Patents

Literature

40results about How to "Improve electrification performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

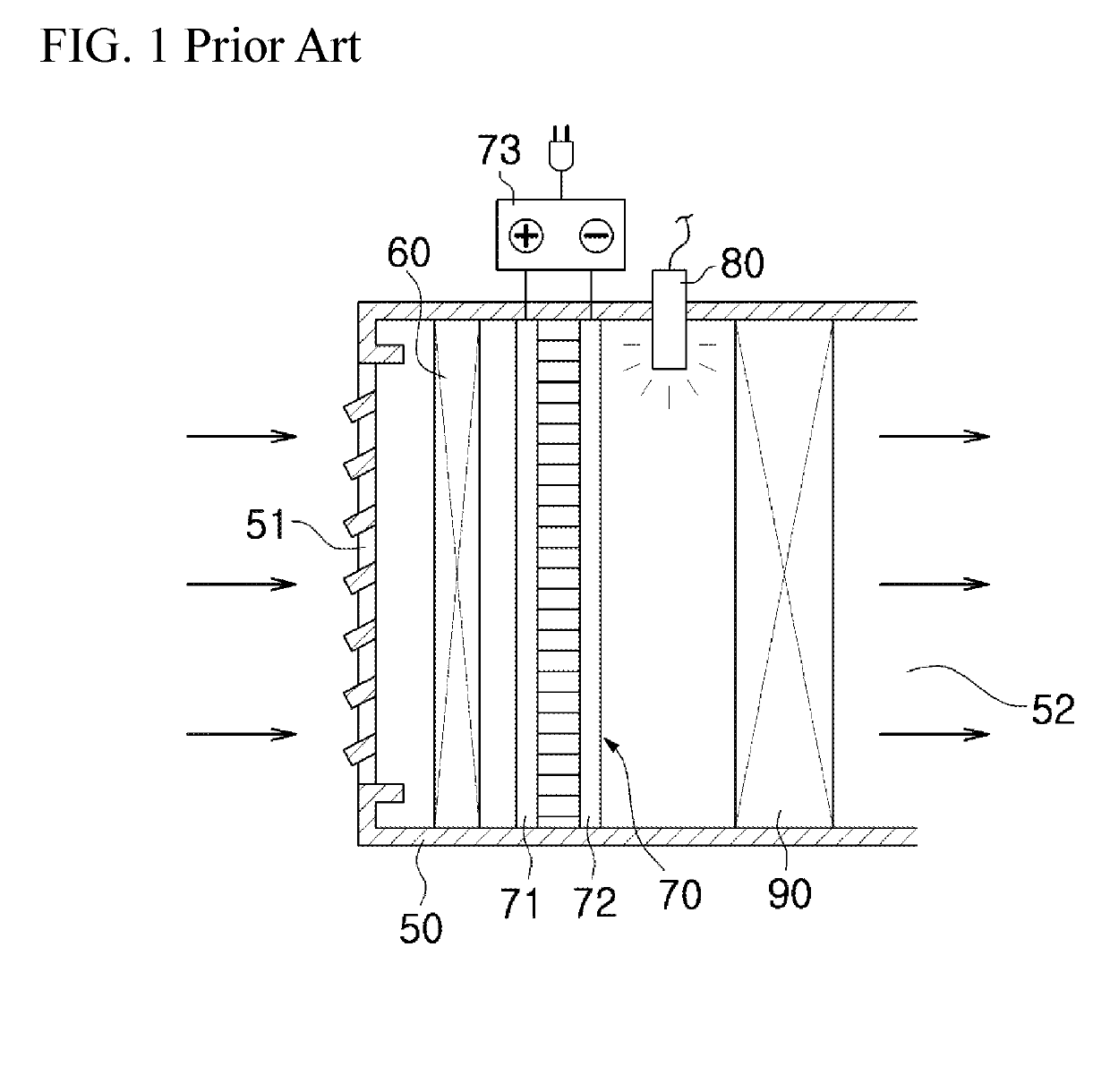

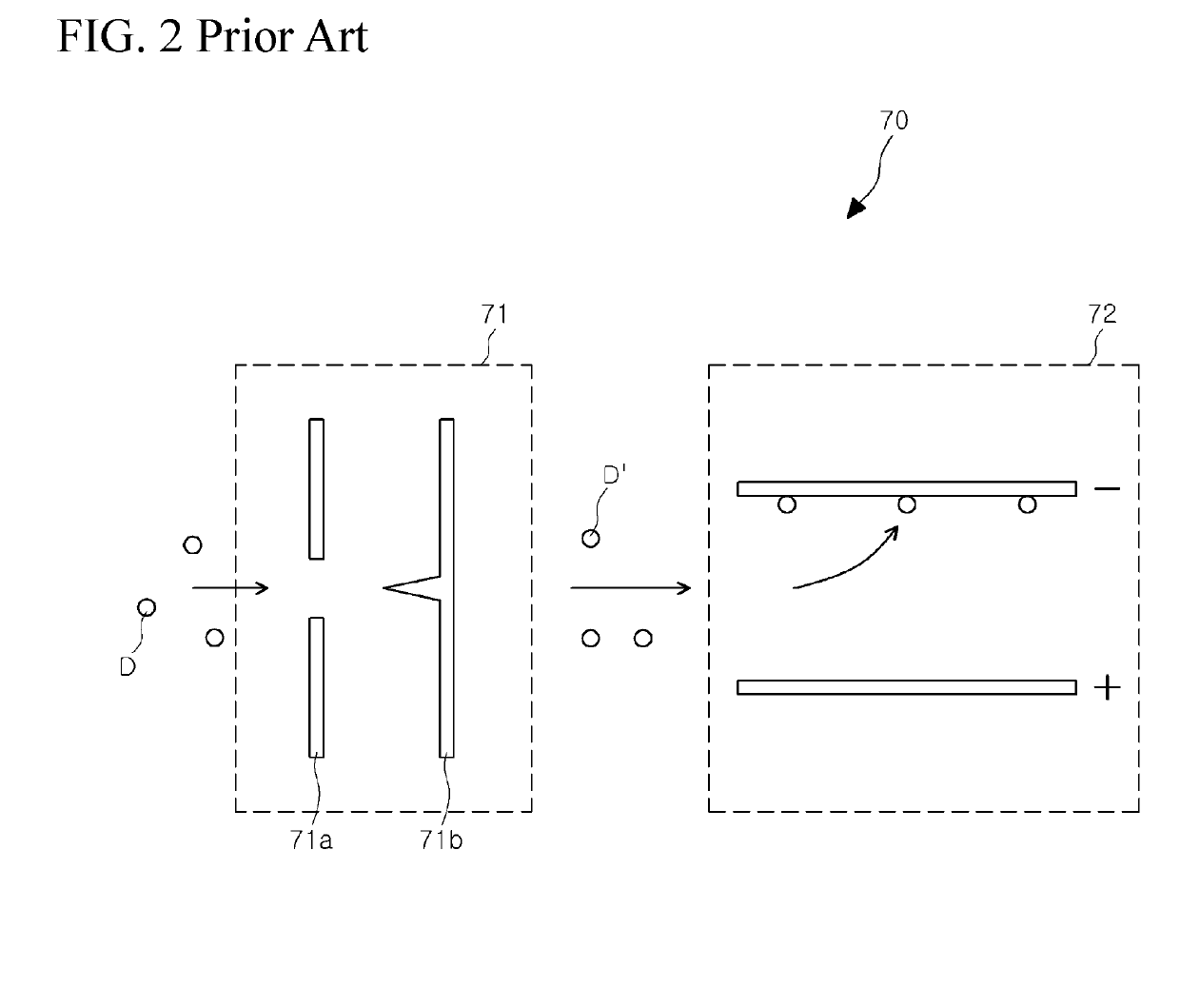

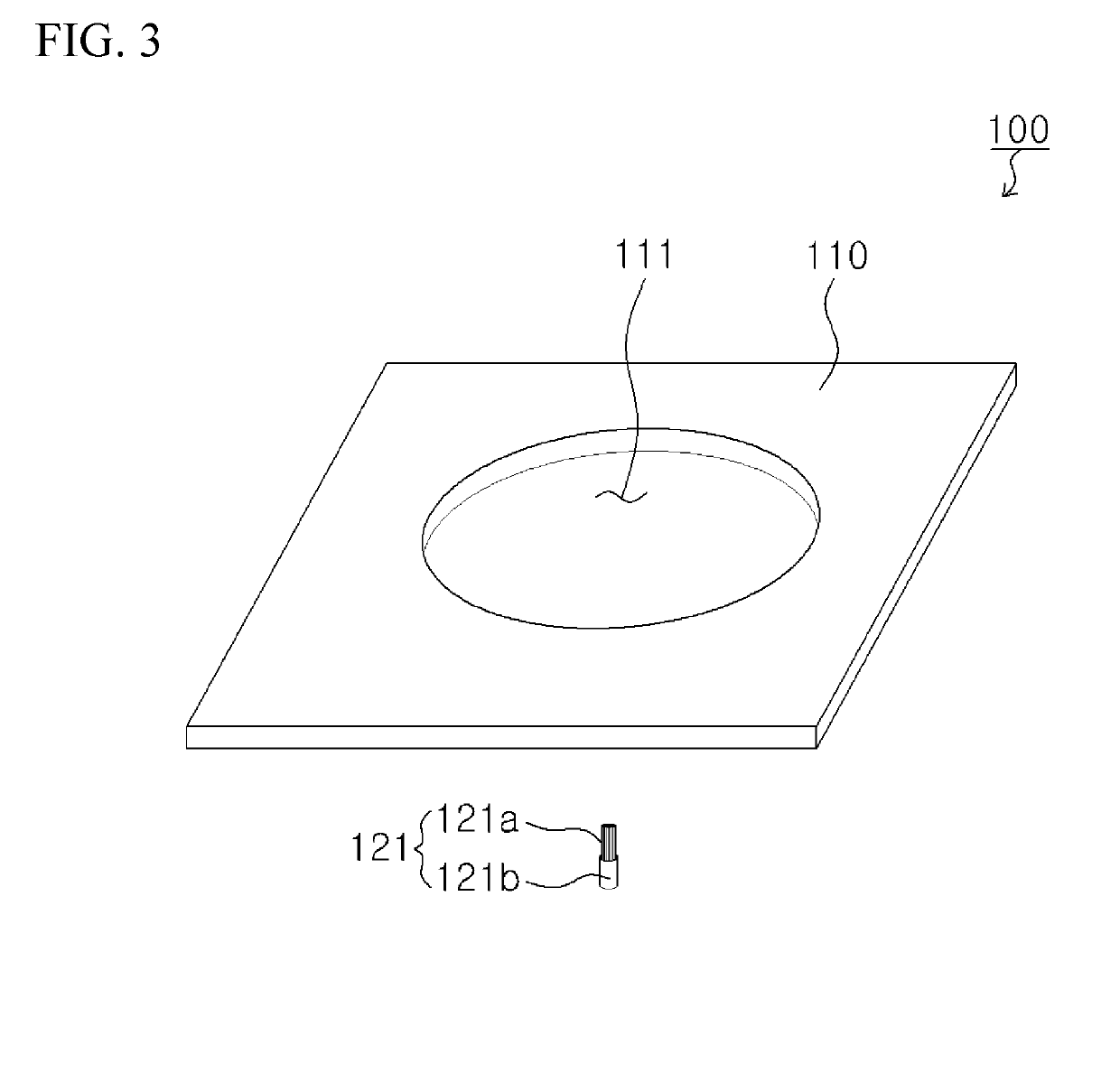

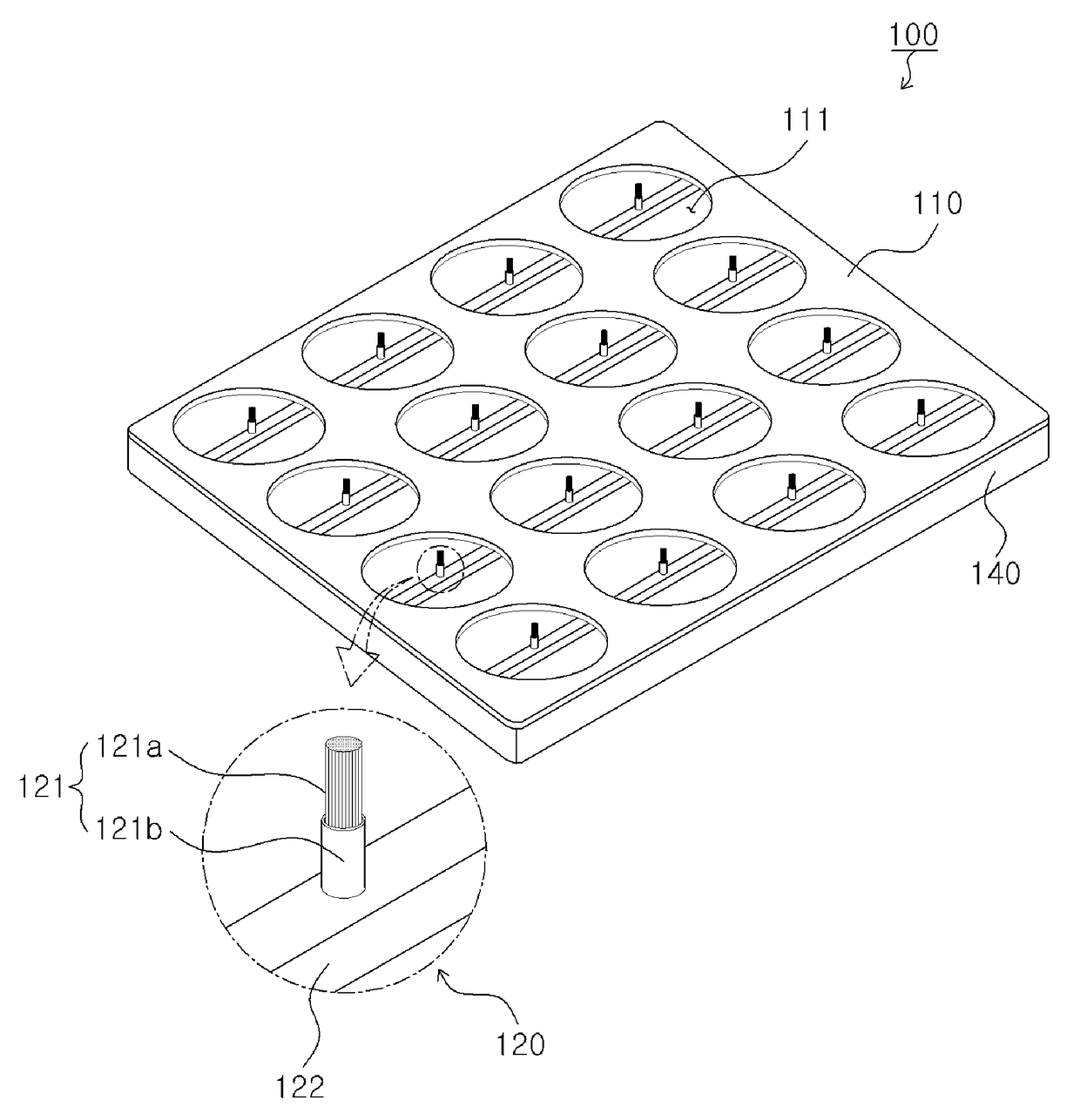

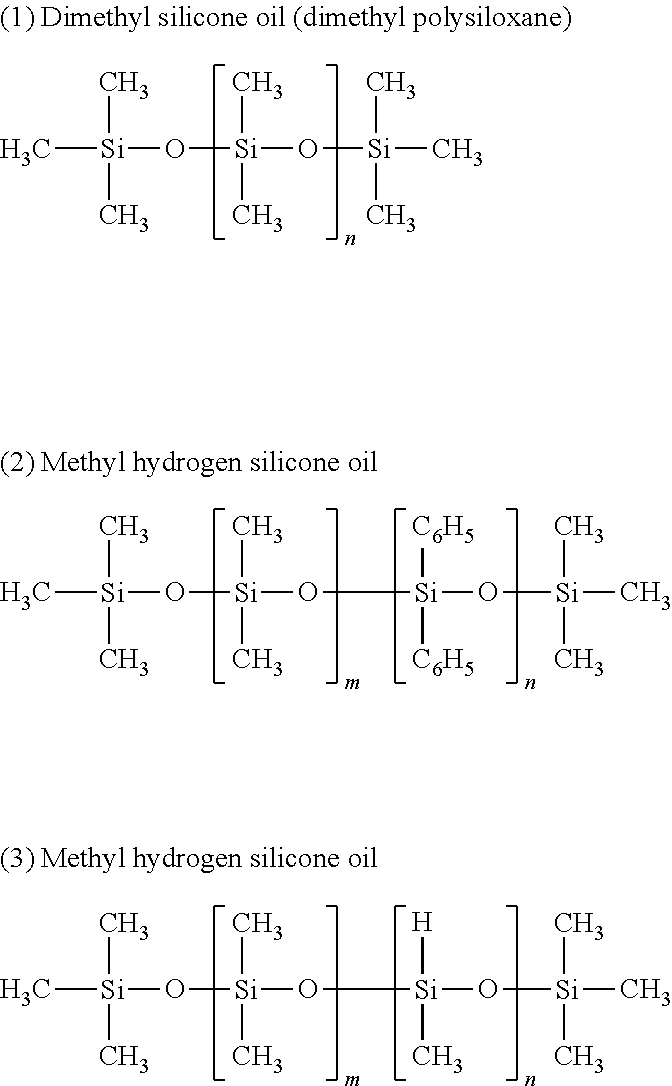

Electrification apparatus for electrostatic dust collector

ActiveUS10384517B2Improve electrification performanceReducing harmful ozone and electromagnetic wavesElectrode carrying meansGas treatmentFiberEngineering

