Electronic cigarette atomizing core, electronic cigarette and atomizing method thereof

A technology of electronic smog and atomization temperature, which is applied in the field of electronic cigarettes, can solve the problems that the tobacco part cannot be atomized immediately, the heat insulation structure of electronic cigarettes is complicated, and the amount of smoke is unstable, so as to achieve sensitive response and high working reliability , smoke volume and smoke temperature stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

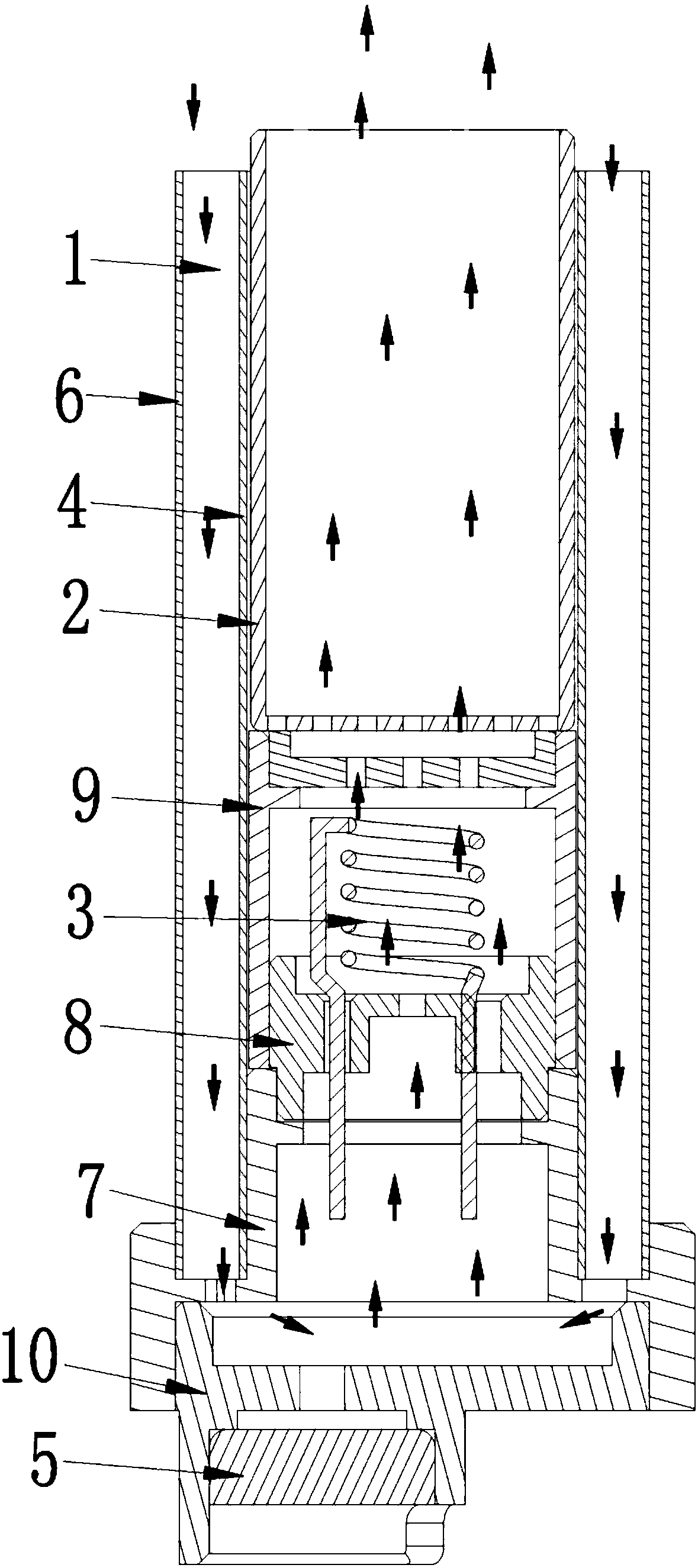

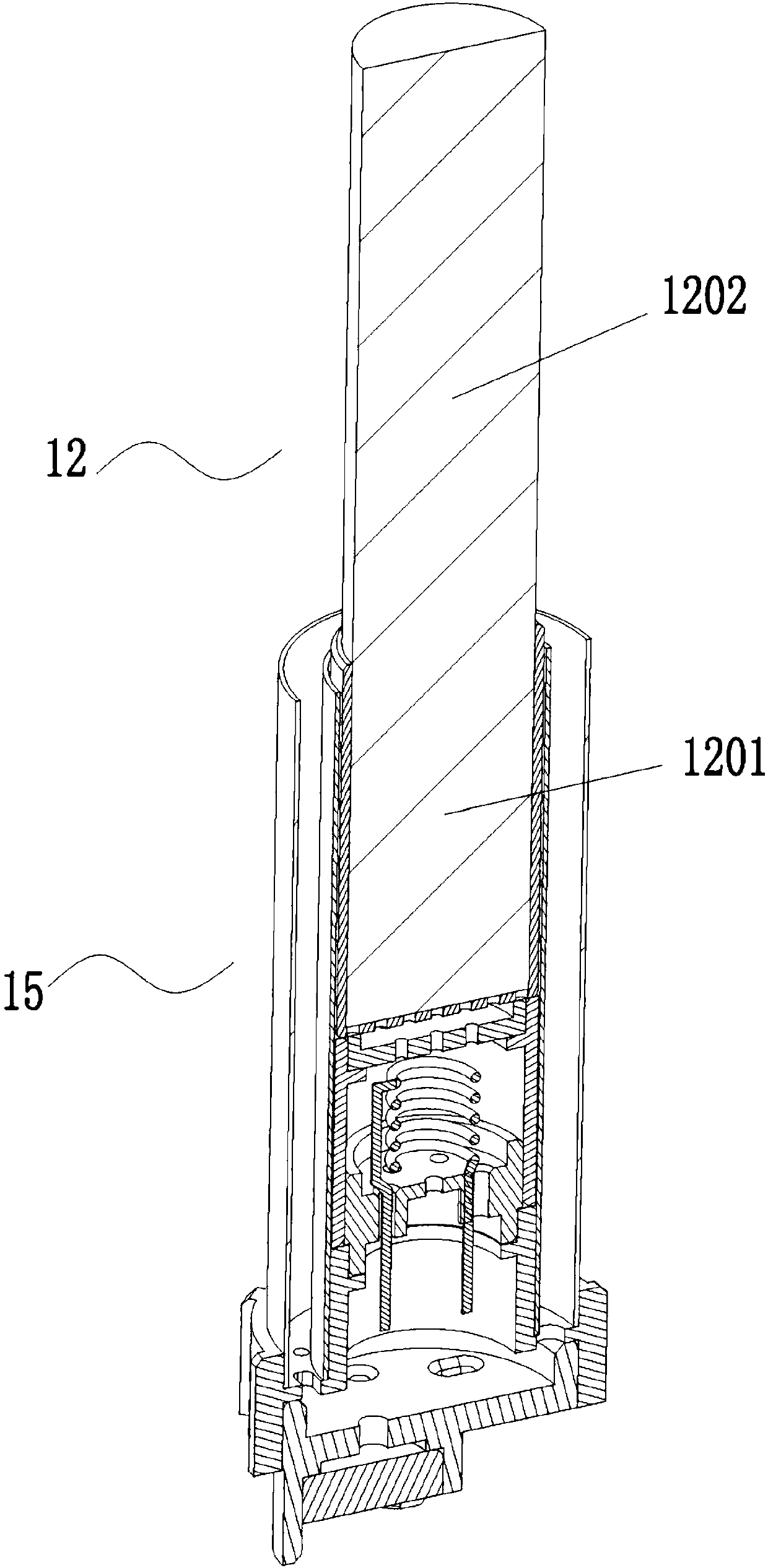

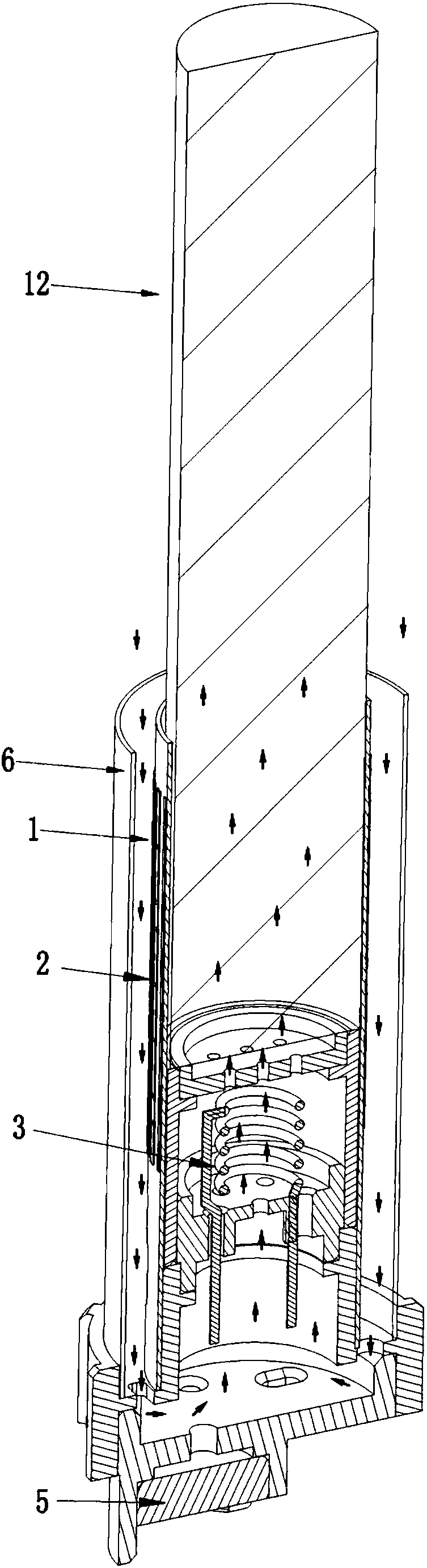

[0046] Such as image 3 As shown, the second embodiment of the atomization core is similar in structure to the first embodiment, the difference is that the first heating unit 2 is a heating pipe, the tobacco part 1201 of the cigarette branch 12 is placed in the heating pipe, and the air intake channel 1 is arranged between the air pipe 6 and the Between the heating pipes and the air intake channel 1 is in contact with the outer wall of the heating pipes. When smoking, outside air enters the air intake channel 1 in the form of airflow, passes through the first through hole (not numbered) and the second heating unit 3 , and then is discharged from the top of the first heating unit 2 . Such as image 3 The direction indicated by the middle arrow is the direction of the airflow.

[0047] For the similar structure in the second embodiment and the first embodiment, the text will not be repeated here, but it will not affect the understanding and realization of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com