Preparation method of water-based long-term antirust agent

A rust inhibitor, water-based technology, applied in the field of preparation of water-based long-term rust inhibitor, can solve the problems such as the rust-proof film is not easy to dry, the rust-proof performance is poor, the rust-proof effect cannot be achieved, and the market gap can be filled. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

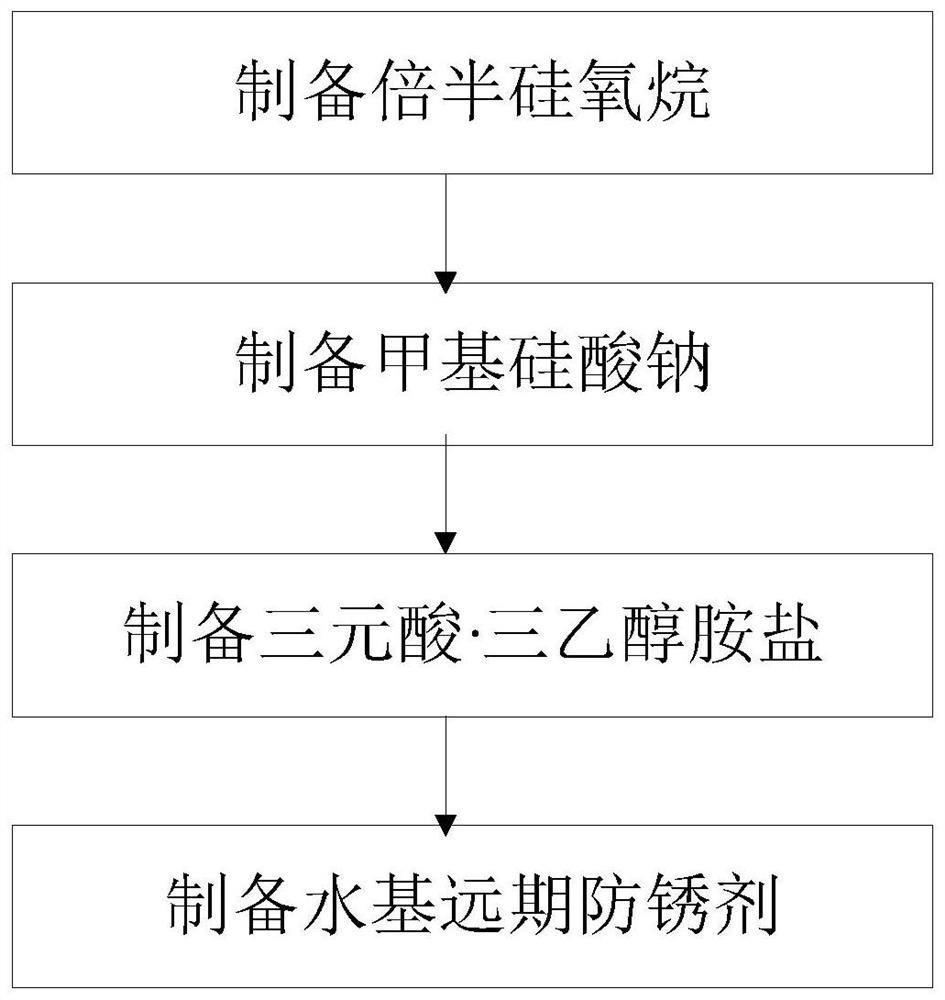

[0037] figure 1 It is a flow chart of an embodiment of a preparation method of a water-based long-term anti-rust agent of the present invention. As shown in the figure, the present invention provides a preparation method of a water-based long-term anti-rust agent, comprising the following steps:

