In-situ device for measuring surface crack spreading rate of thermal barrier coating system

A technology of crack growth rate and thermal barrier coating, which can be used in measurement devices, electromagnetic measurement devices, and electric/magnetic solid deformation measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

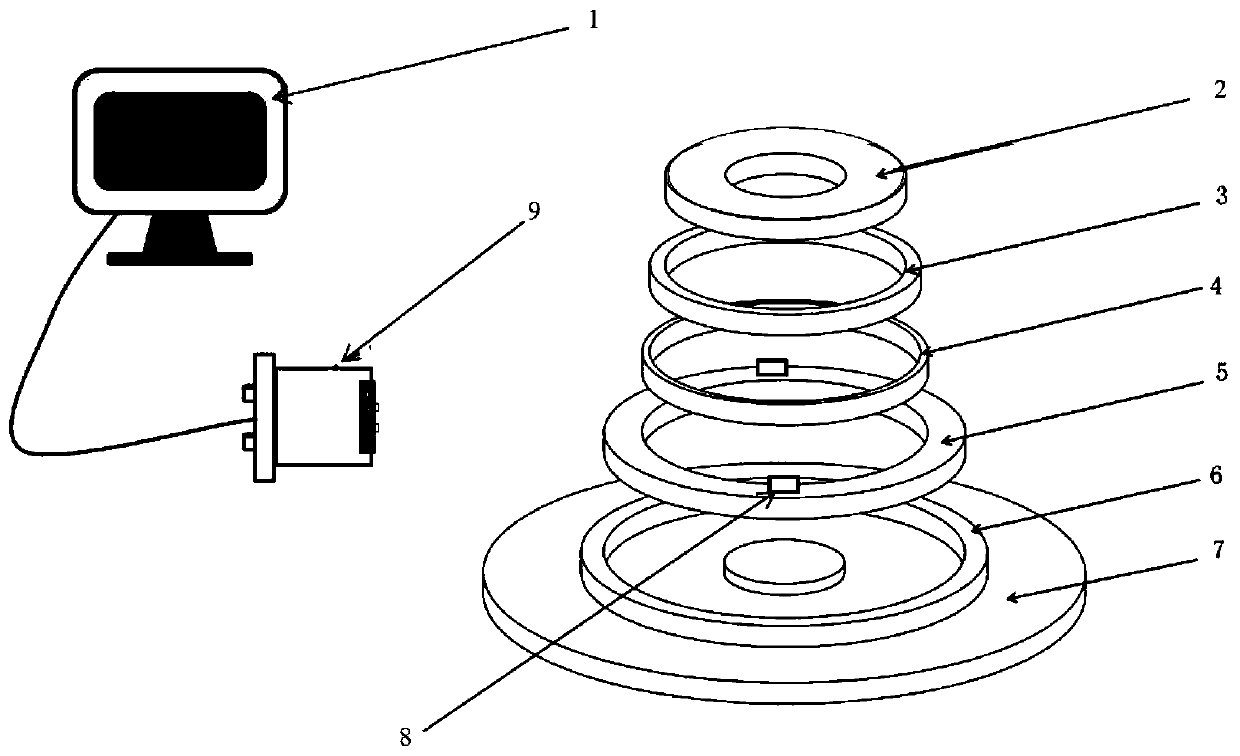

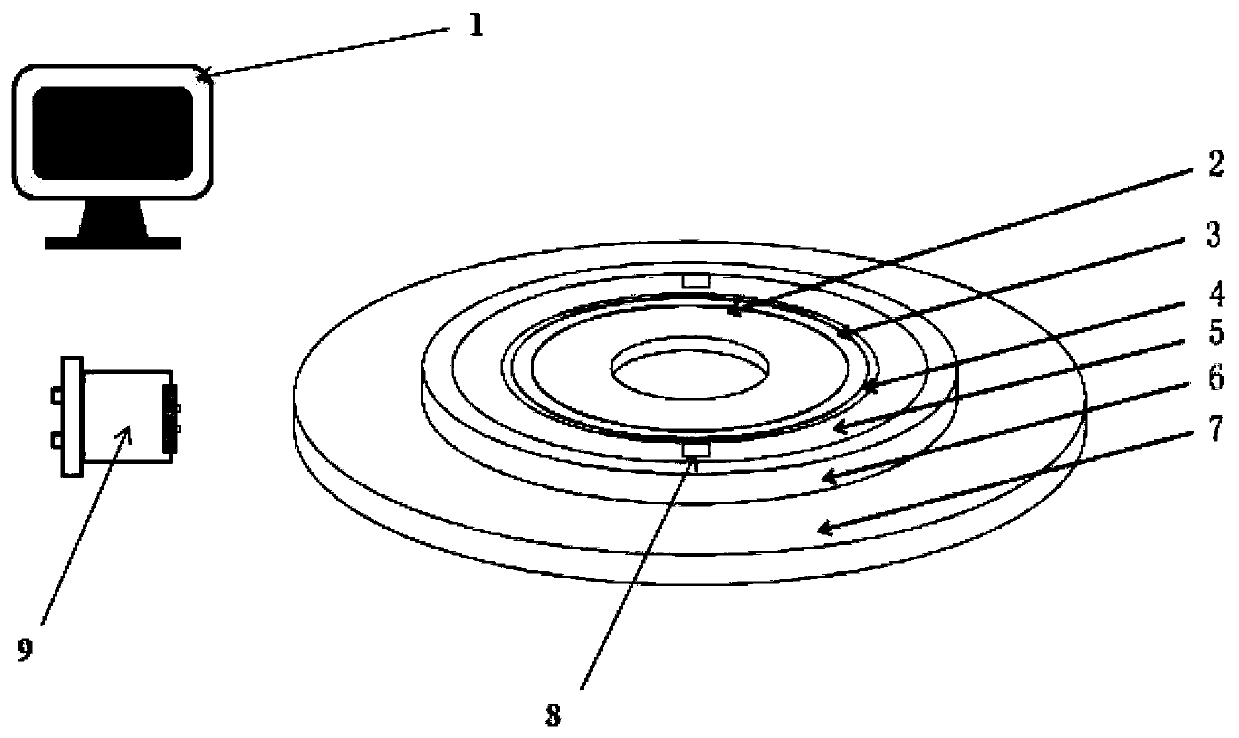

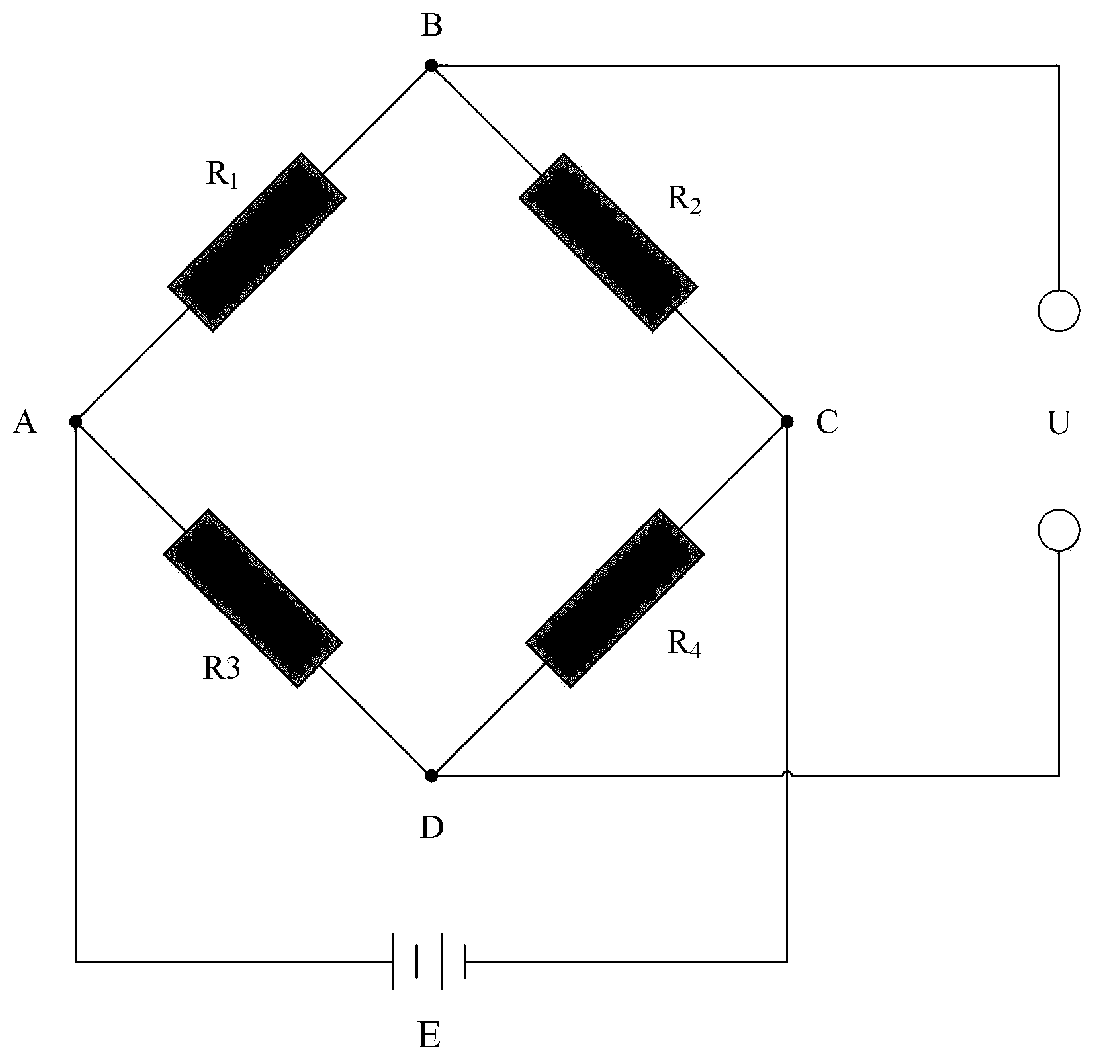

[0023] An in-situ device for measuring the crack growth rate on the surface of a thermal barrier coating system. The device ensures that the temperature of the thermal barrier coating system can be changed during the crack growth rate measurement experiment, and the length of the crack growth process on the surface of the ceramic layer can be monitored in real time. The signal representing the crack is converted into a voltage signal that can be processed by the computer through the conversion of the analog signal. The device comprises a computer (101), a substrate (102), an adhesive layer (103), an aluminum oxide film (104), a ceramic layer (105), a heating plate (106), a fixed plate (107), a resistance strain gauge (108 ) and capture card (109).

[0024] The substrate (102), the bonding layer (103), the aluminum oxide film (104), the ceramic layer (105), and the heating plate (106) are arranged on the fixing plate (107) from inside to outside;

[0025] The computer (101) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com