Owner:HANON SYST

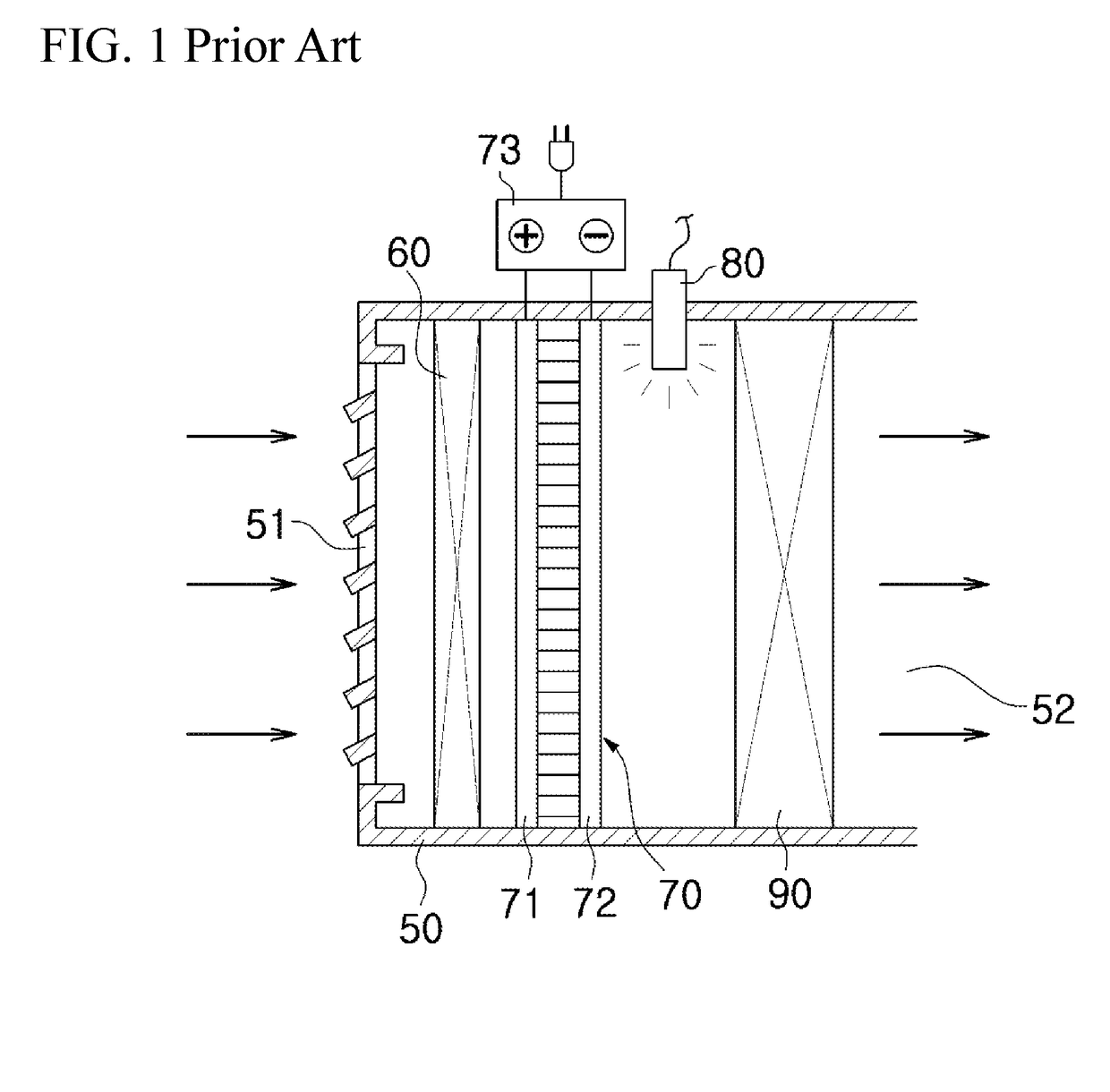

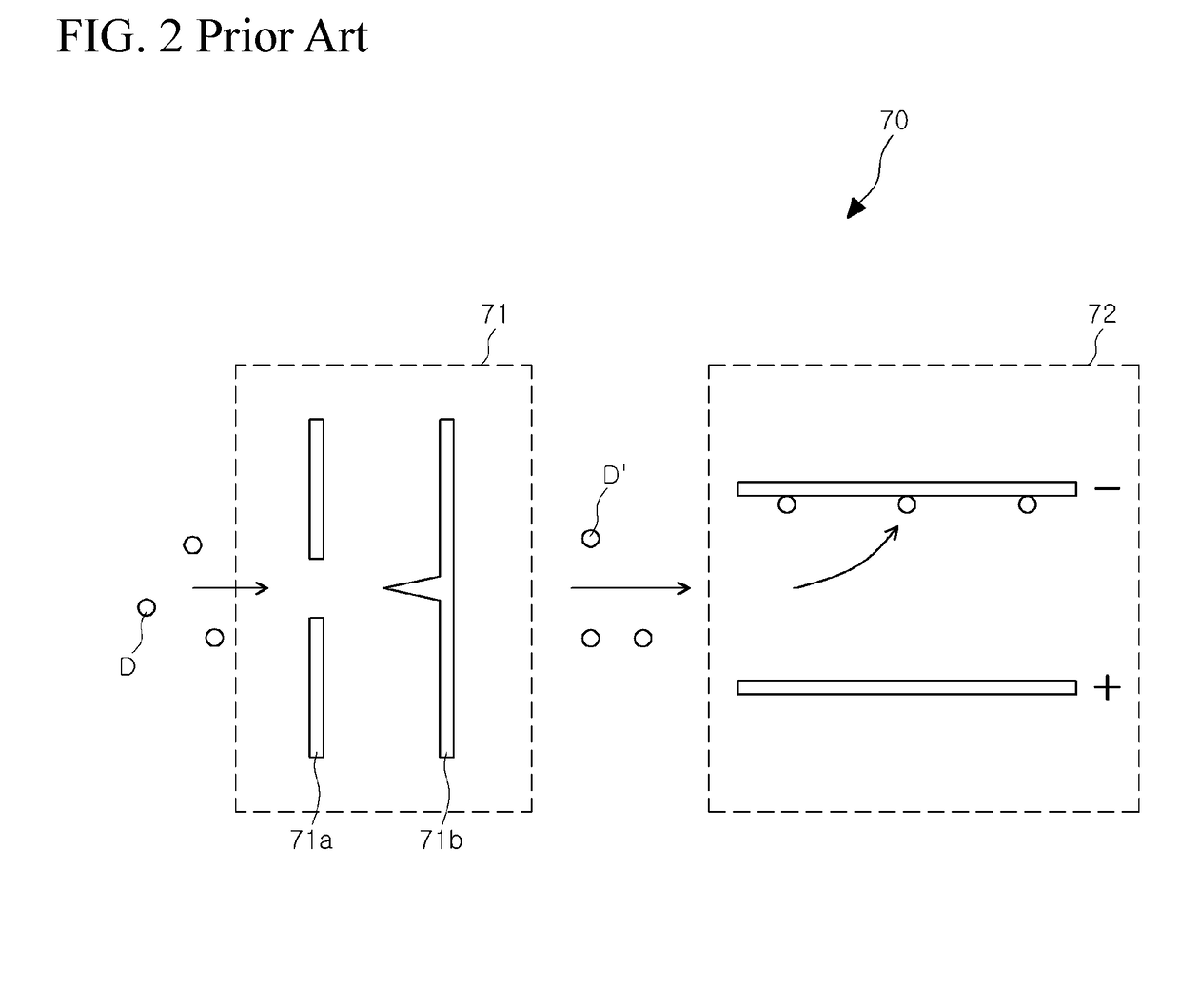

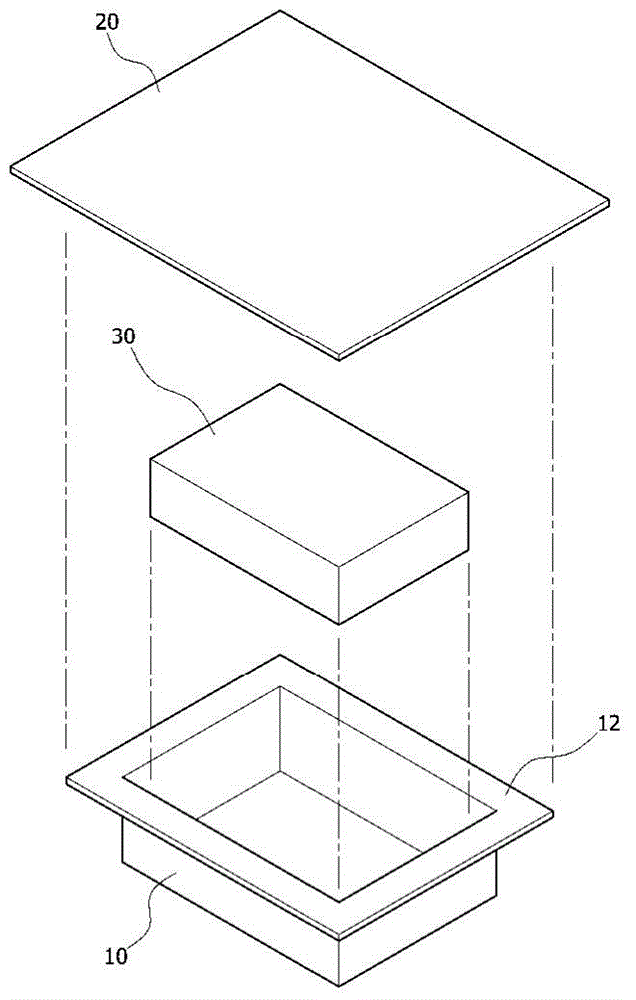

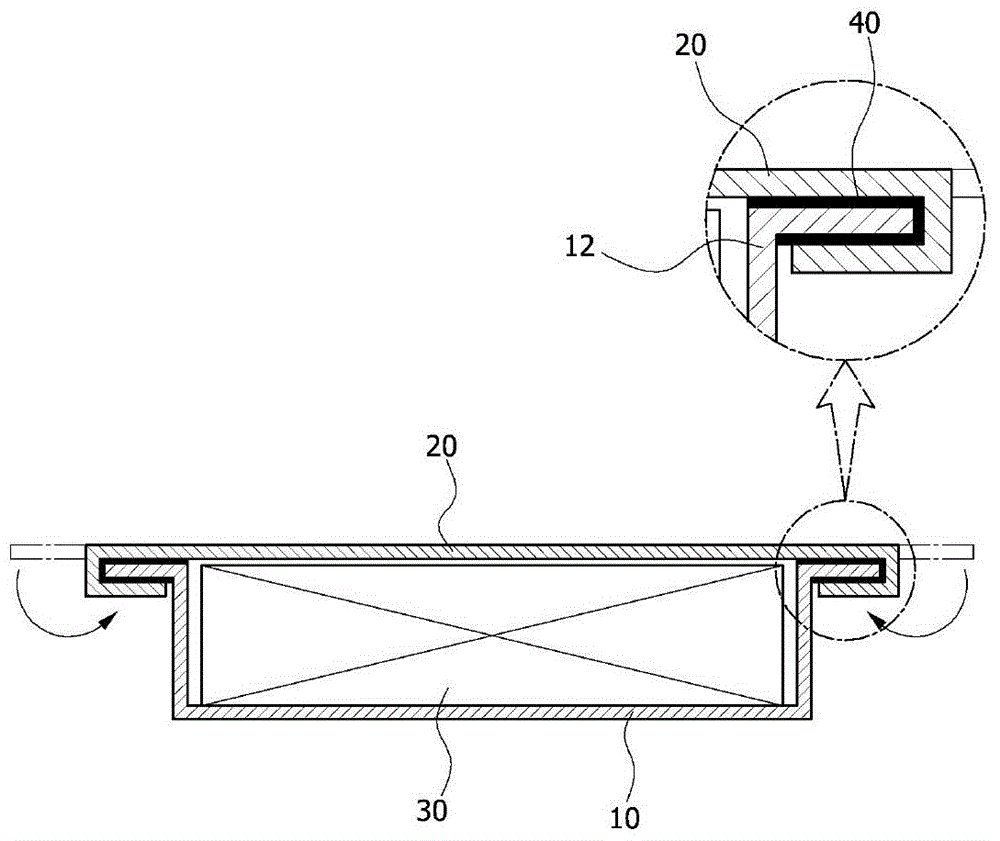

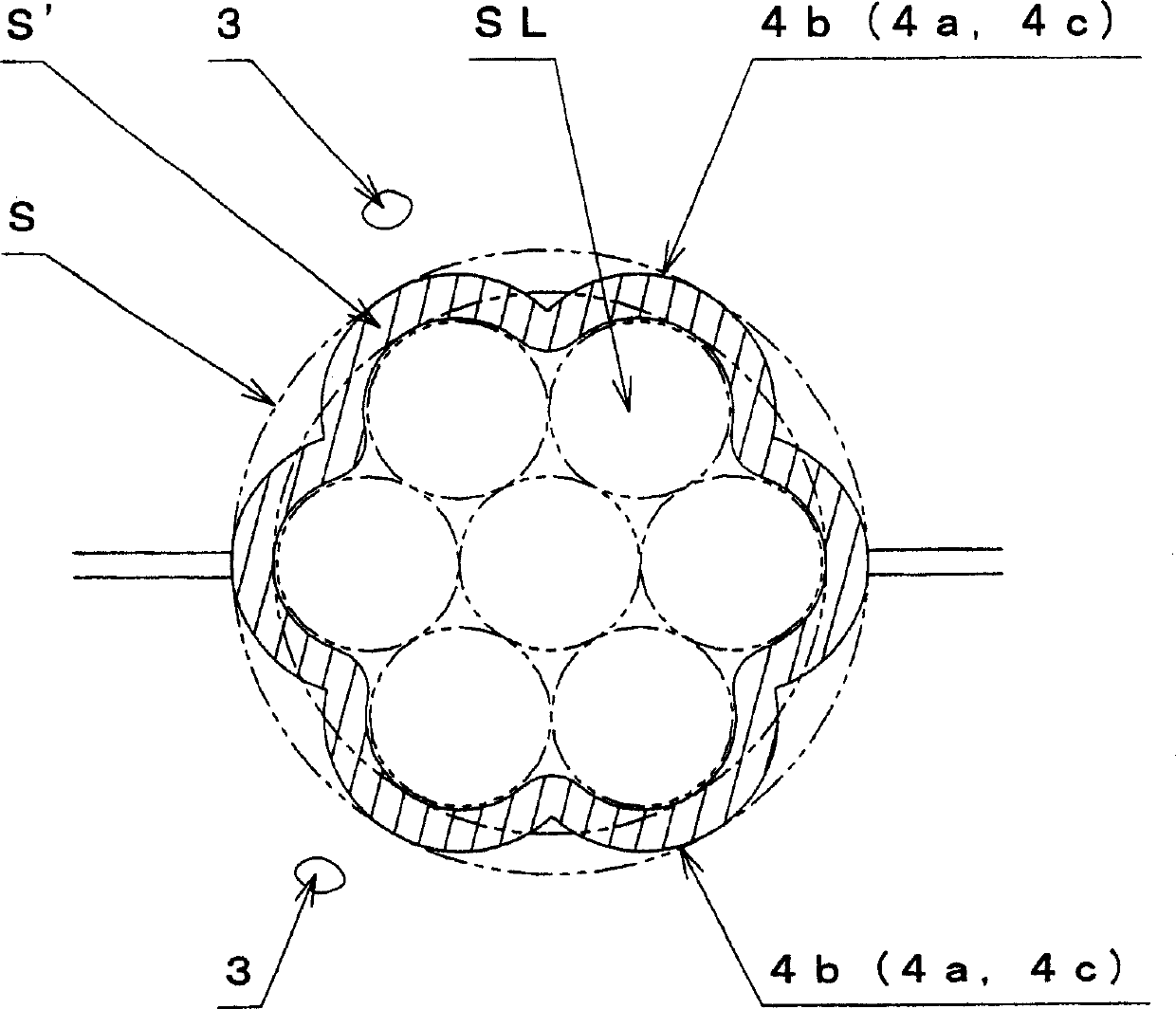

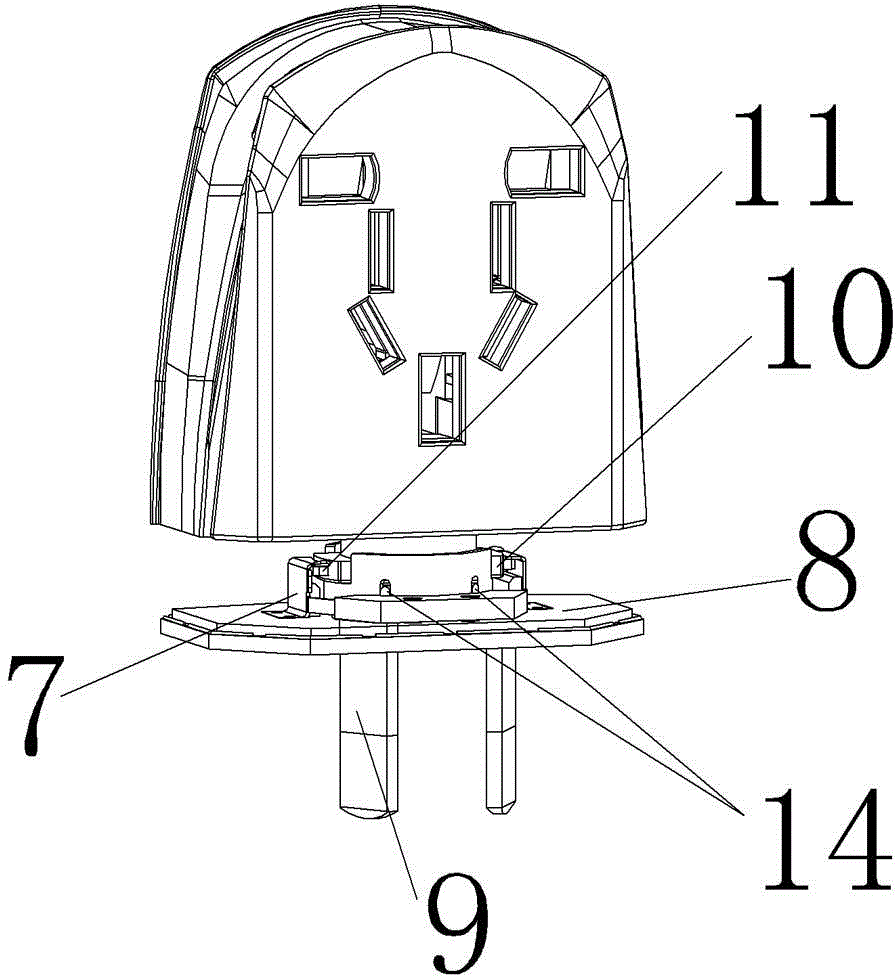

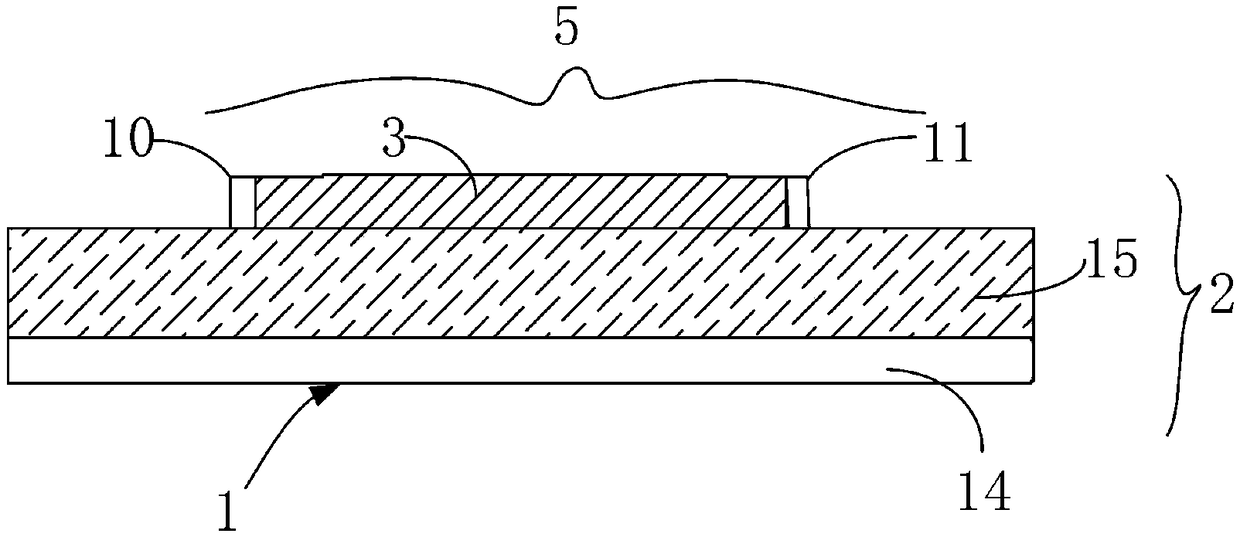

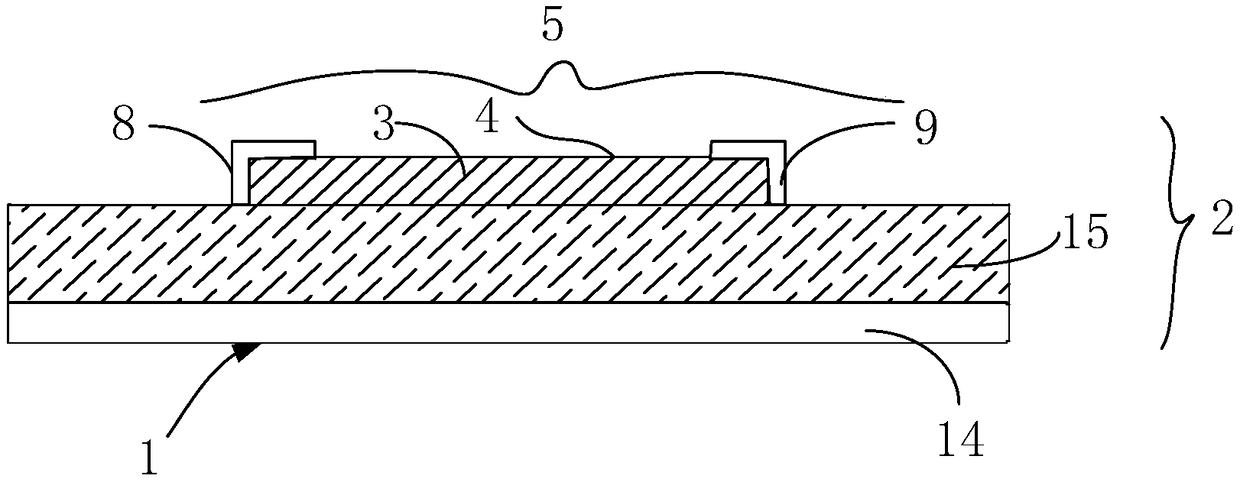

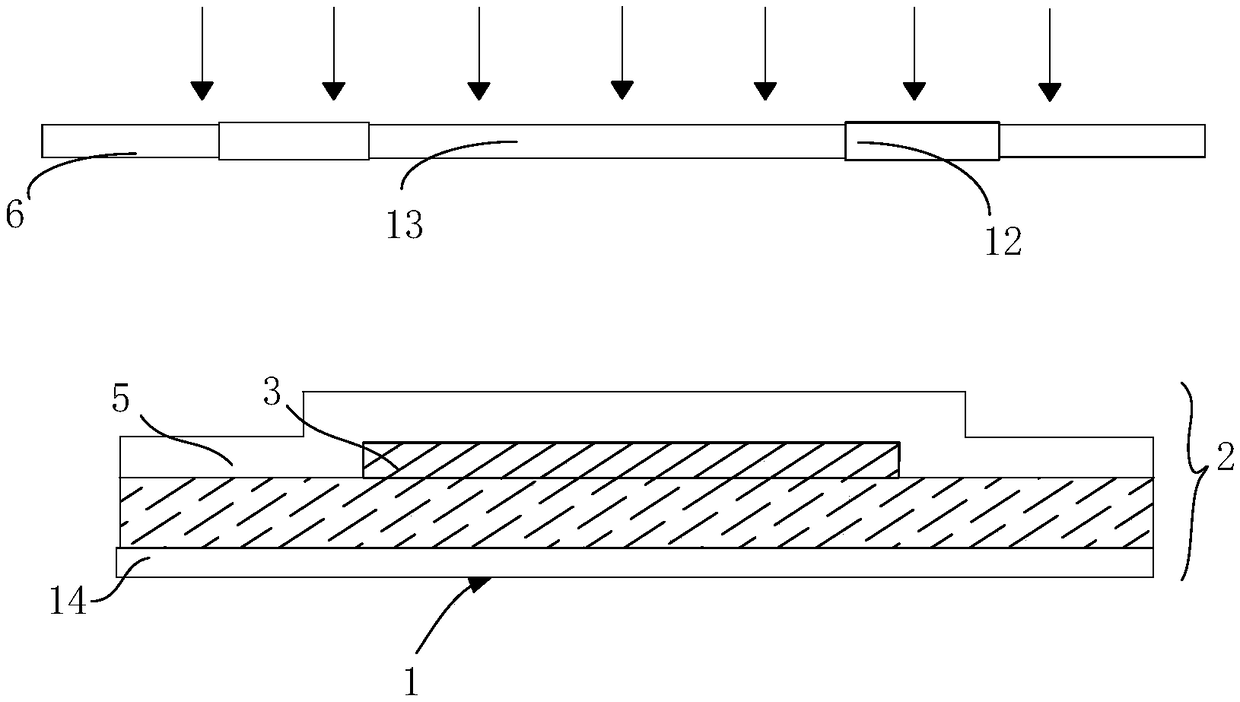

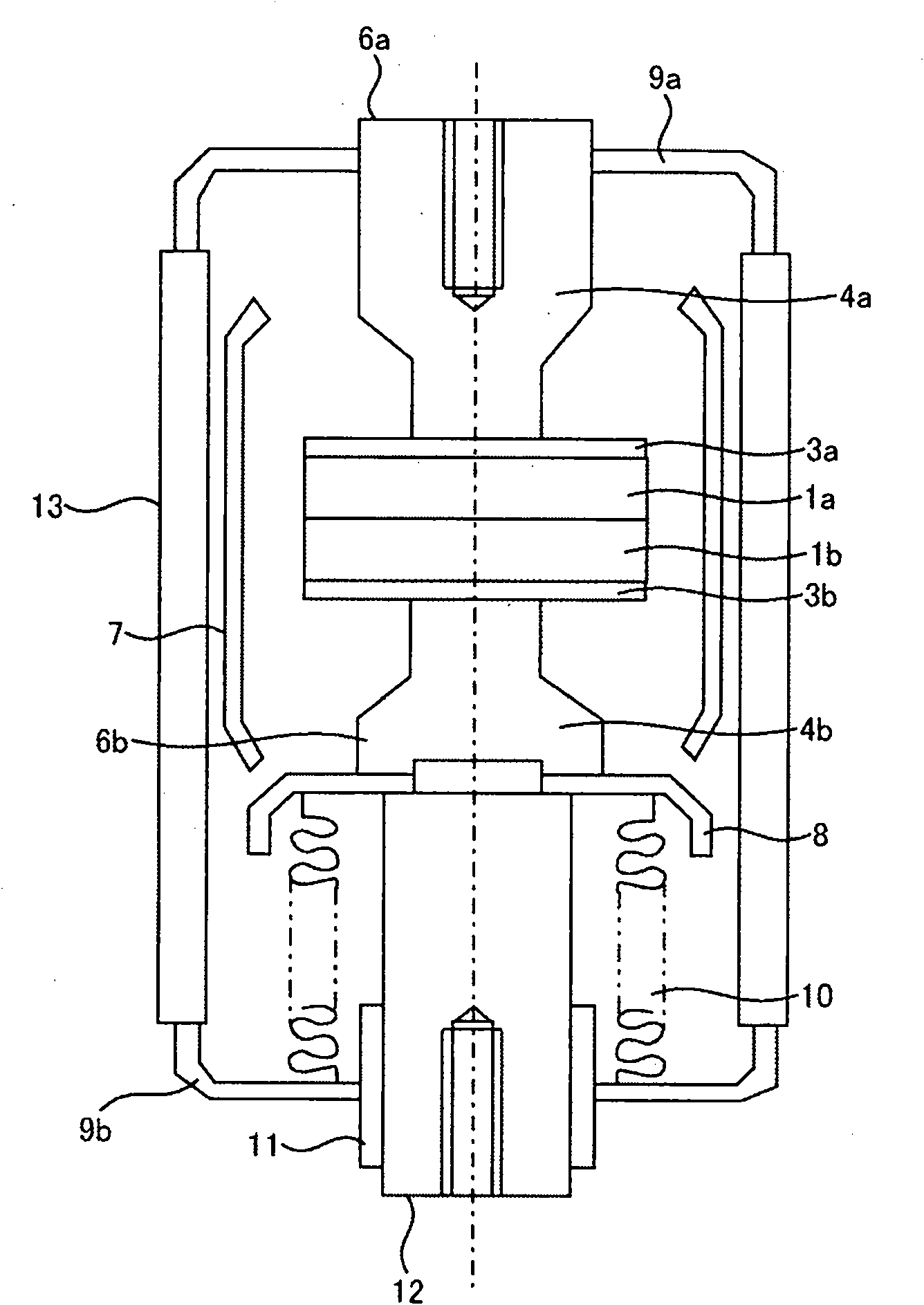

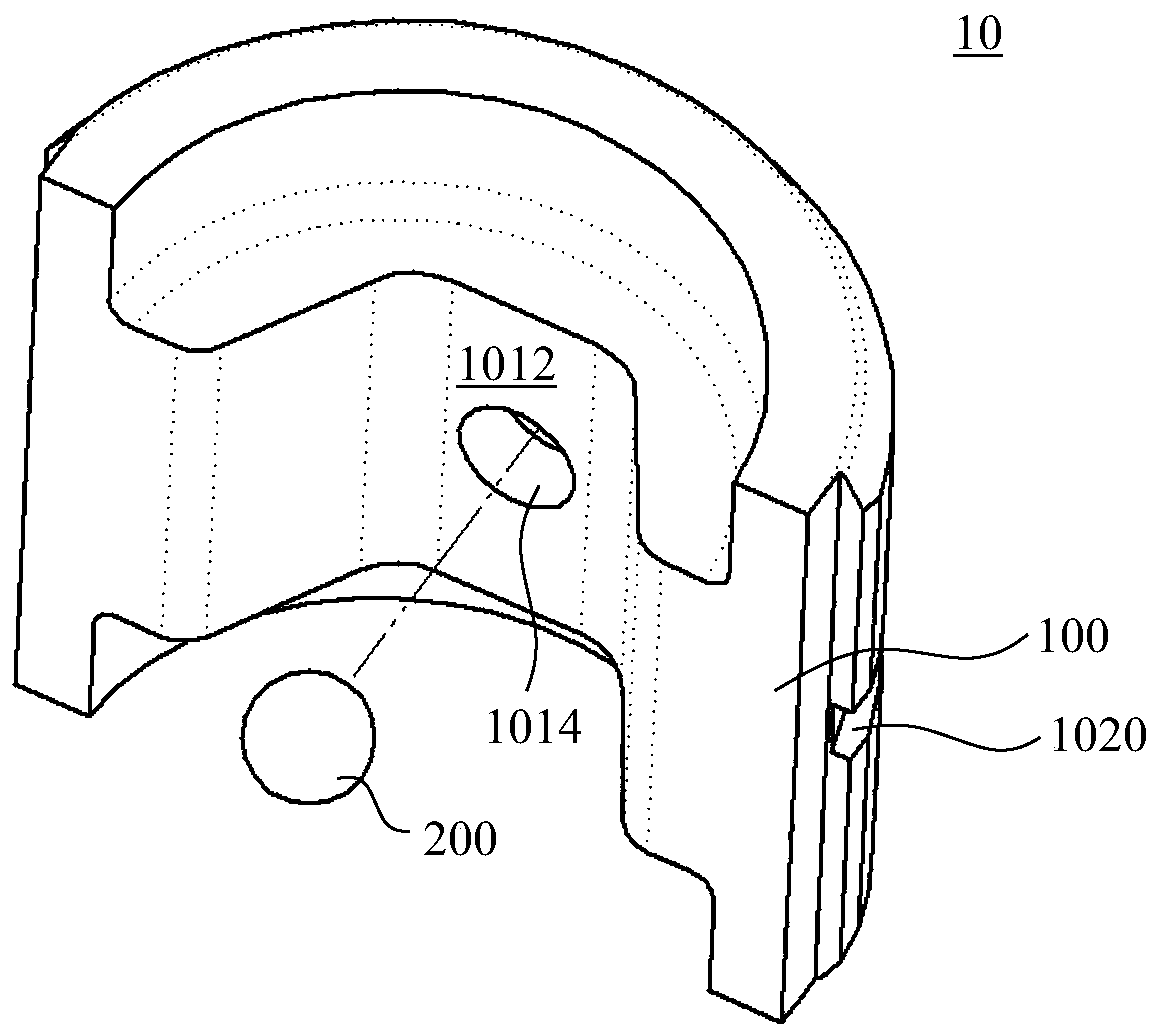

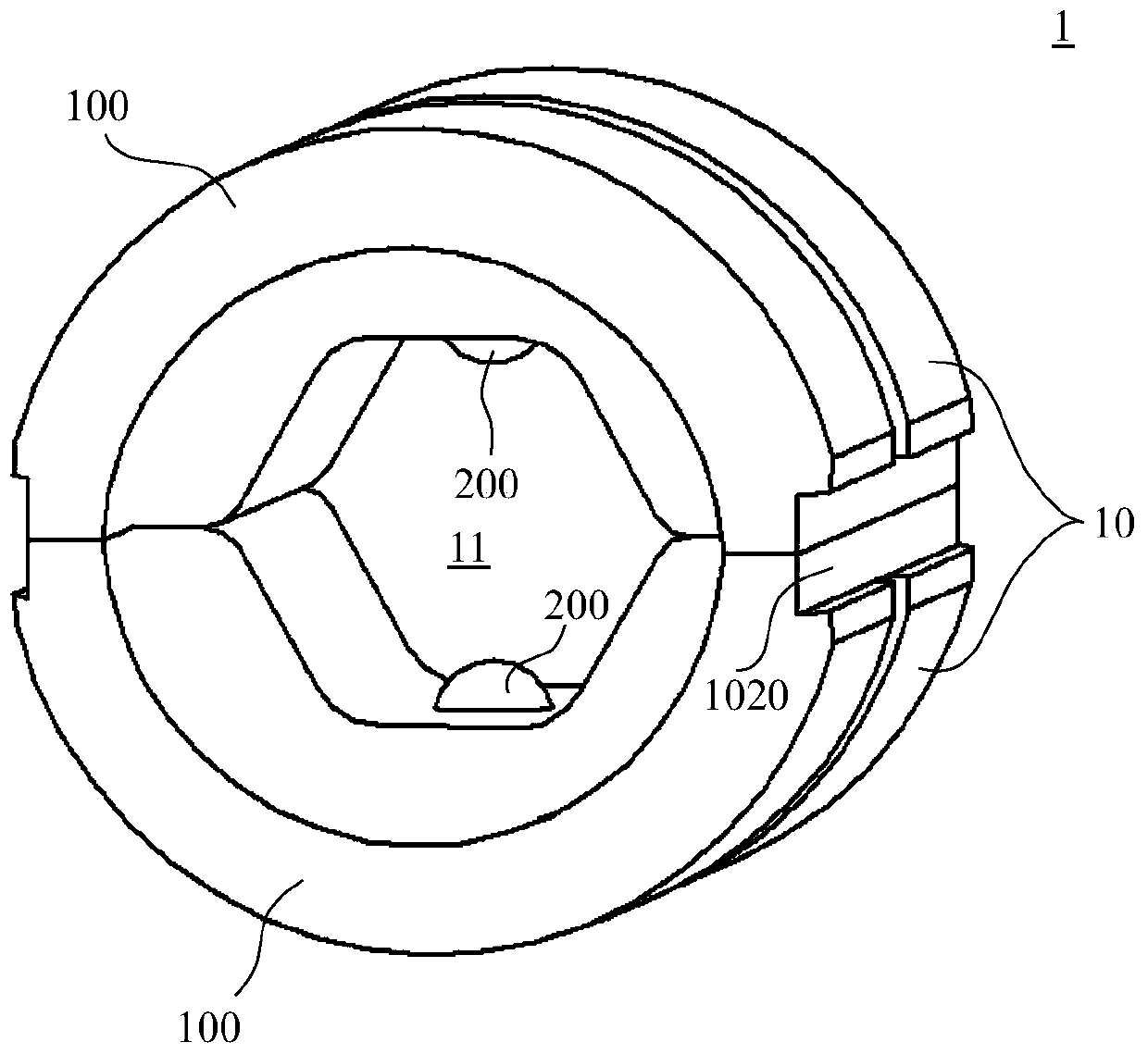

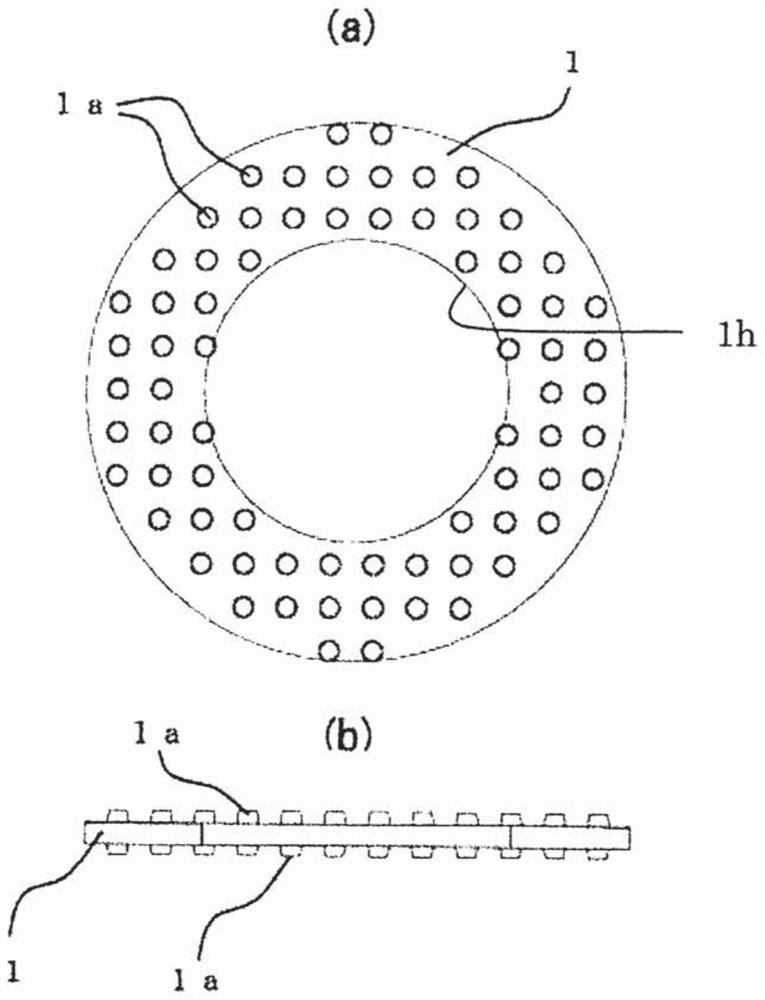

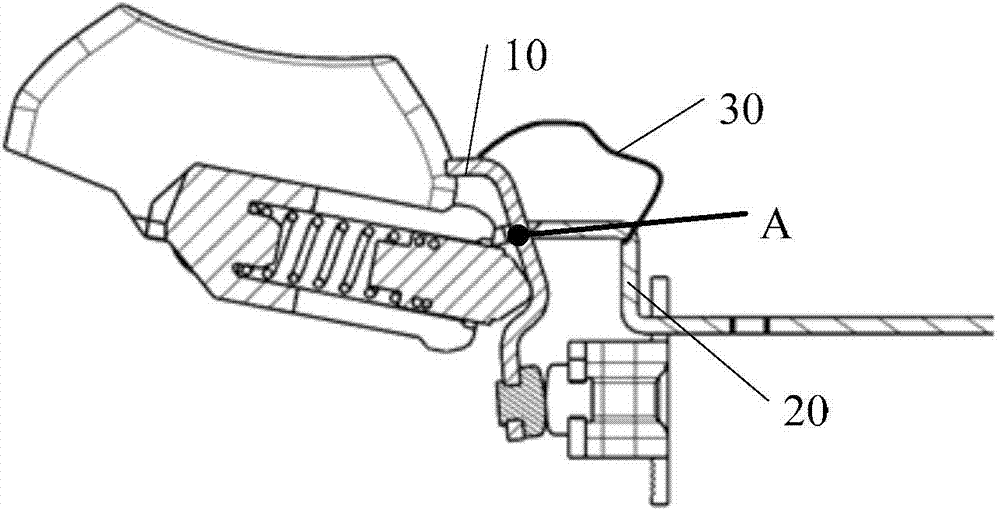

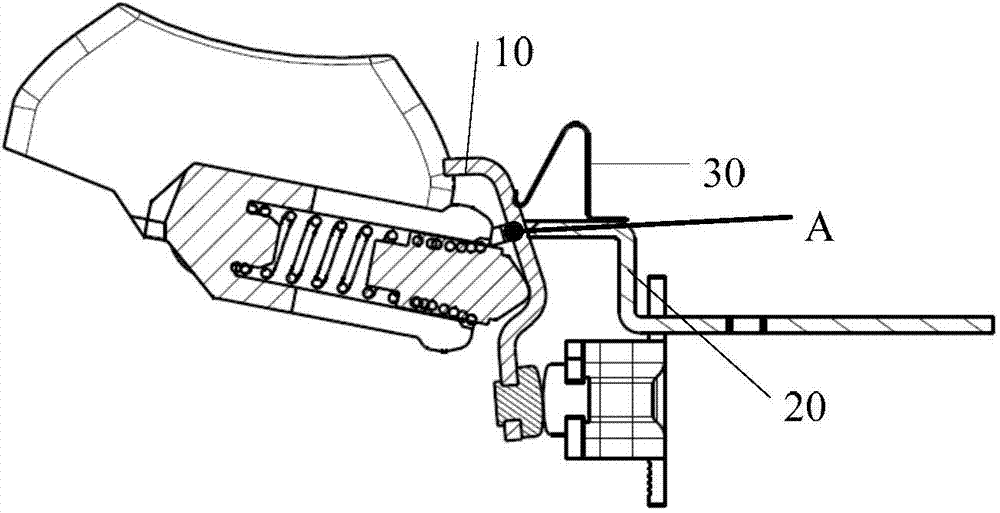

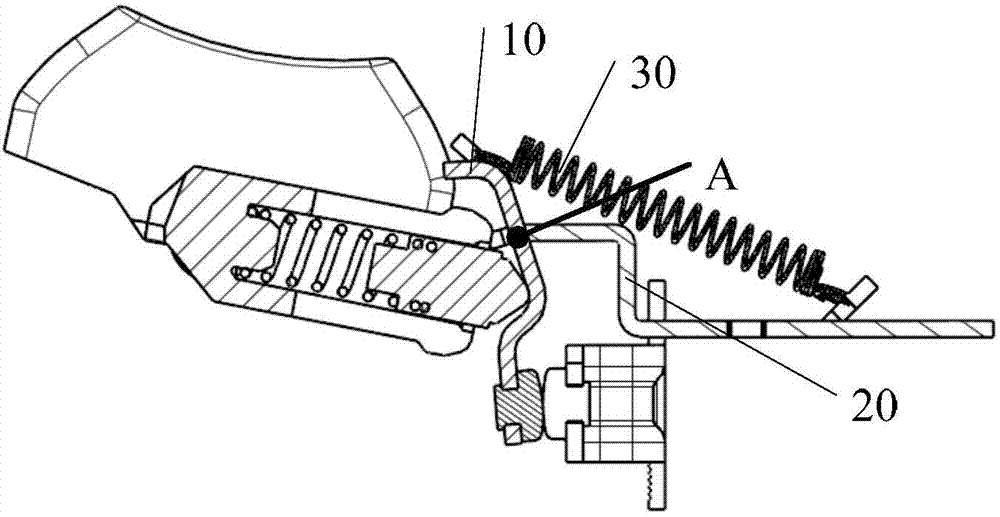

Electrification apparatus for electrostatic dust collector

ActiveUS20170341489A1Improve electrification performanceReducing harmful ozone and electromagnetic wavesElectrode carrying meansGas treatmentElectrostatic precipitatorFiber

An electrification apparatus for an electrostatic dust collector, including: a first electrode part having a shape of a plate having a plurality of through holes formed thereon in such a manner as to apply one of positive and negative electrodes thereto; and a second electrode part having protrusions each having a plurality of fine conductive fibers in such a manner as to protrude outwardly from the through holes of the first electrode part, whereby electrification performance is improved and harmful ozone and electromagnetic waves are reduced.

Owner:HANON SYST

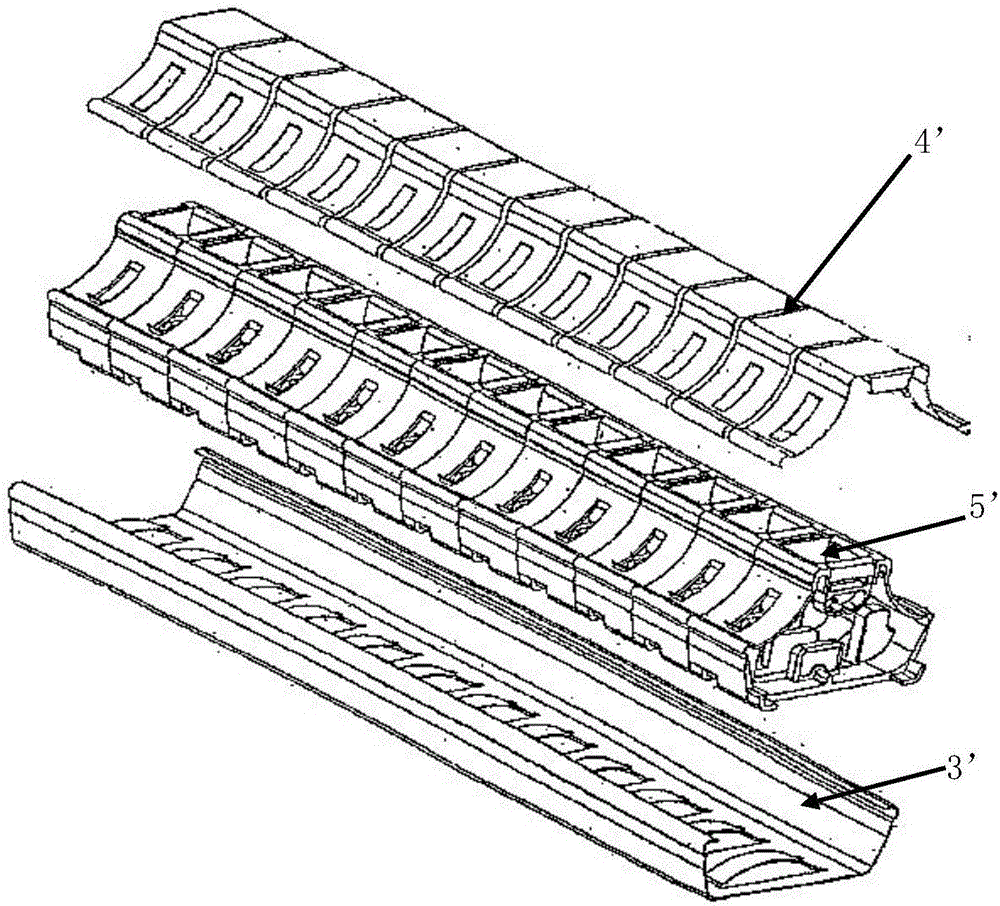

Novel power source tapping integrated device

ActiveCN106099573ASimple structureEasy to installCoupling contact membersCouplings bases/casesElectricityElectrical conductor

The invention discloses a novel power source tapping integrated device. The device is composed of a tapping device and an electric power track; a live line conductor, a null line conductor and a ground line conductor which are insulated from one another are arranged in the electric power track. After being inserted into any position of the electric power track, the tapping device is connected with the live line conductor, the null line conductor and the ground line conductor in the electric power track, so that safe electricity tapping at the position can be realized. The novel power source tapping integrated device is characterized in that the electric power track is formed by connecting a plurality of integrally-molded cavities; each cavity is of a sealed structure with a longitudinal opening; a live line groove and a null line groove where the live line conductor and the null line conductor can be arranged respectively are formed in the sealed structure along two sides of the cavity; and the bottom of each cavity is provided with a protruding structure facing the opening, wherein the protruding structure is adopted as the ground line conductor, and the protruding structure and the cavity are molded integrally. The novel power source tapping integrated device of the invention has the advantages of simpler structure and lower cost.

