Connector terminal for pin header female seat

A technology of connector terminals and sockets, applied in the direction of contact parts, etc., can solve the problems of unsatisfactory matching effect between terminals and pins, affecting product use, poor conduction effect, etc., to achieve good power-on effect, long service life, and stable cooperation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

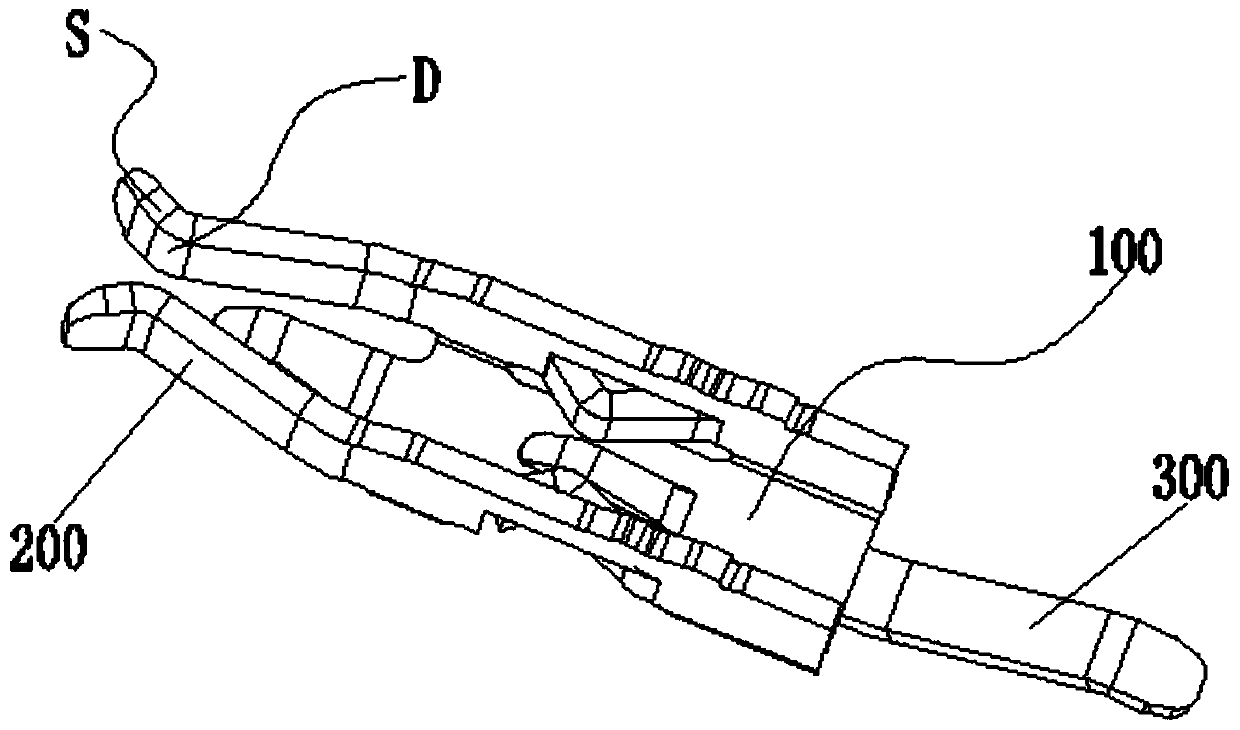

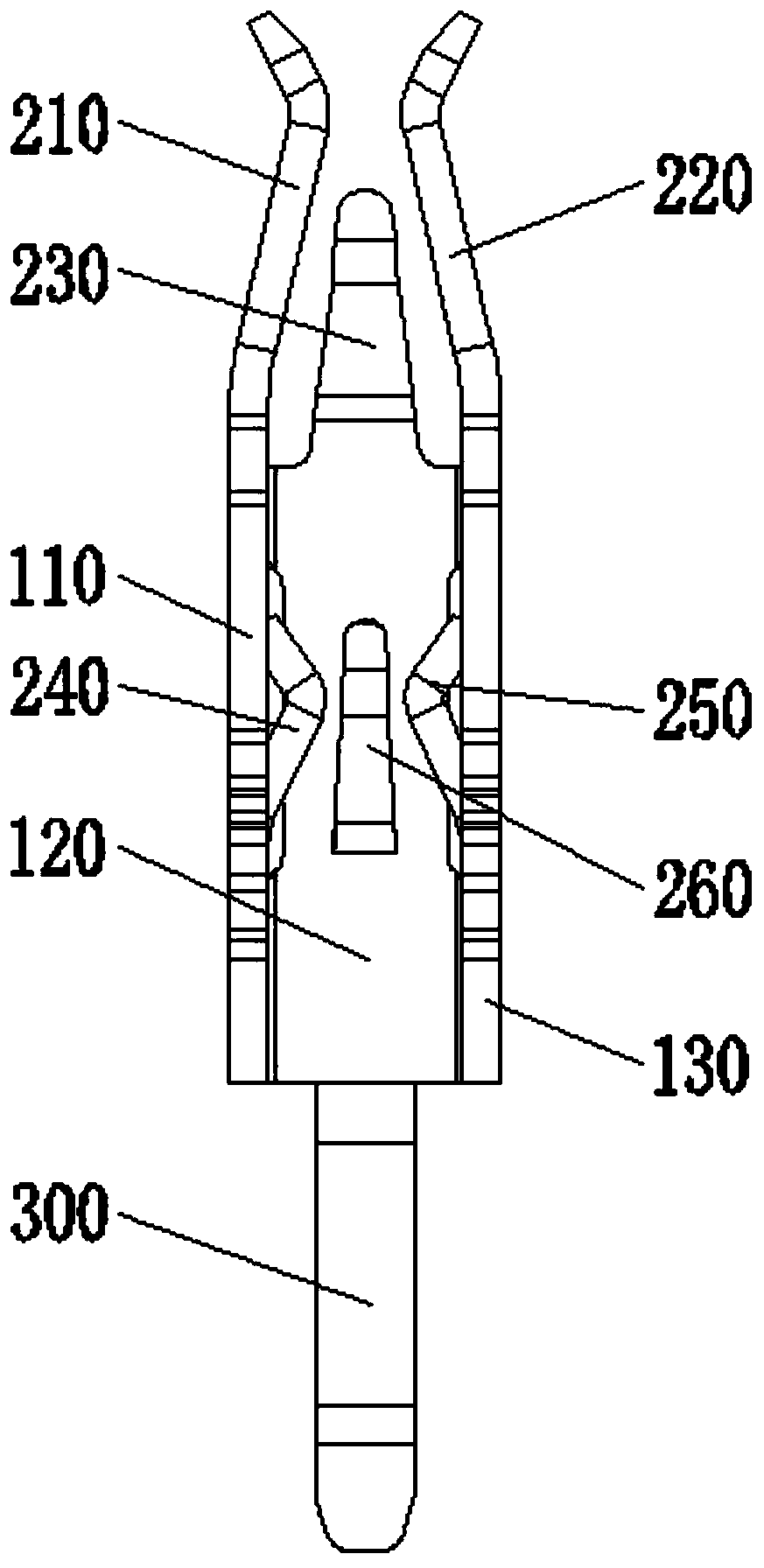

[0023] Embodiment one; Figure 1 ~ Figure 2 As shown, a connector terminal for a pin header includes a pin header and a terminal body 100 fixedly assembled in the pin header. The terminal body 100 is integrally stamped and formed of conductive metal material. The terminal body 100 is provided with at least six contact elastic pieces 200. The terminal body 100 has a groove or a cavity for inserting the pins of the male terminal. The contact elastic pieces 200 each have a raised contact portion S, and the contact portion S It has a contact surface D, and the contact surface D is recessed in the groove or cavity of the terminal body 100. There are only four contact points at most in the traditional terminal body 100, and the contact effect with the pin is not ideal. In this embodiment, six The method of one contact point cooperates with the pin, which has strong stability, good electrification effect, and is not easy to be damaged by repeated plugging and unplugging, which improv...