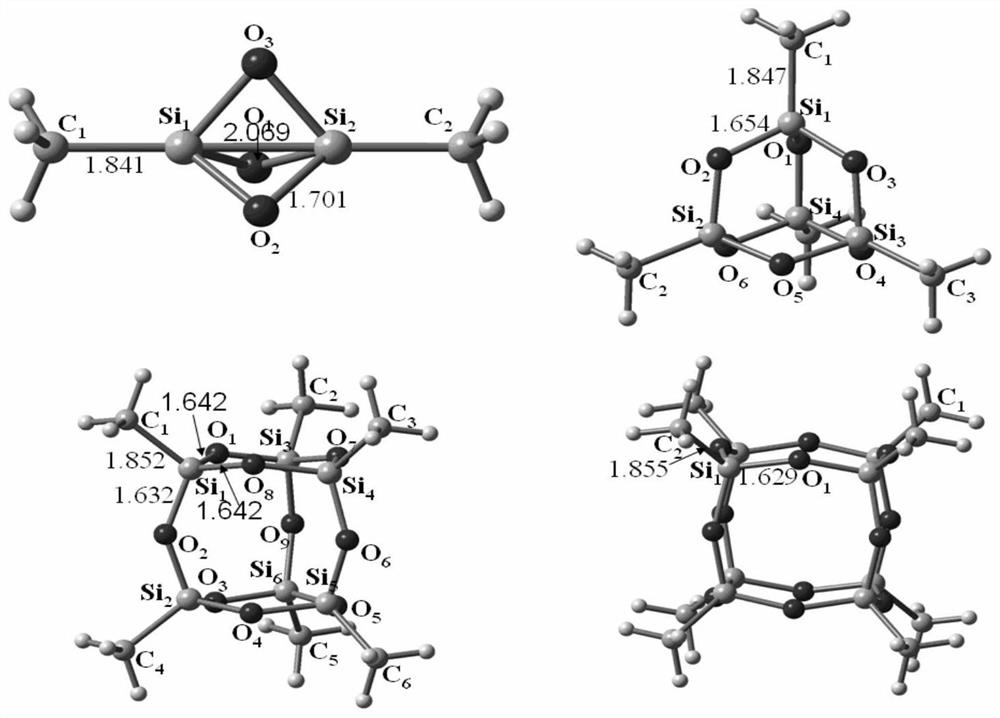

[0038] (1) Preparation of silsesquioxane

[0039] Add an organic solvent to distilled water and stir to form an organic-water two-phase solution, and control the temperature at 25-40°C. Start the agitator and add methyltrichlorosilane dropwise to the organic-water two-phase solution. According to the mass ratio, Distilled water: organic solvent: methyltrichlorosilane ratio is 2-2.5: 1-1.2: 1-1.2, the dropwise addition time is 30-50min, after the dropwise addition is completed, continue to react for 45min, stop stirring, and filter the reaction slurry under reduced pressure , wash the precipitate with water for 2-3 times, transfer the precipitate to a constant temperature oven at 100...

Embodiment 1

[0057] The amount of sodium methyl silicate concentrate plays a very critical role in the developed antirust agent. Because no sodium methyl silicate is added, the antirust agent formulated with other determined raw materials cannot quickly form a dry film on the metal surface , so sodium methyl silicate is an essential raw material in this water-based rust inhibitor. When the concentration is too small, the anti-rust film will be uneven and the anti-rust performance will be poor; but if the concentration is too high, the anti-rust agent will precipitate or precipitate when placed, and a uniform film-forming liquid will not be formed, which will affect its anti-rust effect. The maximum amount to be added within the scope of forming a uniform solution system is 6g / L.

Embodiment 2

[0059] Take different amounts of LS-150, respectively 0g, 1.25g, 2.5g, 3.75g, 5g, 6.25g, in a 250mL beaker, dilute to the mark with 6g / L sodium methyl silicate concentrate, LS-150 The concentrations are 0g / L, 5g / L, 10g / L, 15g / L, 20g / L, 25g / L respectively, and the copper sulfate drop test is carried out on the anti-rust treated test pieces. The experimental results are as follows: Figure 5 As shown, it can be seen that with the increase of the amount of LS-150, the antirust ability becomes stronger and stronger, and when a certain amount is added, the antirust performance begins to deteriorate. Therefore, the optimum range of LS-150 obtained in the experiment is 10g / L-20g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com