Owner:酷闪电器(上海)有限公司

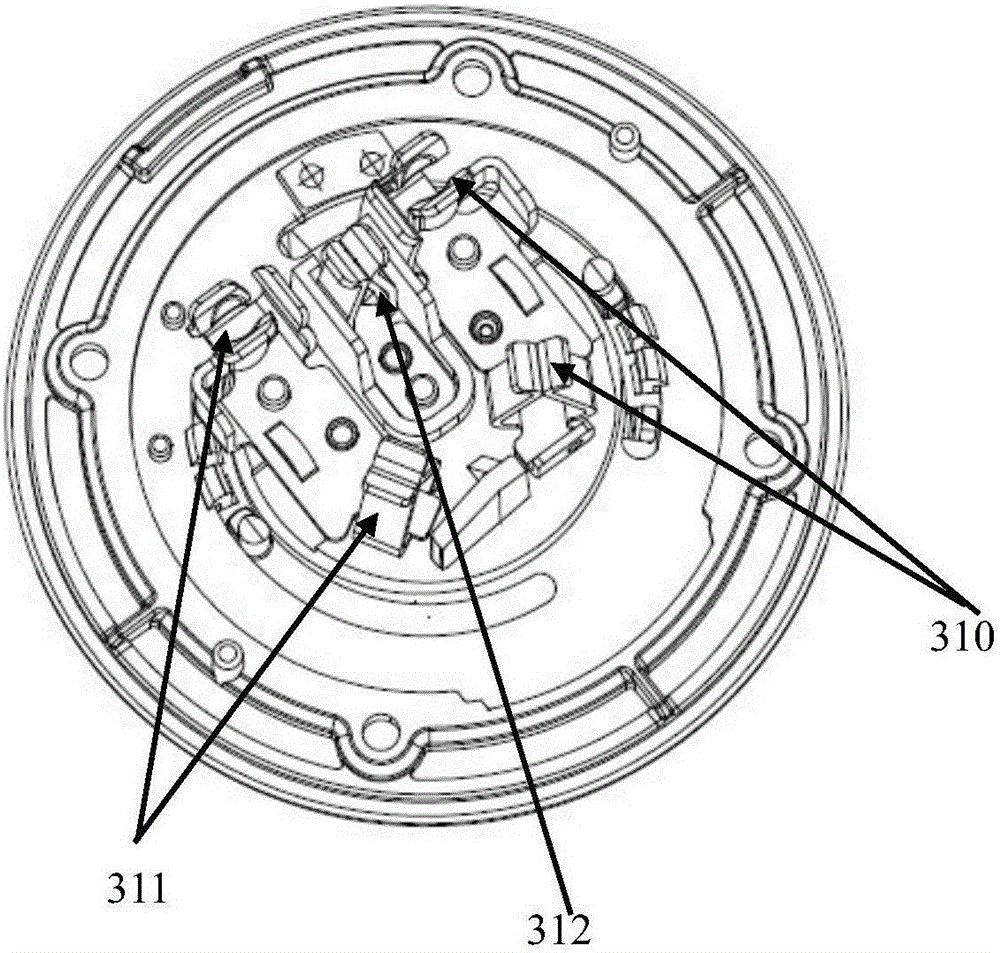

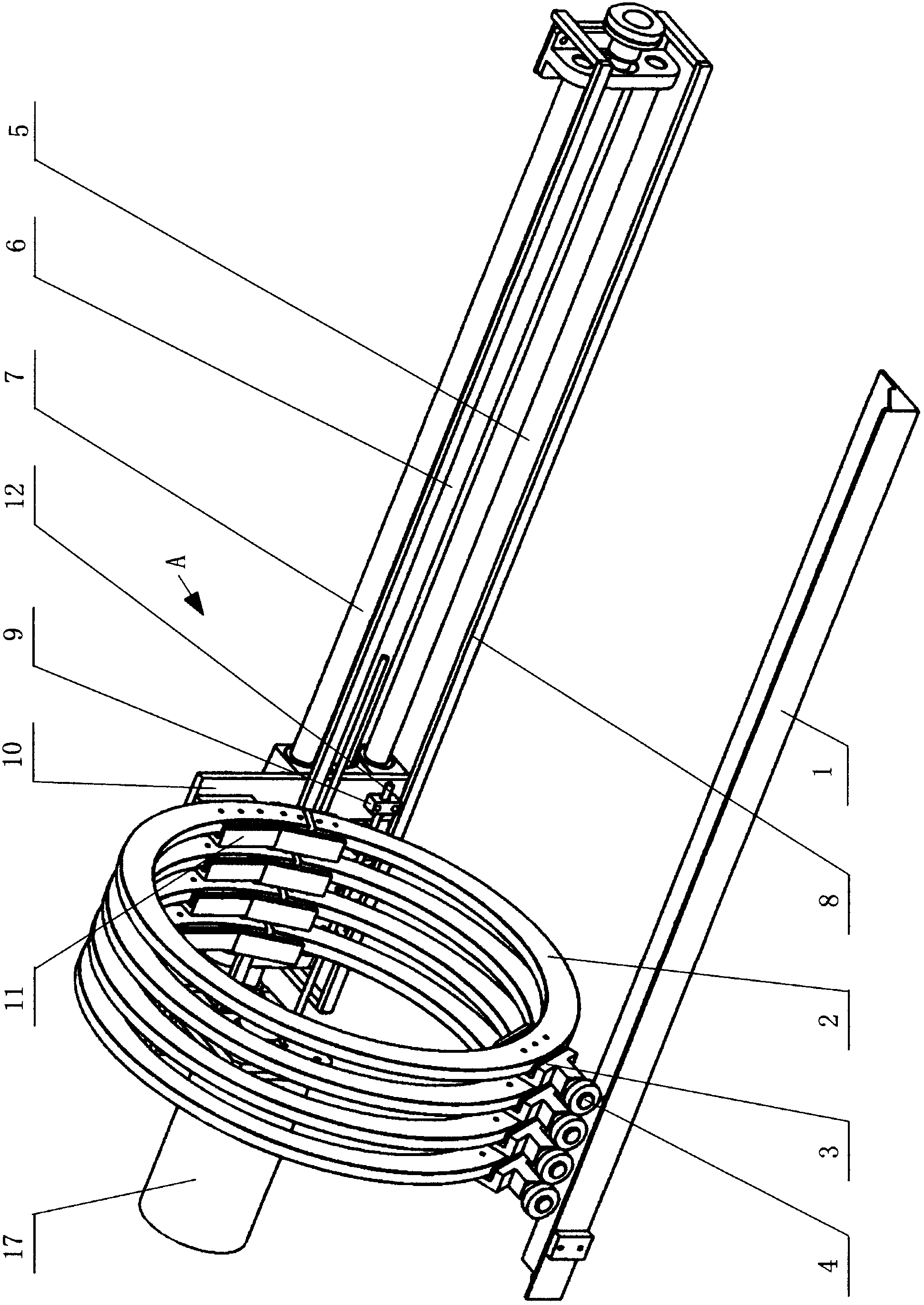

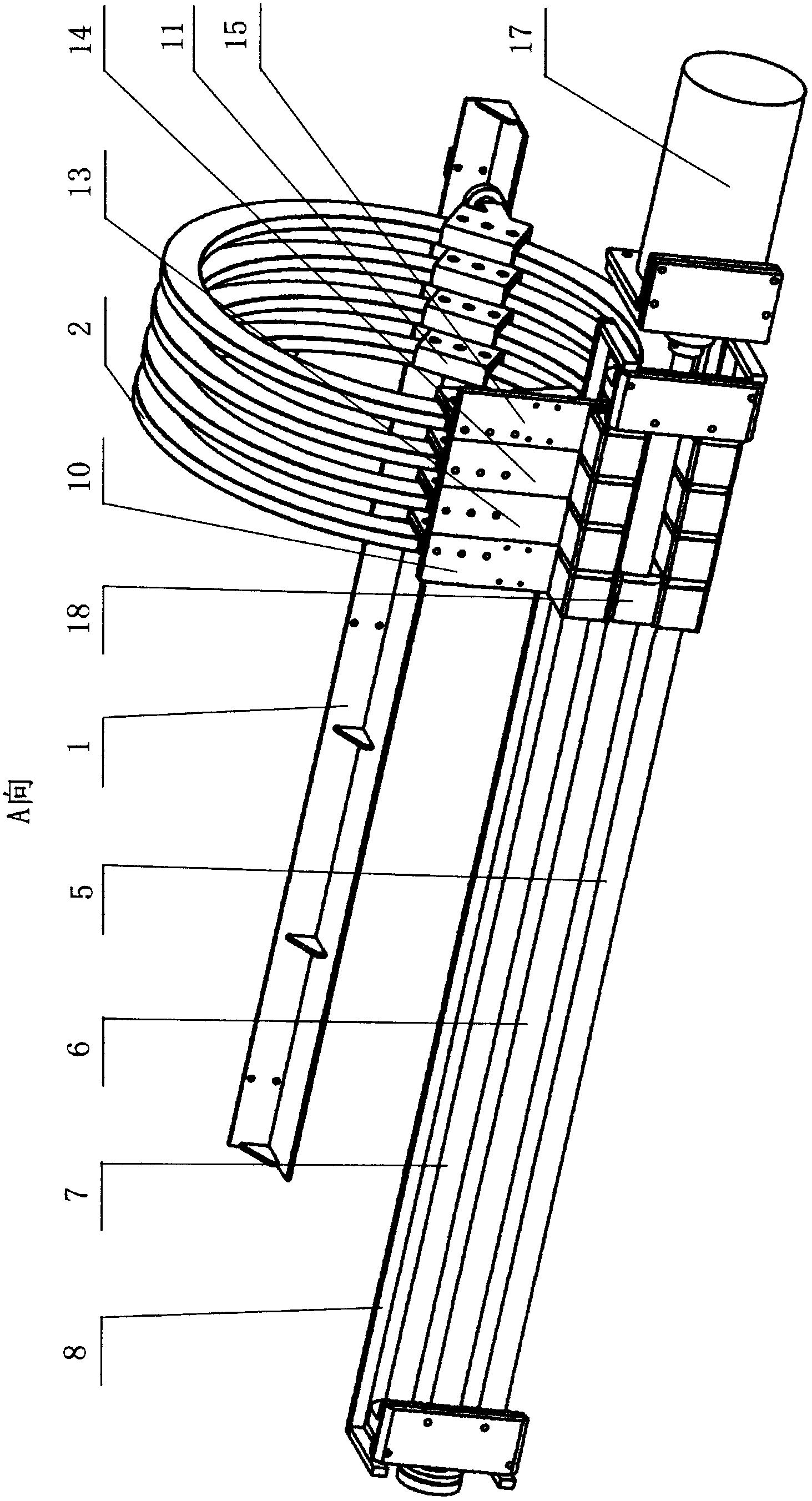

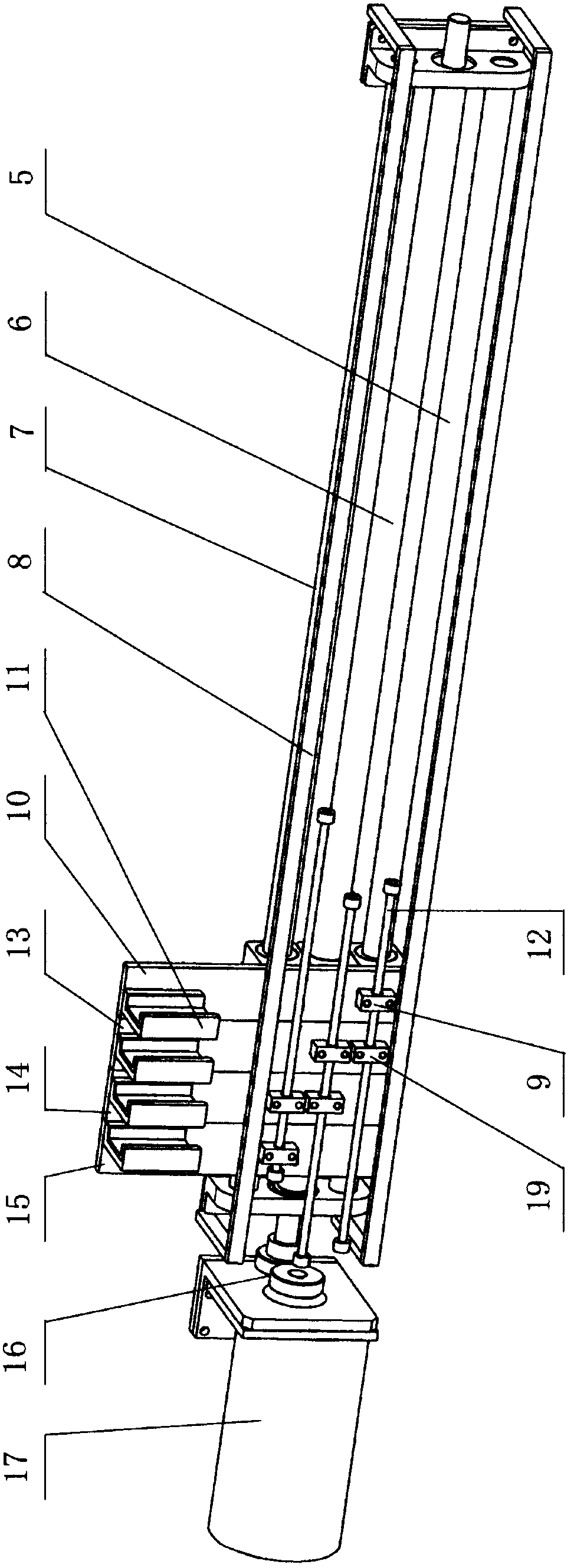

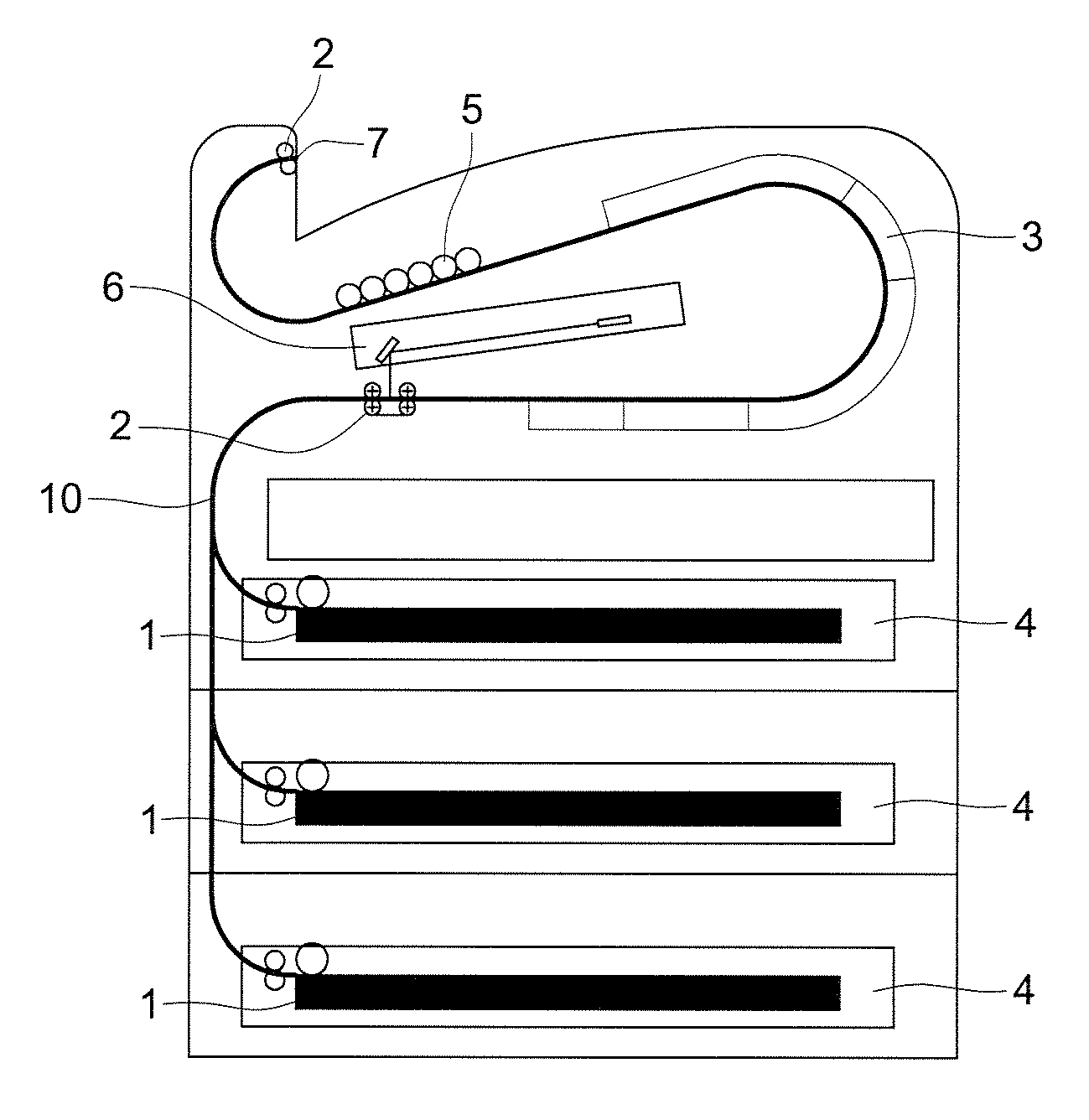

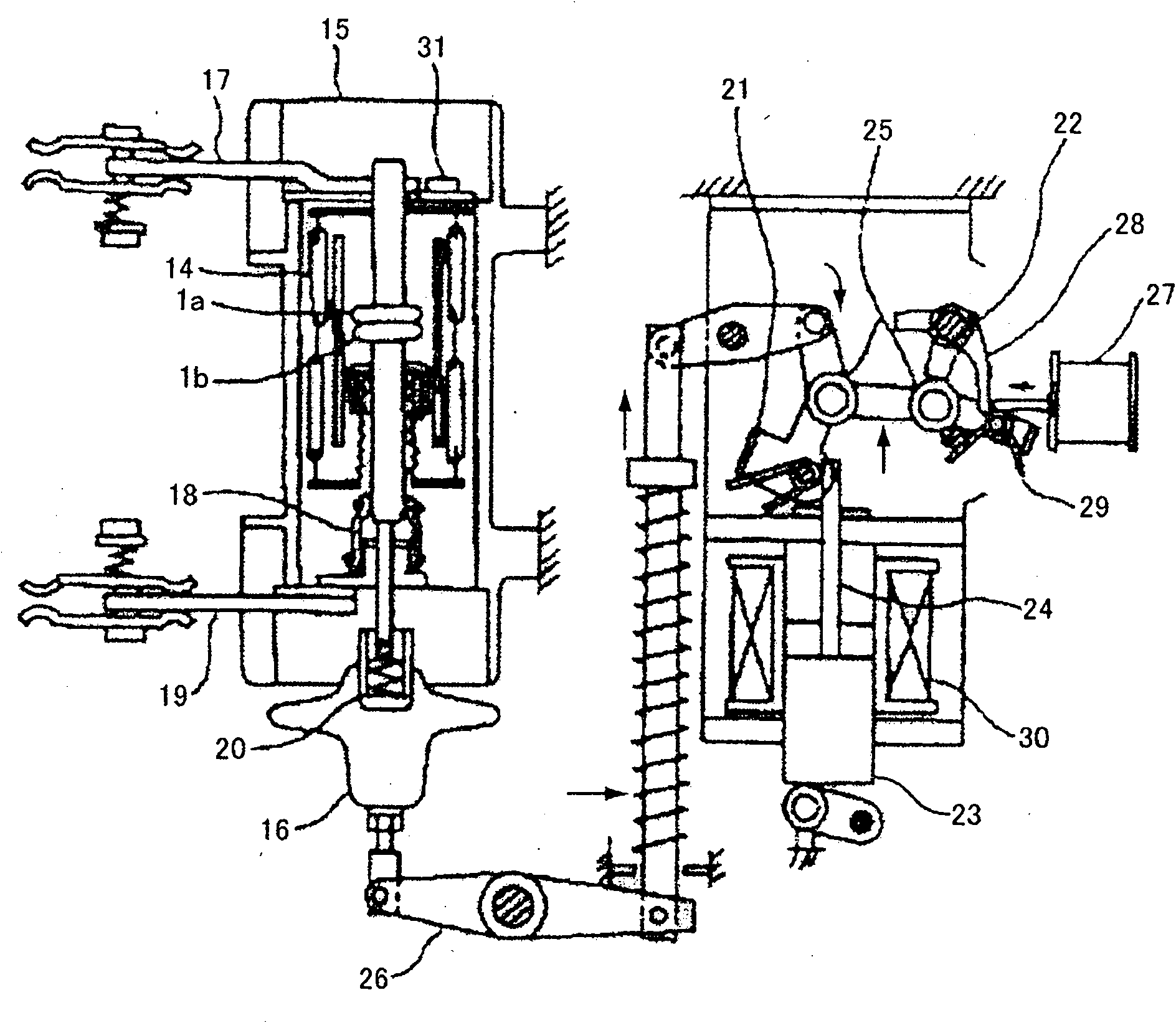

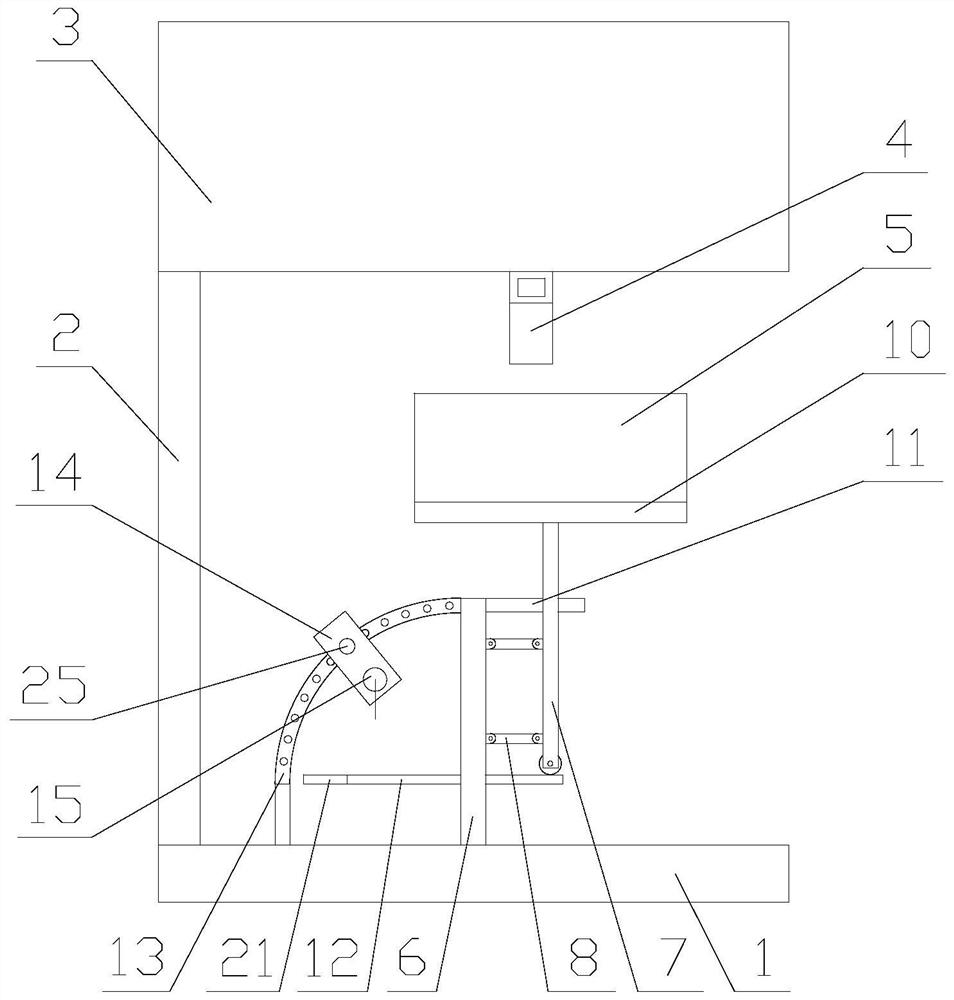

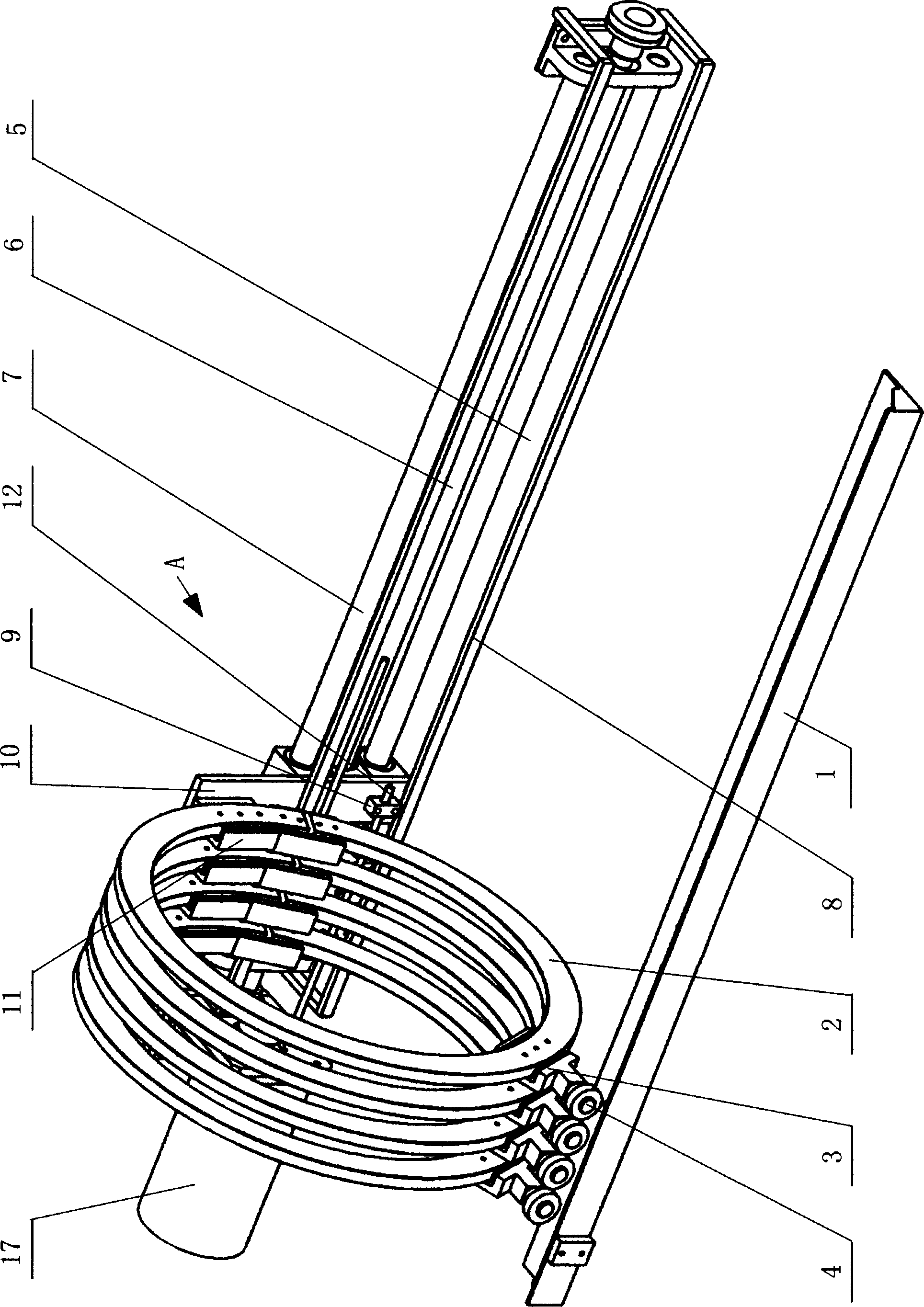

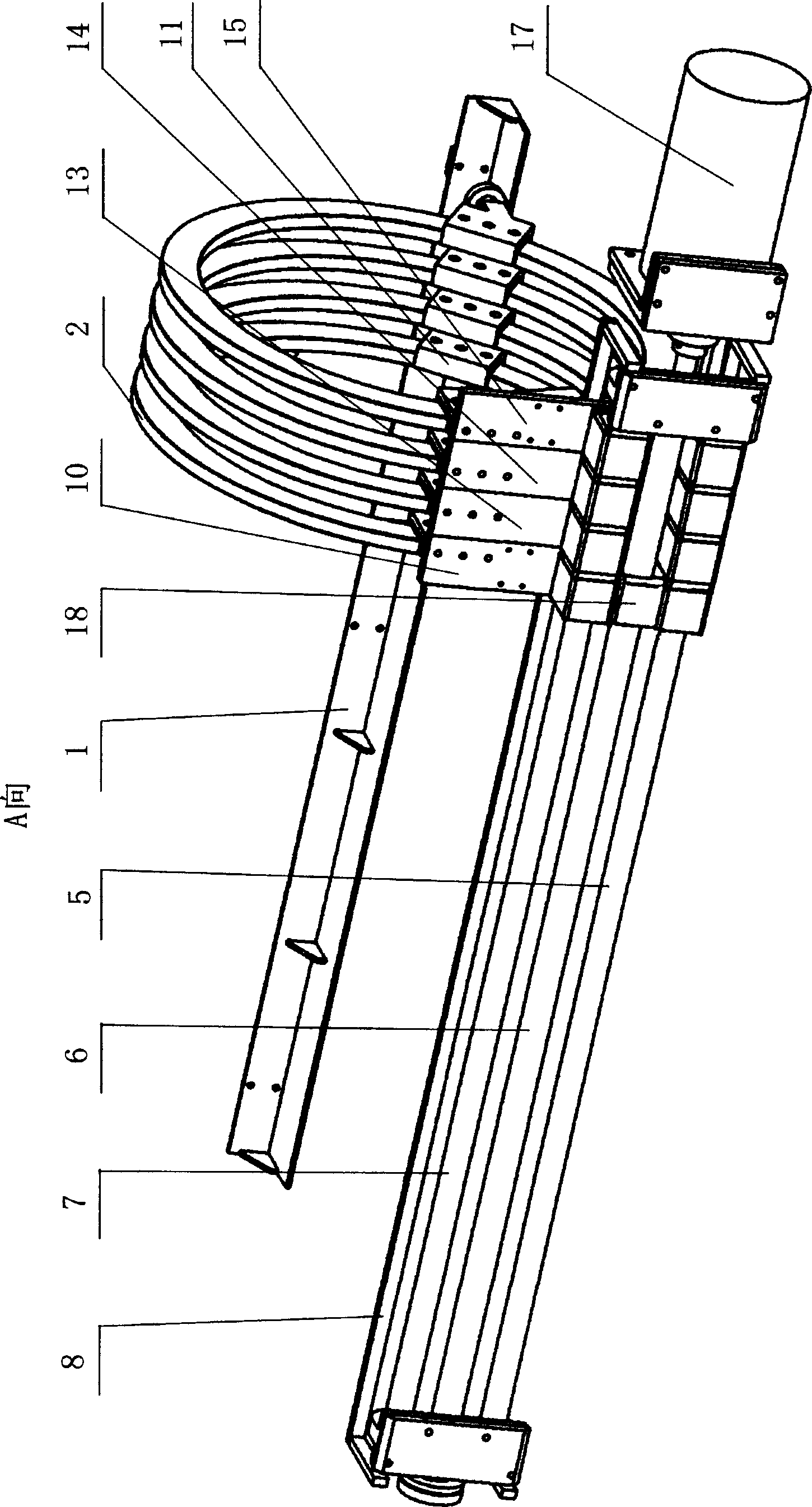

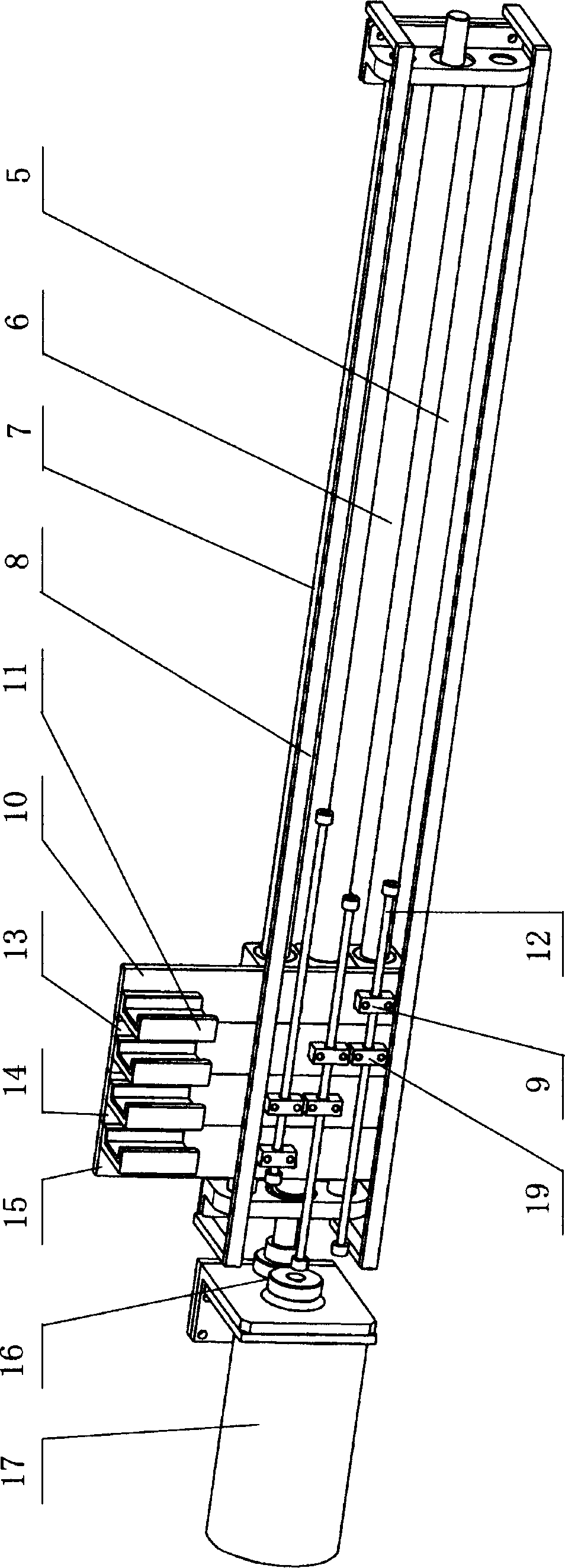

Longitudinal magnetization moving coil device for plain shaft and crank shaft magnetic particle inspection

ActiveCN102706957AEvenly distributedAvoid safety accidentsMaterial magnetic variablesOptical axisEngineering

The invention discloses a longitudinal magnetization moving coil device for plain shaft and crank shaft magnetic particle inspection. The longitudinal magnetization moving coil device comprises a plurality of longitudinal magnetization coils, a moving mechanism and a guide rail, wherein each longitudinal magnetization coil has a round integral structure; the guide rail is positioned on the front side of the longitudinal magnetization coils; the moving mechanism comprises a motor, a support, two guide rods, a screw rod, a connecting rod, coil connecting frames and a coil moving frame; the support is positioned on the back side of the longitudinal magnetization coils; the motor is connected with the left end of the screw rod through a driving device; an upper shaft sleeve and a lower shaft sleeve are arranged on the coil connecting frames, and are respectively sleeved on the two guide rods which are positioned on the support; the quantity of the coil connecting frames is the same as that of the longitudinal magnetization coils; a coil trough is formed on each coil connecting frame; the back sides of the longitudinal magnetization coils are buckled in the troughs of the back sides; coil troughs and a guide wheel are arranged on the coil moving frame; the front sides of the longitudinal magnetization coils are buckled in the coil troughs; and the guide wheel of the coil moving frame is positioned on the guide rail.

