Water line mold

A mold and water pipe technology, which is applied in the field of water transport molds, can solve the problems of easy crushing of water pipes and tearing of water pipes, and achieve the effect of avoiding winding molds and optimizing actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

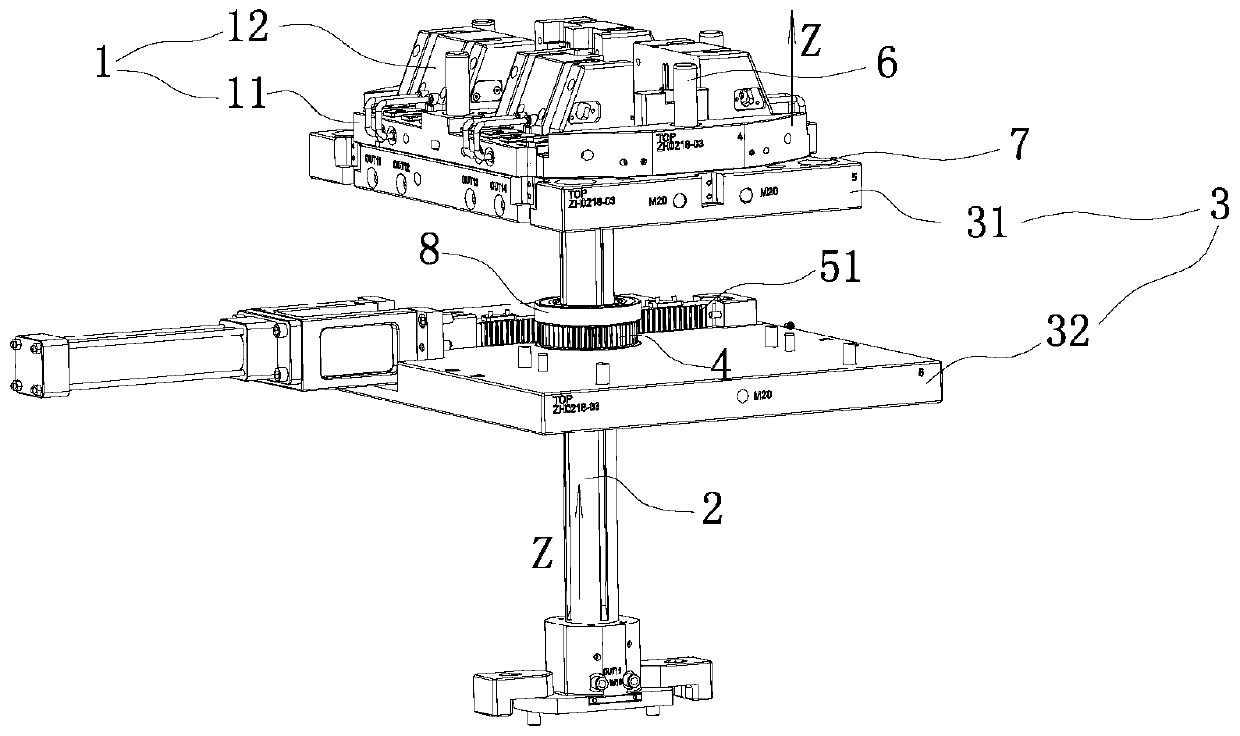

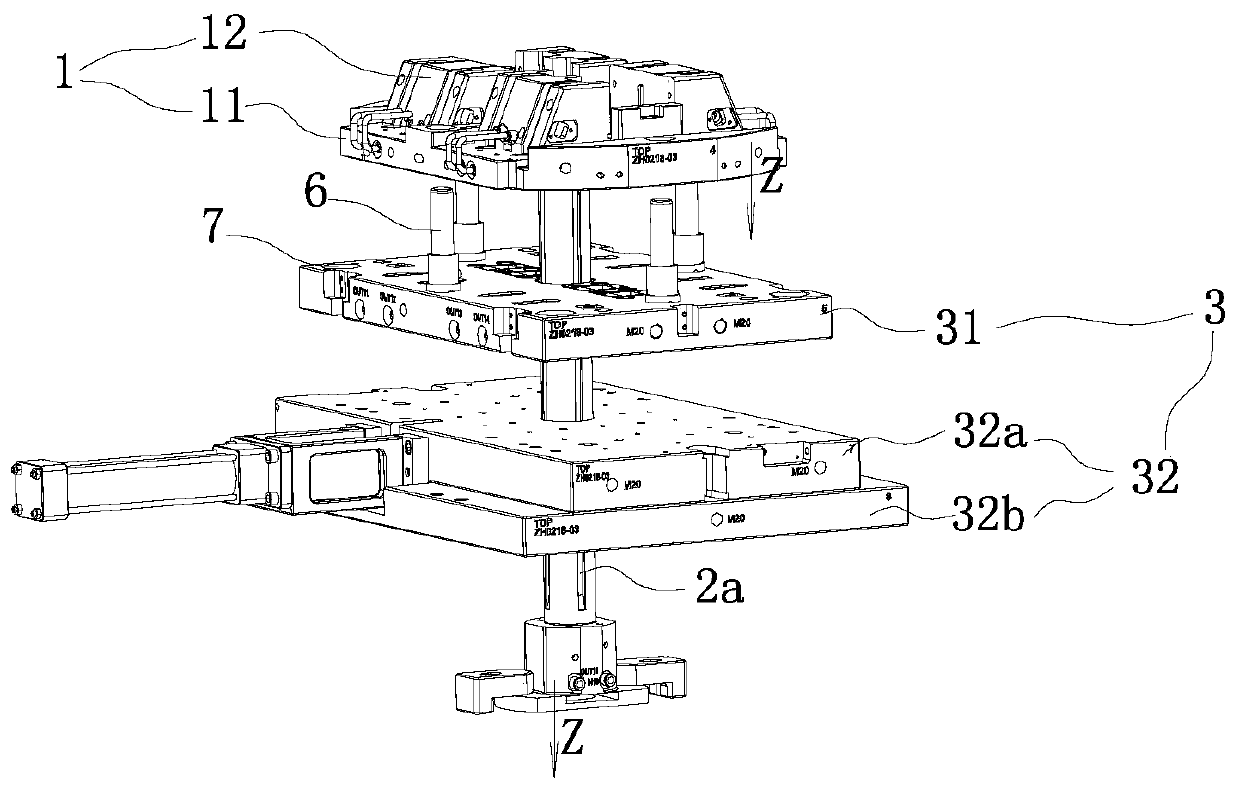

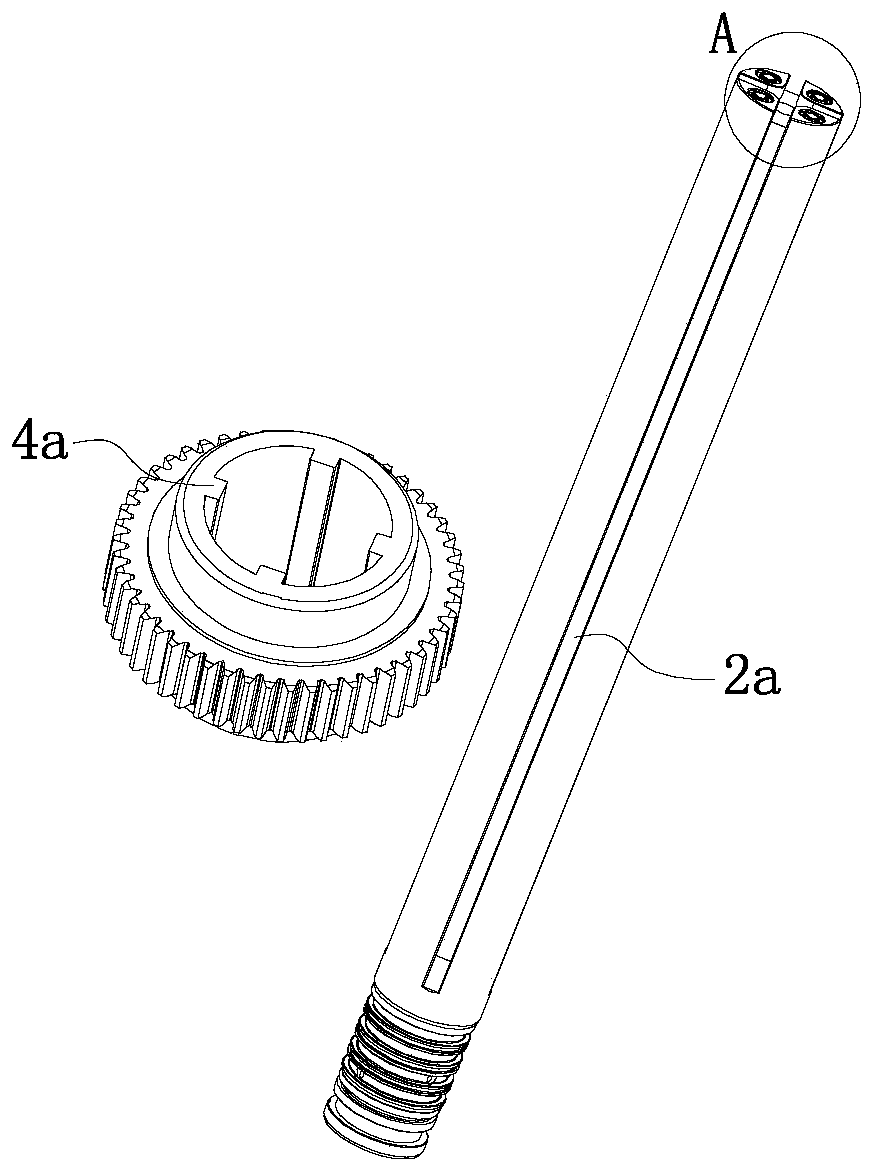

[0020] Such as Figure 1 to Figure 3 Shown, a kind of water conveying mold comprises upper mold, lower mold 1, rotating shaft 2 and fixed plate 3, and mold cavity is formed when upper mold and lower mold 1 close molds; Fixed plate 3 is provided with rotor 4 and rotating power part, The middle part of the rotating shaft 2 passes through the rotor 4, and the rotating shaft 2 is provided with a vertical chute 2a, and the inner ring of the rotor 4 is provided with a bump 4a for connecting the chute 2a; The center slides up and down relatively (relativity of motion); the rotating power part is used to drive the rotor 4 to rotate on the fixed plate 3, and the rotor 4 is used to drive the rotating shaft 2 to rotate through its projection 4a.

[0021] Such as figure 1 and figure 2 As shown, the upper mold, the lower mold 1 and the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com