Flexible electric heating plate and preparation method therefor

An electric heating plate, flexible technology, applied in the direction of electric heating devices, ohmic resistance heating, ohmic resistance heating parts, etc., can solve the problems of unsuitability for industrialized large-scale production, high cost of carbon nanotubes, unfavorable promotion and application, etc., and achieve superior folding resistance , good electrification performance, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

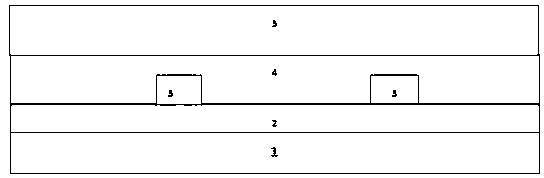

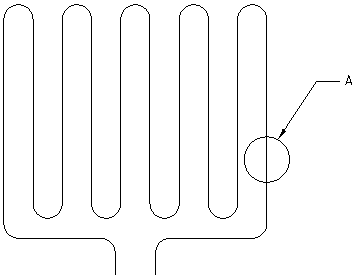

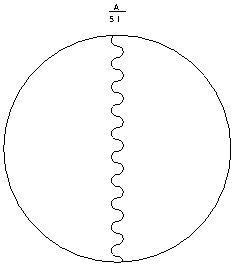

[0041]A flexible electric heating plate, using polyimide as the flexible substrate layer, using epoxy resin glue as the first bonding layer, and evenly coating the epoxy resin glue on the polyimide material, the thickness of the glue layer is less than 8 μm ; Take a nickel-iron alloy film with a thickness of 50 μm as large as the polyimide material as the circuit layer. Before the glue is cured, spread the nickel-iron alloy film on the glue, compact it and let it stand until the glue is cured to obtain the intermediate product a. The nickel-chromium alloy film of the intermediate product a is processed through exposure, development, and etching processes, so that the circuit layer is bidirectionally S-patterned in warp and weft, and the intermediate product b is obtained. Take equal-sized polyimide as the coating layer, and coat nitrile rubber with a thickness of less than 8 μm on the polyester resin as the second adhesive layer. Before the nitrile rubber is cured, stick it to ...

Embodiment 2

[0043] A flexible electric heating plate, using polyester resin as a flexible substrate layer, using silicone rubber as a first bonding layer, and evenly coating silicone rubber on the polyester resin material, the thickness of the adhesive layer is less than 8 μm; The iron-chromium-aluminum alloy film with a thickness of 150 μm is used as the circuit layer. Before the glue is cured, the iron-chromium-aluminum alloy film is flatly spread on the glue, compacted and left to stand until the glue is cured to obtain the intermediate product a. The iron-chromium-aluminum alloy film of the intermediate product a is processed through exposure, development, and etching processes, so that the line layer is bidirectionally S-patterned in warp and weft, and the intermediate product b is obtained. Take an equal-sized polypropylene material as the coating layer, and coat the polypropylene material with silicone rubber with a thickness of less than 8 μm as the second adhesive layer. Before th...

Embodiment 3

[0045] A flexible electric heating plate, using polybutylene succinate as a flexible base material layer, using nitrile rubber as the first bonding layer, uniformly coating the nitrile rubber on the polybutylene succinate material, glue The thickness of the layer is less than 8 μm; take the iron-chromium-aluminum alloy film with a thickness of 5 μm as large as the polybutylene succinate material as the circuit layer, and spread the iron-chromium-aluminum alloy film on the glue before the glue is cured, and compact it And let it stand until the glue solidifies to obtain the intermediate product a. The iron-chromium-aluminum alloy film of the intermediate product a is processed through exposure, development, and etching processes, so that the line layer is bidirectionally S-patterned in warp and weft, and the intermediate product b is obtained. Take equal-sized polyethylene as the coating layer, and coat the polyethylene material with epoxy resin glue with a thickness of less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com