Owner:YANCHENG ELECTRONICS EQUIP FACTORY

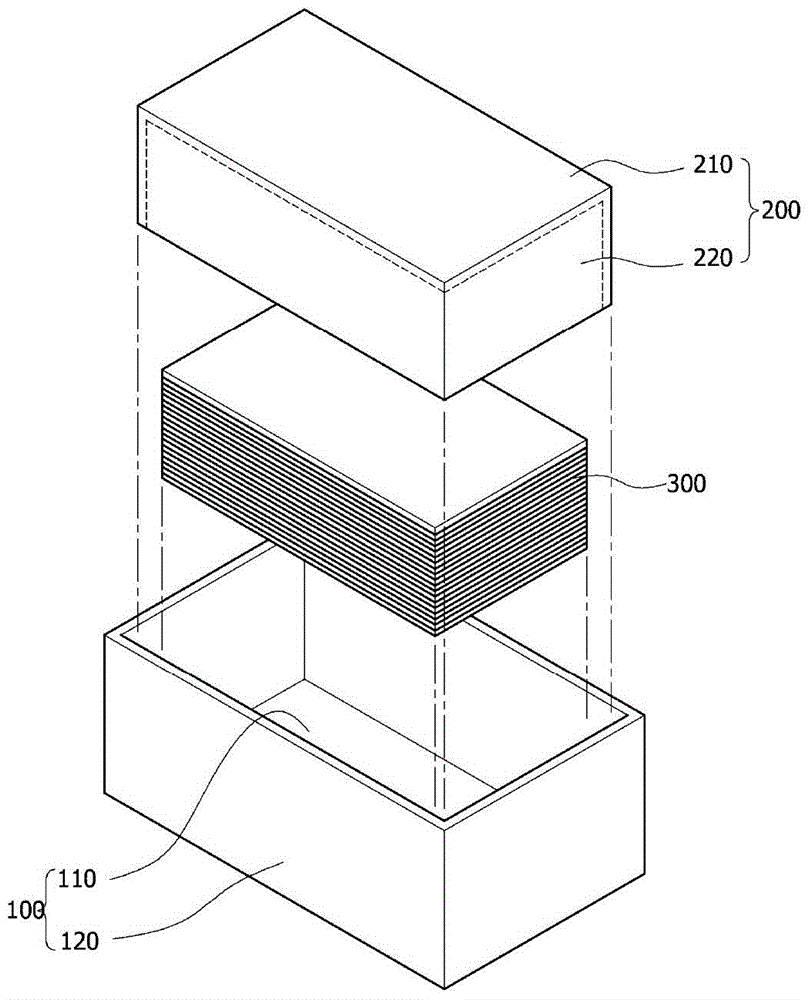

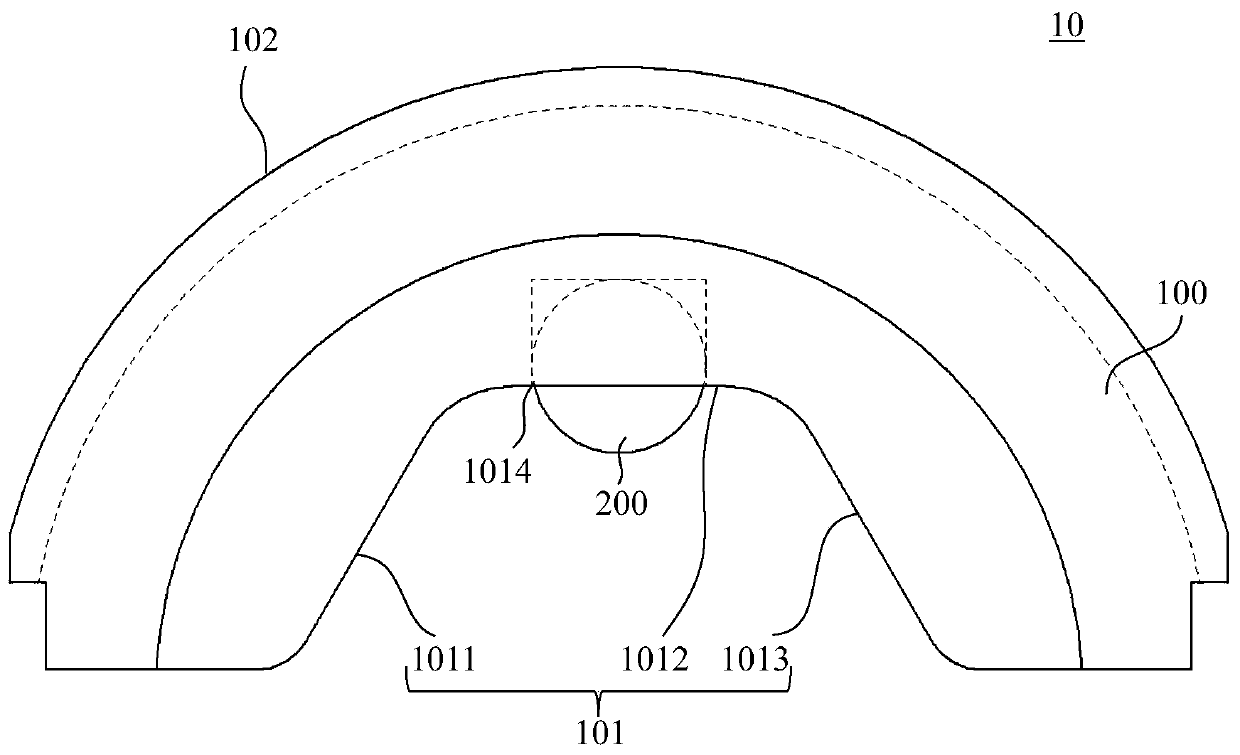

Secondary battery case provided with fastening strengthening unit

InactiveCN104662694ACombination structure is simpleEnhanced couplingSmall-sized cells cases/jacketsCell sealing materialsInterior spaceEngineering

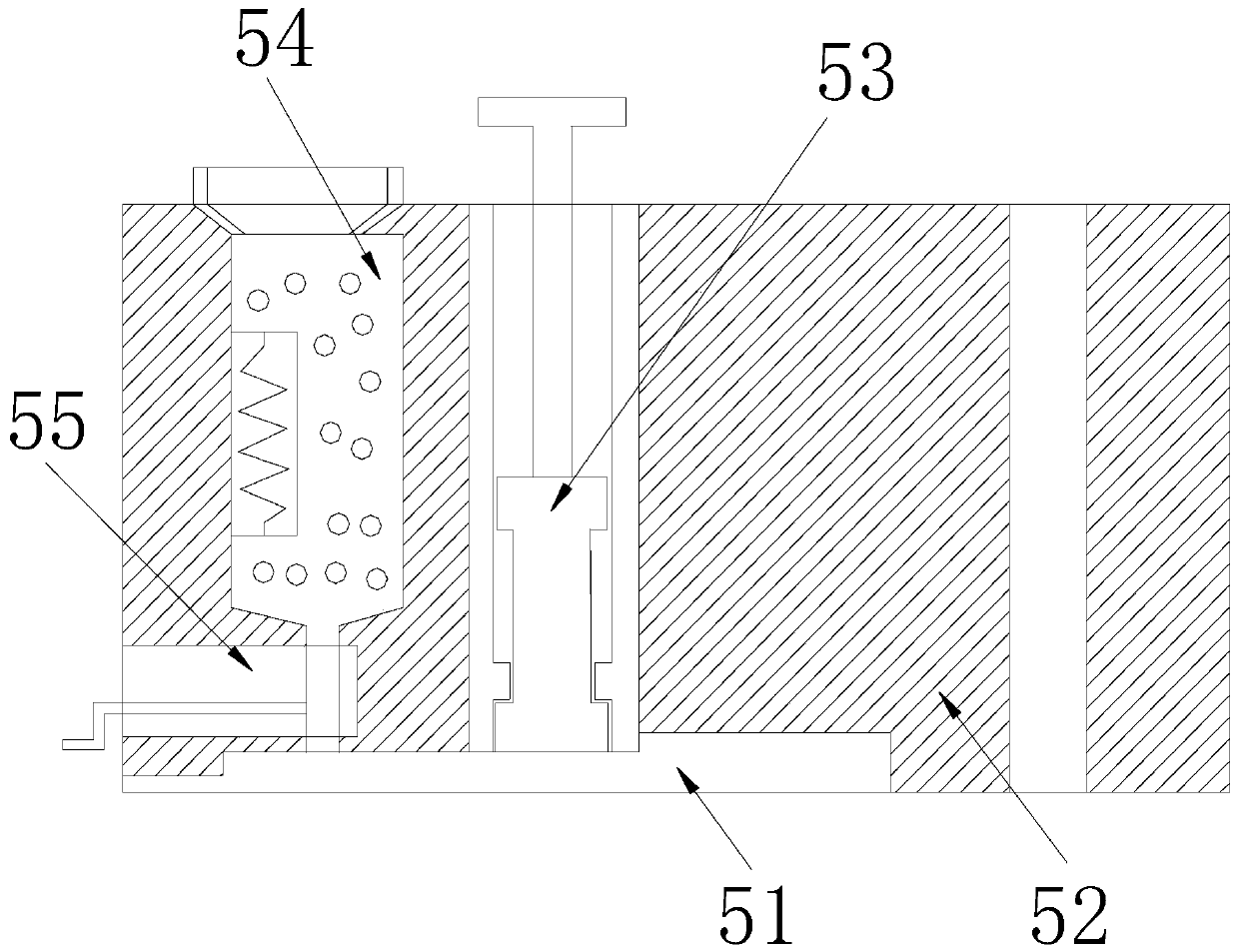

In order to achieve the above described object, a secondary battery case according to the present invention includes: a can configured to have a lower plate and a raised side wall which extends upward from the lower plate and has an inner space of which the upper side is open; and a cap configured to have an upper plate and a dropped side wall which extends downward from the upper plate, has an inner space of which the lower side is open, and is inserted into the inner space of the can in order to isolate the inner space of the can from the outside so that the lower end of the dropped side wall is received by the upper surface of the lower plate. The present invention may include a fastening strengthening unit which surrounds a partial section of the dropped side wall with a partial section of the raised side wall so that fastening and sealing are improved when the can and the cap are fastened with each other. According to the secondary battery case of the present invention, a connection structure for the can and the cap is simplified, and thus product size can be reduced, the fastening and the sealing between the can and the cap are improved, and conductivity with an electrode assembly is improved.

Owner:ROUTEJADE INC

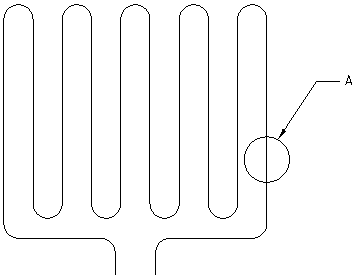

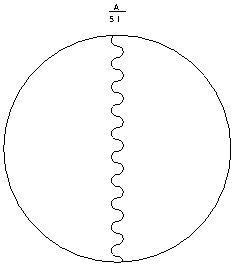

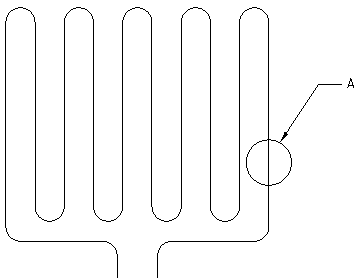

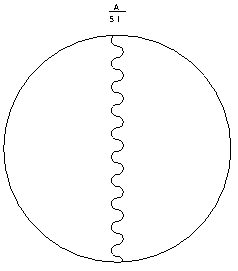

Flexible electric heating plate and preparation method therefor

ActiveCN107708234AGood electrification performanceImprove securityOhmic-resistance heating detailsAdhesiveHigh resistivity

The invention provides a flexible electric heating plate. The flexible electric heating plate comprises a flexible base material layer, a first adhesive layer, a circuit layer, a second adhesive layerand a film covering layer, wherein the flexible base material layer and the film covering layer are insulating materials; the first adhesive layer and the second adhesive layer are curing adhesive; the circuit layer is high-resistivity pure metal or an alloy material; and the circuit layer prepares a longitude and latitude bidirectional circuit by the methods of exposure, developing and etching in a circuit board preparation process in the electric field, and the circuit is 5-150[mu]m in thickness. The flexible electric heating plate disclosed in the invention is excellent in folding resistance, and the safety and service life are greatly improved and prolonged.

Owner:厦门宝益科技有限公司

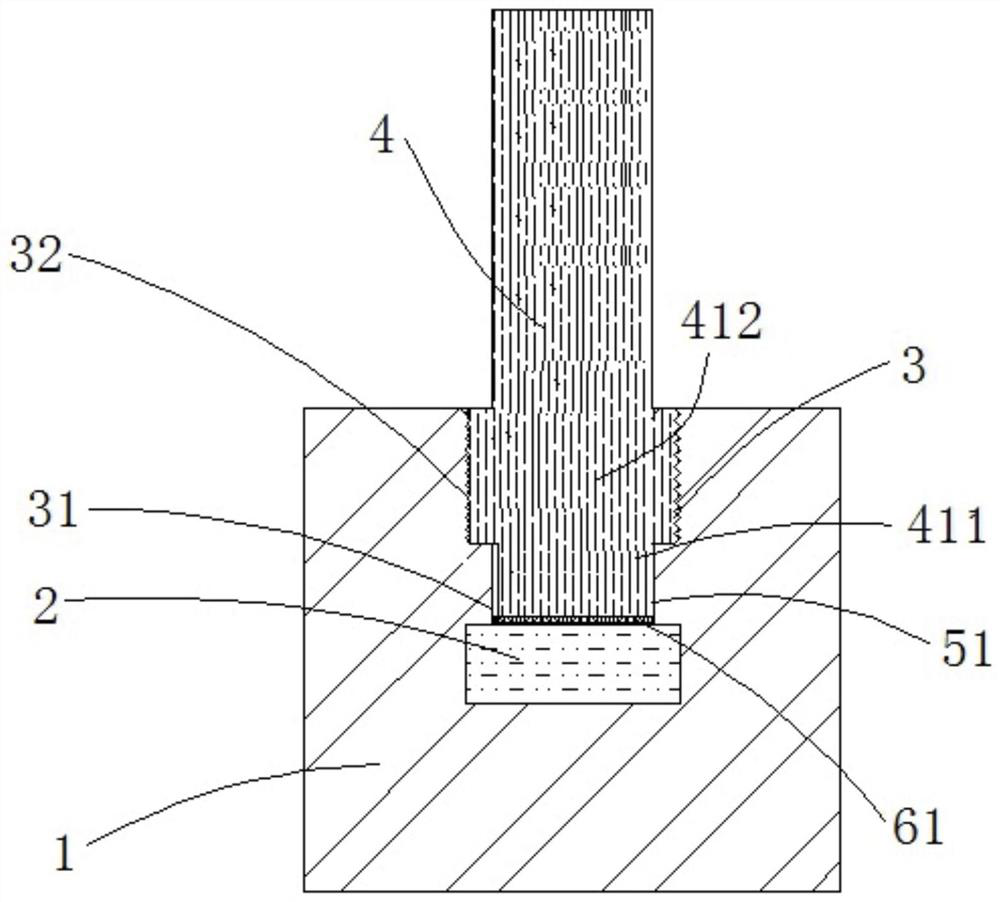

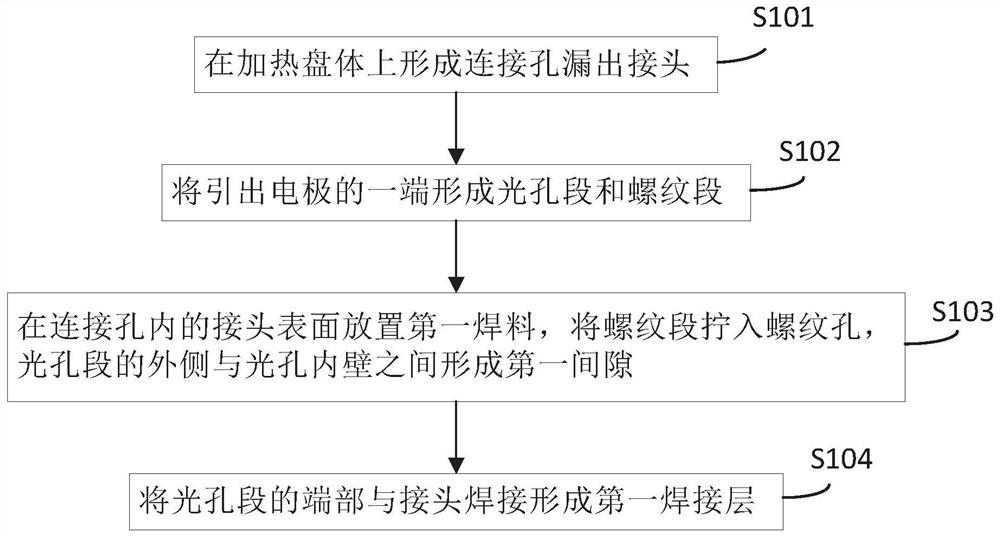

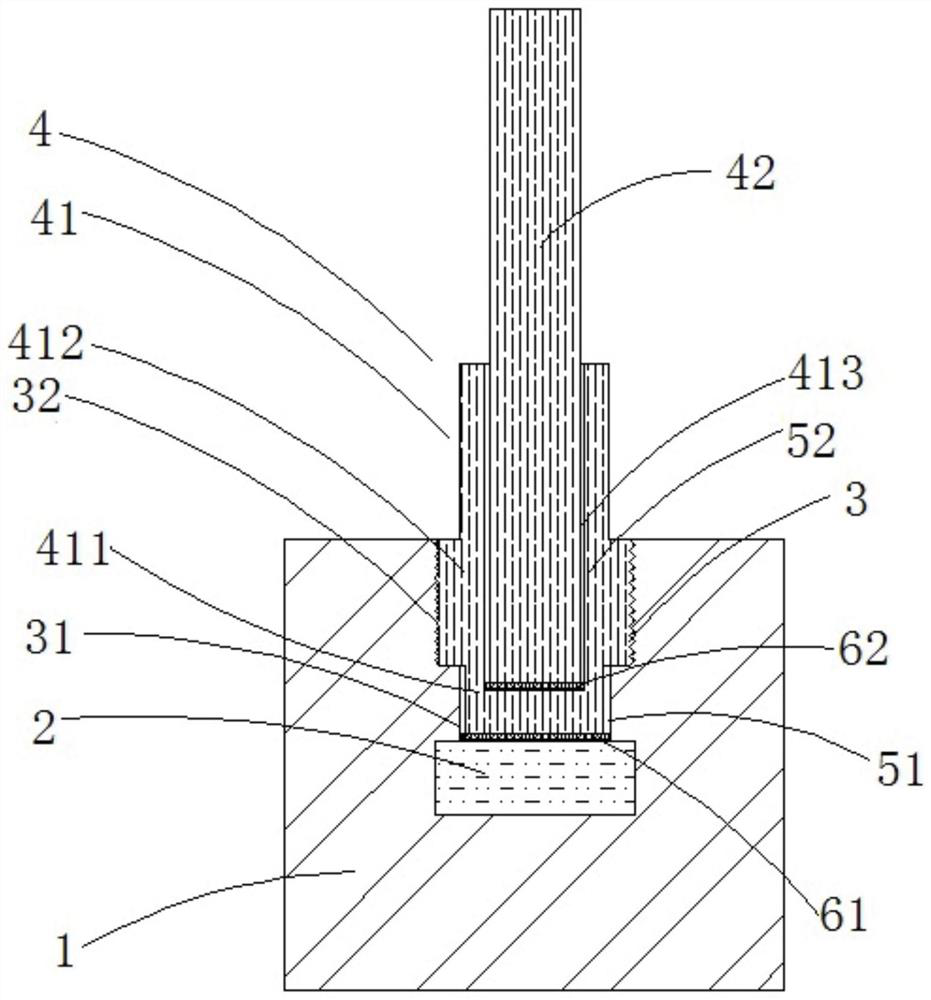

Ceramic heating plate extraction electrode connecting structure and connecting method thereof

PendingCN114158147AGuaranteed uniformityAvoid cracking caused by different thermal expansion coefficientsOhmic-resistance electrodesThermal dilatationCeramic composite

The invention discloses a ceramic heating plate extraction electrode connecting structure and a connecting method thereof.The ceramic heating plate extraction electrode connecting structure comprises a connector, an extraction electrode and a connecting hole which are buried in a ceramic base body, the extraction electrode comprises an electrode pipe section and an electrode rod section, and a first gap is formed between the electrode pipe section and the connecting hole; and a second gap is arranged between the electrode rod section and the electrode tube section, and the width of the gap can ensure the uniformity of heat conduction while avoiding the cracking phenomenon caused by thermal expansion. Ball-milling aluminum oxide powder, zirconium oxide powder and silicon oxide powder according to a certain proportion by using ethanol as a medium, spraying the ball-milled powder on the connecting position of the connecting hole and the extraction electrode, drying to volatilize the ethanol, putting the whole part into a vacuum brazing furnace for brazing at the brazing temperature of 800-1200 DEG C, the vacuum degree of less than or equal to 10-4mmHg, and the heat preservation time of 10-180 minutes, so as to obtain a finished product. And after the heating is finished, cooling to room temperature under the protection of inert atmosphere to form the ceramic composite powder coating with 30-60% of voids.

Owner:SUZHOU KEY MATERIALS TECH

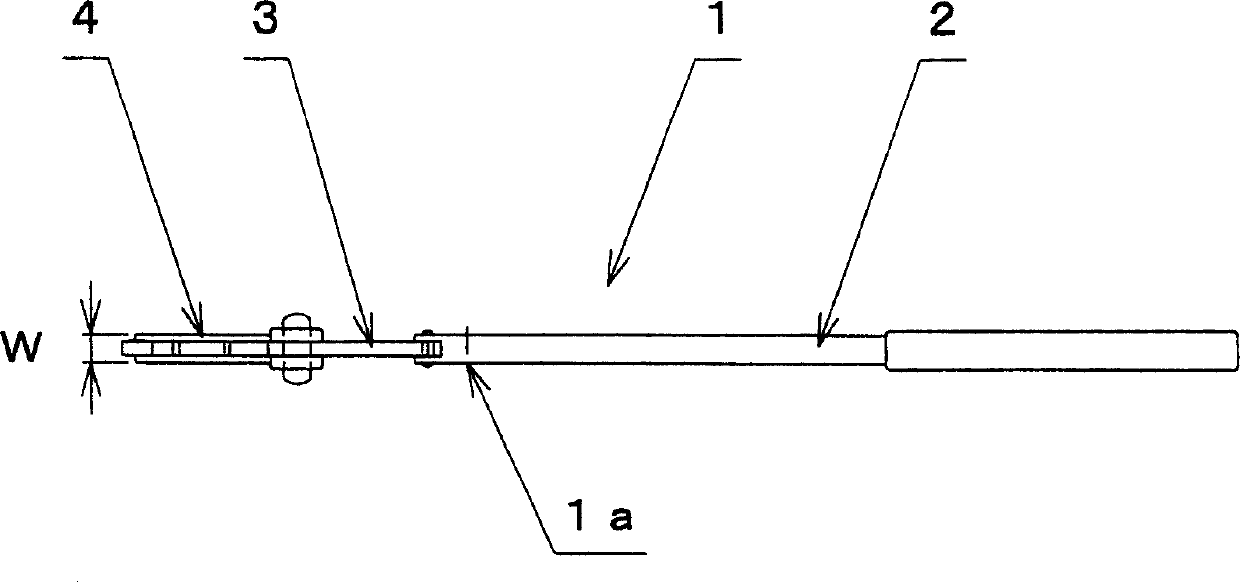

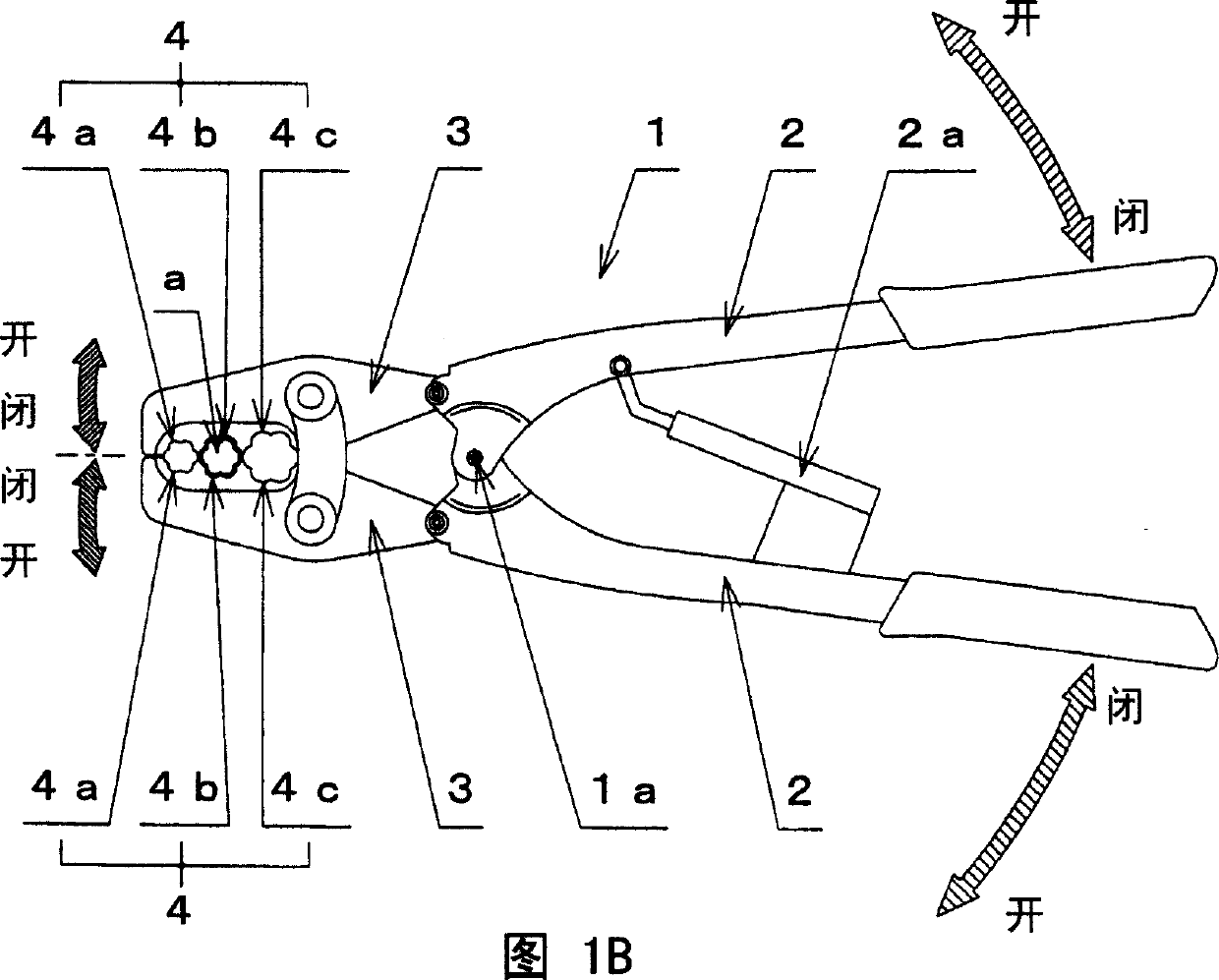

Cylinder sleeve compression method and compressor

InactiveCN1661868AIncrease contact areaImprove work efficiencyShaping toolsLine/current collector detailsCompression methodMechanical engineering

Provided is a cylindrical sleeve compression method for a twisted wire and a compressor wherein a conventional cylindrical sleeve is fitted and inserted and combined with the twisted wire, and the outer peripheral part of the sleeve is compressed in matching with the outer peripheral face of the twisted wire. The compressor has: a pair of handles and a pair of jaw parts which are operated by the pair of handles, is provided with several kinds of paired compression parts which are suited to the peripheral cross-sectional shape of the twisted wire at the center part of the pair of jaw parts, and which have a prescribed width; and corresponds to a plurality of sizes of the cylindrical sleeves. Because the whole peripheral face of the cylindrical sleeve is compressed by using the compression part of the compressor, a gap between the twisted wire and the cylindrical sleeve is made to be adhered, and a contact area is made increased.

