Beer raw material warehousing mistake prevention method and system

A raw material warehouse and raw material technology, applied in conveyors, storage devices, transportation and packaging, etc., can solve problems affecting the stability of beer quality, and achieve the effects of avoiding economic losses, preventing wrong selection, and stabilizing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

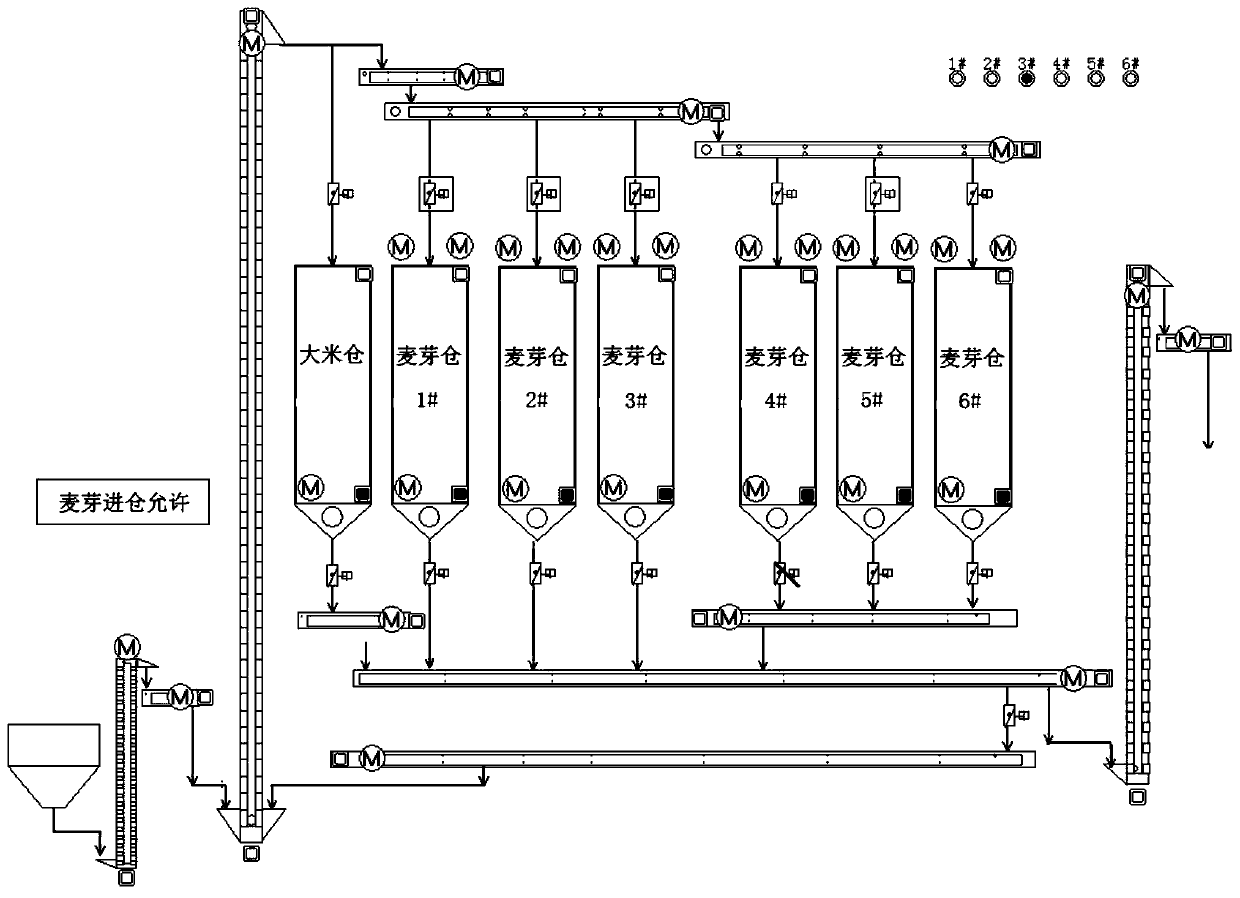

[0018] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

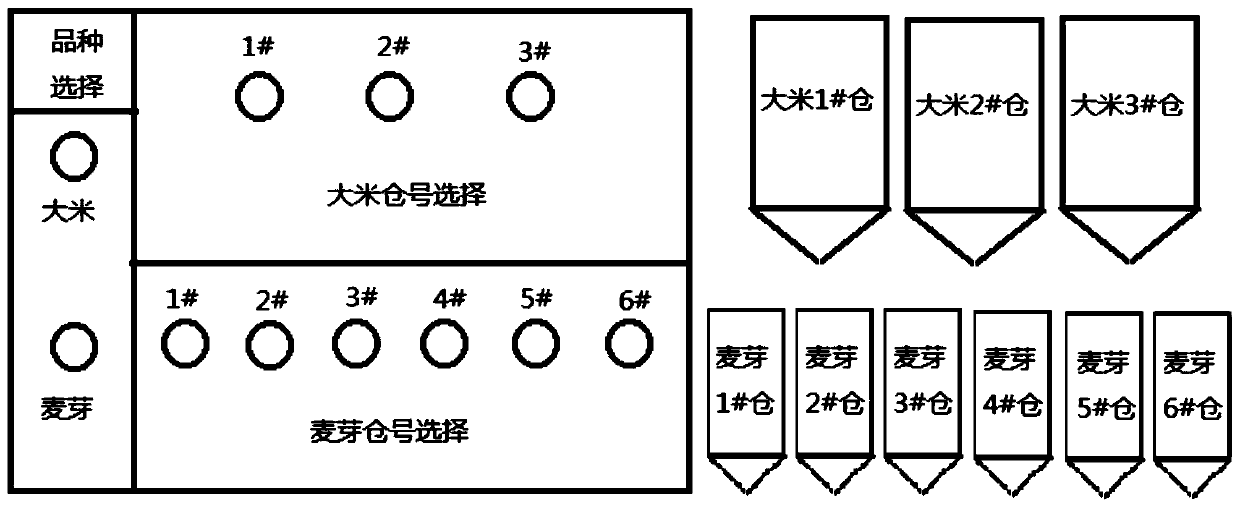

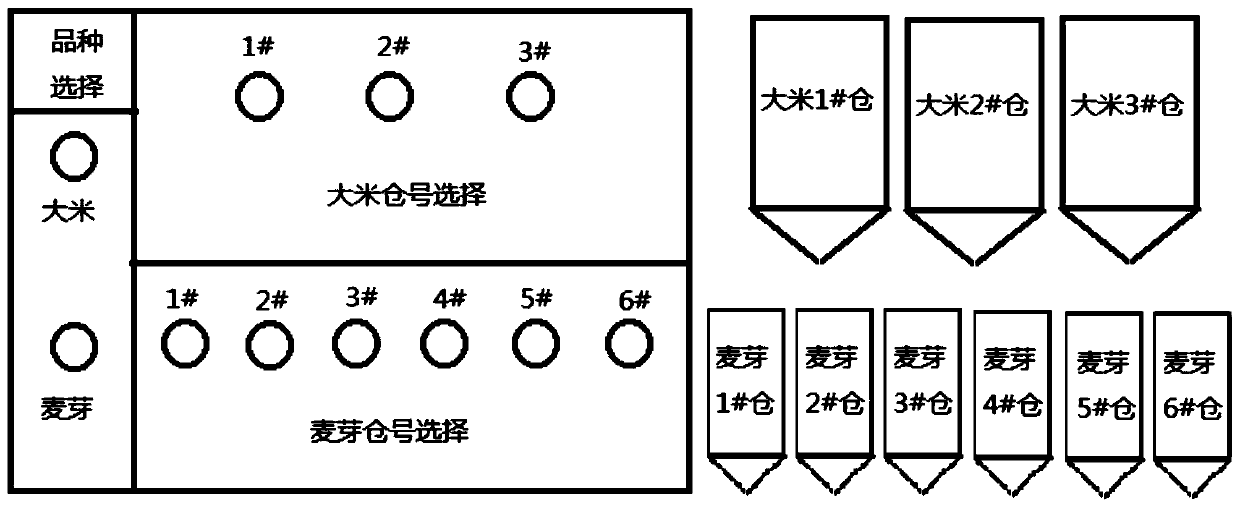

[0019] refer to Figure 1-2 , a kind of beer raw material warehousing error prevention method, comprises the following steps,

[0020] S1. Receive the selected raw material type information from the on-site feedback from the silo, and mark the selected raw material type;

[0021] S2. Receive the selected raw material bin number information fed back from the bin site, and mark the selected raw material bin number;

[0022] S3. Send the information to be confirmed to the site of the silo, and wait for the feedback and confirmation from the site of the silo;

[0023] S4. If the confirmation is correct, start feeding the raw material bin corresponding to the raw material bin number; otherwise, return to step S1.

[0024] In step S1, the selected raw material types are displayed as optional, and other raw material types are displayed as unavai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com