Ceramic heating plate extraction electrode connecting structure and connecting method thereof

A connection structure and lead-out electrode technology, applied in the direction of ohmic resistance electrode, ohmic resistance heating parts, etc., can solve the problems of relatively large difference in thermal expansion coefficient, increase the amount of filler, increase cost, etc., to reduce cracking phenomenon, ensure uniformity, The effect of good electrification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

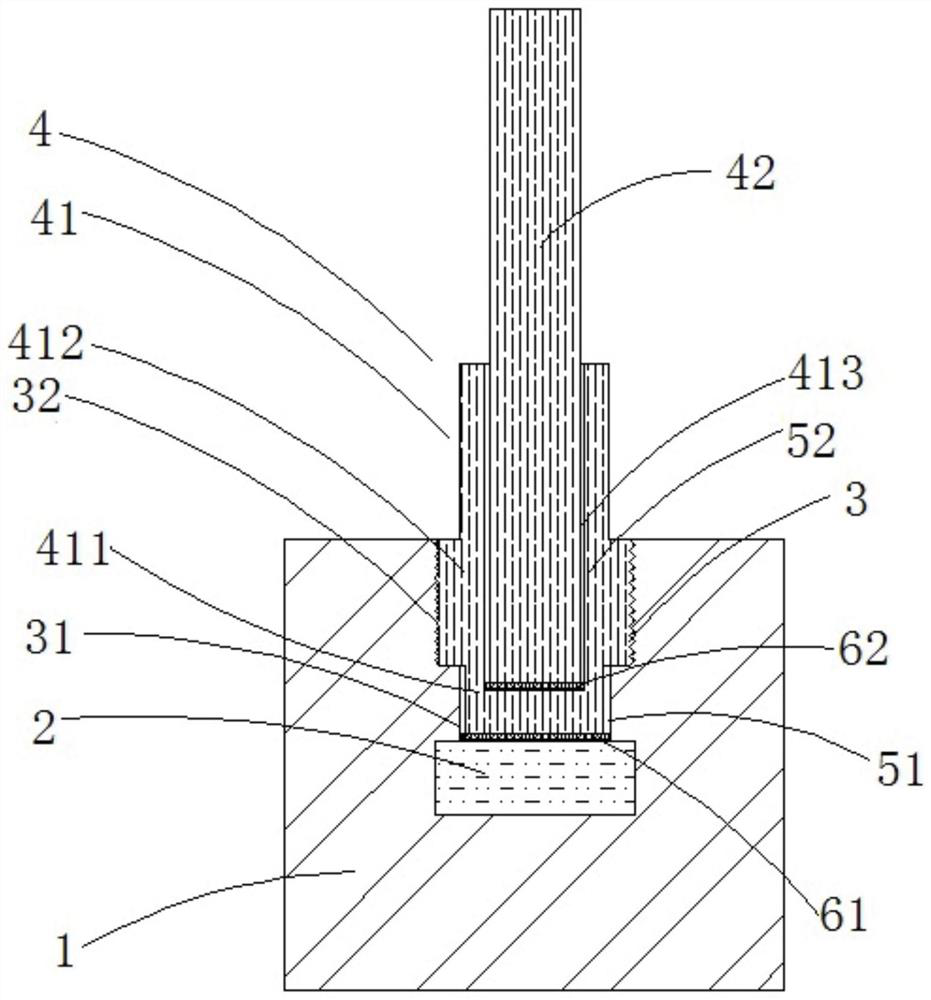

[0069]Preparation and use of ceramic composite powder: The main components of ceramic composite powder are two or more of alumina, zirconia, calcium oxide, silicon oxide, barium oxide, lithium oxide, boria, etc., alumina and zirconia The particle size is 0.1-2um, the mass ratio of alumina and zirconia is 0.25-4, and the mass of other oxides is less than 50% of the total mass. A certain proportion of the above-mentioned compounds is ball-milled with ethanol for 2 hours and then sprayed onto the graph. The connection position of the connection hole 3 and the lead-out electrode 4 in the center is enough. The alcohol is volatilized by drying, and the whole part is put into a vacuum brazing furnace for brazing. The brazing temperature is 800-1200°C and the vacuum degree is 10^ - 4mmHg, the highest temperature holding time is 10-180min, after heating, cool to room temperature under the protection of an inert atmosphere.

[0070] For specific composite powders, for example, apply 500...

specific Embodiment approach

[0075] By dividing the crest of the ceramic part into a large fillet and the bottom of the tooth into a small fillet, the gap between the two fillets is just enough to put a welding wire with a wire diameter of 0.1-1mm.

[0076] The implementation method is: the welding wire is coiled in advance through the thread bottom of the electrode tube section, and then screwed into the connecting hole thread together with the welding wire, and the two are welded together by vacuum brazing, which can effectively increase the stability of the lead-out electrode and the connecting hole sex.