Owner:木本昌范

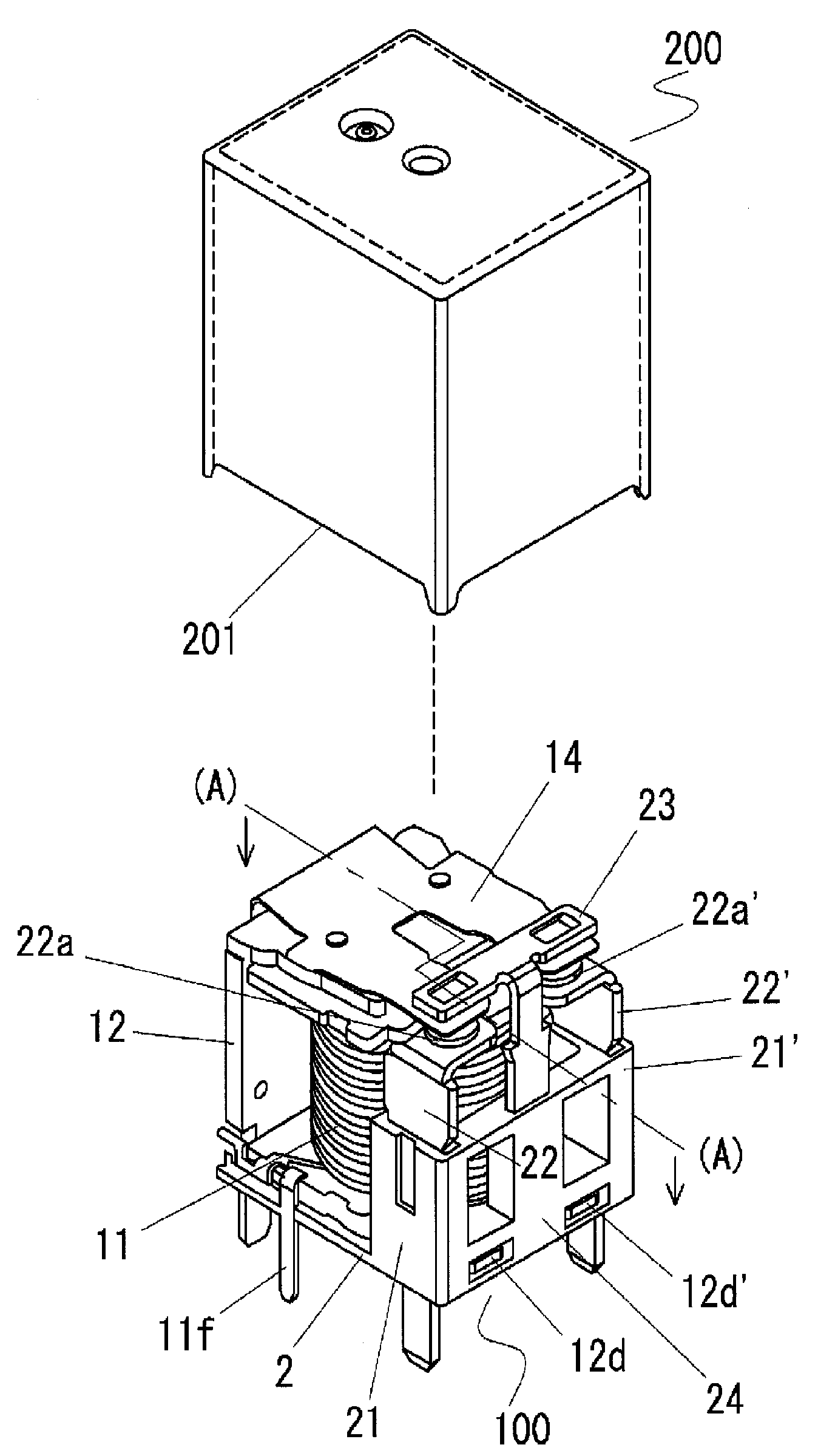

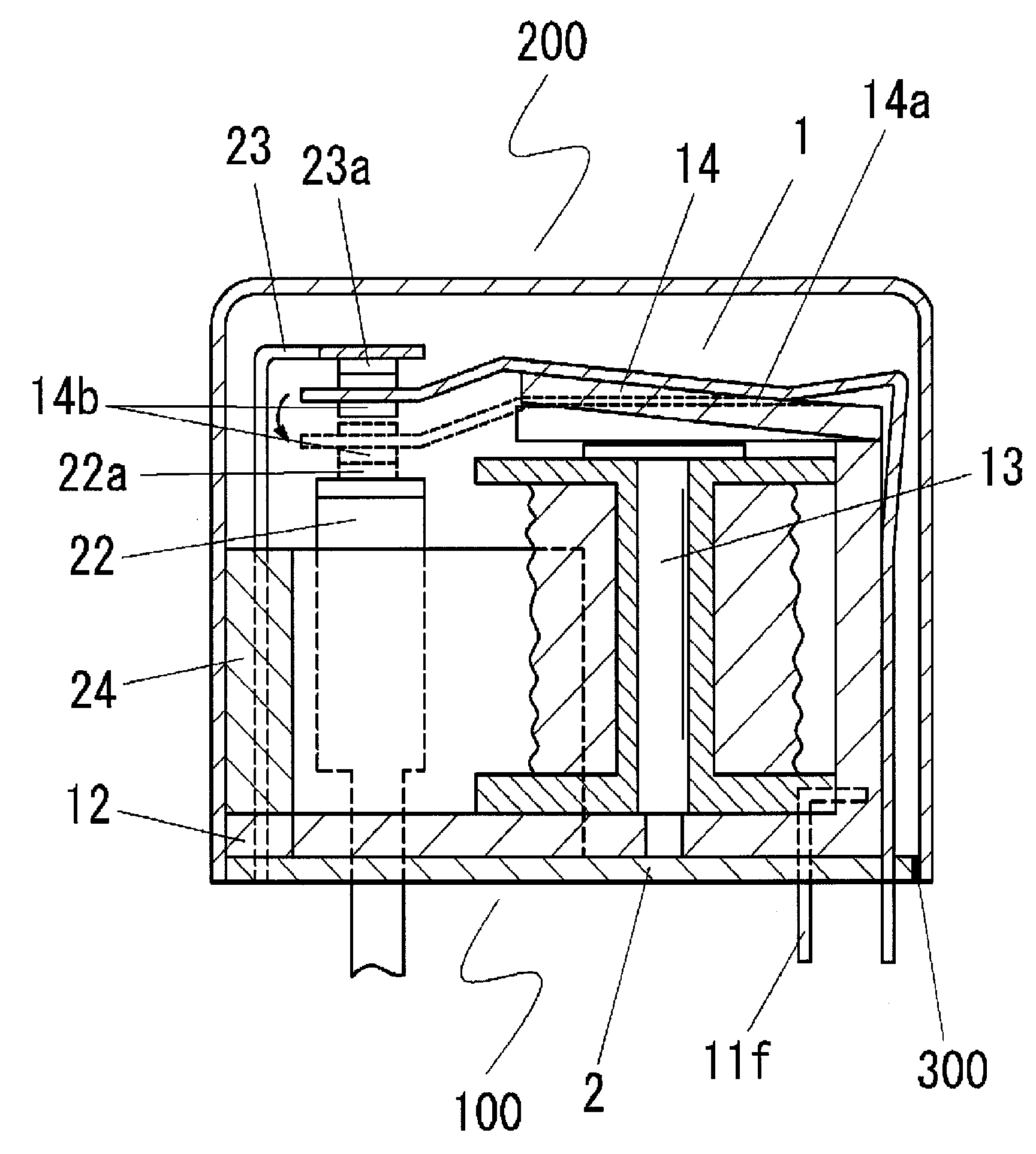

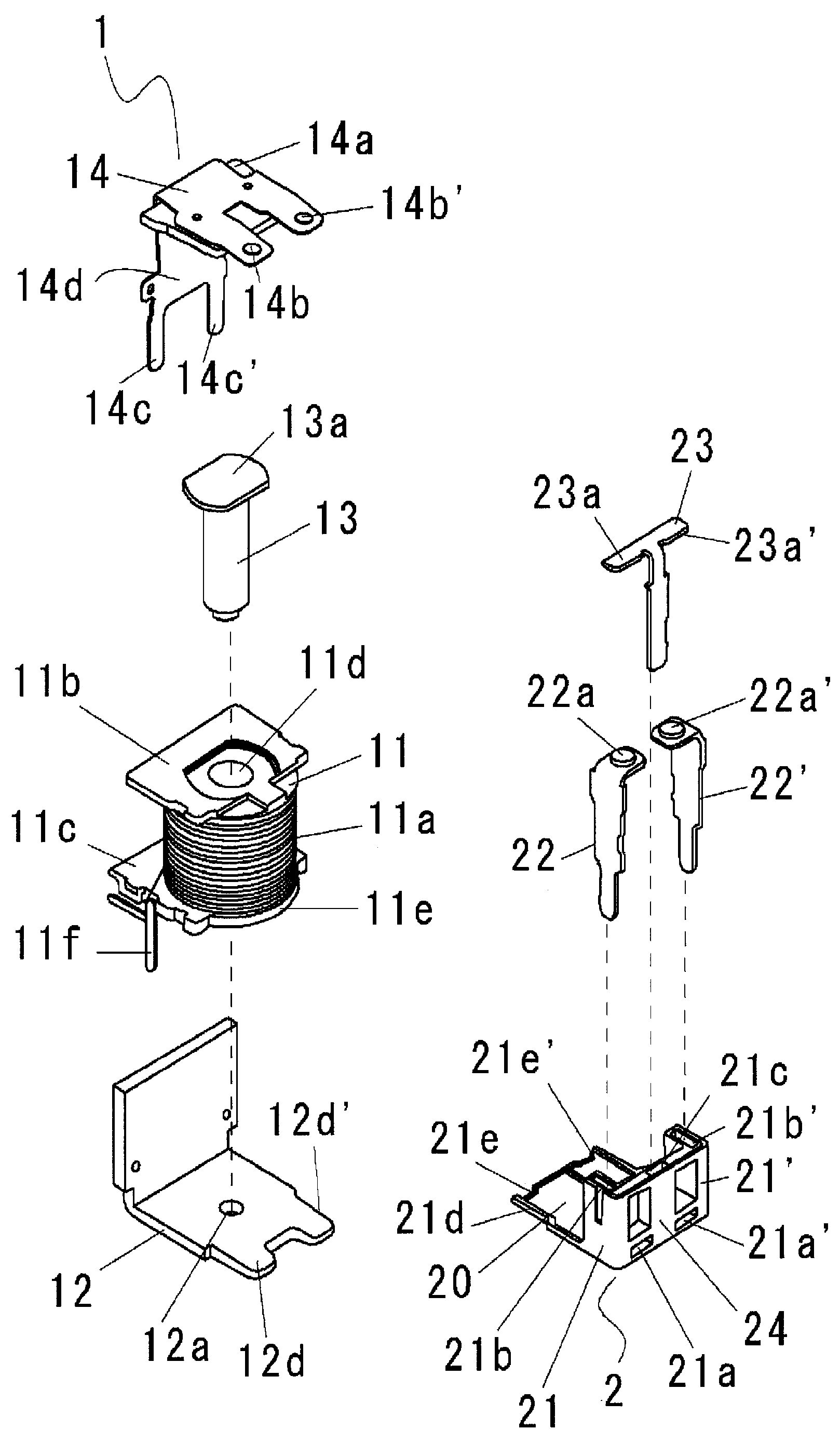

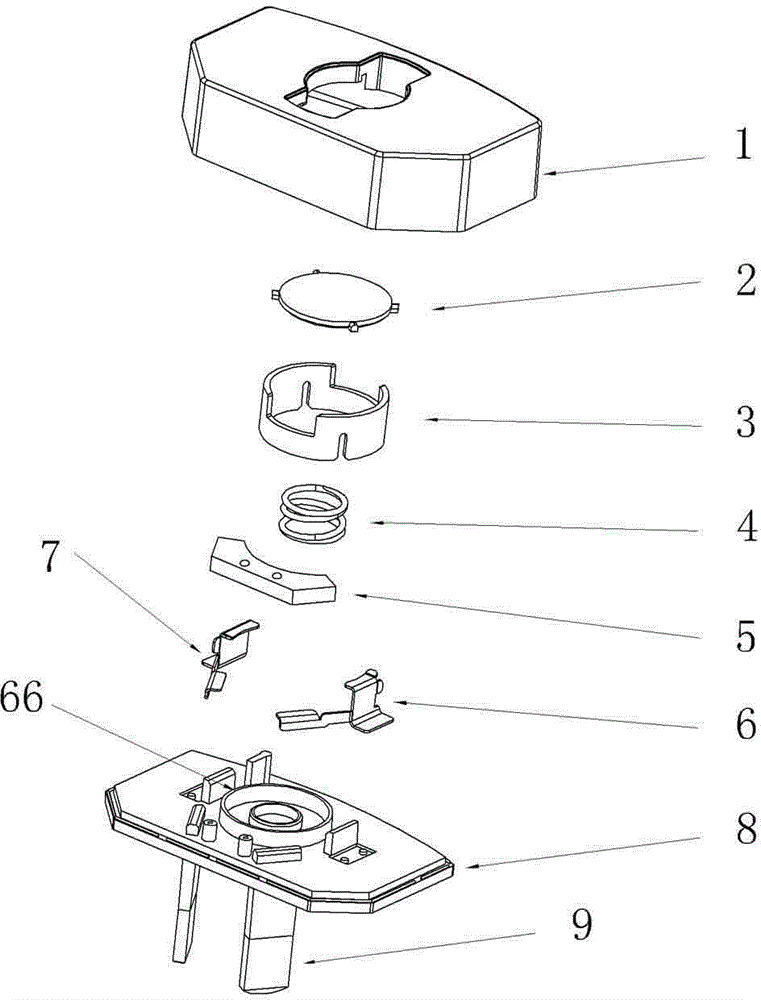

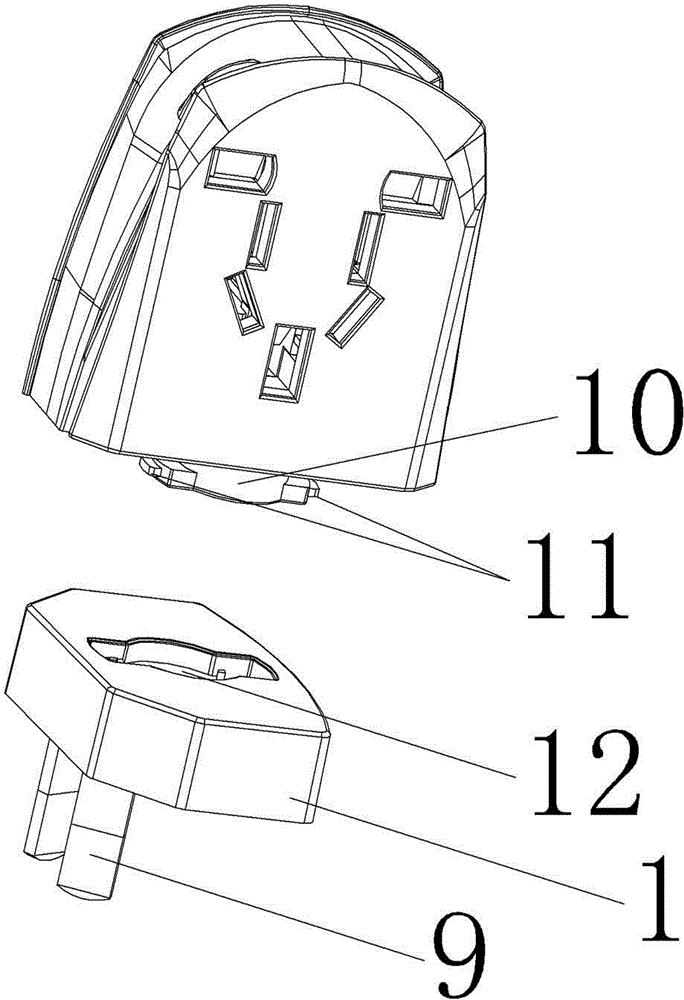

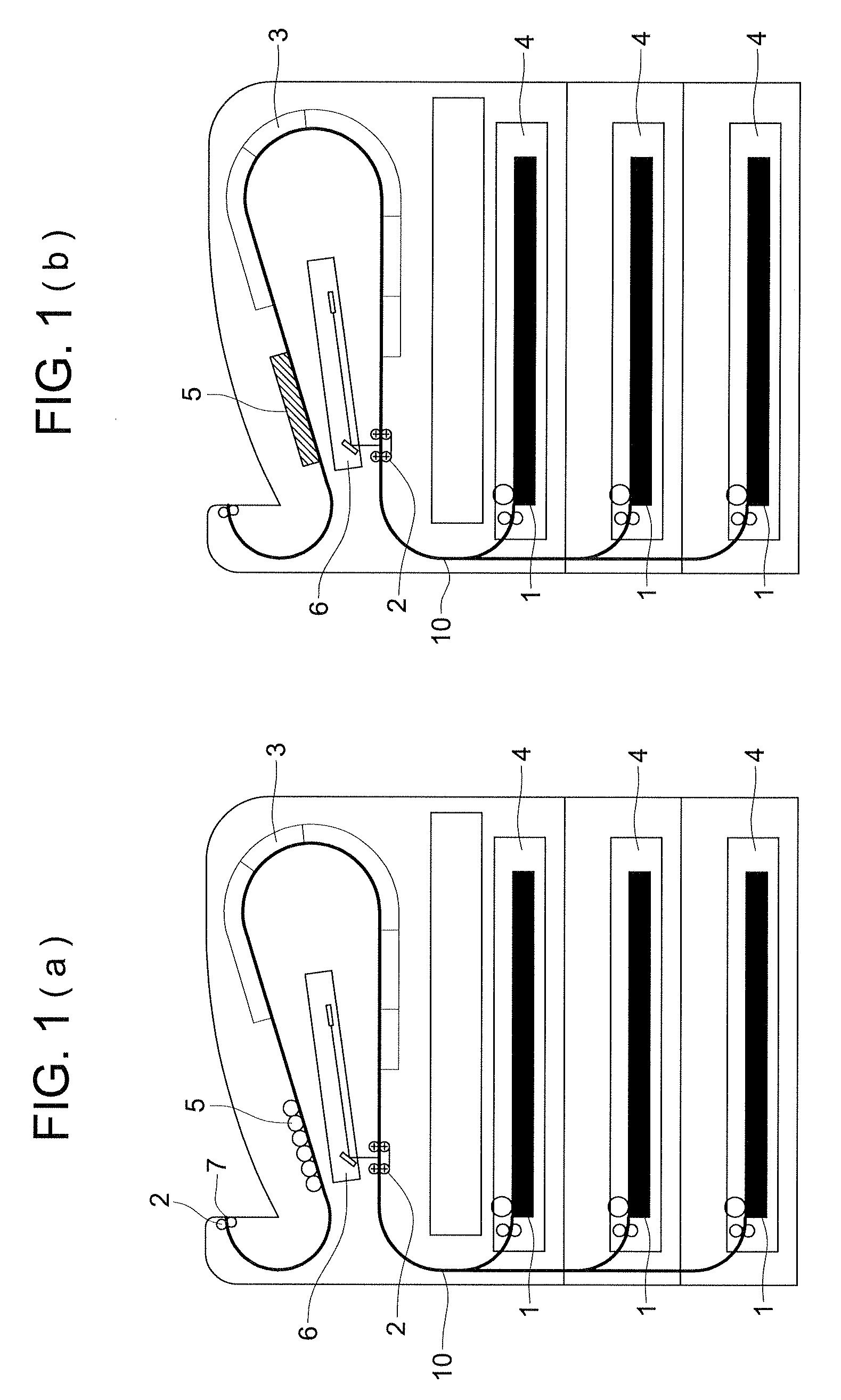

Electromagnetic relay

ActiveCN102113077ASufficient insulation distanceThe overall thickness is thinElectromagnetic relay detailsContactsPower flowElectromagnet

The issue is to provide a small electromagnetic relay with superior conduction characteristics that has high insulating capacity between two fixed contact terminals and between the fixed contact terminals and the backstop, and, by having few malfunction-generating factors, exhibits highly reliable contact between contacts. The electromagnetic relay is configured with an electromagnet block provided with a movable contact spring (14) that rocks by means of current flowing to a coil, two fixed contact terminals (22) and (22') that have fixed contacts, a backstop (23) that has two movable contact touch parts, and a base block (2) that holds thecomponents. The base block (2) has fixed contact terminal holding parts (21) and (21'), the base part (20) of which has a rectangular shape, and that hold the fixed contact terminals at two opposing sides of the rectangular shape, and a backstop holding part (24) that holds the backstop (23) in the middle of one side between the two sides.

Owner:IRMIN ELECTRONIC EQUIP CO LTD

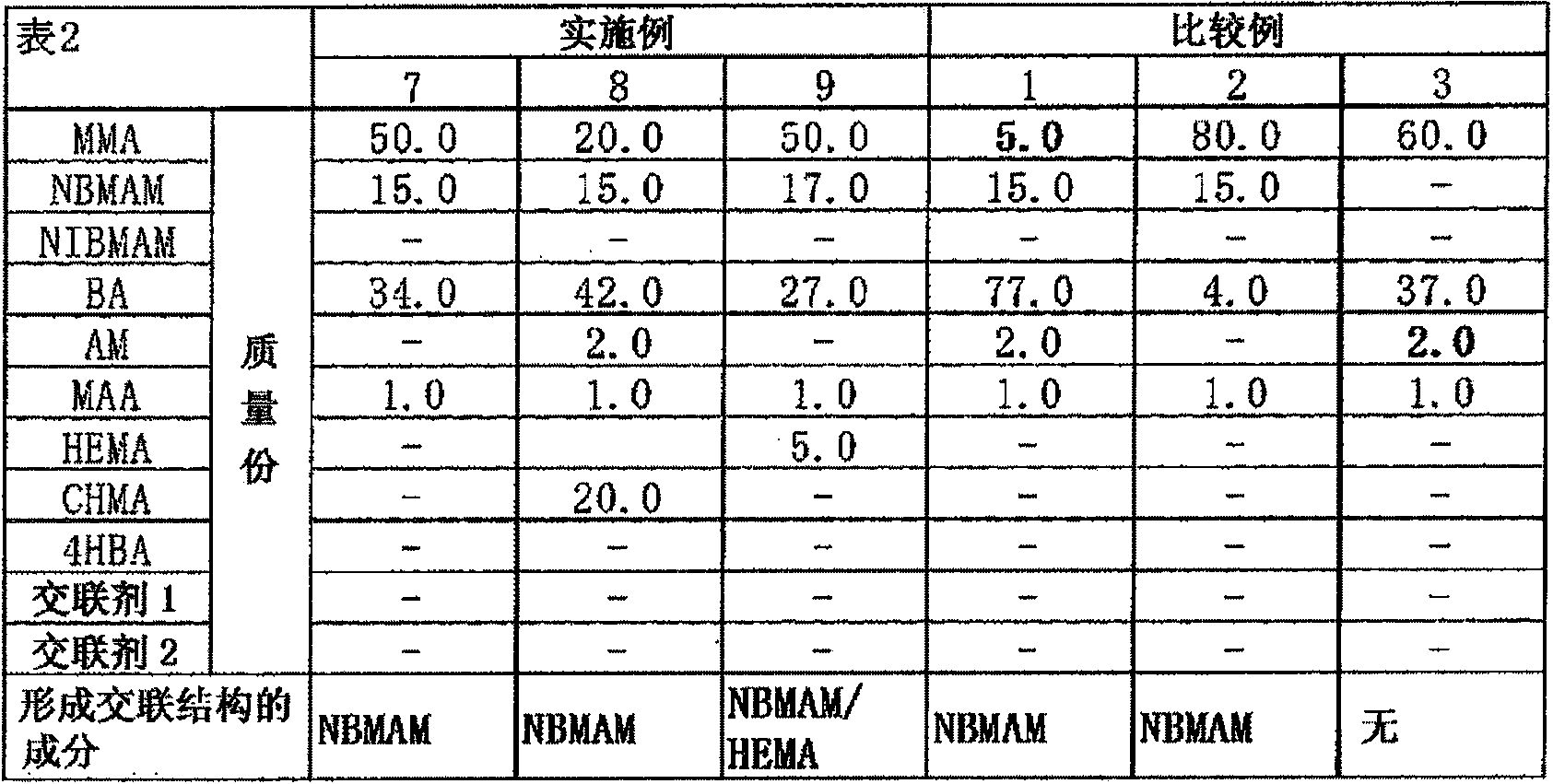

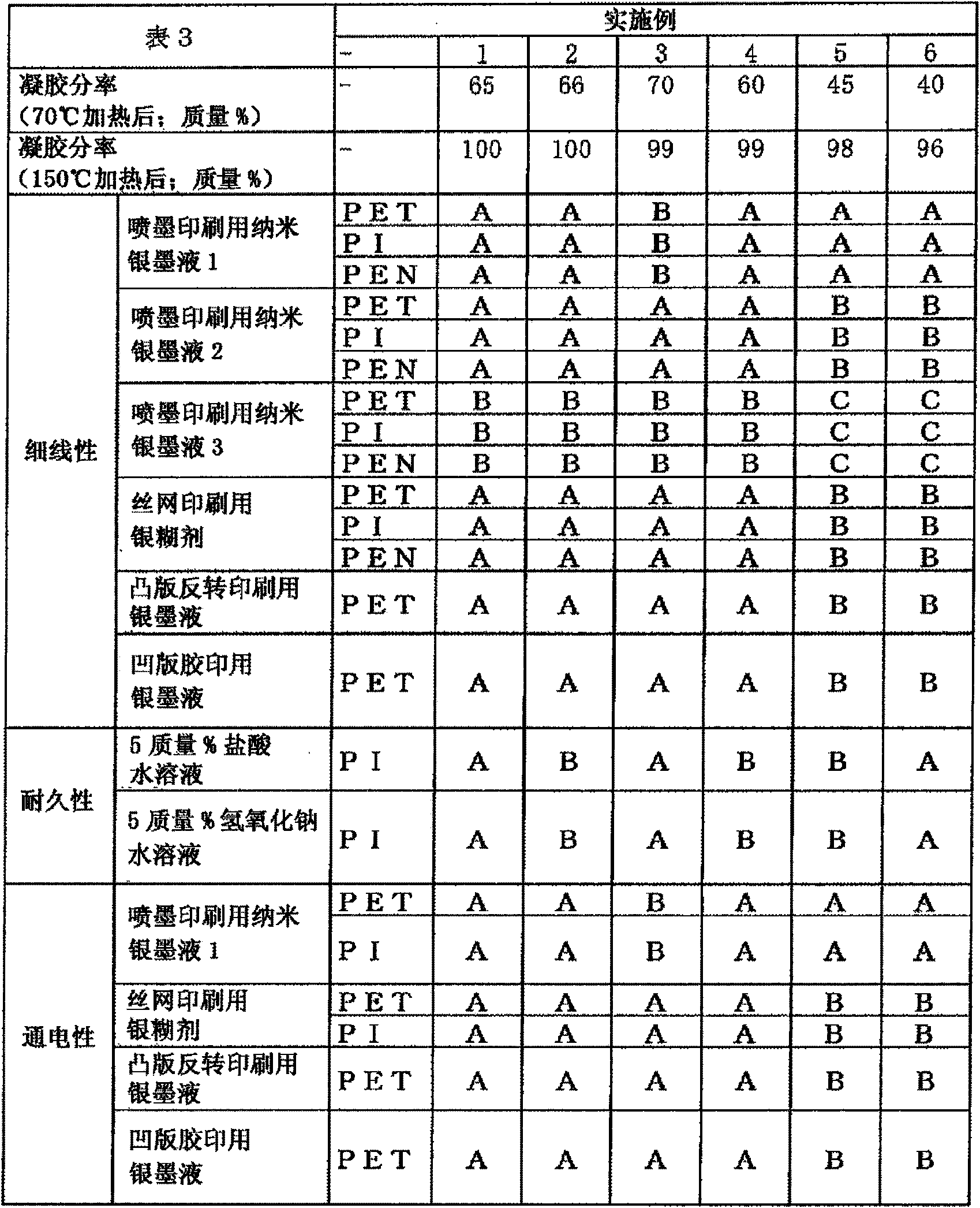

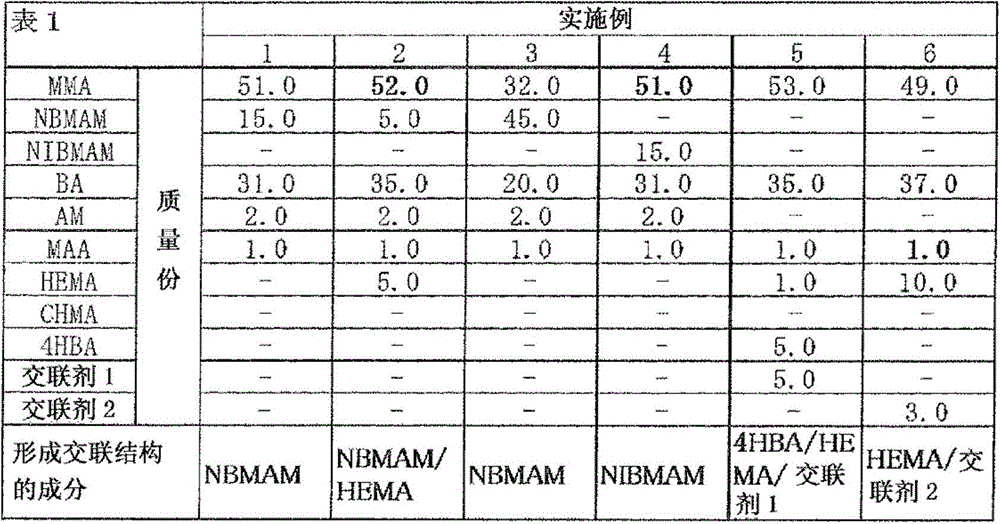

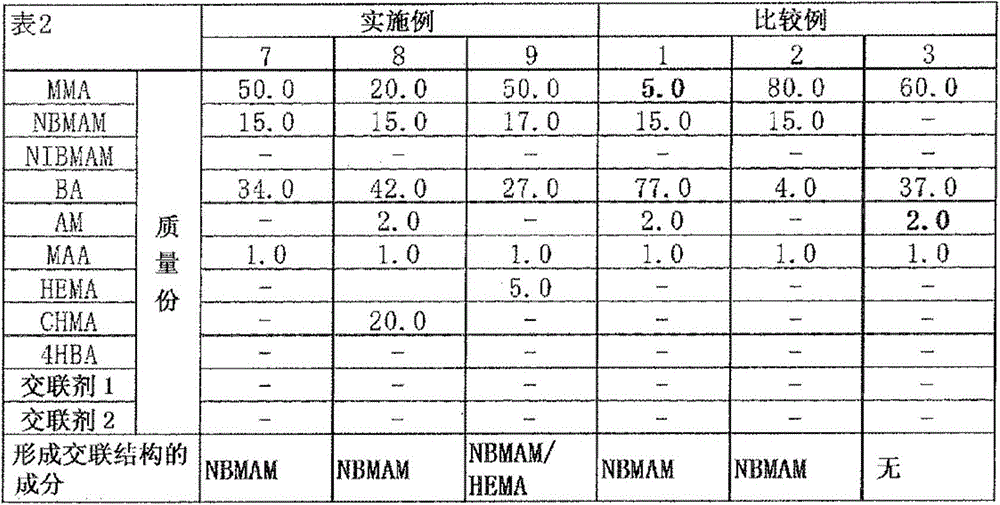

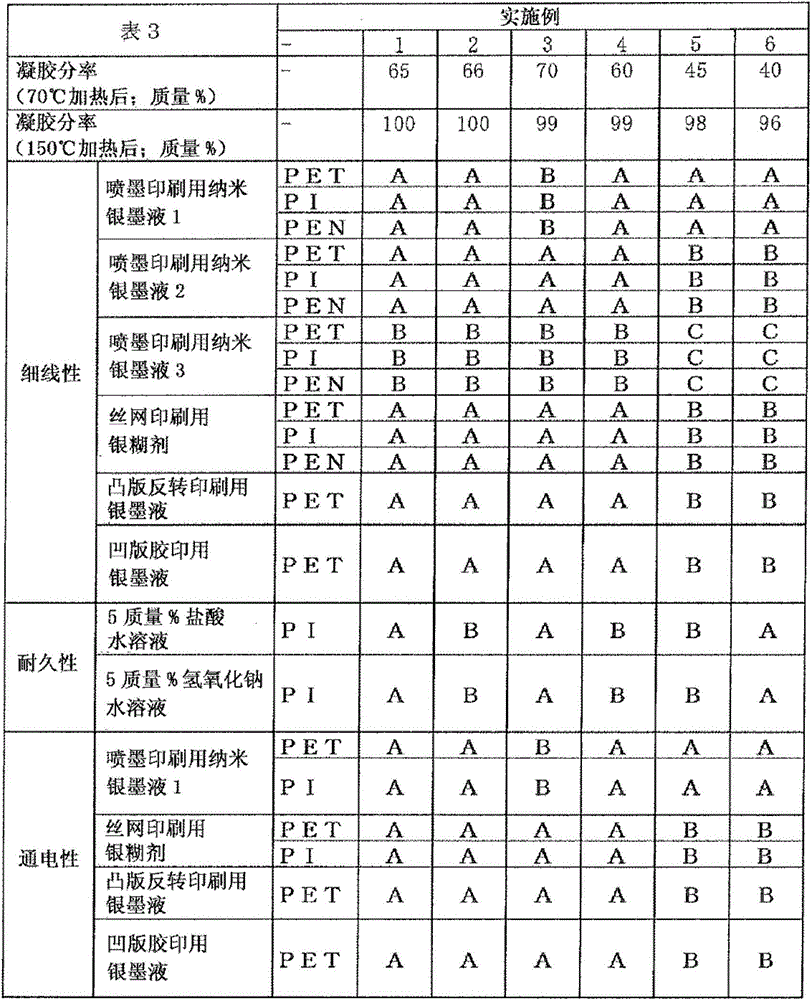

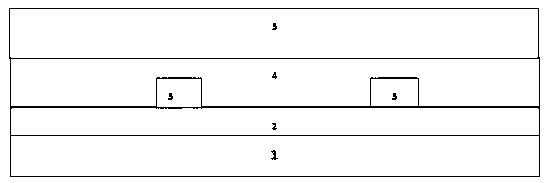

Conductive pattern and method for producing same

ActiveCN103535120AExcellent fine lineImprove electrification performancePrinted electric component incorporationConductive pattern formationCross-linkMethyl acrylate

Owner:DIC CORP

Combinable-type power adapter

ActiveCN104064907ASimple structureReduce manufacturing costCoupling contact membersTwo-part coupling devicesConvertersElastomer

The invention relates to a power plug, and specifically relates to a combinable-type power adapter. The combinable-type power adapter is provided with a clamp position on a power supply conversion bottom shell. Metal pins on the clamp position abut against a clamp position groove to enable a safety rotation valve to rotate 90 degrees, then, to be buckled at the lower ends of the bending portions of electrode sheets of a plug pin module and to be electrically connected with the electrode sheets of the plug pin module, thereby enabling the electrical connection to the firmer and more reliable; an elastic sheet is arranged at the lower portion of the safety rotation valve; an elastic body is arranged between the elastic sheet and the plug pin module bottom shell; and when a power supply conversion module assembly is assembled into a plug pin module assembly, the elastic sheet compresses the elastic body under the action of the power supply conversion module assembly, and the elastic body counter-acts on the elastic sheet, thereby helping to improve the power-on effect which can be influenced by loose fit due to the wearing of the metal pins and the electrode sheets of the plug pin module. The power adapter is simple in structure, low in production cost and convenient to operate.

