Cylinder sleeve compression method and compressor

A compression method, cylindrical technology, applied in the direction of wire tensioning equipment, line/collector parts, connections where permanent deformation plays a role, etc., can solve the problems of huge development costs and time, and achieve rapid operation and Reliability, reduction of electrical fires, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

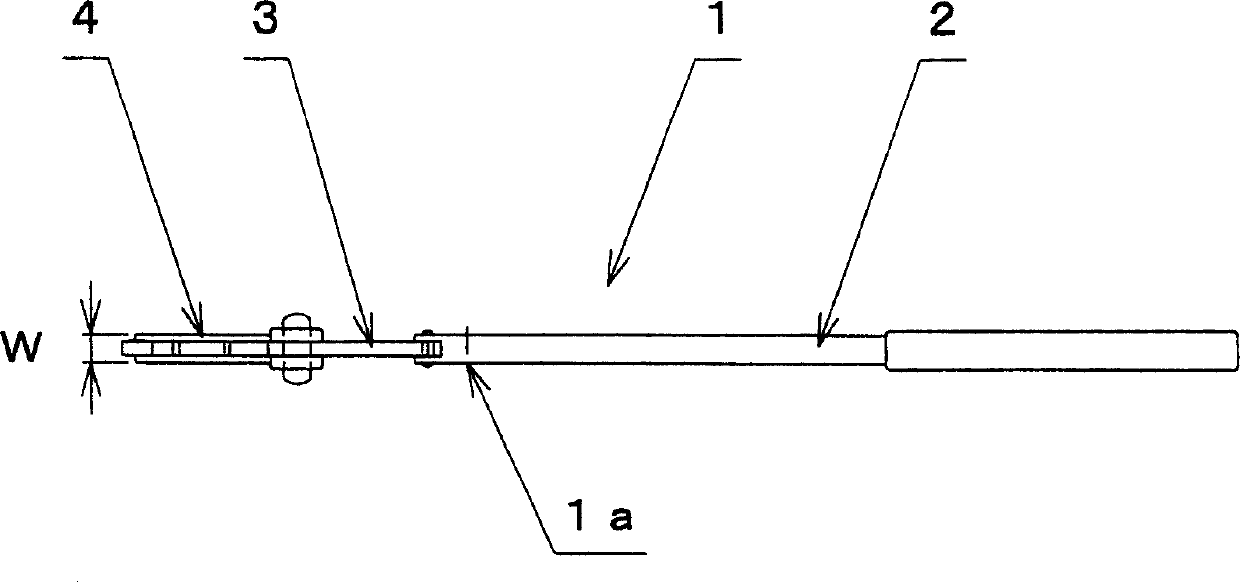

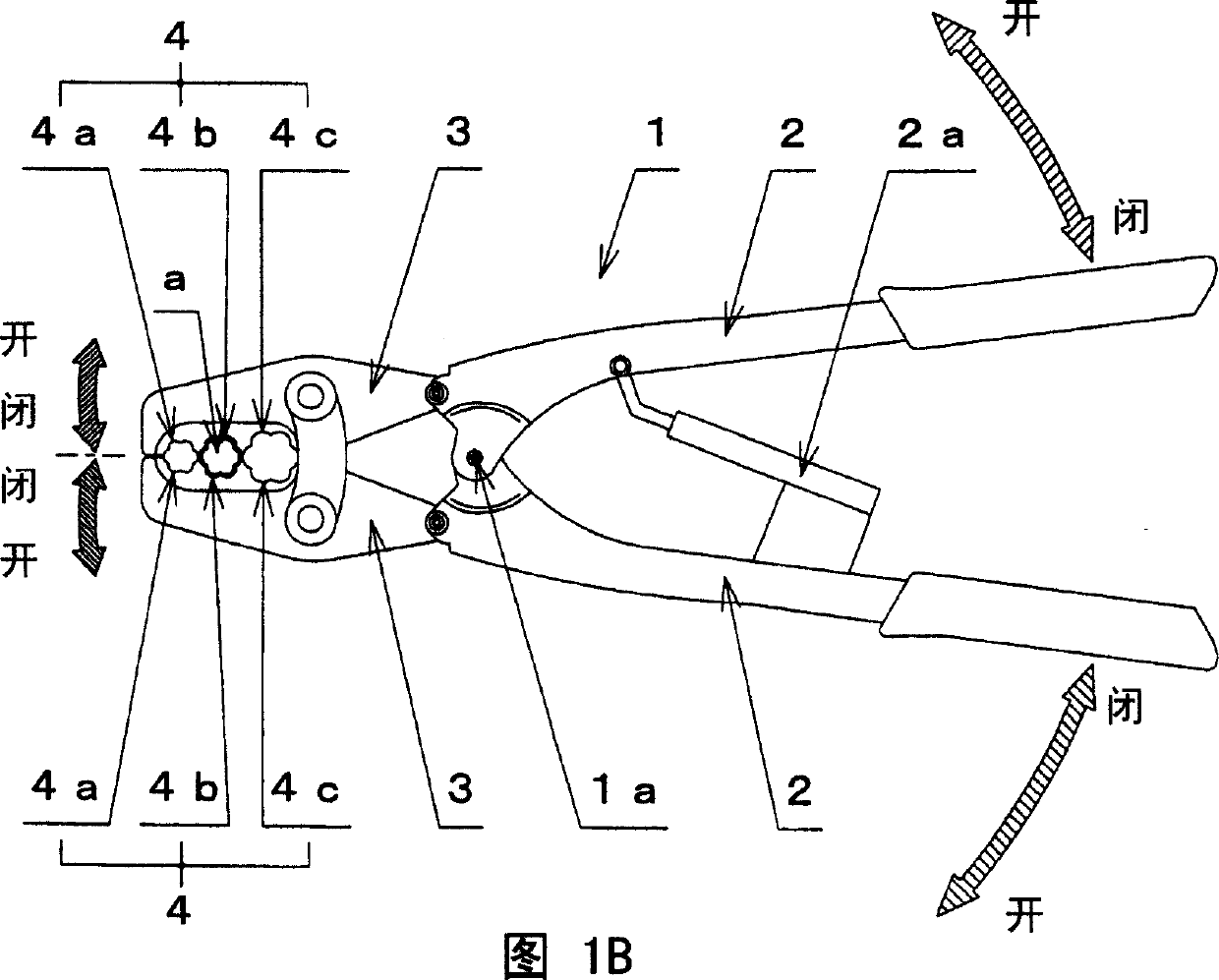

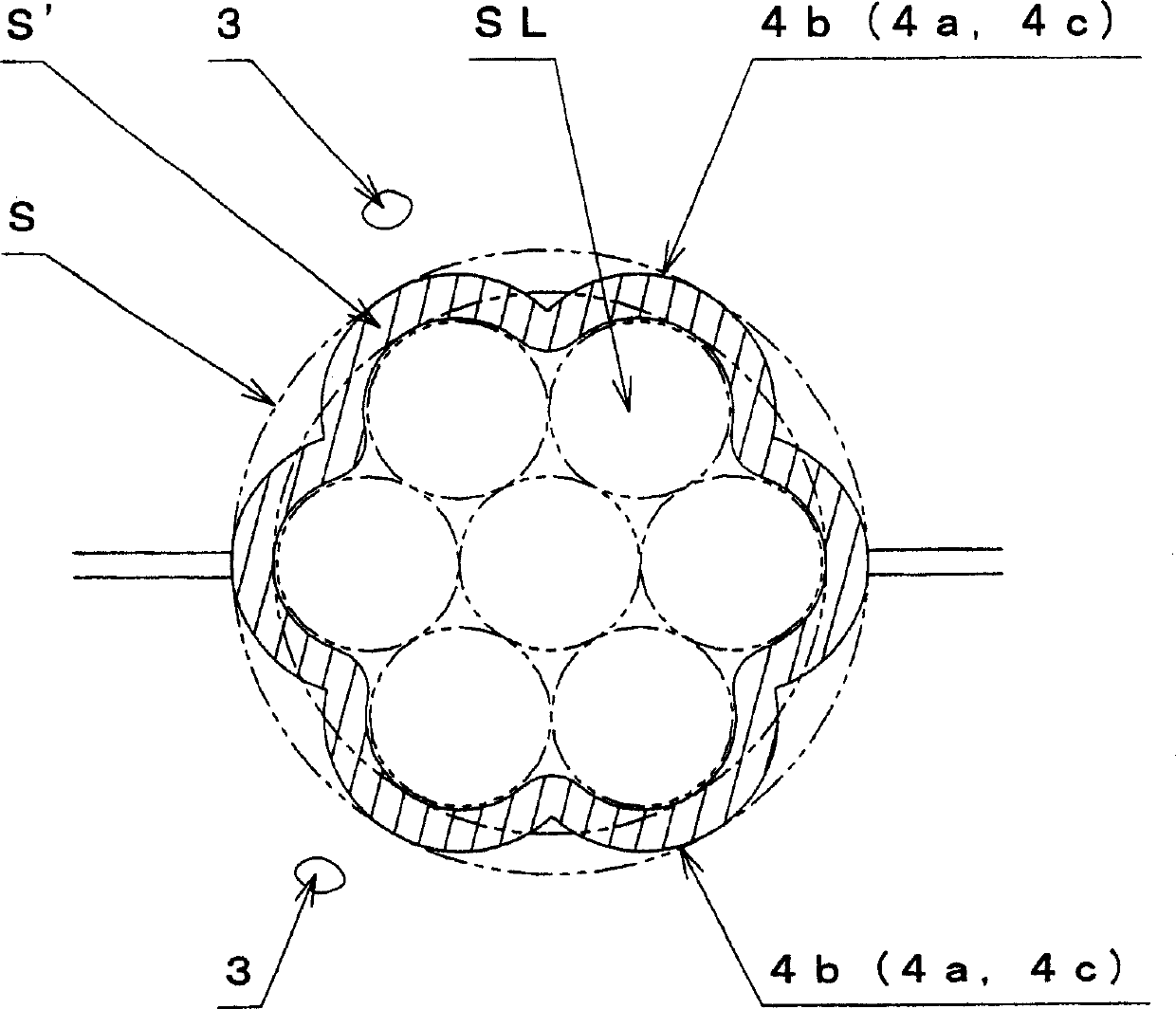

[0018] If an embodiment of the present invention is described in detail with FIGS. 1-4, the specific situation is as follows: when the twisted wire used to insert the terminals of the electric meter and the switch into the connection part is compressed by the cylindrical sleeve S, it is compressed in a cross direction. The device 1 is clamped and compressed, and the stranded wire SL and the sleeve S are compressed and fixed. The above-mentioned cross compressor 1 is formed so as to face compression grooves adapted to the cross-sectional outer peripheral shape of the strand SL.

[0019] In addition, a terminal of a power meter, a switch, etc. is inserted into a compressor of a cylindrical sleeve S for twisted wire used for a connection portion, and this compressor 1 is constituted by a compressor for twisted wire having the following characteristics. That is: the compressor 1 has a pair of handles 2, and a pair of jaws 3 for working with the pair of handles 2, and the central p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com