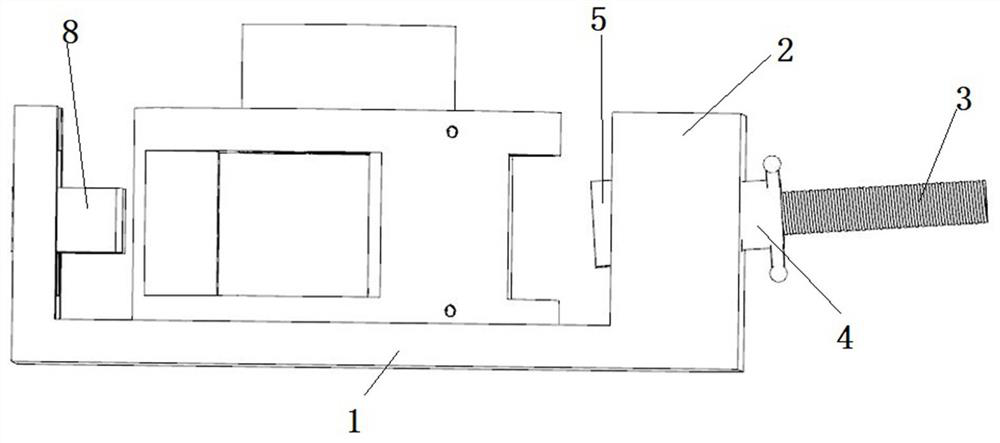

[0020] Such as Figure 1 to Figure 3 As shown, the clamp includes a base 1 and a first clamping mechanism and a second clamping mechanism oppositely arranged on the base 1 .

[0021] The first clamping mechanism includes a positioning plate 2 fixed on the base 1, a screw 3 facing the second clamping mechanism, and a screw threaded on the outside of the screw 3 such as Figure 6 The rotating threaded sleeve 4 is shown; when the rotating threaded sleeve 4 rotates, the screw rod 3 is driven to move along the straight line where the screw rod 3 is located through the thread. The rotary threaded sleeve 4 is arranged obliquely downward toward th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com