A power transformer

A transformer, power technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

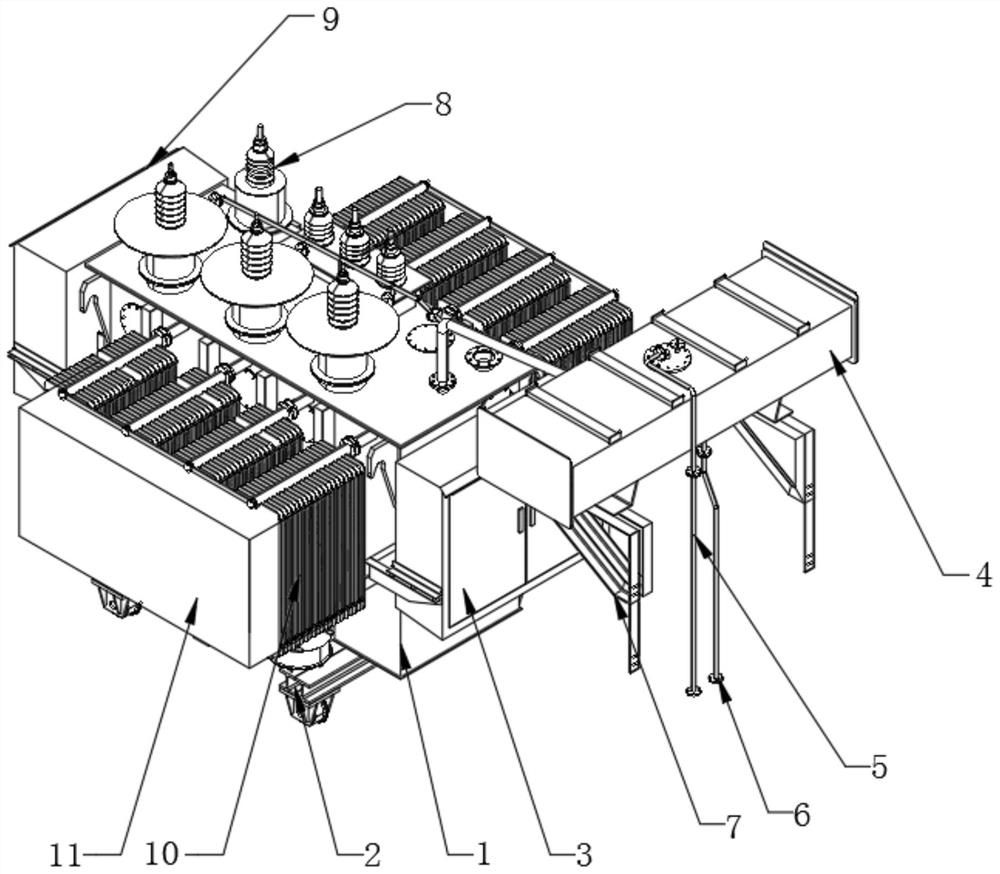

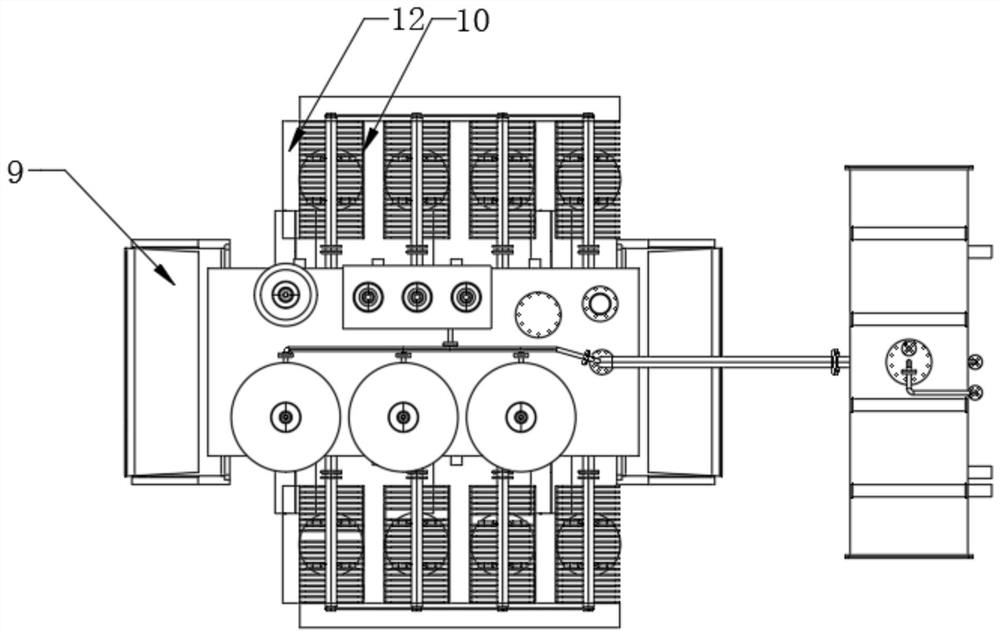

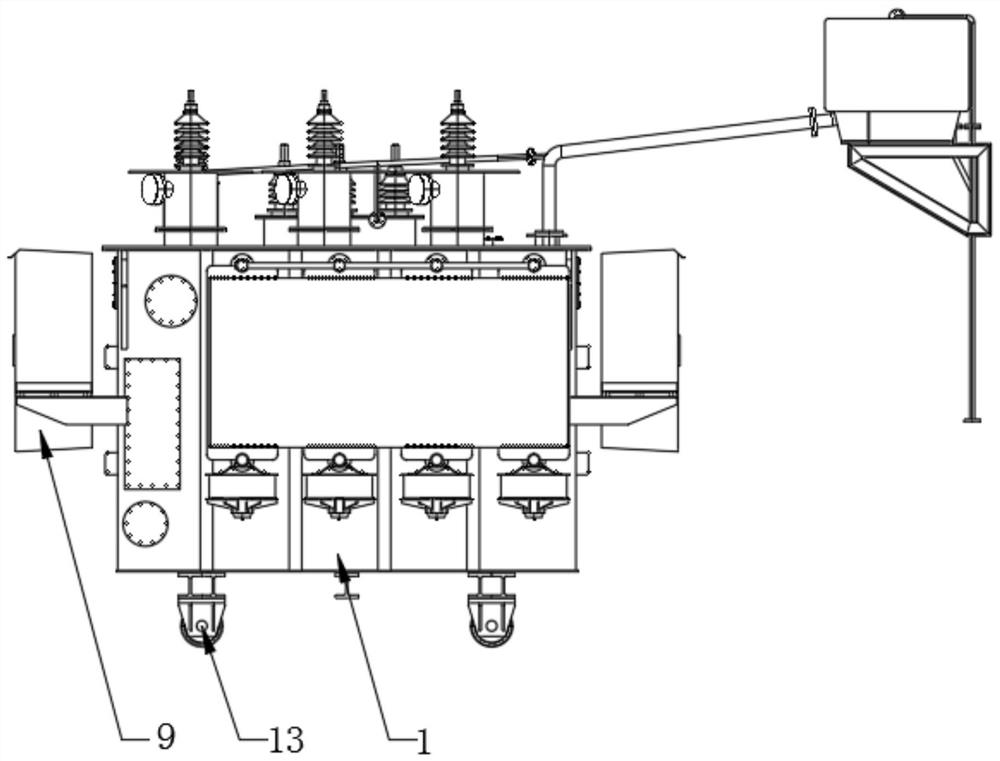

[0023] Embodiment one, by Figure 1-7 Given, the present invention provides a transformer for electric power, comprising a transformer body 1, the two ends of the bottom of the transformer body 1 and the central part are welded with an I-shaped steel frame 2, one side of the transformer body 1 is equipped with an electrical box 3, and the transformer body 1 One side of the top is connected with an oil conservator 4, the middle part of the top of the oil conservator 4 is provided with an oil filling port 5, the middle part of the bottom end of the oil conservator 4 is provided with an oil discharge port 6, the bottom end of the oil conservator 4 is provided with a fixing device 7, and the transformer body 1 The top of the transformer is provided with an insulating sleeve 8, the other side of the transformer body 1 is installed with a coolant tank 9, both sides of the transformer body 1 are installed with heat dissipation plates 10, and the outer side of the heat dissipation plat...

Embodiment 2

[0038] Embodiment two, by Figure 1-7 Given, the present invention provides a transformer for electric power, comprising a transformer body 1, the two ends of the bottom of the transformer body 1 and the central part are welded with an I-shaped steel frame 2, one side of the transformer body 1 is equipped with an electrical box 3, and the transformer body 1 One side of the top is connected with an oil