Owner:刘宇敦

Display panel and manufacturing method thereof

InactiveCN109116605AWill not affect the electrical connection effectThorough electrical connectionSolid-state devicesNon-linear opticsMetalMaterials science

The invention discloses a display panel and a manufacturing method thereof. The display panel comprises a first substrate; a metal layer arranged on the first substrate, wherein the metal layer comprises an electric contact region for electrically connecting with a corresponding conductive component; and a protective layer covered on the metal layer and avoiding the electric contact region, wherein the protective layer is located on the metal layer, the metal layer can be effectively prevented from corroding due to the protection of the protective layer with a certain thickness when performingthe anode etching, so that the corrosion on the circuit is reduced, and the circuit break caused by short-circuit due to large resistance is avoided.

Owner:HKC CORP LTD

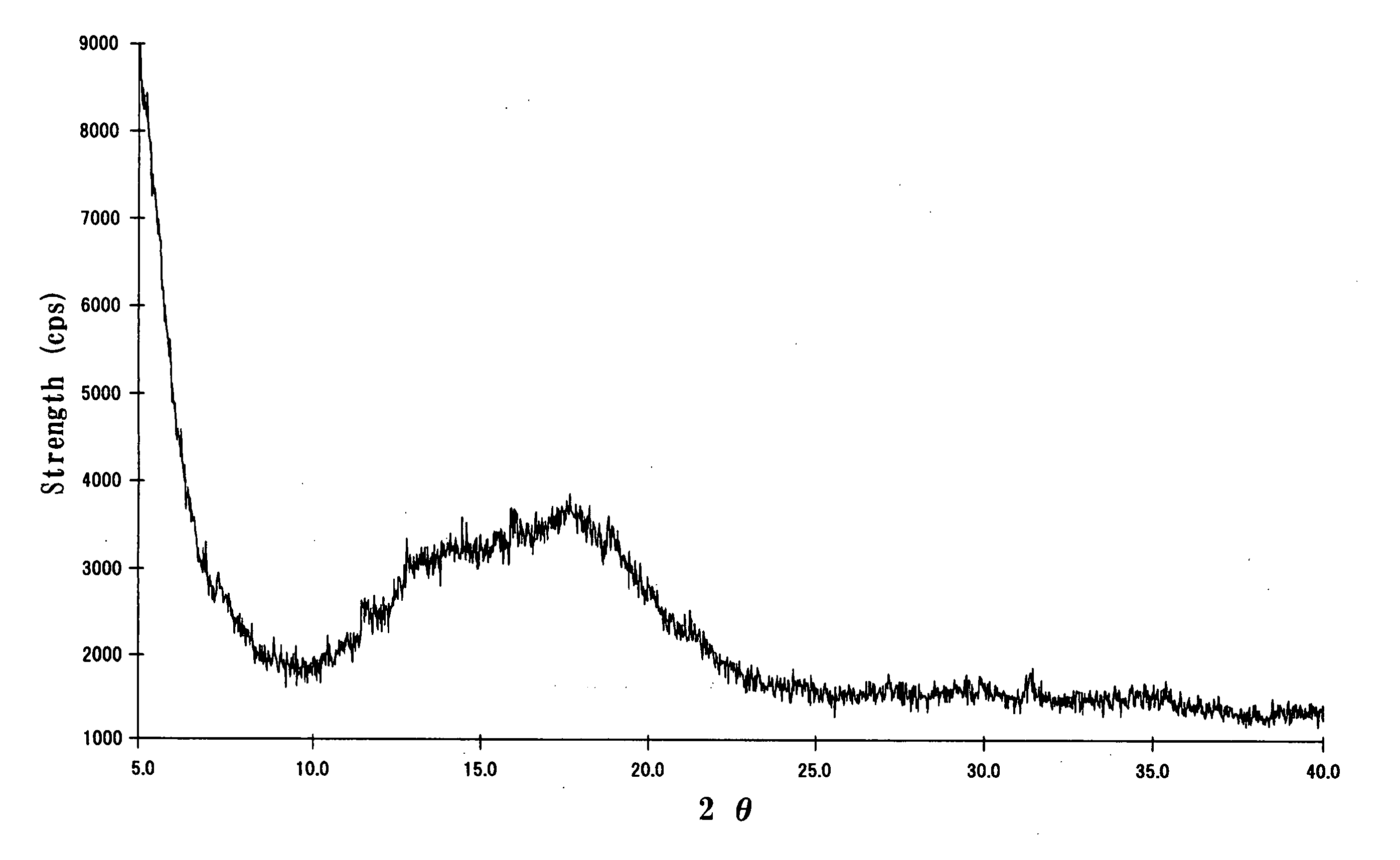

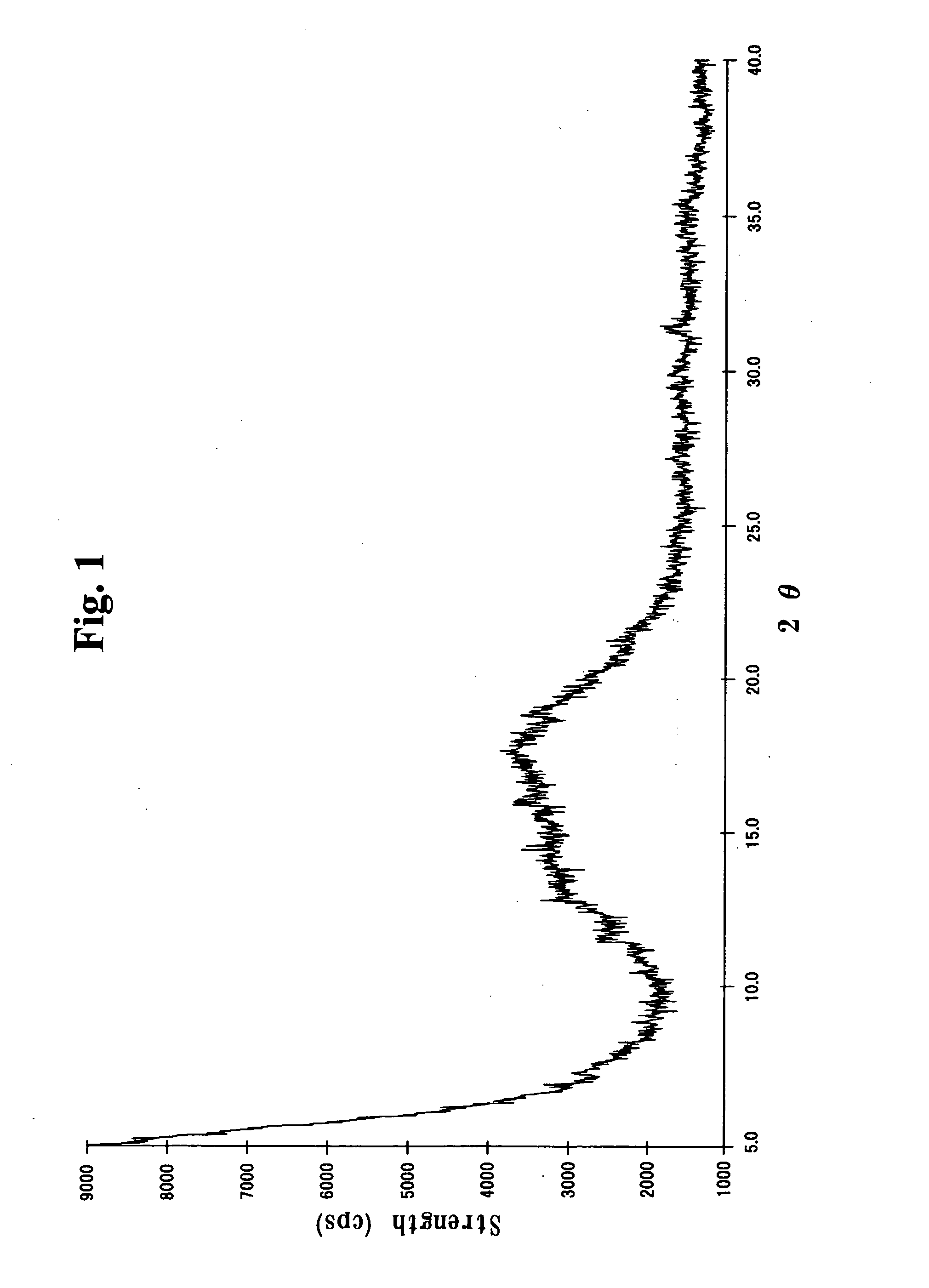

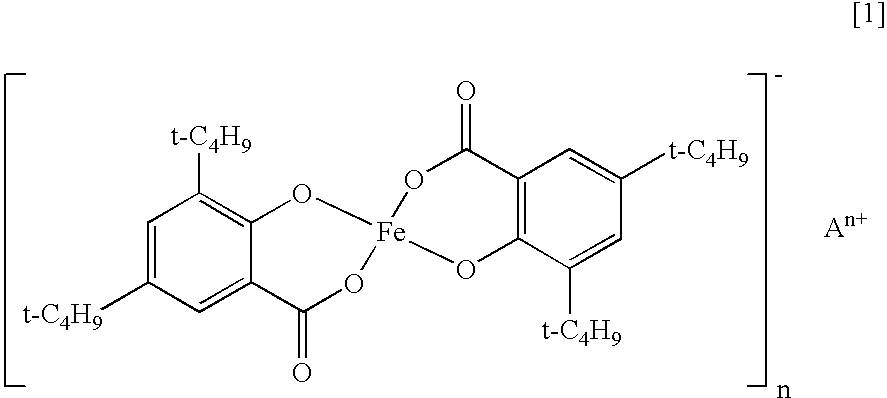

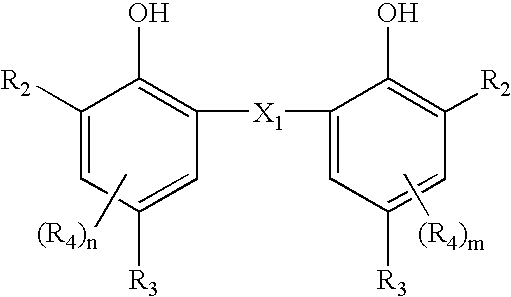

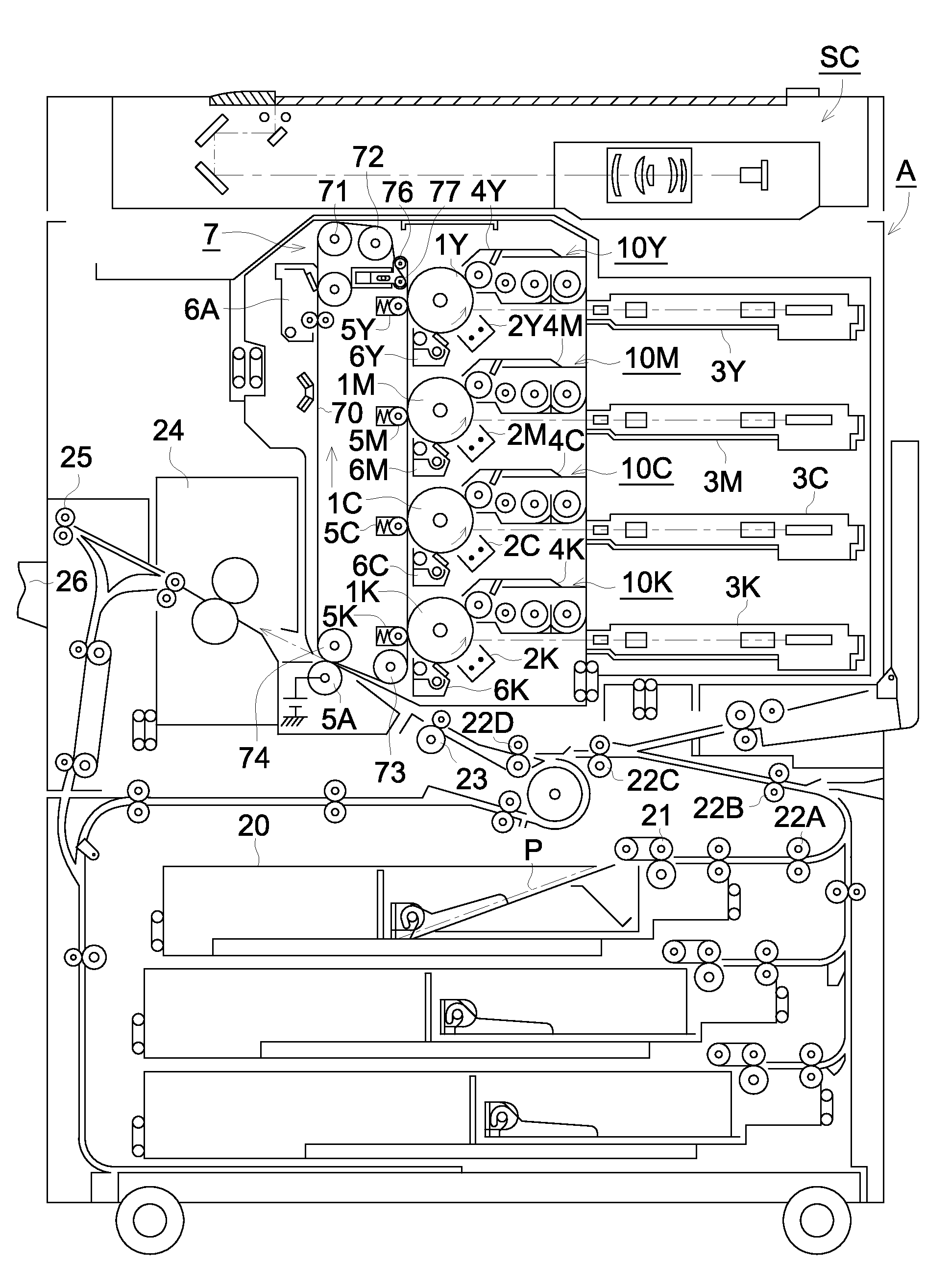

Toner for electrostatic image development

A toner for electrostatic image development comprises components of a charge control agent, a binding resin, and colorant. The charge control agent is an aromatic-oxy-carboxylic acid iron-including compound. The toner has its particle size distribution with: a volume-average particle diameter (D50) ranging from 5 to 13 microns that is determined by a cumulative 50% volume particle diameter from a largest particle diameter, and a degree of particle size dispersion (D25 / D75) ranging from 1.20 to 1.50 that is calculated by a cumulative 25% volume particle diameter (D25) and a cumulative 75% volume particle diameter (D75) as same as the above determined D50.

Owner:ORIENT CHEM INDS

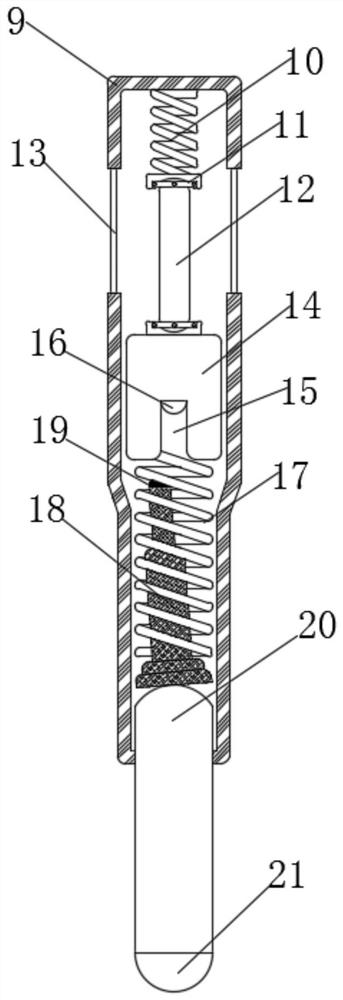

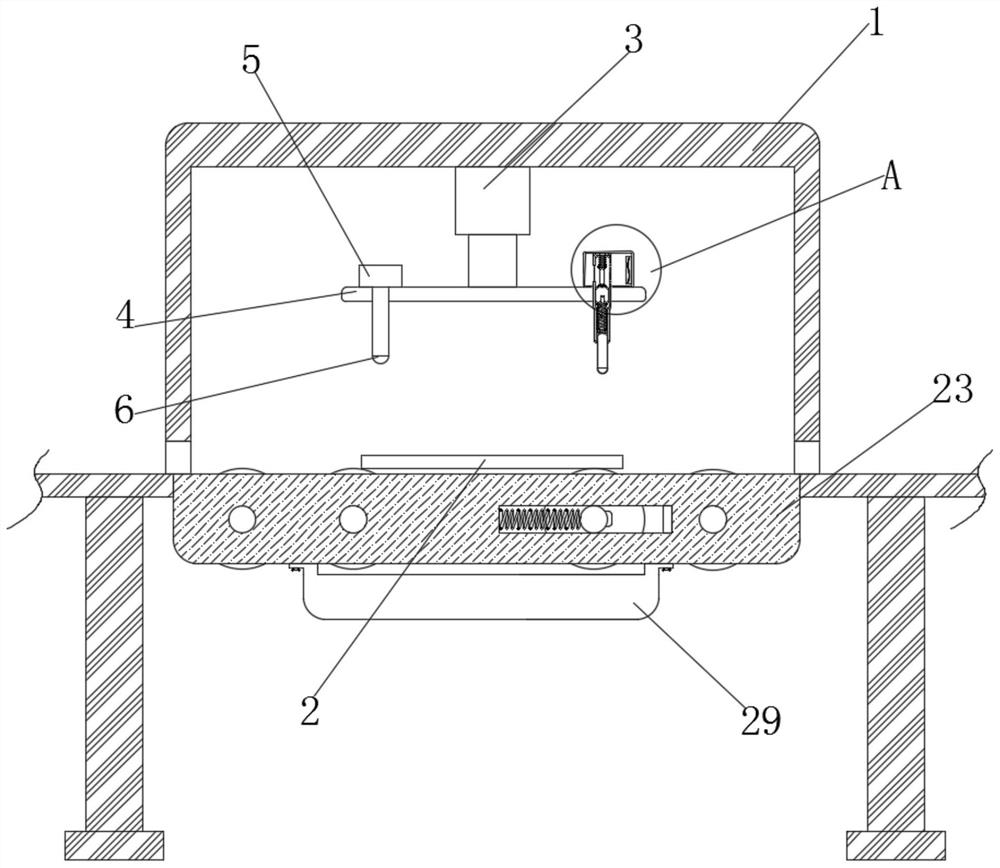

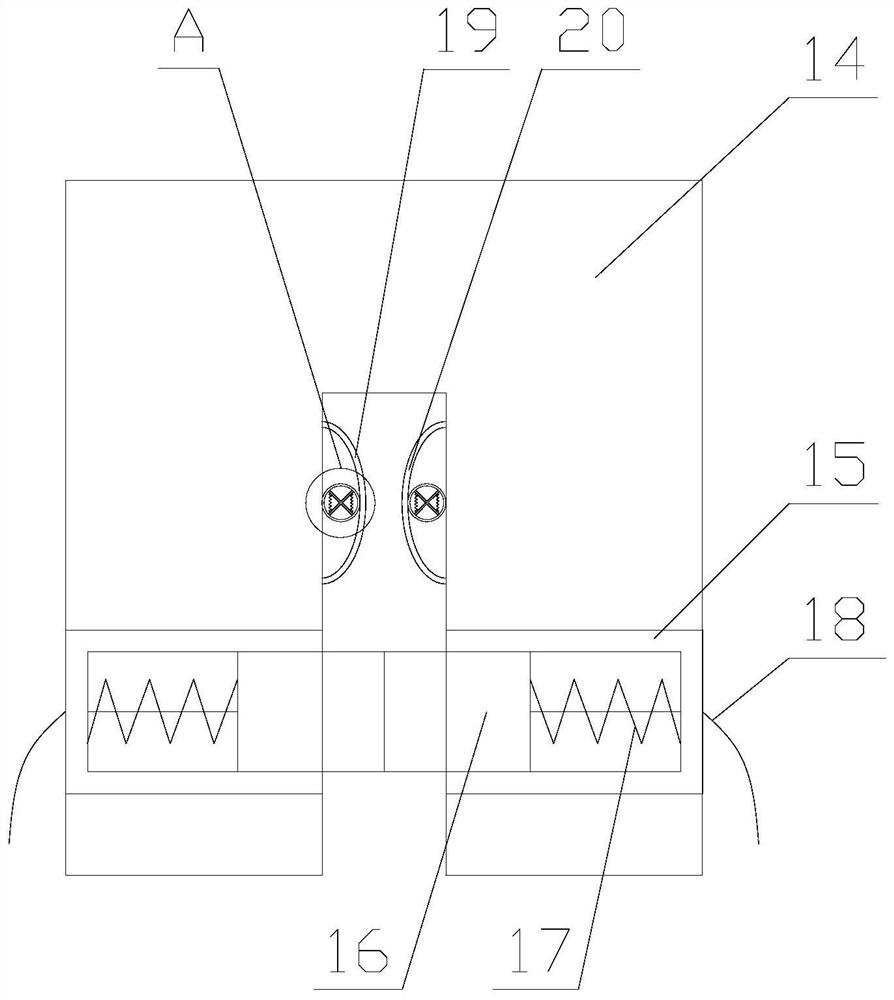

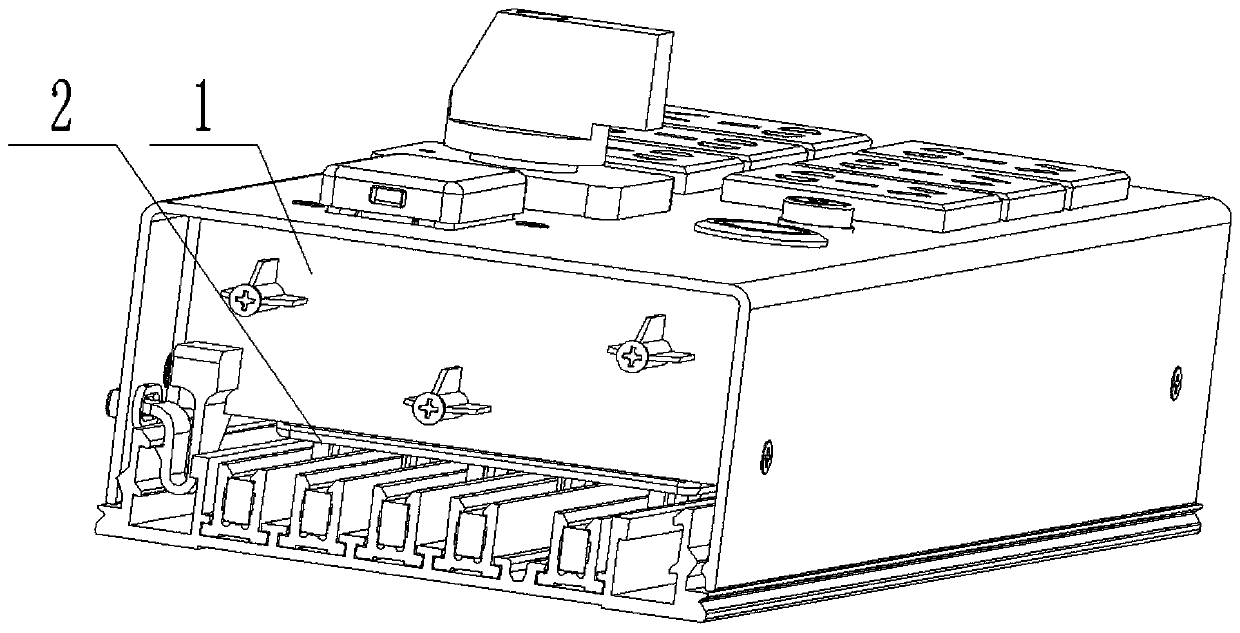

Intelligent detection circuit board energization device

ActiveCN112474434AImprove electrification performanceImprove work efficiencyPrinted circuit testingSortingElectric lightEngineering

The invention relates to the technical field of circuit boards, and discloses an intelligent detection circuit board energization device. The device comprises a casing and a circuit board, the upper end of the casing is fixedly connected with a telescopic device, the bottom end of the telescopic device is fixedly connected with a first long plate, the left side of the first long plate is fixedly connected with a power generation device, the bottom end of the power generation device is fixedly connected with a first contact, and the right side of the first long plate is fixedly connected with afirst sealing shell. According to the intelligent detection circuit board energization device. A sliding block extrudes a first spring to enable an electric lamp to be matched with a baffle, lamplight penetrates through a glass baffle to irradiate a photoresistor, the photoresistor is electrically connected with an electromagnetic device, the electromagnetic device enables a second roller to slide in a second notch by attracting a first magnetic block, the circuit board with good power on surface falls into the collecting device,unqualified products and qualified products in the circuit boardare intelligently separated, and the effect of collecting the circuit board is achieved.

Owner:吉安市瑞鸿电子有限公司

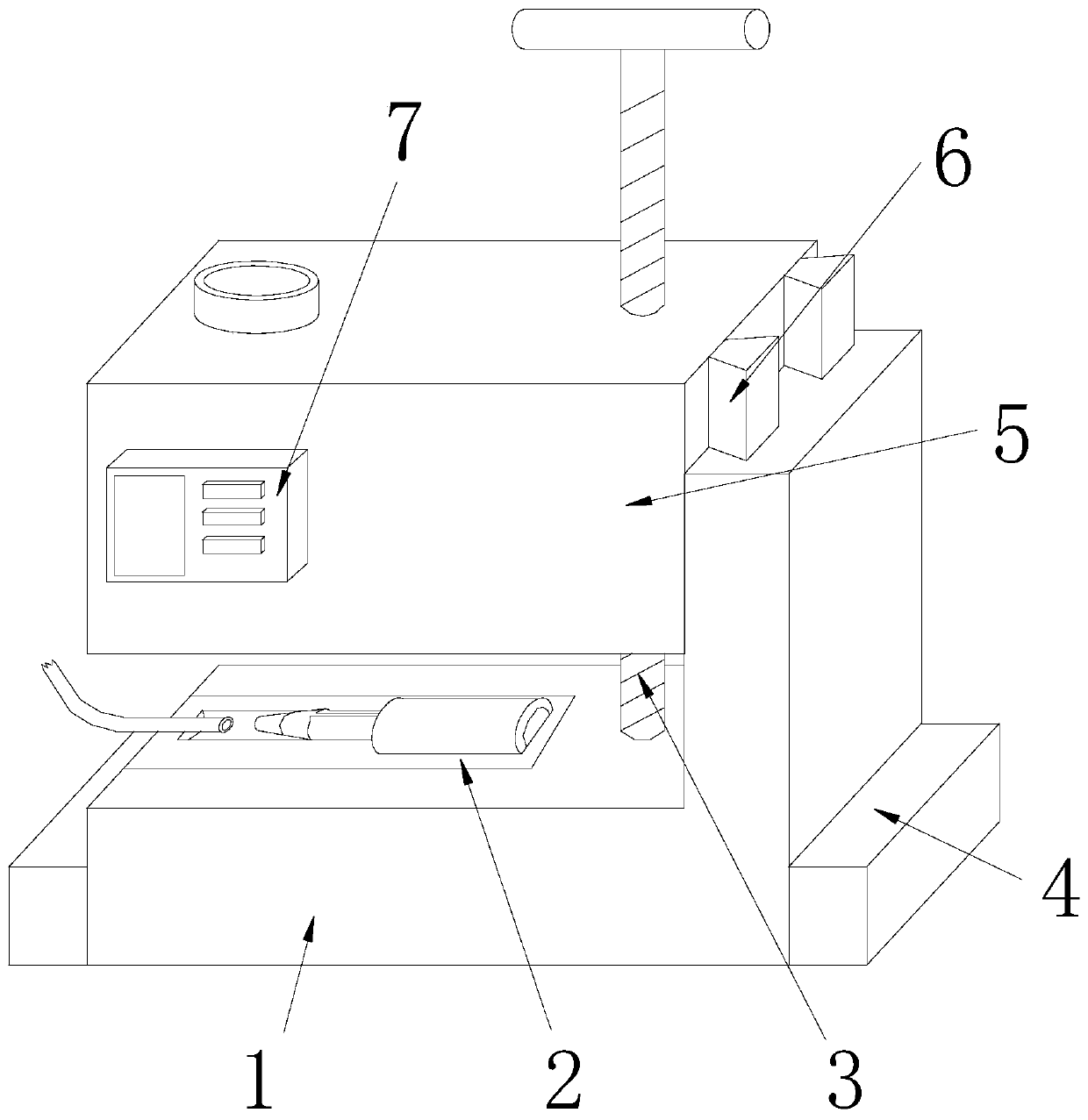

Hot-melt adhesive type aluminum alloy terminal pressing mold for wire harness fixing

ActiveCN110071407AImprove the fixing strengthFlexible rotationLiquid surface applicatorsDustproof/splashproof/drip-proof/waterproof/flameproof connectionCopper wireAlloy

The invention discloses a hot-melt adhesive type aluminum alloy terminal pressing mold for wire harness fixing. The structure comprises a worktable, a lower pressing mechanism, a rotating rod, a sidefixing plate, an upper stable pressing mechanism, a trapezoidal limit column and a control panel, wherein the lower pressing mechanism is embedded on the upper surface of the worktable. In the hot-melt adhesive type aluminum alloy terminal pressing mold for wire harness fixing provided by the invention, the sealing groove and the sol pressing groove seal and fix the wire harness and the aluminum alloy terminal by providing the upper stable pressing mechanism, which facilitates the injection and pressing at the joint of the wire harness and the aluminum alloy terminal; the conical teeth and thepressing cylinder cooperate with each other to firstly press the aluminum foil and then extrude the surface of the aluminum foil to form a pit, thereby improving the fixing of the aluminum foil to the copper wire and improving the tensile strength with closer contact of the two and better power-on performance; and the multi-page runner and the rebound rod cooperate to control the falling speed and the amount of falling of the size such that the size just wraps the bare copper wire at the joint and the equipment can also be used normally in a humid environment while increasing tensile strength.

Owner:浙江凯思特科技有限公司

Silver salt photothermographic dry imaging material

InactiveUS20070054225A1Improve stabilityReduce foggingPhotothermographic systemsSilver halide emulsionsSilver behenateCompound (substance)

A silver salt photothermographic dry imaging material is disclosed, comprising on a support a light-sensitive layer comprising light-insensitive aliphatic carboxylic acid silver salt particles, light-sensitive silver halide grains, a binder and a reducing agent, wherein the reducing agent comprises a compound represented by the following formula and 80 to 100 mol % of total aliphatic carboxylic acid silver salts constituting the aliphatic carboxylic acid silver salt particles is accounted for by silver behenate.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Magnetic toner composition having superior electrification homogeneity

InactiveUS7070895B2Improve electrification performanceReduce the differenceDevelopersAverage diameterEngineering

The present invention relates to a magnetic toner composition, and more particularly to a magnetic toner composition having an improved chargeability and excellent uniform chargeability, and that is capable of reducing a difference in electrostatic charge between a toner remaining in a cartridge or in a developing unit and that of a newly supplied toner. A magnetic toner composition of the present invention comprises magnetic toner particulate comprising a binder resin and a magnetic substance, a conductive fine powder having a specific surface area of 30 to 300 m2 / g, a hydrophobic silica having a specific surface area of 100 to 240 m2 / g, and an inorganic fine powder having an average diameter of 0.1 to 4.O μm.