Embodiment 2

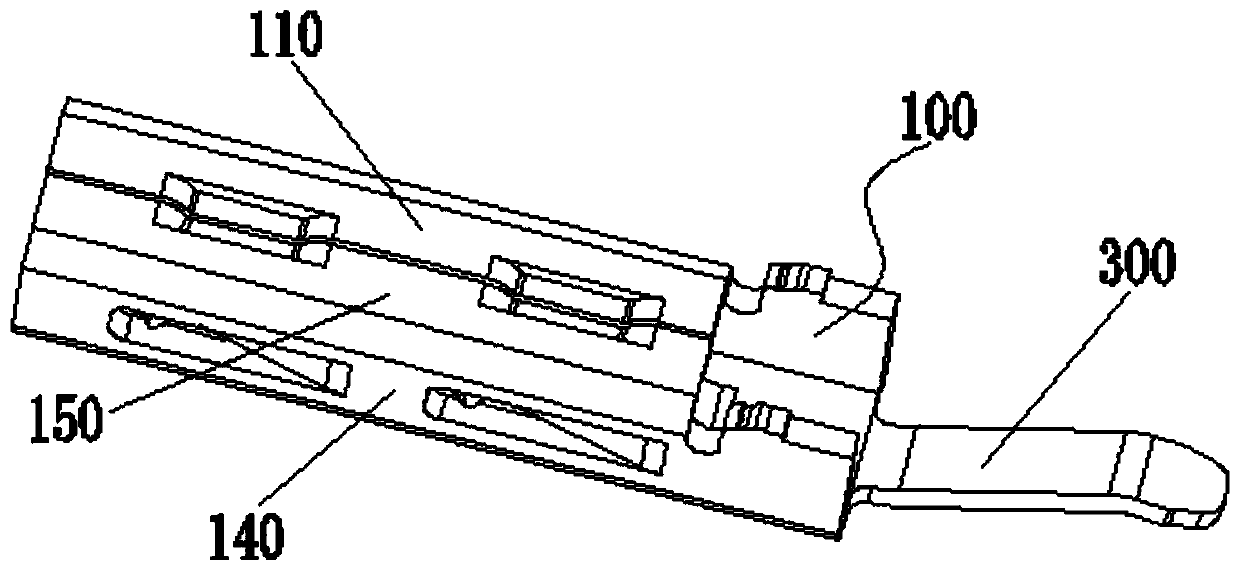

[0028] Embodiment two; Figure 3 ~ Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the terminal body 100 is stamped to form a first bent portion 110 , a second bent portion 120 , a third bent portion 130 , a fourth bent portion 140 and The fifth bending portion 150, the first bending portion 110 and the fifth bending portion 150 are on the same horizontal plane, the first bending portion 110 is perpendicular to the second bending portion 120, and the fifth bending portion 150 is perpendicular to the fourth bending The bent portion 140, the second bent portion 120 and the fourth bent portion 140 are parallel to each other and are perpendicular to the third bent portion 130, the first bent portion 110, the second bent portion 120, and the third bent portion 130 1. The fourth bending part 140 and the fifth bending part 150 form a cavity for inserting the pin. Embodiment 1 adopts a half-wrapped structure, while this embodiment adopts a four-wrapp...

Embodiment 3

[0032] Embodiment three; as Figure 6 As shown, the difference between the present embodiment and the second embodiment is only that the bending direction of the contact spring 200 is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com