Longitudinal magnetization moving coil device for plain shaft and crank shaft magnetic particle inspection

A technology of longitudinal magnetization and magnetic particle flaw detection, applied in the direction of material magnetic variables, etc., can solve problems such as fire, easy damage, easy ignition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

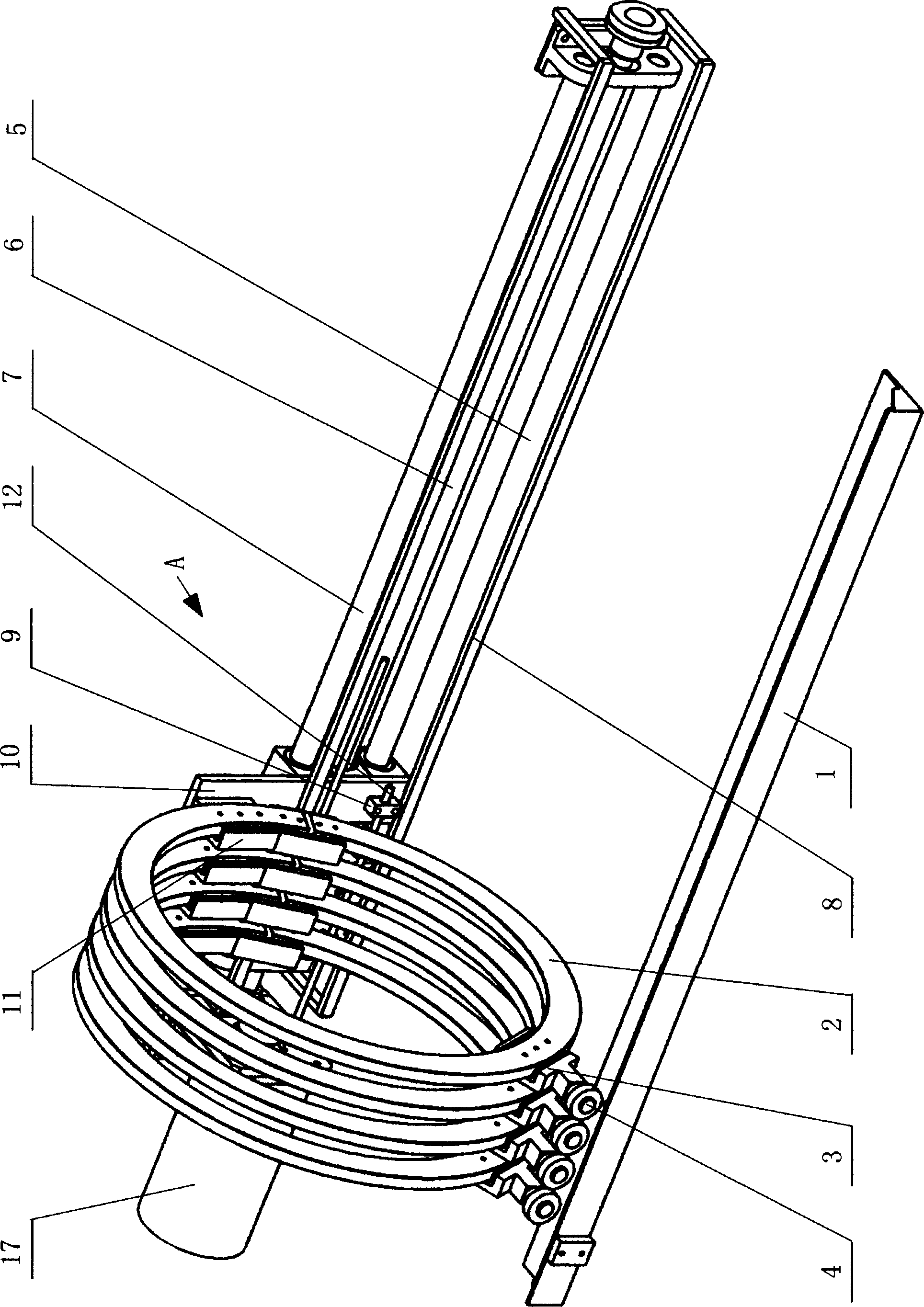

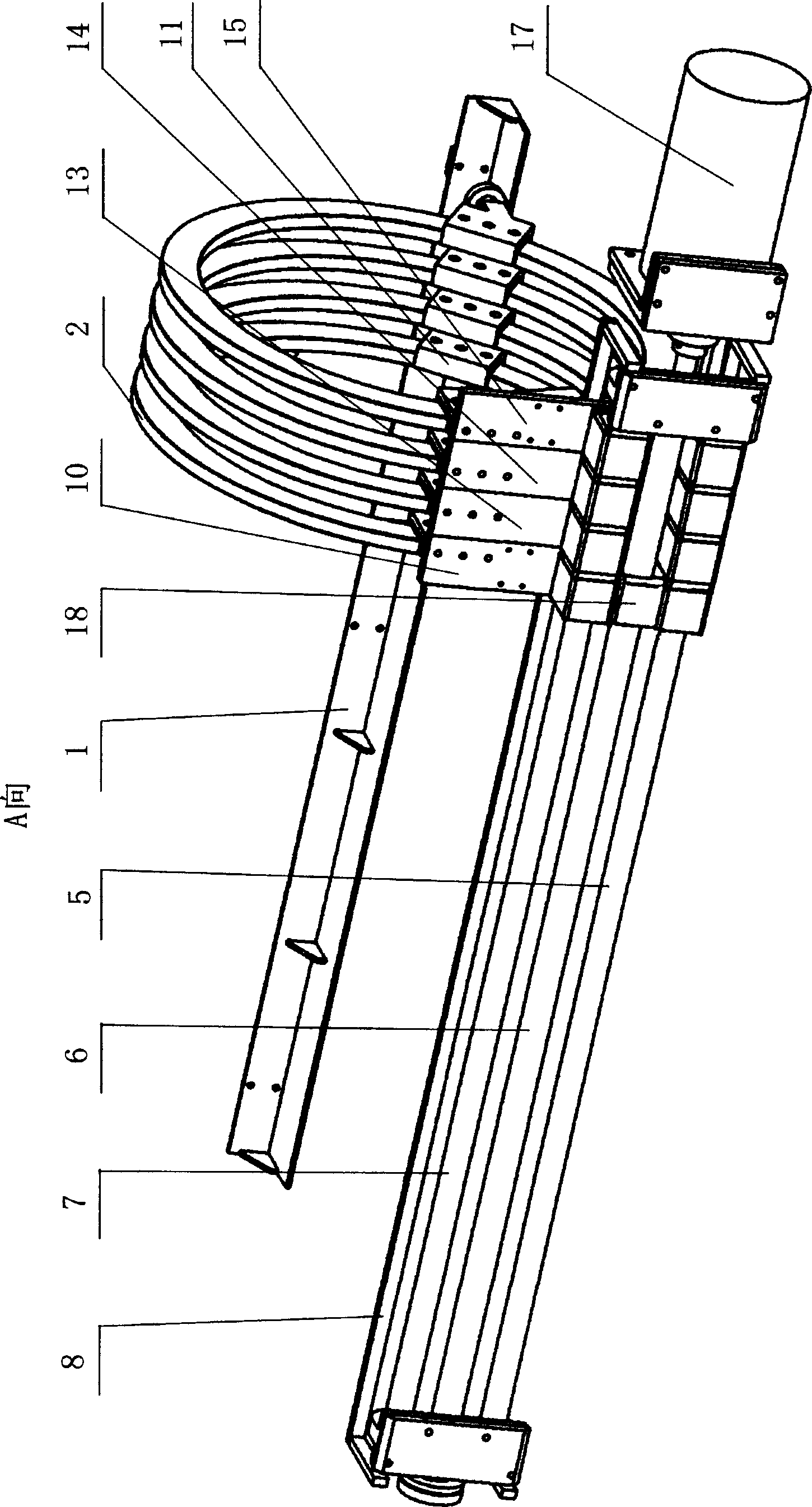

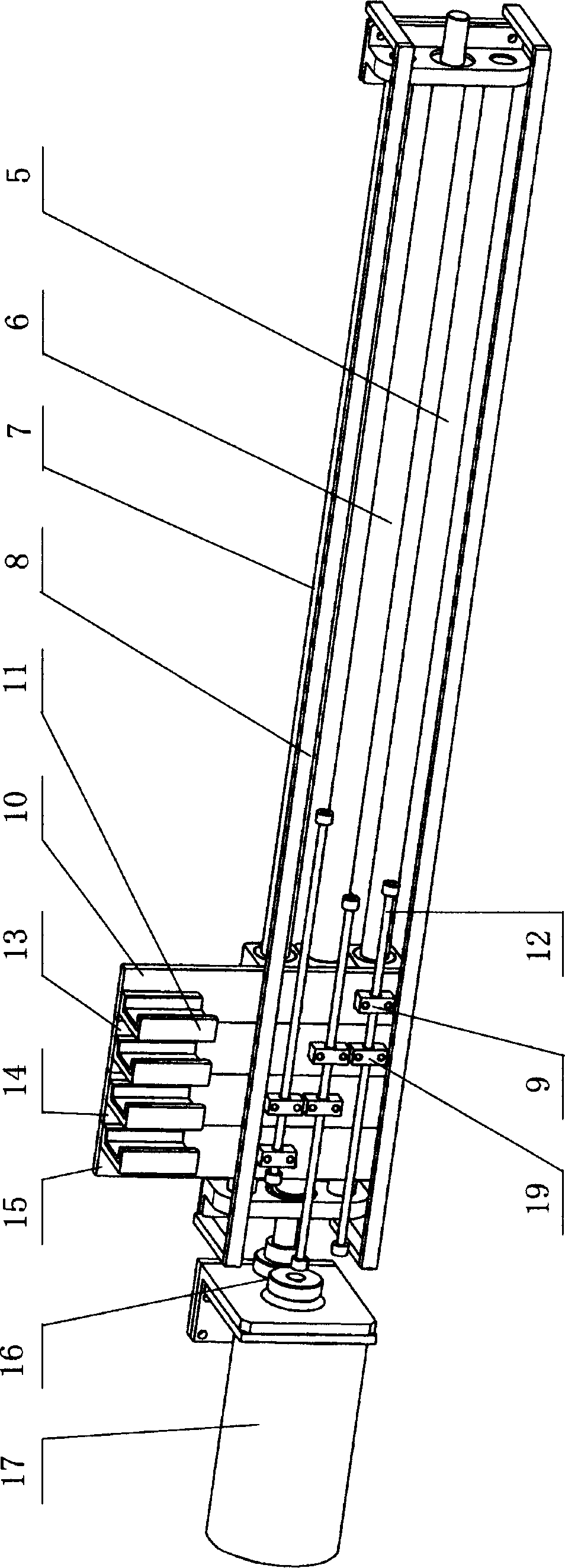

[0013] figure 1 , figure 2 and image 3 Among them, a longitudinal magnetization moving coil device for optical axis and crankshaft magnetic particle flaw detection, which includes several longitudinal magnetization coils 2, and also includes a moving mechanism and a guide rail 1. The longitudinal magnetization coil 2 is a circular overall structure. The guide rail 1 is located on the front side of the longitudinal magnetization coil 2 . The moving mechanism contains a motor 17, a support 8, two guide rods, a screw mandrel 6, a connecting rod 12, a coil connecting frame and a coil moving frame. The support 8 is positioned at the rear side of the longitudinal magnetization coil 2, and the two ends of the screw mandrel 6 are arranged on the left end and the right end of the support 8 respectively, and two guide rods, i.e., the upper guide rod 7 and the lower guide rod 5, are located at the ends of the screw rod 6 respectively. Above and below, the two ends of the upper guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com