Owner:LG CHEM LTD

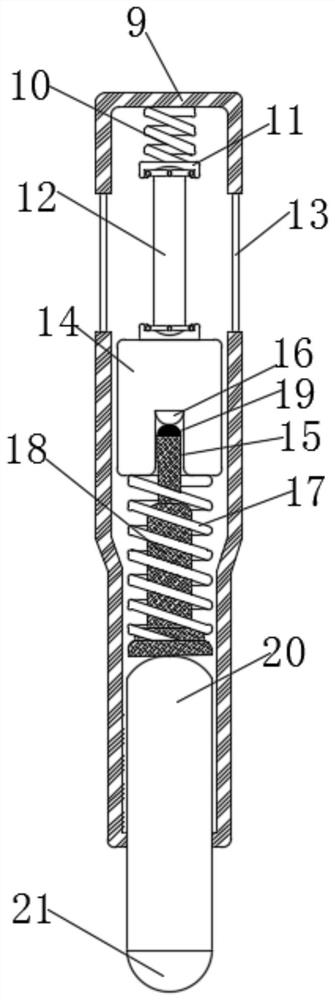

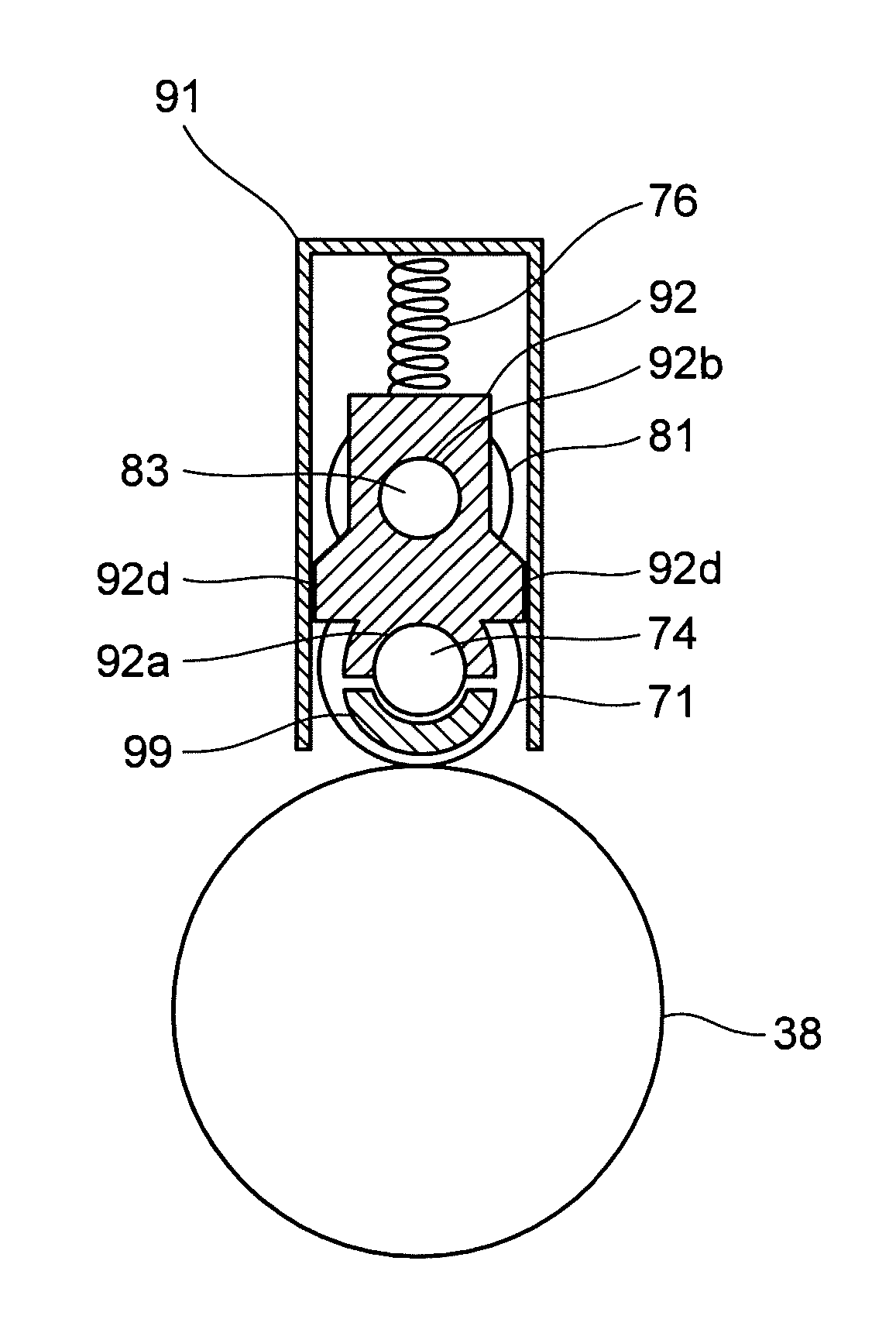

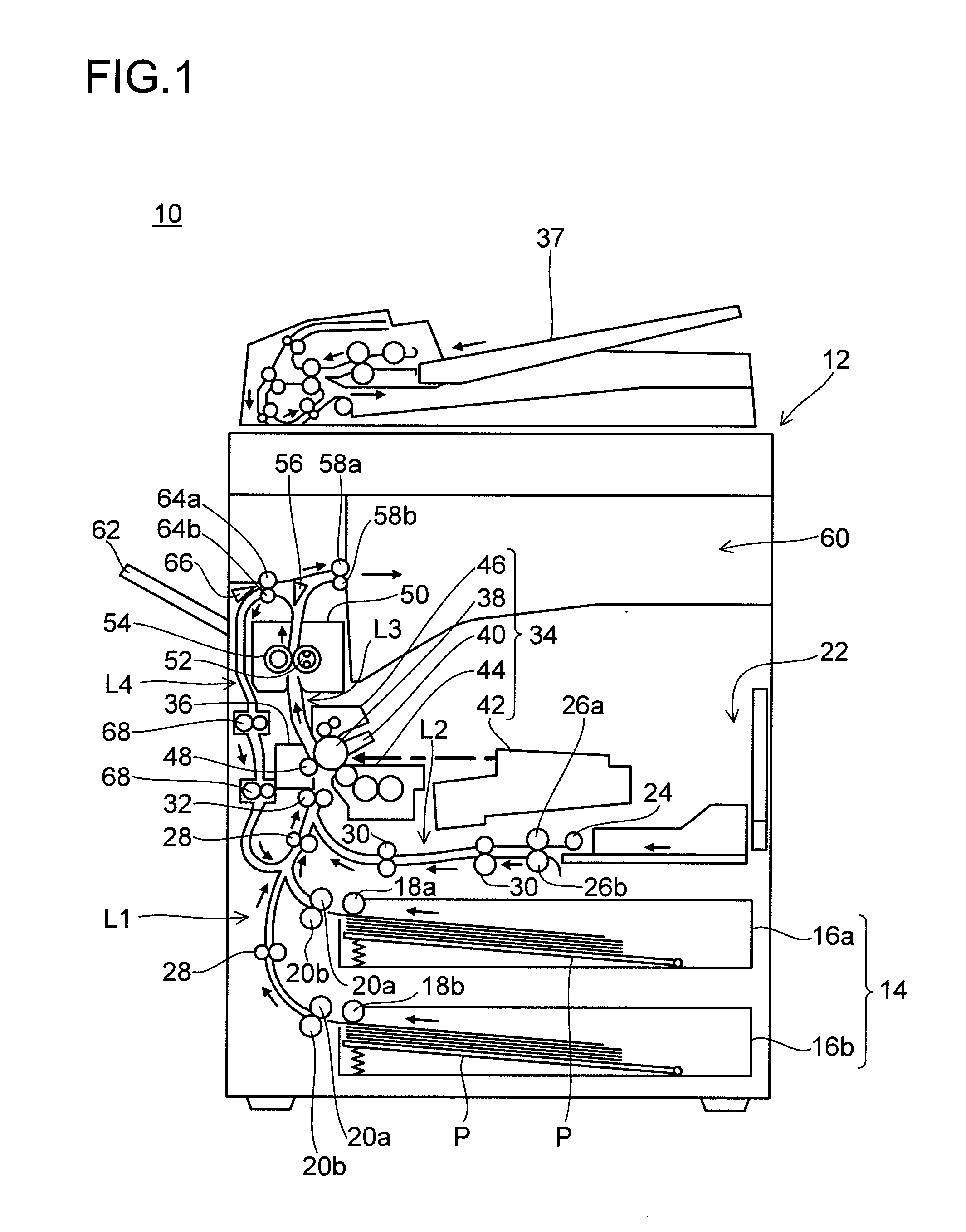

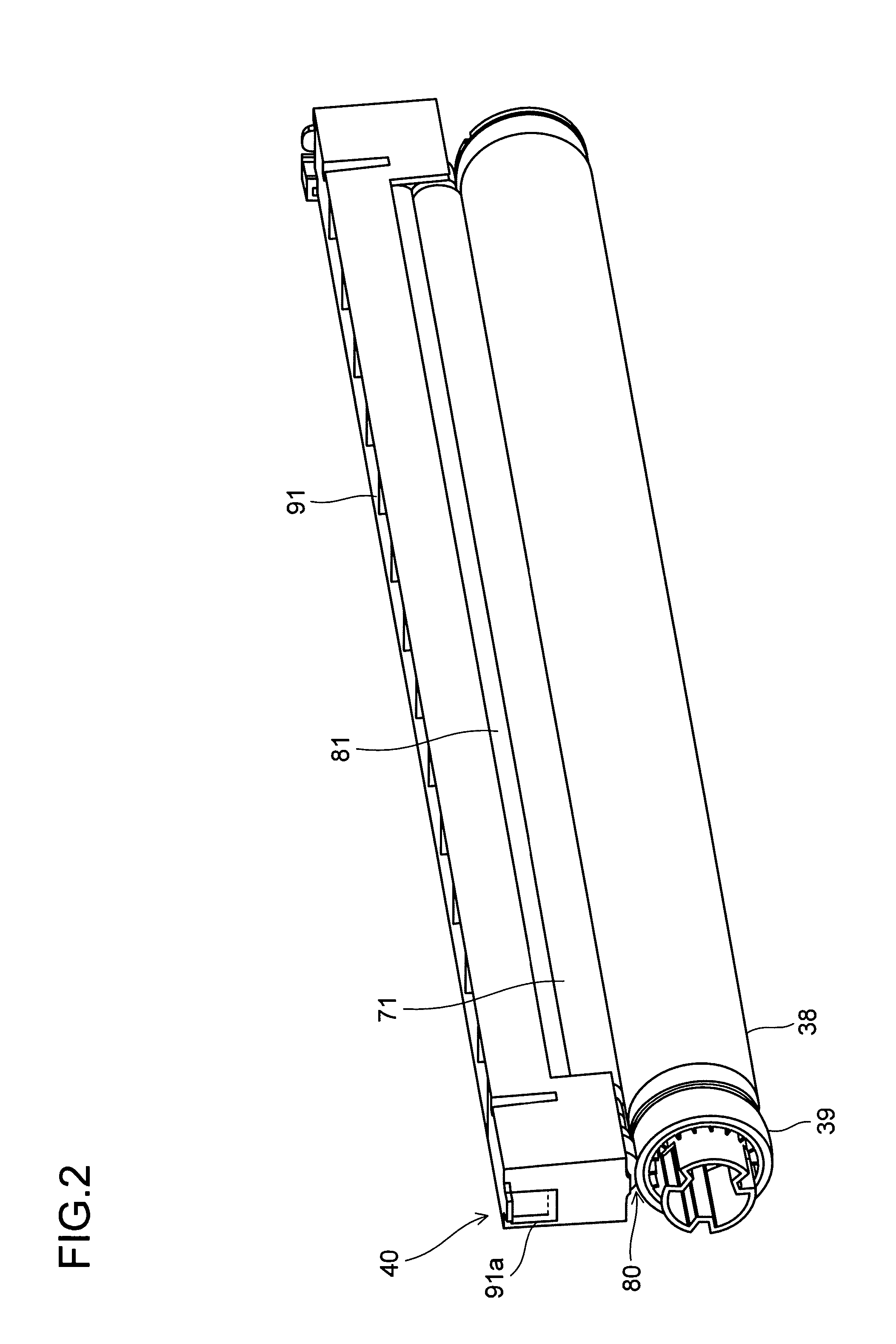

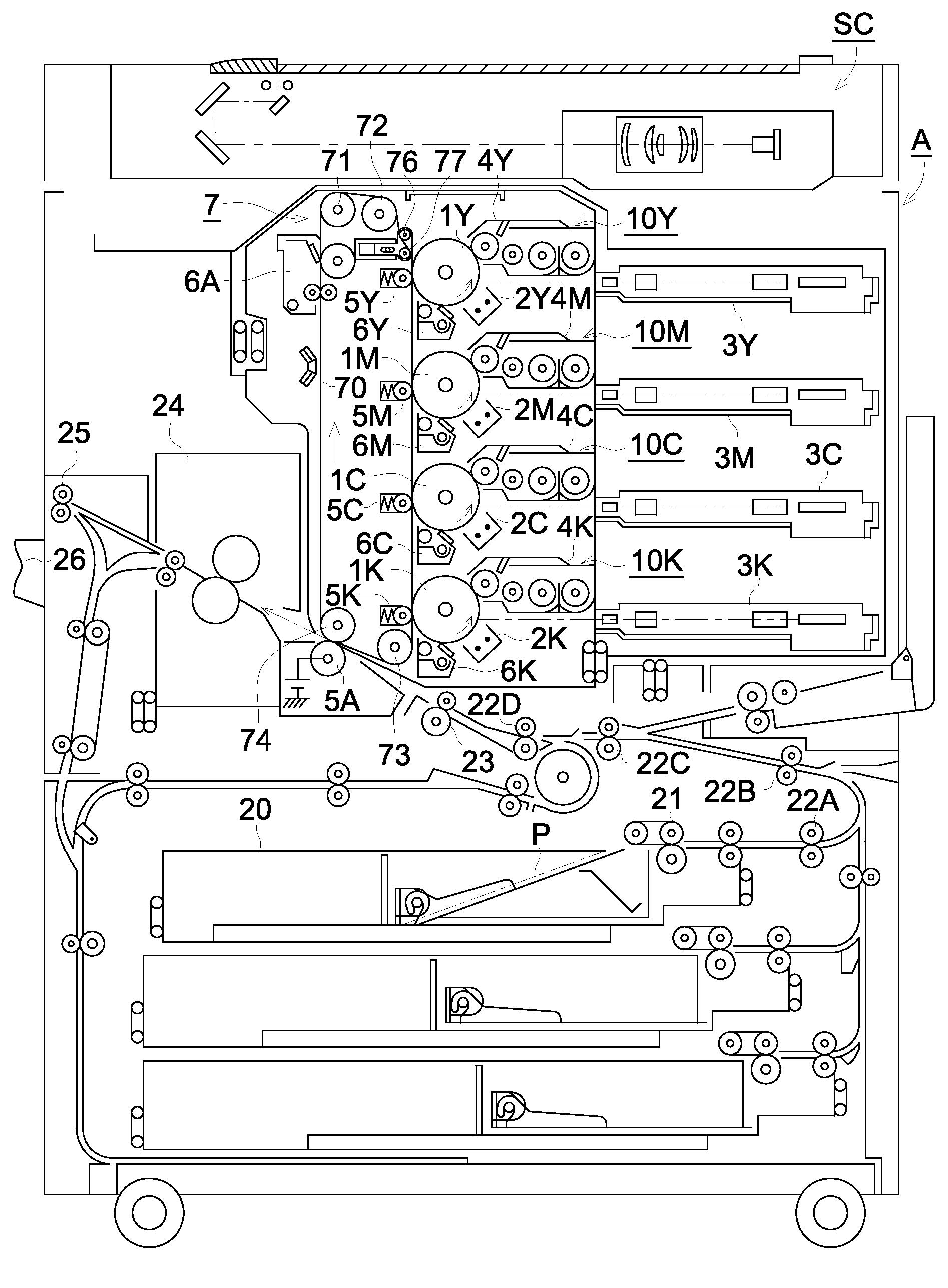

Electrification apparatus and image forming apparatus including the same

InactiveUS20120121295A1Improve electrification performanceImprove performanceElectrographic process apparatusCorona dischargeImage formationEngineering

An electrification apparatus includes: an electrification roller that rotates touching an image carrier to electrify a surface of the image carrier; a support member that by means of a bearing portion, supports rotatably a rotation shat which is disposed at an end portion in a shaft direction of the electrification roller; and a cover member that is disposed on the rotation shaft and covers a portion of the rotation shaft which is near the bearing portion.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

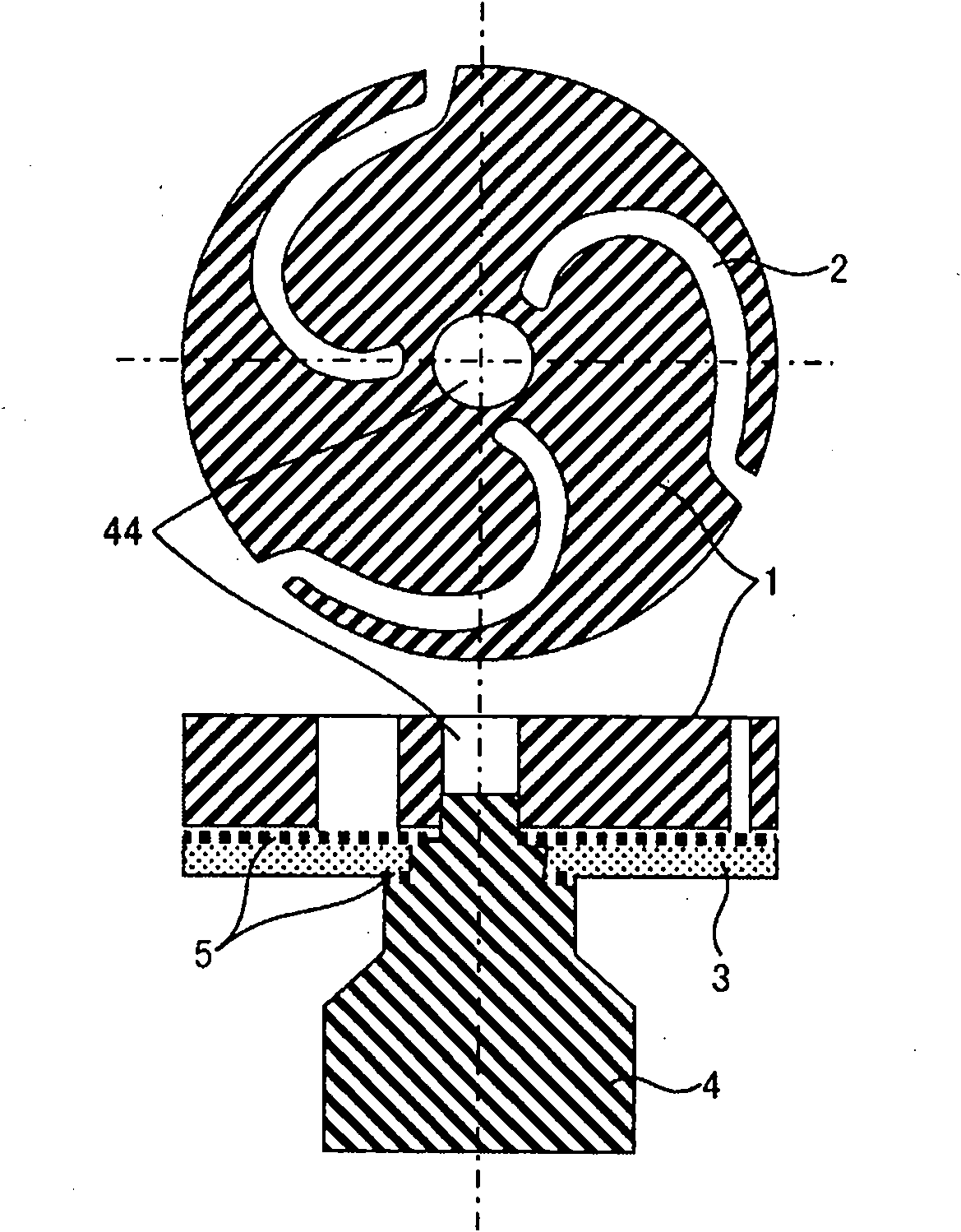

Electric contact for vacuum valve and vacuum interrupter using the same

InactiveCN102064026AWelding separation force is smallImprove electrification performanceContact materialsHigh-tension/heavy-dress switchesCrystalliteChromium

The present invention relates to an electric contact with a low deposit separation force and excellent electric conductivity as well as interruption characteristics. The electric contact comprises chromium, copper and Te and an intermetallic compound consisting of chromium, copper and tellurium and a chromium tissure are dispersed in a copper matrix, characterized in that: the intermetallic compound is present in grains and at grain boundaries of the copper matrix, and interfaces between the chromium and the copper.

Owner:HITACHI LTD

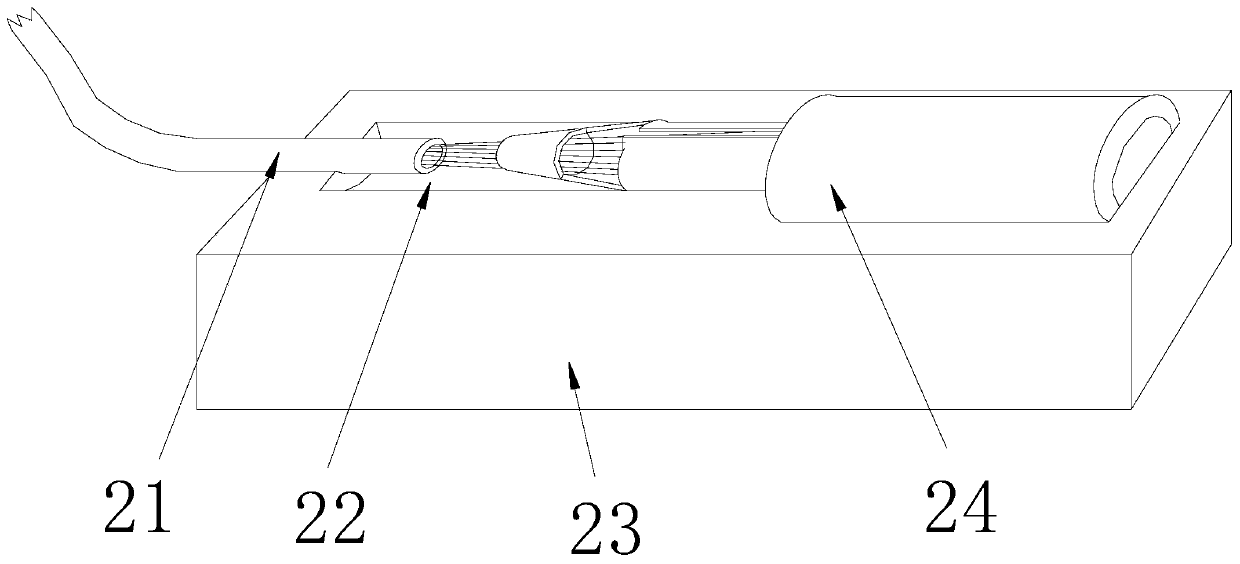

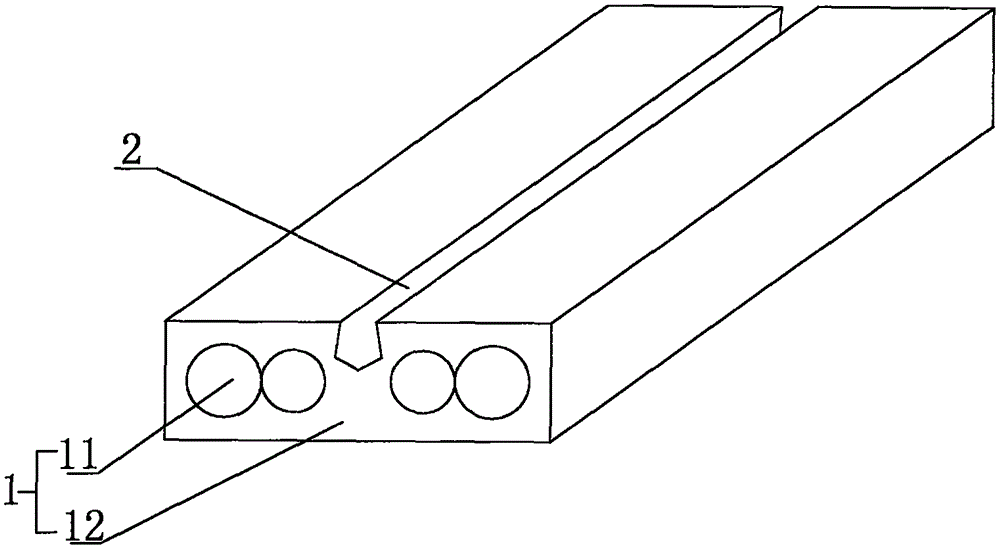

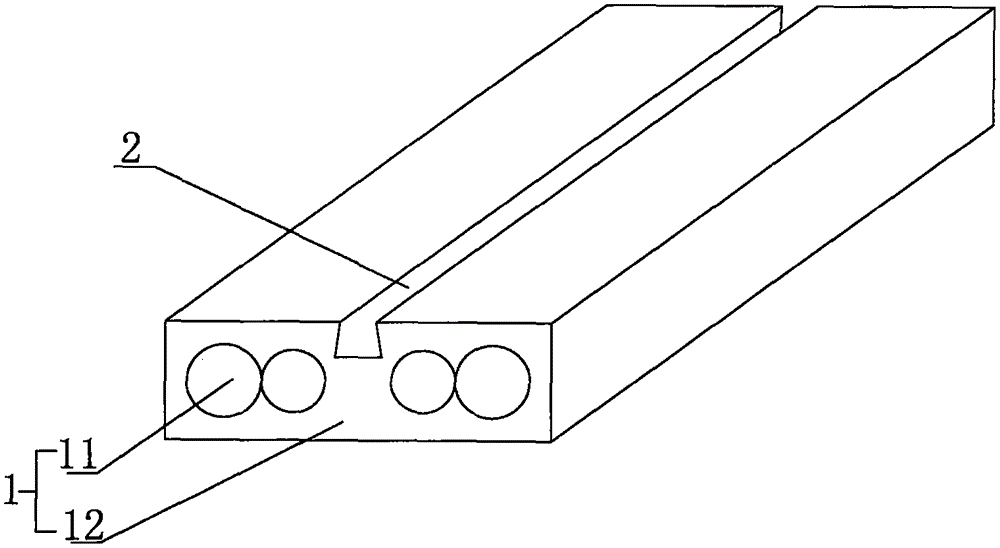

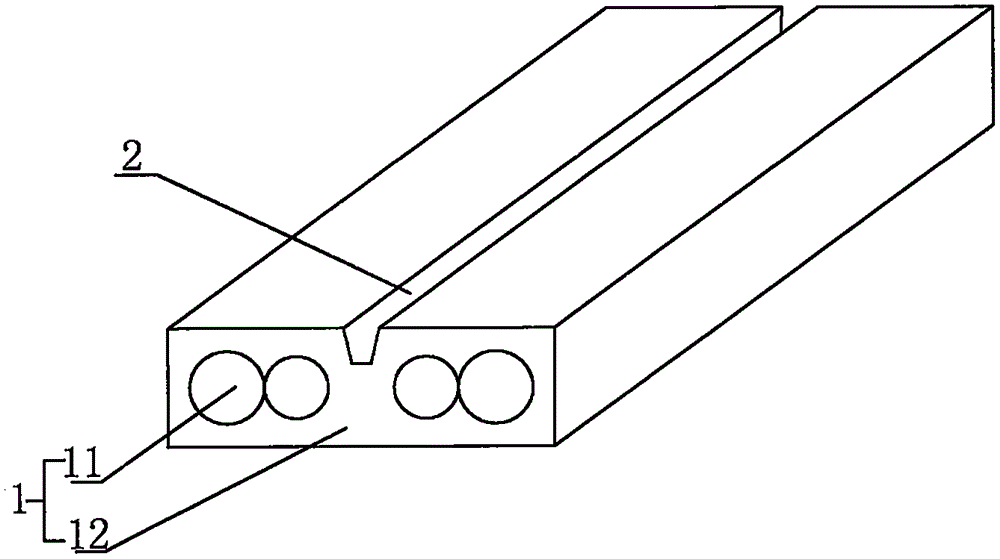

Pre-insulated flat cable

InactiveCN105321606AHigh precisionAccurate and reliable electrical connectionFlat/ribbon cablesInsulated conductorsElectrical connection

The invention discloses a pre-insulated flat cable, which comprises a cable body, wherein the cross section of the cable body is rectangular; the cable body comprises two or more cable cores and an insulating layer; the insulating layer wraps the cable cores from the outside; the cable cores are arranged in parallel; and a positioning groove parallel to the trend of the cable cores is arranged between at least two adjacent cable cores. The cross section of the pre-insulated flat cable is rectangular; meanwhile, the positioning groove is arranged between the cable cores; and the pre-insulated flat cable is embedded into the positioning groove through a positioning device of tooling equipment for mounting a puncture needle, so that accurate positioning of the puncture needle and accurate electrical connection with the outside can be facilitated.

Owner:NINGBO RONGHE WIRE CO LTD

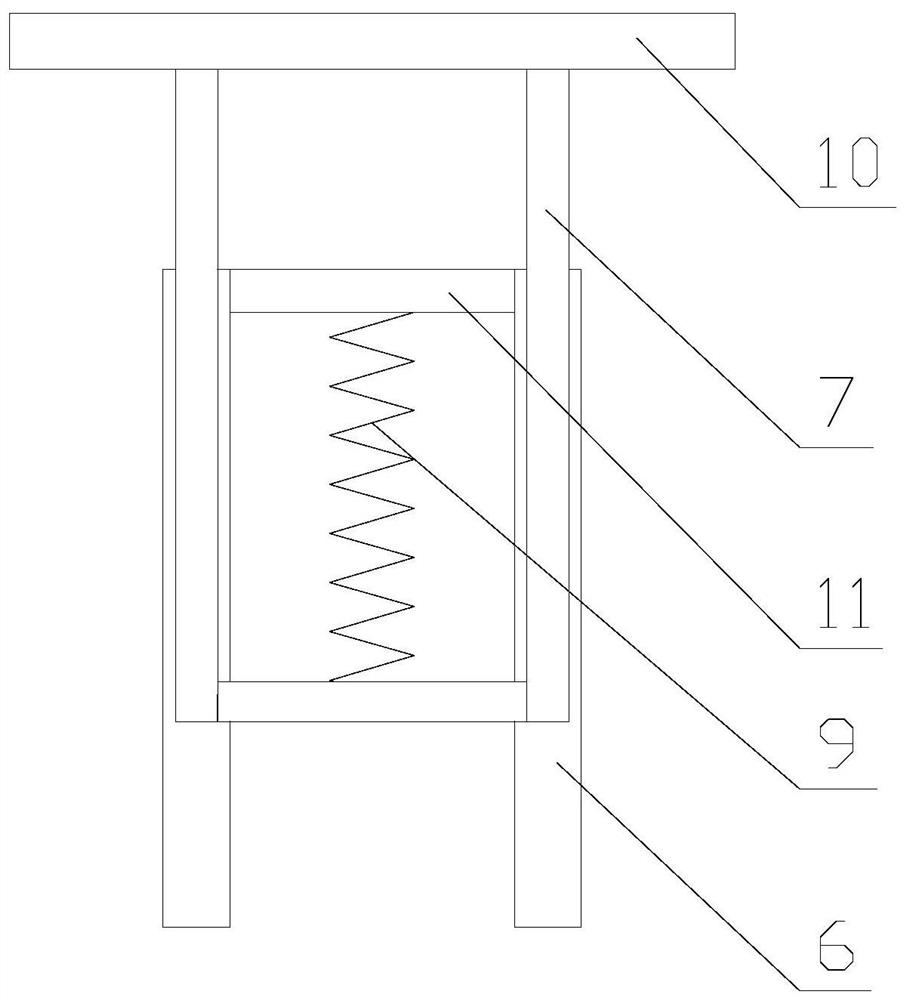

Casting device for metal products

InactiveCN111842867AReduce usageFirmly connectedMolten metal supplying equipmentsWeighing apparatus detailsElectrical conductorEngineering

The invention relates to a casting device for metal products. The casting device comprises a base, a fixing rod, a furnace body, a liquid outflow pipe, a die, a weighing mechanism and a power-on mechanism. The furnace body is arranged above the base through the fixing rod, the liquid outflow pipe is arranged at the bottom of the furnace body, the weighing mechanism is arranged on the base, and thedie is located under the liquid outflow pipe. According to the casting device for the metal products, the weighing mechanism drives the power-on mechanism to run, the liquid injection amount is controlled, compared with an existing casting device, the device can control the solution amount needed by casting the workpieces, and therefore the casting effect is improved; compared with an existing weighing mechanism, a pure mechanical structure is adopted for the weighing mechanism, use of electronic elements such as sensors is avoided, the service life of the device is prolonged, and the stability of the device is improved; and compared with an existing power-on mechanism, through multi limiting and fixing of the mechanism, a first electrical sheet, a second electrical sheet and a conductorare more stably connected, and a better power-on effect is achieved.