conservator 4, the middle part of the top of the oil conservator 4 is provided with an oil filling port 5, the middle part of the bottom end of the oil conservator 4 is provided with an oil discharge port 6, the bottom end of the oil conservator 4 is provided with a fixing device 7, and the transformer body 1 The top of the transformer is provided with an insulating sleeve 8, the other side of the transformer body 1 is installed with a coolant tank 9, both sides of the transformer body 1 are installed with heat dissipation plates 10, and the outer side of the heat dissipation plat...

experiment example

[0054] Experimental object: the cooling rubber tube prepared in Example 1 of the present invention was used as the experimental group 1, the cooling rubber tube obtained in Example 2 was used as the experimental group 2, and the cooling rubber tubes on the market were selected as the comparison group 1 and the comparison group two.

[0055] Experimental purpose: Under the same conditions, test the performance of each group of cooling rubber tubes.

[0056]

[0057]

[0058] EPDM (ethylene propylene diene monomer) is the most excellent elastomer material. EPDM is also called saturated rubber. Compared with unsaturated rubber such as NR (natural rubber), NBR (nitrile rubber), etc., its chemical stability and thermal High stability. When used in radiator coolant hoses, EPDM not only has good heat resistance, aging resistance and ozone resistance, but also has excellent coolant resistance and chemical stability. The structure of TATD is similar to that of other autumn Lamb ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap