Pre-insulated flat cable

A flat cable, piercing technology, applied in the direction of flat/ribbon cables, insulated cables, cables, etc., can solve problems such as difficult positioning of the needle and cable, affecting the electrical connection between the cable and the outside, and the connection deviation between the cable core and the needle , to achieve the effect of good electrification performance, simple structure and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

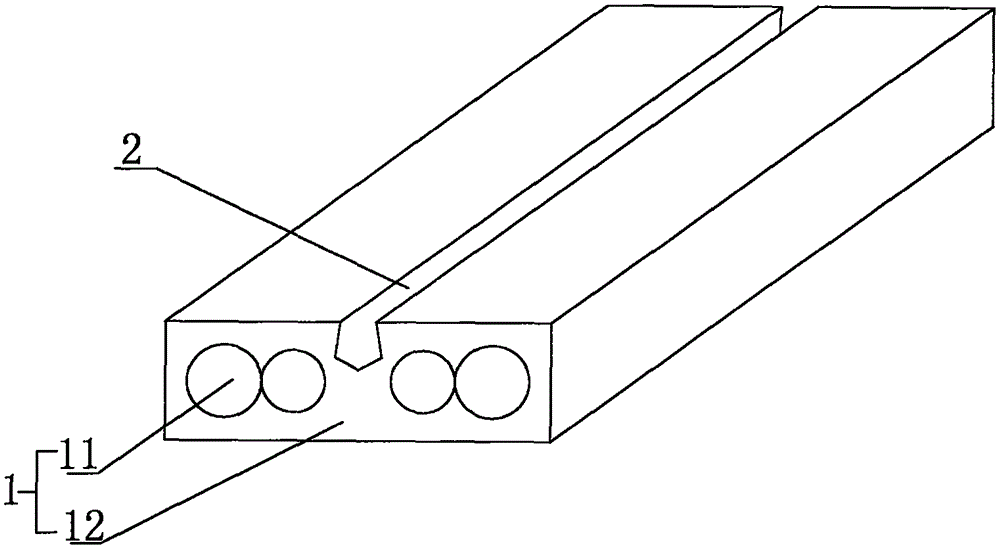

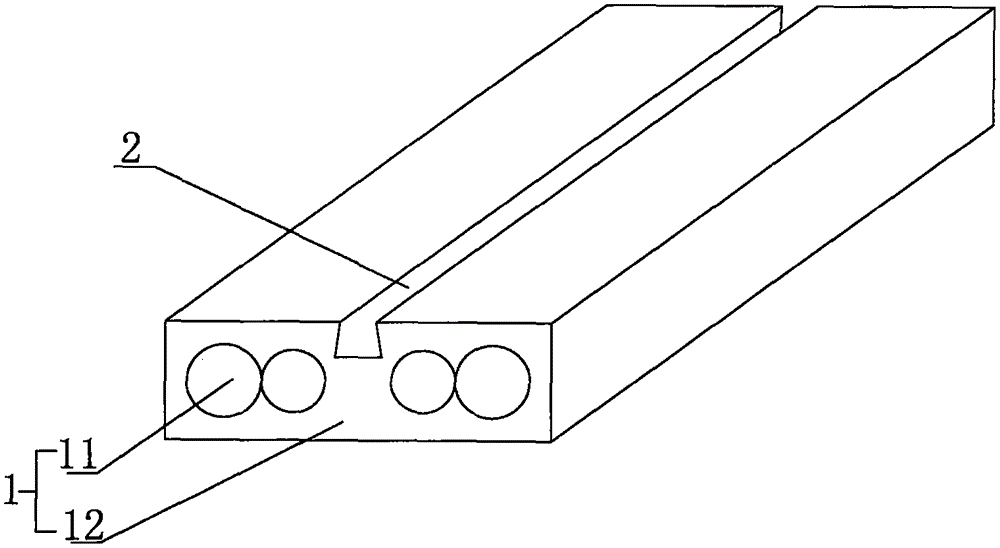

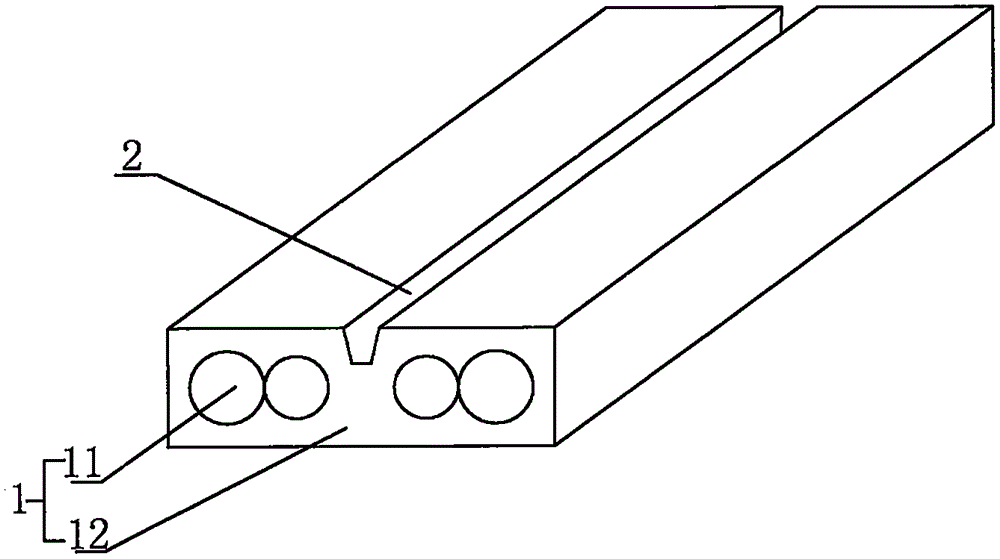

[0019] Piercing flat cable of the present invention such as Figure 1 to Figure 4 As shown, including the cable body 1, the cross-sectional shape of the cable body 1 is rectangular, so as to facilitate the precise and reliable piercing of the needle from the outer surface of the cable, and avoid slipping on the outer surface when piercing on the traditional round cable, thereby As a result, the piercing position deviates from the original position, resulting in a situation where the accuracy and reliability of the electrical connection between the cable and the outside are not high.

[0020] The cable body 1 includes a cable core 11 and an insulating layer 12. The insulating layer 12 is arranged on the outside of the cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com