Embodiment 1

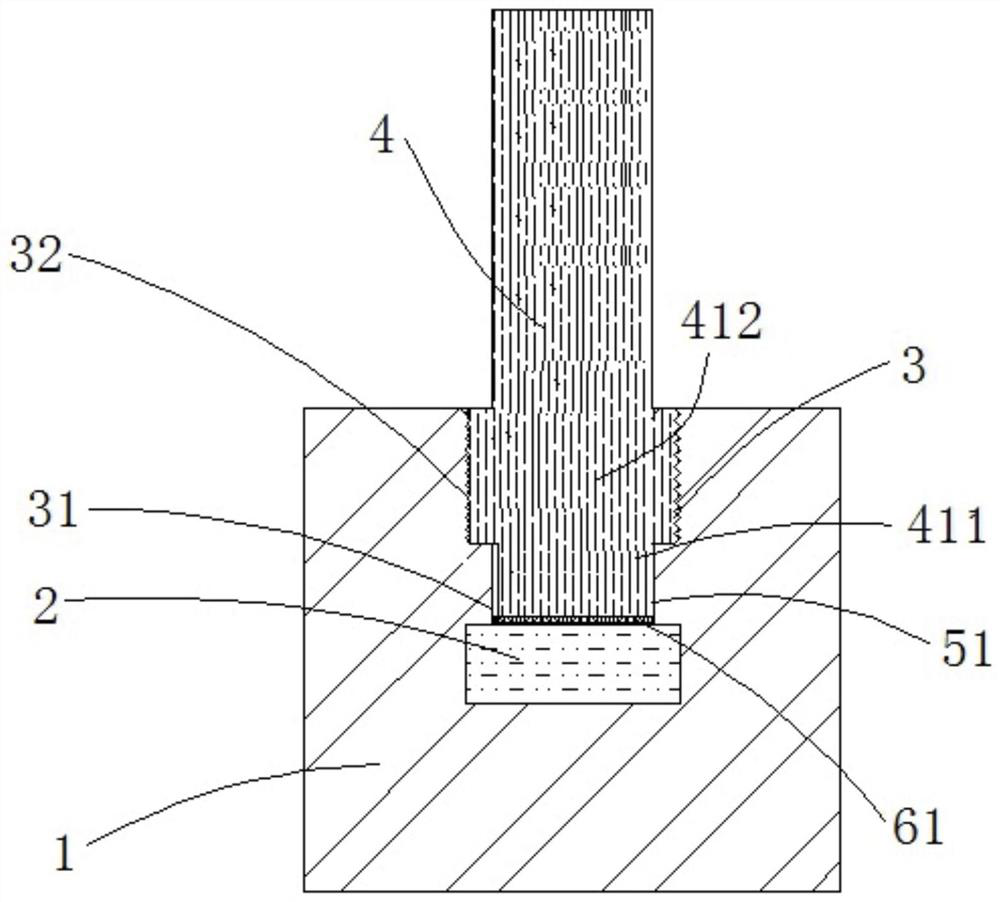

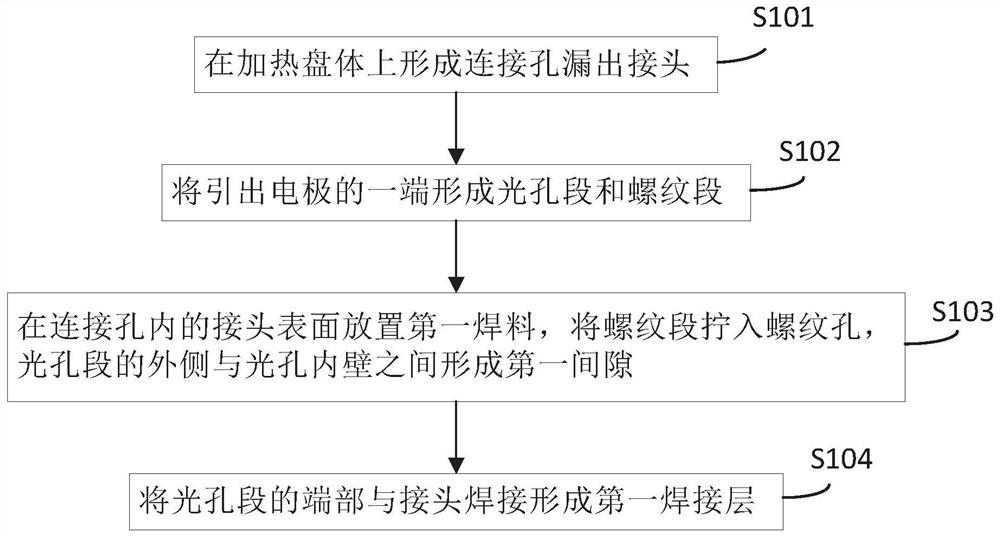

[0078] Such as image 3 As shown, the embodiments of the present application provide a connection structure for leading out electrodes of a ceramic heating plate. Ceramic heating plates are suitable for semiconductor chemical vapor deposition equipment. The lead-out electrode connection structure includes: a joint 2 arranged in the heating plate body 1 , a connection hole 3 and an lead-out electrode 4 arranged on the heating plate body 1 .

[0079] The joint 2 is used to connect the radio frequency electrode and the heating component in the heating plate body 1 . In this embodiment, there are multiple joints 2, which are respectively connected to the radio frequency electrodes and the two poles of the heating component.

[0080] The connecting hole 3 corresponds to the joint 2 and leaks out of the surface of the joint 2 to facilitate the connection between the joint 2 and the lead-out electrode 4 . The connecting hole 3 includes a light hole 31 and a pre-fixed hole 32 , and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com