Axial locking drill chuck

An axial locking, drill chuck technology, applied in the direction of the chuck, can solve the problems of low safety performance and efficiency of the drill chuck, and achieve the effects of simple structure, increased loosening torque, practical and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

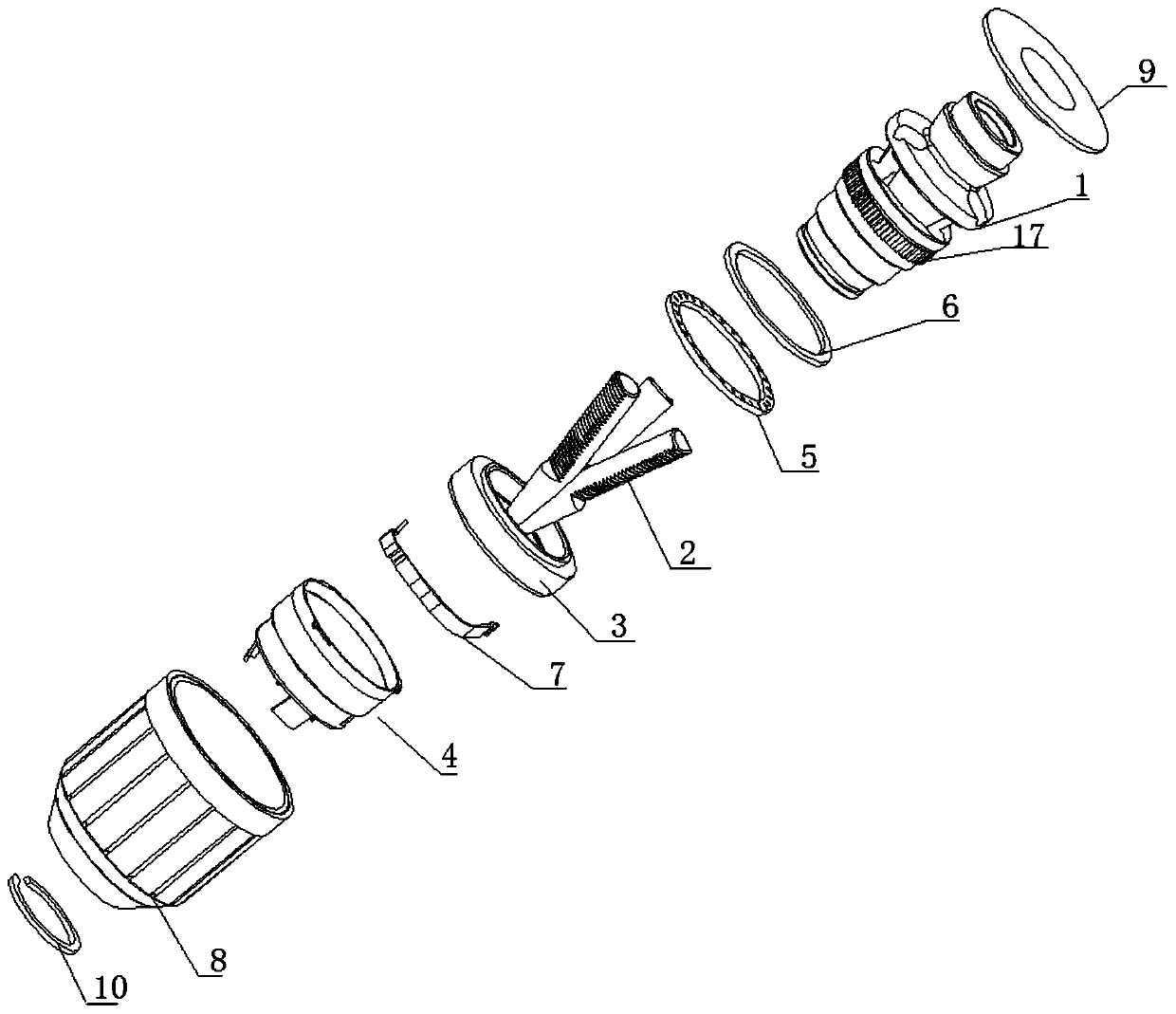

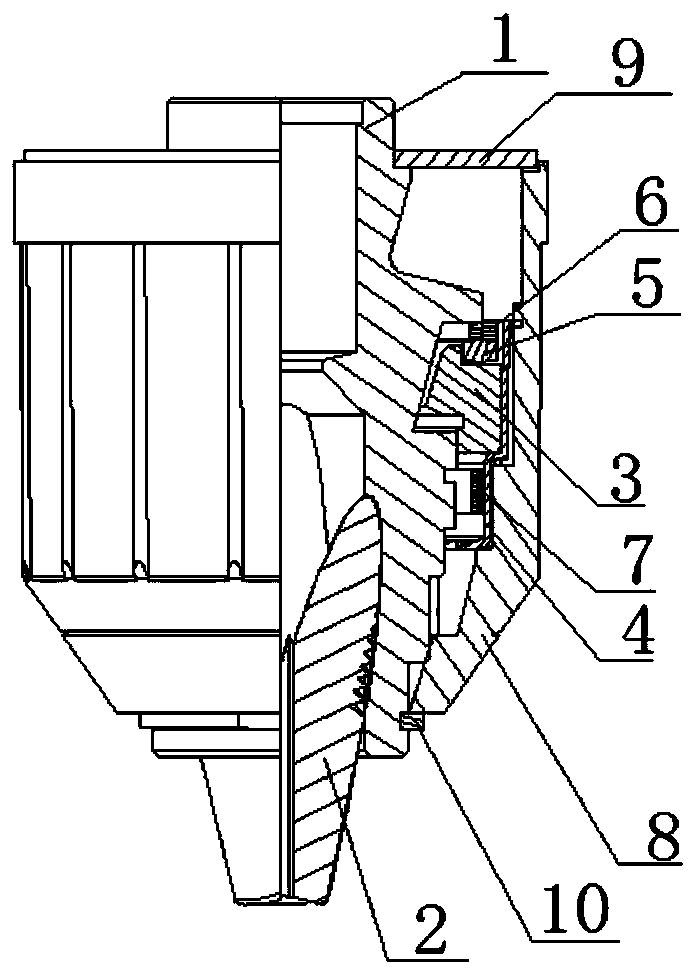

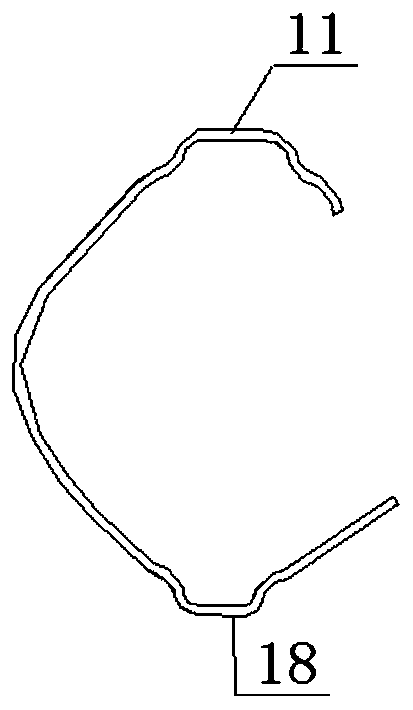

[0032] Such as figure 1 and figure 2 As shown, the present invention includes a drill body 1, jaws 2, nuts 3, nut sleeves 4, bearings 5, bearing pads 6, shrapnel 7, outer casing 8 and rear cover 9, and three jaws 2 are respectively arranged on the drill body In the three oblique holes evenly distributed along the circumferential direction on 1, the screw nut 3 and the jaw 2 are connected by threads, and the threads of the screw nut 3 and the jaw 2 form a thread transmission mechanism, and the bearing 5 is located on the support of the rear end surface of the screw nut 3 In the groove, the bearing pad 6 is arranged between the bearing 5 and the end face of the drill body 1; the nut sleeve 4 is interference-fitted on the nut 3, the jacket 8 and the nut sleeve 4 cooperate, and the rotation of the jacket 8 drives the nut sleeve 4 to rotate , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com