Owner:南京道卡机电科技有限公司

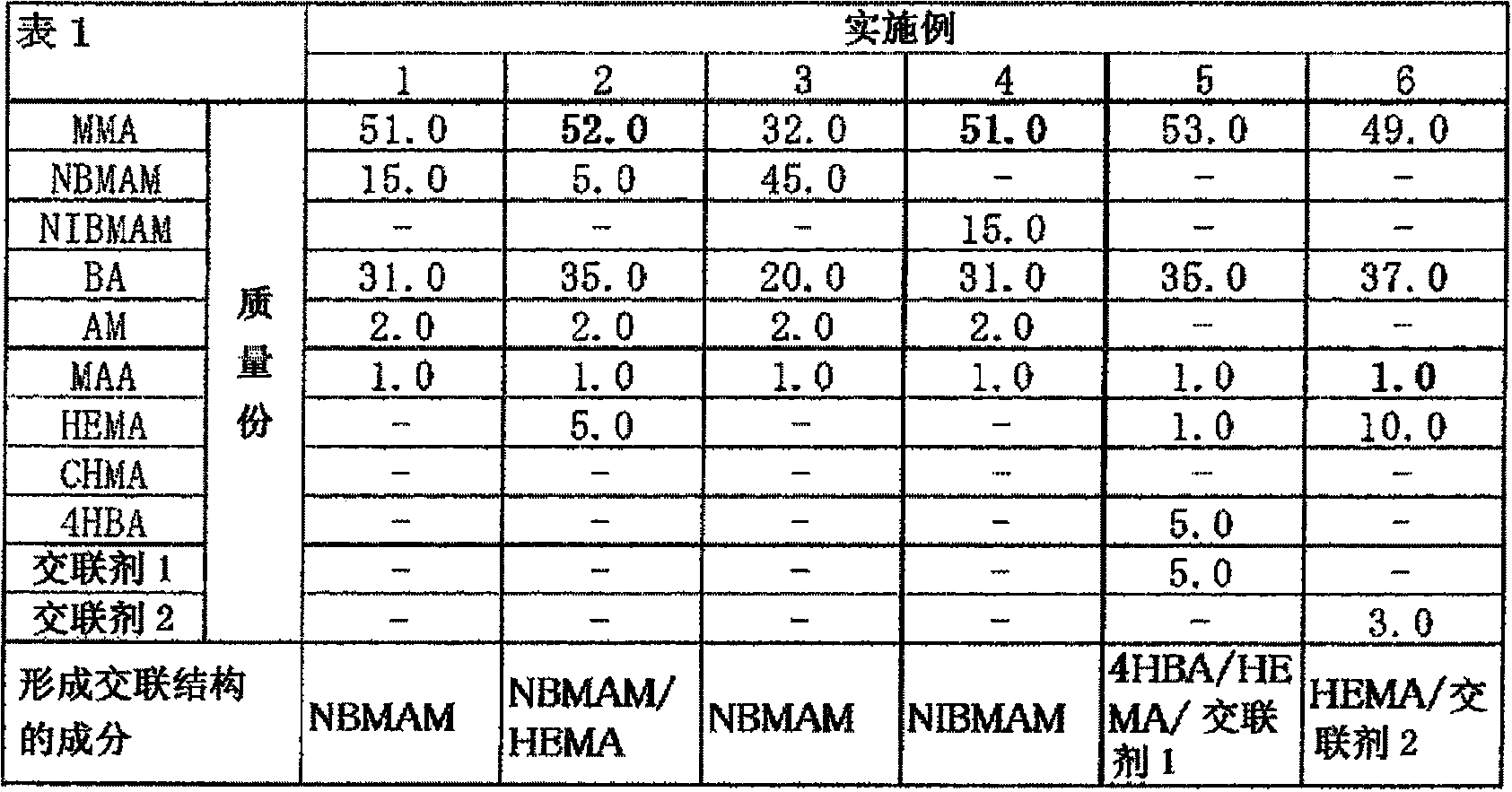

Conductive pattern and manufacturing method thereof

ActiveCN103535120BExcellent fine lineImprove electrification performancePrinted electric component incorporationConductive pattern formationCoated surfaceConductive materials

The present invention relates to a conductive pattern characterized in that it has a layer (A) including a support, a receiving layer (B) and a conductive layer (C), wherein the receiving layer (B) is formed by Formed by cross-linking the above-mentioned resin layer (B1) after coating the surface of the resin layer (B1) containing the vinyl resin (b1) with conductive ink containing the conductive substance (c) forming the conductive layer (C). , The above-mentioned vinyl resin (b1) is a resin obtained by polymerizing a monomer mixture containing 10% by mass to 70% by mass of methyl (meth)acrylate.

Owner:DIC CORP

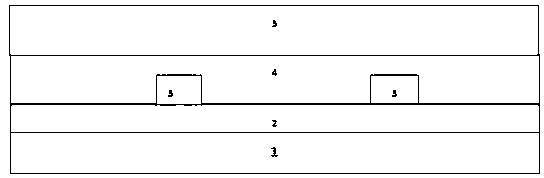

A kind of flexible electric heating plate and preparation method thereof

ActiveCN107708234BImprove electrification performanceImprove securityOhmic-resistance heating detailsAdhesiveEngineering

The invention provides a flexible electric heating plate. The flexible electric heating plate comprises a flexible base material layer, a first adhesive layer, a circuit layer, a second adhesive layerand a film covering layer, wherein the flexible base material layer and the film covering layer are insulating materials; the first adhesive layer and the second adhesive layer are curing adhesive; the circuit layer is high-resistivity pure metal or an alloy material; and the circuit layer prepares a longitude and latitude bidirectional circuit by the methods of exposure, developing and etching in a circuit board preparation process in the electric field, and the circuit is 5-150[mu]m in thickness. The flexible electric heating plate disclosed in the invention is excellent in folding resistance, and the safety and service life are greatly improved and prolonged.

Owner:厦门宝益科技有限公司

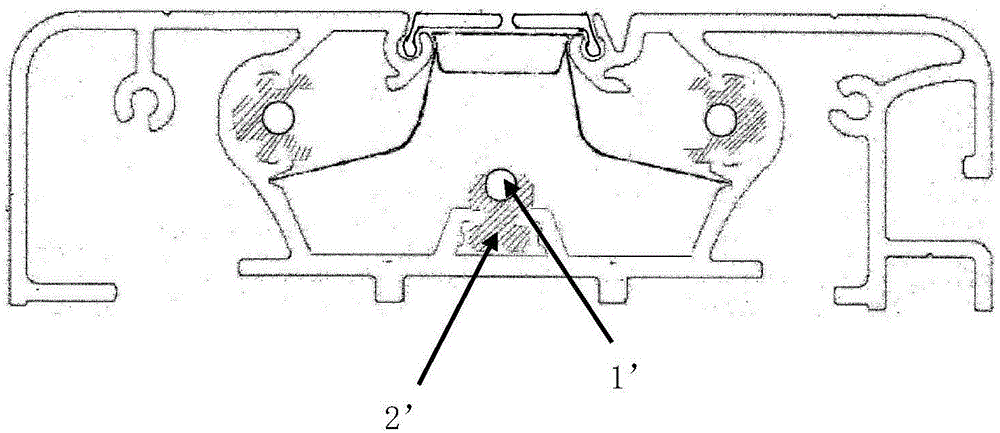

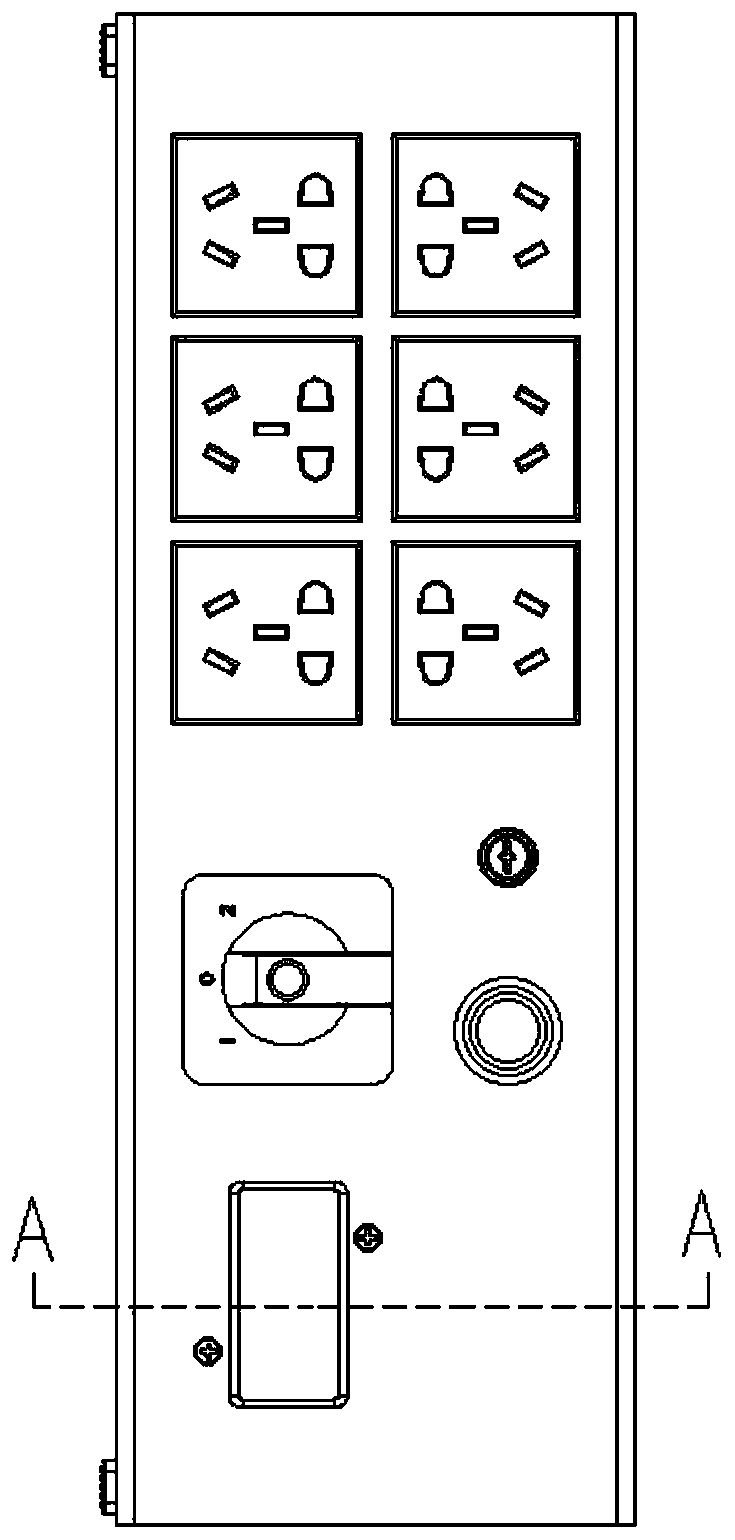

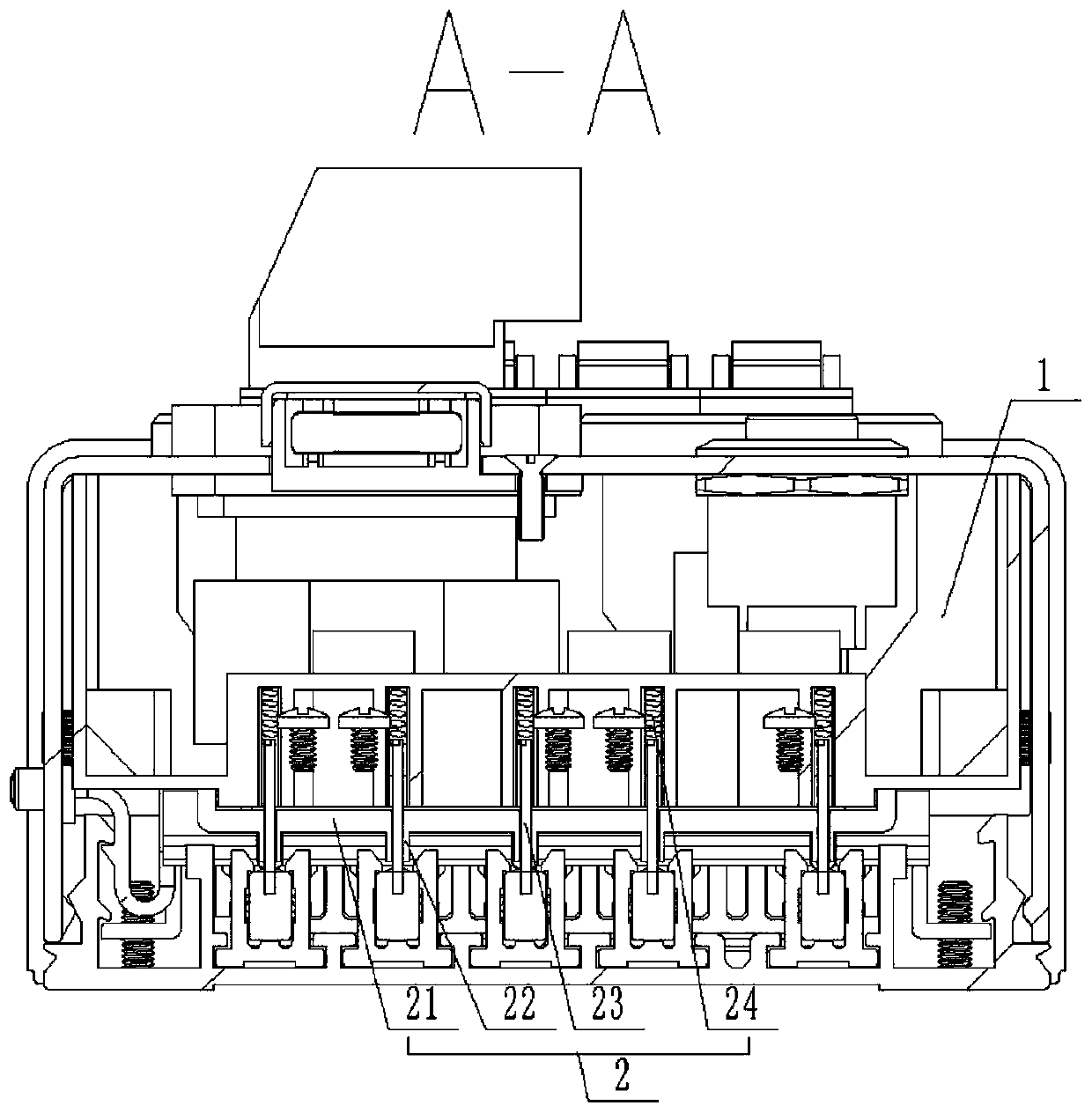

End pressure interface device for power distribution module and conductive copper bar in track-type bus

PendingCN109818179AFlexible Power Distribution FunctionPracticalCoupling contact membersComputer moduleEngineering

The invention discloses an end crimping interface device for a power distribution module and a conductive copper bar in a track-type bus. The end pressure interface device comprises a power distribution bottom shell, and the end pressure interface device is mounted on the power distribution bottom shell. The end pressure interface device comprises a connecting panel, and the connection panel is integrally provided with a connection groove according to the arrangement spacing of conductive copper bars in the track-type bus, wherein the interior of the connecting groove is movably connected witha conductive copper piece, one end of the conductive copper piece extends out of the connecting groove to be connected with the conductive copper strip in the track-type bus, and the other end of theconductive copper piece extends to the upper part of the connecting panel, and the top end of the conductive copper piece is sleeved with a reset spring which is embedded in the power distribution bottom shell. The device is simple in structure, is ingenious in design and is convenient to mount and dismount. The plug-in power distribution bottom shell with an electric hot plug function can be flexibly supported at any position of the trunk body of the track-type bus in cooperation with a locking buckle structure.

Owner:郭乃斌

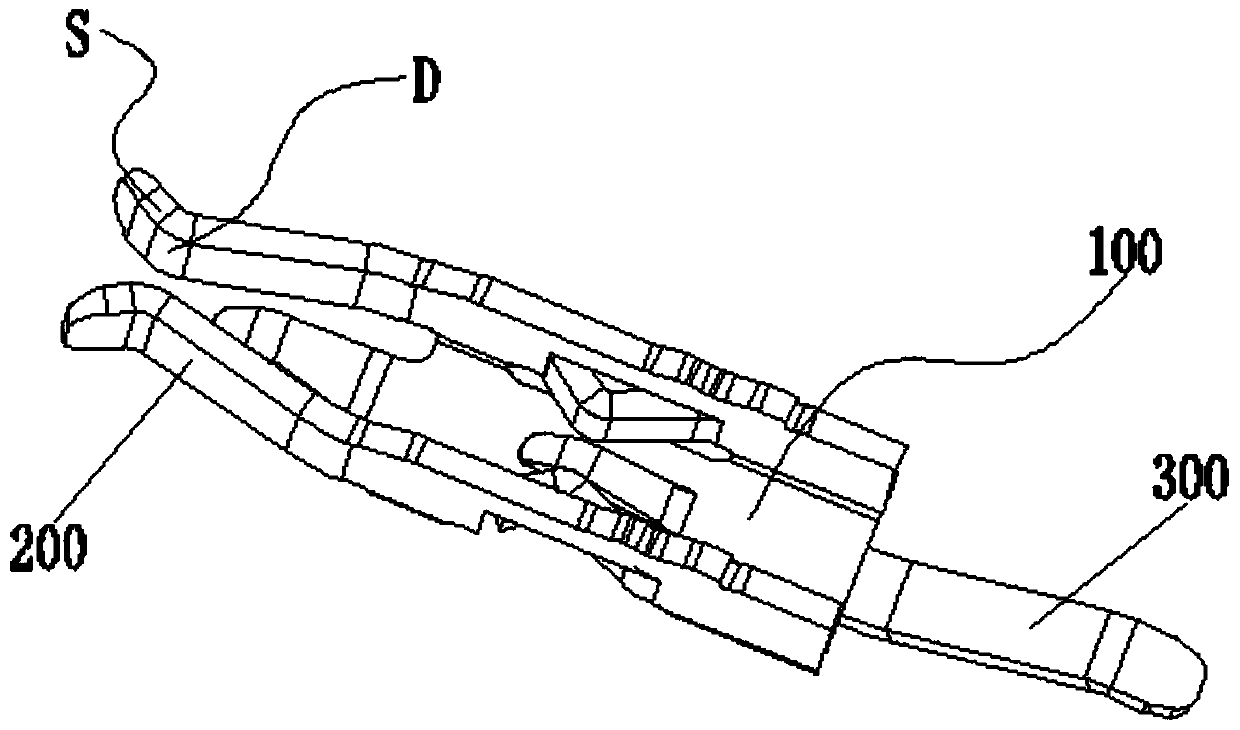

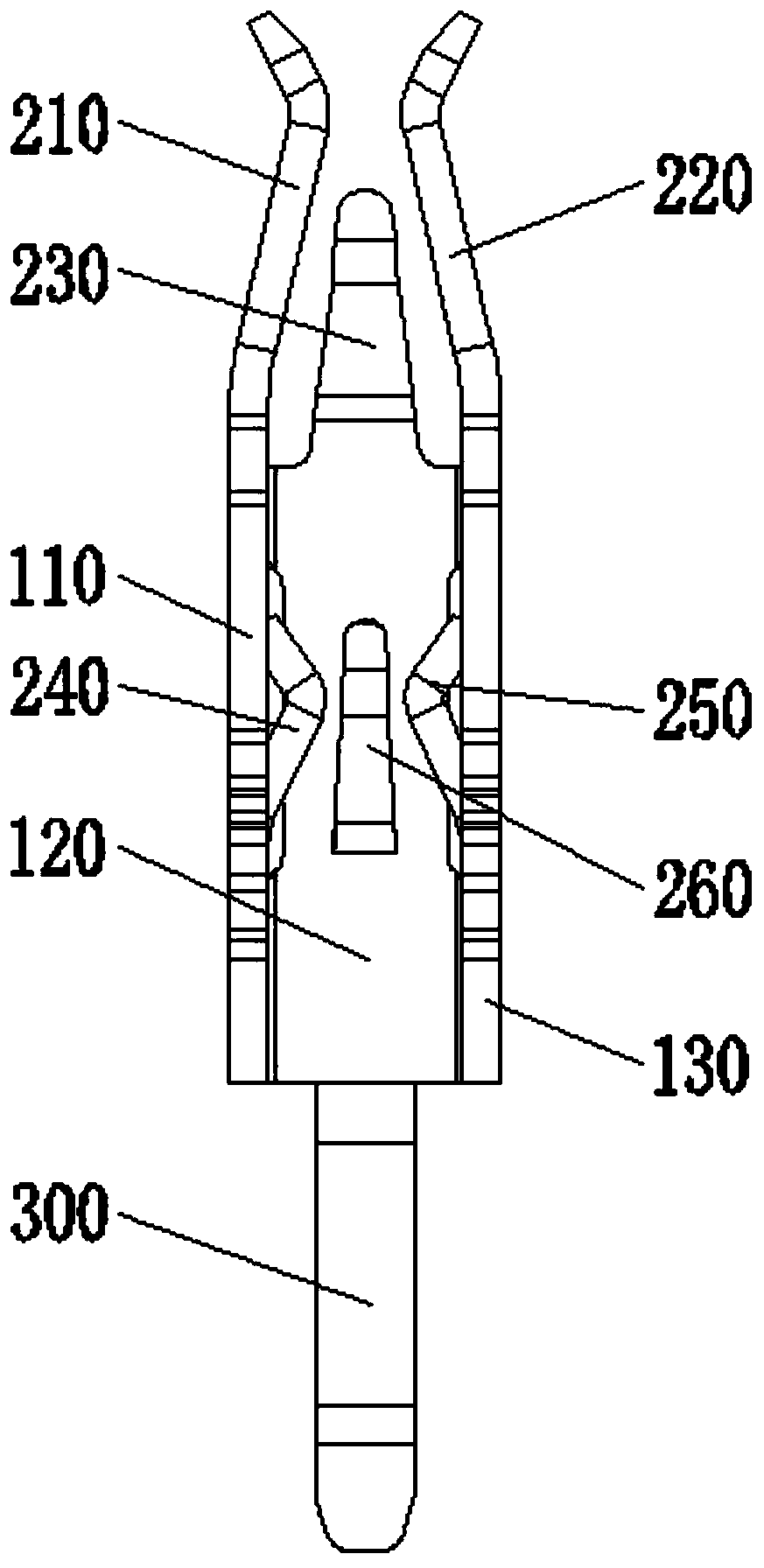

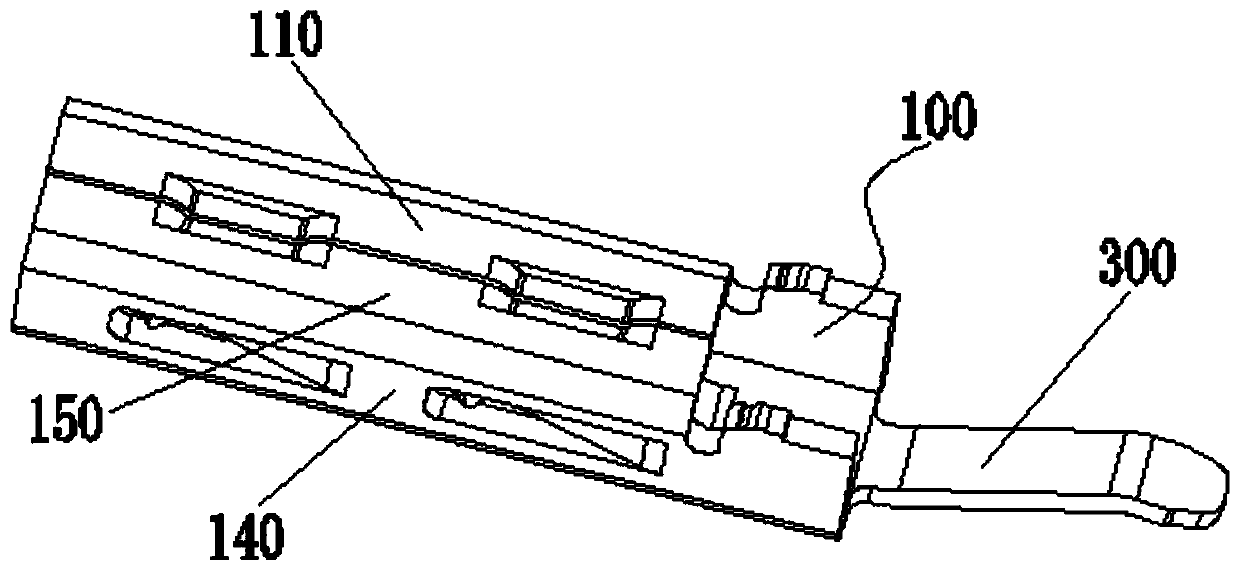

Connector terminal for pin header female seat

The invention provides a connector terminal for a pin header female seat. The terminal comprises a pin header female seat and a terminal body fixedly assembled in the pin header female seat, and the terminal body is made of a conductive metal material and is formed through integral stamping. The terminal body is provided with at least six contact elastic sheets, the terminal body is provided witha mold groove or a mold cavity for inserting a pin of a male head terminal, each contact elastic sheet is provided with a convex contact part, each contact part is provided with a contact surface, andthe contact surfaces are sunken in the mold grooves or the mold cavities of the terminal body. The product is formed through integral stamping and is convenient to process, and the terminal is internally provided with six or eight contact points for contacting the contact pins, so that the matching between the terminal and the contact pins is more stable, the electrifying effect is better, the terminal is not easy to damage after being plugged for many times, the service life is long, and the practicability is very high.

Owner:浙江华愉科技有限公司

Crimping die part and crimping die

PendingCN110034476AGood crimping effectSimple manufacturing processLine/current collector detailsEngineeringMechanical engineering

Owner:EMERSON PROFESSIONAL TOOLS SHANGHAI

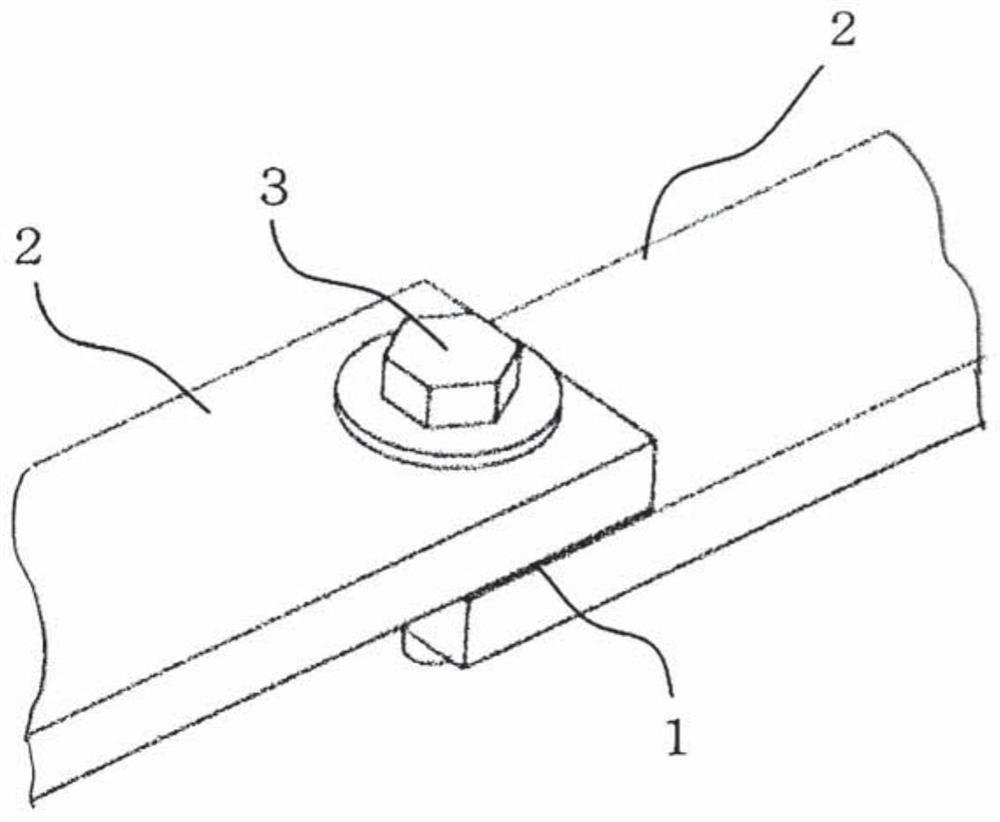

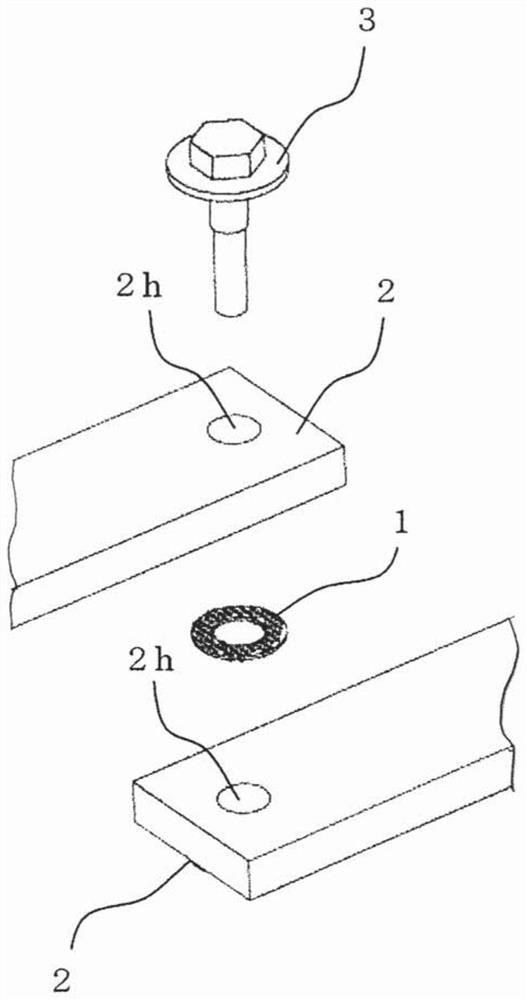

conductor connection device

ActiveCN107735906BPrevent reformationImprove electrification performanceClamped/spring connectionsConnection contact member materialElectrical conductorCorrosion resistant

[Problem] When conductors are connected to one another, conventionally the conductors are plated with silver or tin, which are conductive and corrosion resistant, in order to prevent the formation of oxide films on the surface of the conductors, and to prevent electrolytic corrosion resulting from different types of metal coming into contact with one another. Plating the entire conductor results in an increase in cost, and partial plating requires the addition of a masking operation, and depending on the shape of the conductor, may result in a cost that is higher than coating the entire conductor. [Solution] According to the present invention, when conductors are to be connected using a fastener, an electrically conductive member for connection of conductors is interposed between the two conductors. A plurality of protruding portions are formed on the surfaces, of the electrically conductive member for connection of conductors, that come into contact with the conductors. A plating layer is formed on the contacting surfaces that include the protruding portions, by means of an electrically conductive and corrosion-resistant plating process. When the conductors are connected to one another using a fastener, the contact pressure of the protruding portions causes oxide films on the electrically conductive member for connection of conductors to be removed.

Owner:MITSUBISHI ELECTRIC CORP

Longitudinal magnetization moving coil device for plain shaft and crank shaft magnetic particle inspection

ActiveCN102706957BEvenly distributedAvoid safety accidentsMaterial magnetic variablesOptical axisEngineering

The invention discloses a longitudinal magnetization moving coil device for plain shaft and crank shaft magnetic particle inspection. The longitudinal magnetization moving coil device comprises a plurality of longitudinal magnetization coils, a moving mechanism and a guide rail, wherein each longitudinal magnetization coil has a round integral structure; the guide rail is positioned on the front side of the longitudinal magnetization coils; the moving mechanism comprises a motor, a support, two guide rods, a screw rod, a connecting rod, coil connecting frames and a coil moving frame; the support is positioned on the back side of the longitudinal magnetization coils; the motor is connected with the left end of the screw rod through a driving device; an upper shaft sleeve and a lower shaft sleeve are arranged on the coil connecting frames, and are respectively sleeved on the two guide rods which are positioned on the support; the quantity of the coil connecting frames is the same as that of the longitudinal magnetization coils; a coil trough is formed on each coil connecting frame; the back sides of the longitudinal magnetization coils are buckled in the troughs of the back sides; coil troughs and a guide wheel are arranged on the coil moving frame; the front sides of the longitudinal magnetization coils are buckled in the coil troughs; and the guide wheel of the coil moving frame is positioned on the guide rail.

Owner:YANCHENG ELECTRONICS EQUIP FACTORY

Rocker switch

InactiveCN104733208AIncreased durabilityReliable electrical connectionTumbler/rocker switch detailsEngineeringLife test

The embodiment of the invention discloses a rocker switch. The rocker switch comprises a silver bridge, a supporting part and a conductive connecting part used for connecting the silver bridge with the supporting part electrically, the silver bridge is hinged to the supporting part, one end of the conductive connecting part is connected with the silver bridge, and the other end of the conductive connecting part is connected with the supporting part. The conductive connecting part is added to the rocker switch, so that it is guaranteed that the silver bridge and the supporting part are electrically connected all the time when the silver bridge bounces briefly in a life test process, electrocorrosion to the hinge joint between the silver bridge and the supporting part can be reduced when the silver bridge and the supporting part bounce briefly, and energization performance after a life test is improved. The rocker switch has good durability.

Owner:SCHNEIDER ELECTRIC (AUSTRALIA) PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com